Study of dust in clean rooms

Accueil » Expertise » Laboratories » Study of dust in clean rooms

EOLIOS, a unique know-how in Europe

- A passionate team

- Sizing of treatment systems

- Dust modeling

- On-site measurement of particle concentrations

- Decontamination study

- Optimization of air quality

Our projects :

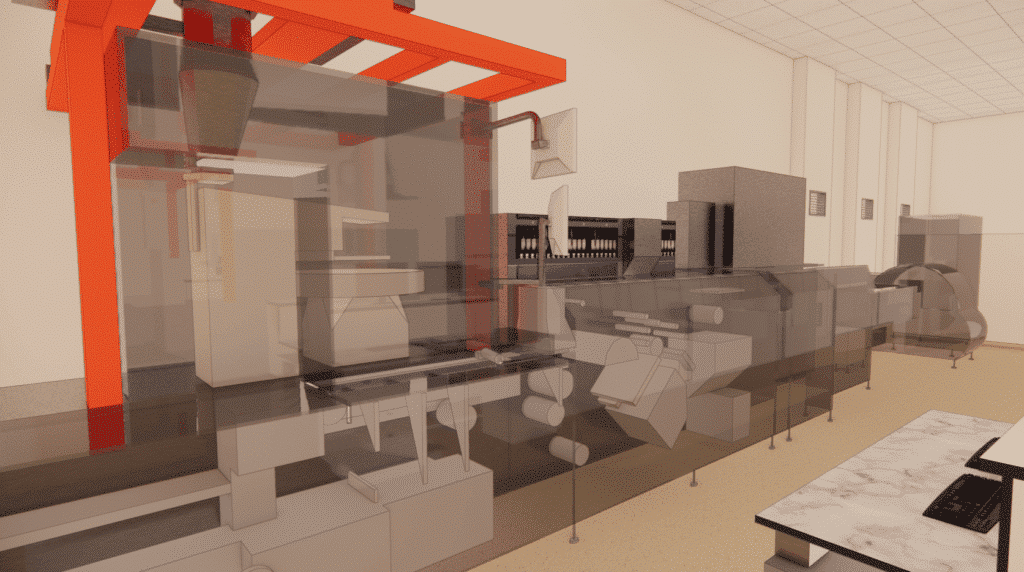

EOLIOS is a CFD design office specialized in the study of dust dispersion and low speed aeraulics. We offer our technical expertise to understand and simulate the different aeraulic phenomena specific to clean rooms, in order to analyze the problems encountered and to propose solutions adapted to your problems.

How does cleanroom airflow work?

Why study cleanroom aeraulics?

Airflow within cleanrooms is a crucial aspect of the design and operation of these environmentally sensitive spaces. Indeed, the control of cleanroom airflow is fundamental to maintain a clean and controlled environment for the manufacture of products sensitive to contamination such as semiconductors, pharmaceuticals, medical devices and electronic products.

This control of cleanroom airflow minimizes air and surface contamination, which reduces the risk of product failure and batch rejection, and improves the quality and reliability of manufactured products. Air contamination can come from a number of sources, such as workers, equipment, materials, the outdoor environment and airflow disturbances.

Fine dust control, a recurring problem in clean rooms.

Fine dust control is a recurring problem in controlled environments such as clean rooms. Fine dusts are small particles that can be difficult to filter and control in clean environments such as these sensitive environments.

Fine particles can come from many sources, such as workers, equipment or materials. They can also be generated by the production processes themselves, such as etching, spraying or pharmaceutical processes. It is important to maintain an adequate level of quality and safety to prevent the spread of dust and potential contaminants.

Dust can damage products, affect quality and cause additional costs or delays in industrial processes.

What are the reasons why CFD simulation is used to study cleanrooms?

How can CFD help you design your projects?

CFD (Computational Fluid Dynamics) simulation is commonly used for the study of sensitive aeraulics such as clean rooms.

