Simulation CFD spray booth

Accueil » Expertise » Industrial Process » Simulation CFD spray booth

EOLIOS, a unique know-how in Europe

EOLIOS carries out studies of paint booths to optimize performance using CFD simulation tools.

Our projects :

CFD simulation of paint booths

In a competitive economic environment and increased focus on environmental protection, paint companies for large industrial sites are looking more than ever at alternative technologies and processes that can improve the efficiency of the painting process.

This applies in particular to automotive paint technologies, where many new strategies and approaches have been developed over the past decade to increase efficiency and the flexibility, à reduce costs and operating costs and minimize the impact on the environment, while at the same time providing world-class paint quality.

The current trend in painting is that aircraft manufacturers are generally adopting strategies previously developed and tested by automotive paint companies to improve quality and reduce operating costs.

Requirements for the design of painting halls

The purpose of aircraft paint booths is to provide a ventilated, clean, temperature-controlled space for coating.

Air ventilation is necessary to ensure the removal of hazardous vapors and spray paint particles. In addition, it is important that the ventilation air circulates evenly around the aircraft to achieve a paint coating of high quality. Typically, in the painting cabins of small airplanes, helicopters… a horizontal longitudinal flow is created, thanks to which the ventilation air supplied near the nose of the fuselage spreads further on the length of the aircraft. The air is then removed from the paint booth at a distance behind the aircraft.

This design of paint booths is energy efficient (relatively low air consumption is required).

The problem with this ventilation method can be the appearance of a grainy, uneven surface resulting from the drying of the paint. The roughness of the paint layer occurs due to the dried particles of the aerosol, due to the spray of paint from the nose of the aircraft and its transfer by a longitudinal air flow towards the rear of the aircraft. The drying is then heterogeneous and differences in surface graininess may appear. Such a superficial defect may be unacceptable for the most demanding, for example, private business aircraft.

CFD simulation for paint booths and hangars

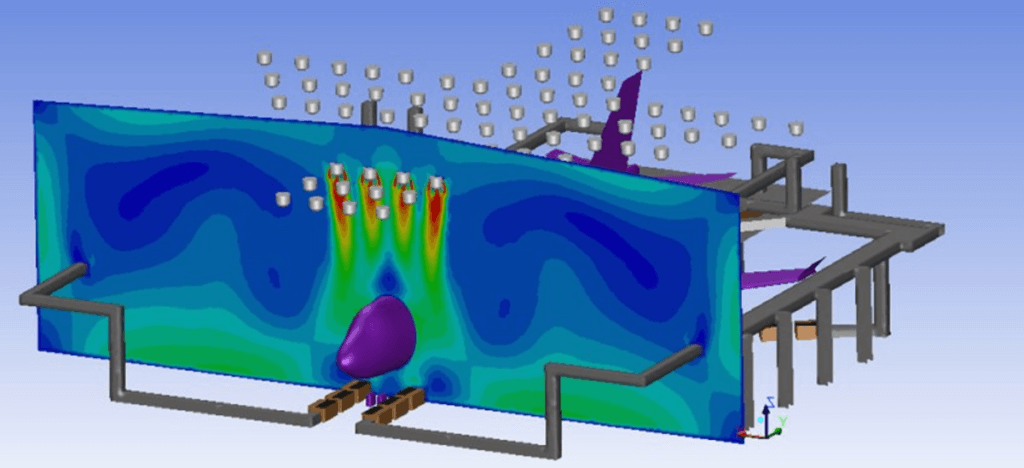

Here, the CFD simulation results presented showed that the shape and positioning of the inlet and outlet air inlets are critical to minimizing the recirculated air flows under the wings of an aircraft. The final optimized hangar design includes a cross-shaped ventilation system combined with exhaust zones located in key areas under the aircraft.

At the same time, the total flow rate required to achieve the airflow velocity of 0.3 m/s at a distance of 1.5 m from the aircraft was found to be almost identical to the airflow rate of less efficient conventional paint spraying systems.

CFD simulation for paint booths

The assessment of climatic and particle removal conditions must be carried out not only in theentire hangar, but also in each local area, taking into account the size of the space and the impact of each system. The only method to accurately calculate these parameters and estimate the air flows in space is CFD simulation.

CFD methods of gas modeling allow, with professional software and computing power corresponding to the level of complexity of the considered problem, to visualize the flows of particles, toestimate the concentration of harmful substances, ofstudy the temperature distribution in the workshop (critical scenarios and a number of other parameters.

At the design stage, this allows to evaluate the efficiency of the system and toavoid financial losses at the operation stage.

Energy efficiency strategies

In the following steps, we explore common shop energy saving strategies that can be used to minimize operating costs in a paint shed. The largest amount of energy consumed is for air conditioning – temperature and humidity control. Therefore, measures to reduce the amount of air conditioning are the most effective in reducing energy consumption during painting.

Two strategies are often used in paint shops to minimize energy consumption. The first is air recirculation. By recirculating a significant portion of the air drawn from the spray booths back into the spray booth, the amount of air that must be fully conditioned is significantly reduced, resulting in a significant reduction in energy consumption. This is the most effective way to reduce energy consumption. The proportion of recirculated ventilation air depends on the chemical composition of the paints and the volume of coating applied and can be as high as 80%.

The second strategy for reducing energy consumption is to control air levels on the drying line, a concept originally developed by automotive paint suppliers in collaboration with paint equipment manufacturers. For any coating applied, some temperature and humidity requirements must be respected in order to achieve the required drying rate of the paint to obtain a finish of high quality. If the air is too cold and/or dry, the solvent willwill evaporate quickly from the paint, causing a bubble defect. Conversely, if the air is too hot and/or humid, the solvent will evaporate much more slowly. This will lead to a low viscosity of the applied coating, which in turn will lead to the stain formation.

Therefore, paint manufacturers typically specify specific temperatures and humidity levels that must be maintained to ensure that the evaporation rate of the solvent is sufficient to avoid any of these types of defects.

CFD simulation for paint booths

The values of the possible indicators of temperature and humidity are located along a calculated curve predetermined on the psychrometric diagram, each combination of parameters corresponding to a certain equivalent evaporation driving force (water vapour pressure in the air) so that the drying rate of the paint is the same under all conditions along the drying line.

The advantage of this strategy is that during the coldest months, the ventilation air is regulated to lower values of the line parameters – and vice versa, during the warmest months. This results in both energy savings and reduced utility costs. Using this strategy can reduce the energy requirements of heaters and chillers by 50% and 60%, respectively.