Laboratory fume cupboard qualification

Accueil » Expertise » Laboratories » Laboratory fume cupboard qualification

EOLIOS is able to carry out the pre-qualifications for the design of your fume cupboards as well as the containment tests:

- Contamination control

- Dispersion of pollutants and gases

- Design of laboratory premises

- Study of critical failure scenarios

- Identification of bypass and recirculation air flows

- Improved air distribution and cooling efficiency

- Precise dimensioning of the grid layout

- Optimization of thermal comfort

- Study of the set points of the air treatment systems.

Continue browsing :

Our latest news:

Our projects :

Our fields of intervention :

Laboratory fume cupboard and normative context

context

The laboratory fume cupboard is a system of protection system generally used in places where hazardous substances are manipulated. Its mission is to limit human exposure to these harmful substances by capturing and evacuating toxic fumes and other volatile dusts generated in its enclosure thanks to an air suction flow. To ensure that their performance is maintained over time, laboratory fume hoods are subject to periodic inspections

Current French legislation

Currently the evaluation of the operation of laboratory fume cupboards is subject to the European standard EN 14175. This standard details the methodology to be used to evaluate the performance of laboratory fume hoods during qualification tests, reception or routine. Thus, during an inspection, frontal air speed tests at the entrance to the fume cupboard must be carried out by hot-wire anemometry. In the same way a containment test with SF6 tracer gas must also be performed as well as a qualitative visualization of flux with smoke.

Old regulation: The XPX 15-203 standard

- In France, for fume cupboards installed before 2006, the controls had to comply with the methods defined by the French standard XP X 15-203 . The XPX 15-203 standard notably set frontal air velocity thresholds and containment levels.

- Frontal air speed: 0.4 m/s

- Containment: concentration of tracer gas in the opening plane of the fume cupboard lower at any point than 0.1 ppm.

The EN 14175 standard: new airflow test parameters

The threshold values to be respected

- Frontal air speed: no threshold value, BUT in France 0.4 m/s

- Containment: no threshold value BUT in France, the French standard XP 15-206 has been developed to complement the EN 14175 standard. It sets a threshold of 0.1 ppm for the average concentration of SF6 tracer gas (sulphur hexafluoride)

- Much higher number of parameters tested.

Mandatory controls

- Extract air flow: The measurement is carried out by measuring the extraction flow in the extraction duct to check the aeraulic characteristics of the installation and serve as a comparison for future checks.

- Frontal air velocity: The measurement is carried out by thermal anemometry. The measured values will serve as reference values for future periodic checks.

Containment and robustness of the containment: The measurement is performed by SF6 tracing

The principle of the containment test with SF6 gas:

- Generate SF6 tracer gas at specific locations within the fume cupboard working volume.

- Take the air from different places, at the level of the plane of the opening of the fume cupboard.

- Measure the concentration of SF6 in order to quantify the leakage of chemical substances from inside the work volume to the personnel handling the chemicals.

For standard NF EN 14175, the number of measurement points depends on the width of the fume cupboard. Part 3 of the standard specifies how to calculate test positions. During the tests, the mobile facade is opened to 500 mm.

CFD modeling of laboratories and clean rooms

Global understanding of thermo aeraulic phenomena

Simulations can contribute to a better understanding of the issues in order to develop relevant technical solutions from the design stage. Laboratories can be simulated in their entirety and allow the simultaneous analysis of the impact of many phenomena.

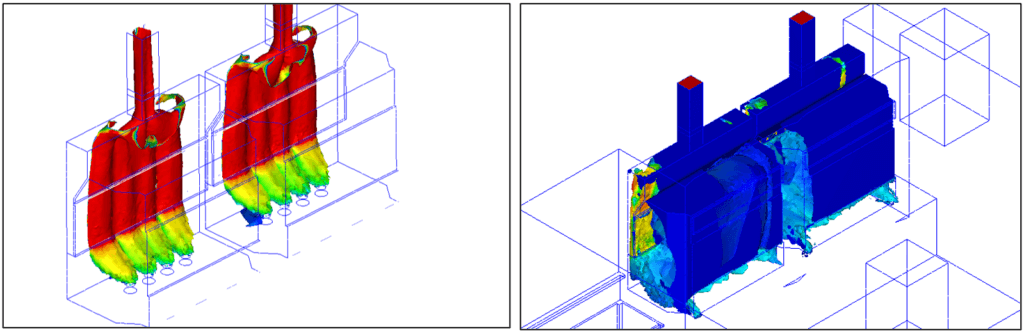

The realization of CFD study of qualification of fume cupboard allows in particular to highlight the presence of parasitic air flow disturbing the entrance of the fume cupboards.

Design of laboratory rooms and clean rooms

At the beginning of the design process, setting up a large number of experimental prototypes can quickly become expensive and time- consuming . CFD Simulation allows the simulation of a large number of prototypes, in a shorter period of time, in order to quickly gather information for the optimization of systems and the placement of fume cupboards.

CFD: a new laboratory design protocol

Simulation provides access to many parameters that are difficult to access through experiments, in particular because simulations instantly provide measurement data for any point and not exclusively localized. This makes it possible to precisely identify potential leaks during the containment of the fume cupboards. Integrating CFD simulation into its design protocols means integrating a team of experts who will have a different perspective in the search for a solution, the qualification of fume cupboards is thereby secured and accelerated.

CFD-based method for the qualification of fume cupboards

Air flow modeling method

To achieve an instantaneous spatial measurement of air velocity, we use this method based on precision fluid mechanics. The flows brought into play in this context are governed by partial differential equations called the Navier-Stokes equation. These equations being analytically insolvable, we use the finite element calculation method to solve them numerically. This method makes it possible to have a solution as close as possible to a physical problem.

To solve a physical problem using this method, it is advisable to know in advance the conditions of the system’s inlets and outlets, in our case it will be the supply, return and suction flow rates of the various fume cupboards.

These conditions are specified in hypotheses in the note and must imperatively be verified for the conclusions announced in this note to be valid.

Numerical confinement measurement method

During the qualification of fume cupboards, it is essential to control the rate of leakage of polluting agents so as not to contaminate the user. In order to model this pollutant, we use different methods to simulate a tracer gas in order to guarantee a fine precision and thus obtain the most reliable results.

Numerical validation of fume cupboard qualification

In order to know if the containment meets the current standard, we model the diffusion of the tracer within the fume cupboard in a stationary manner. Once the results have been obtained, we use an iso-volume method to check that all the tracer is included in the fume cupboard at the regulatory scale. If the result is verified, the fume cupboard meets the confinement conditions imposed by the legislation.