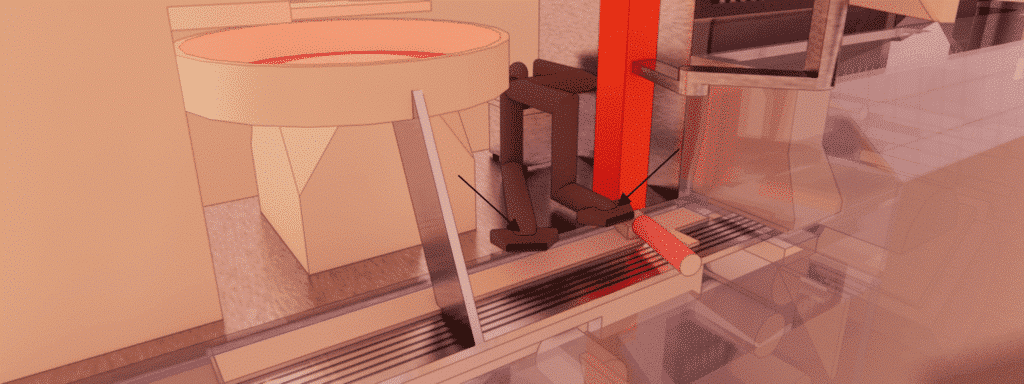

First of all, CFD simulation allows to model the specific behaviors of air and particles related to the atypical environment of clean rooms, thus allowing to predict the distribution of contaminants and air in the space. This low speed aeraulics can be complex to anticipate and particular phenomena like dead zones or recirculation zones or other phenomena can appear.

In addition, the CFD simulation allows to simulate the effects of various cleanroom configurations, such as the location of the different air outlets, air filter configurations, air flow optimization.

Why use CFD simulation to study fine particles?

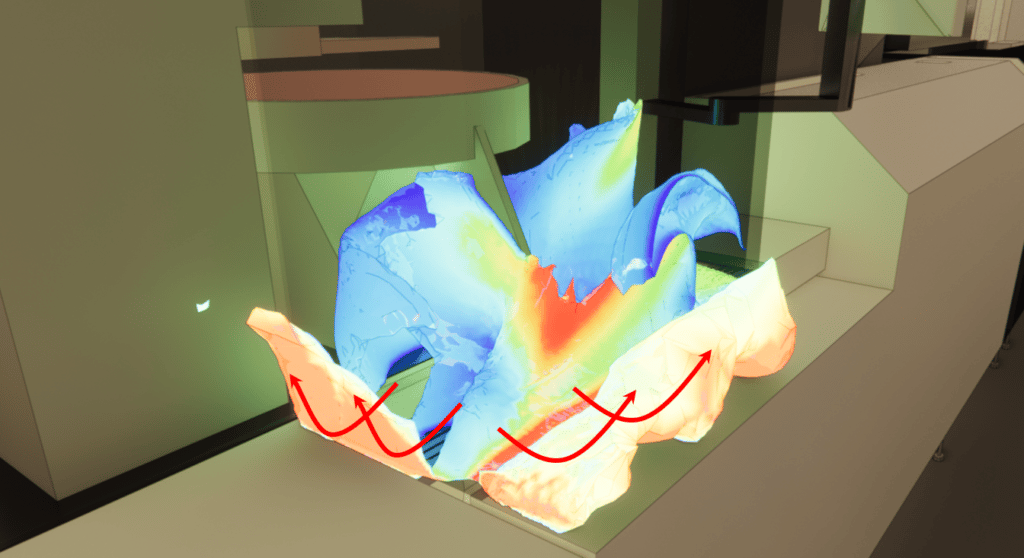

CFD simulation can also help to identify areas of high contamination risk. Indeed, in industrial environments, the use of products that can be very powdery is relatively common. The use of such a product can lead to contamination of the environment and thus compromise the quality and safety of cleanrooms.

In this type of environment, the use of CFD simulation makes sense. Indeed, thanks to the simulation, it is possible to control your various designs, to foresee the zones which can be at risk and to take measures adapted to the encountered problems in order to correct them quickly and at lower cost.

CFD simulation, a valuable aid for cleanroom compliance?

Using CFD simulation, it is possible to test different cleanroom design scenarios and validate their compliance with current standards and regulations. CFD simulation can also help optimize the operating parameters of the cleanroom, such as air velocity, temperature distribution or relative humidity of the environment.

In addition, it is possible to determine the time needed to completely remove the contaminants (decontamination study) and to decontaminate the cleanroom space and the time needed to bring the facilities into operation. This ensures a high level of cleanliness and minimizes the risk of contamination.