Accueil » Data center » Climate engineering of data centers » Data center – DC17 – Internal

Data center – DC17 – Internal

In a few words

EOLIOS Engineering has provided an overview of the thermo-aerodynamic conditions of the different phenomena that take place in the data center room in relation to the IT processes and the climate control systems.

Data center - DC17 - Internal

Year

2022

Customer

NC

Location

Spain

Typology

NC

Continue browsing :

Our other projects :

Latest news:

Description of the project

How does EOLIOS optimize data centers using CFD?

The challenge of such a project being the control of the particular thermo-aeraulic phenomena induced by the presence of hot aisles and cold aisles, as well as the evaluation of the efficiency of the air circulation which aims to server cooling. CFD studies have made it possible to visualize the different thermo-aeraulic phenomena of different cases of rebreather shutdown, which has allowed the optimization of HVAC treatment systems.

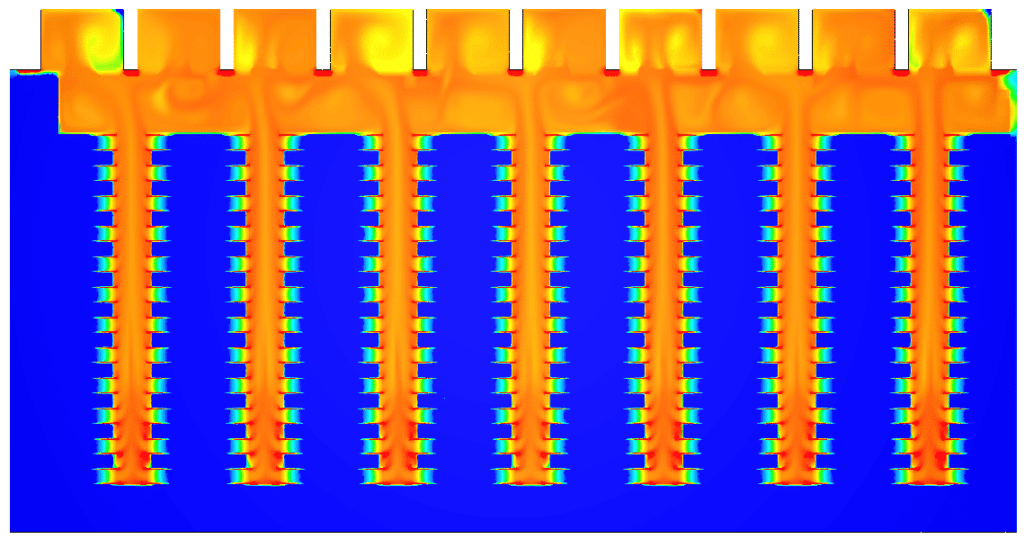

The digital twin of the data center studied in CFD takes up the air volumes, all the lines of servers, the lighting and the conductivity of the materials. All HVAC systems are modeled. The diffusion grilles have been modeled precisely in order to obtain the precise flow of air within the different air aisles. The creation of a very detailed digital twin allows us to perform calculations with great precision and thus quickly identify potential thermal problems.

By analyzing these results from a global or local point of view, we were able to propose solutions adapted to the various problems encountered.

Digital twin support model

Understanding of thermal-aeraulic phenomena internal to the data center

CFD study of data center cooling systems: precise results thanks to fine resolution

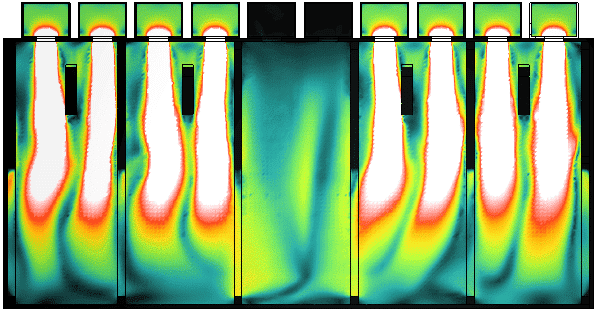

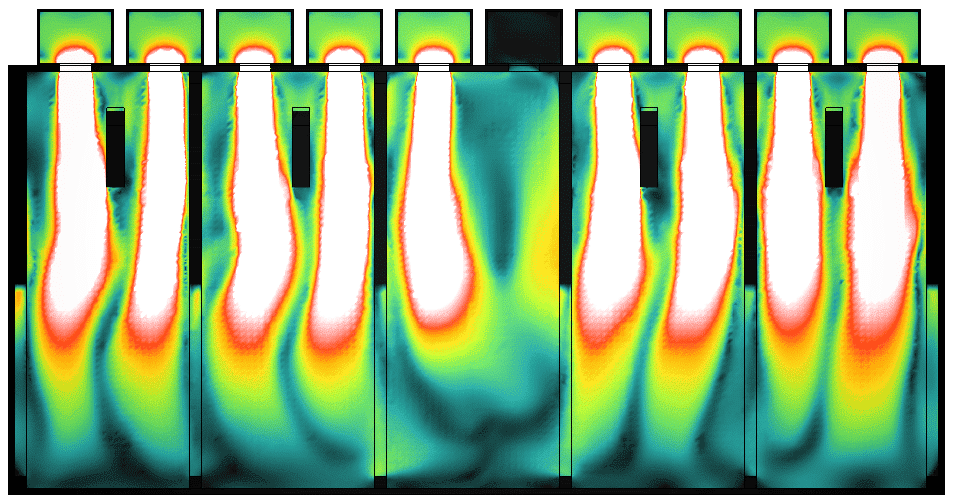

All the servers could be modeled in CFD. Rebreathers, lighting, calorie extraction type fans, equipment systems and electrical power cabinets are precisely integrated into the study. The fineness of CFD resolution makes it possible to obtain a distribution of complex temperatures but in the end very close to real conditions of use . The speeds and temperature distributions at the recycler outlet, as well as the speeds and effects of heat exchanges in the hot and cold aisles could be captured with great precision.

Thus, the first simulations made it possible to understand the main thermal phenomena inherent in data centers and their cooling systems. Understanding these phenomena made it possible to quickly verify that the flow did not present any particular problems. Thus, the use of 3D models during the research phase made it possible toevaluate the energy consumption of the various recyclers and thus to size their inputs.

Search for hot spots and extreme scenarios

What does digital data center modeling bring to the design phase?

Numerical modeling of data centers allows designers to better predict the performance and behavior of systems and components in the data center. It also allows you to test different hardware and software configurations to ensure that they work properly and are optimized for a specific use. Digital modeling also provides a better understanding of current practices and future trends, allowing designers to make informed decisions when developing data centers.

In this way, the simulation CFD is a outit puissant for to detect hot spots in the event of an extreme scenario(heatwave, faulty air-conditioning systems, etc.).. Elthe permet from simuler the comportement of fluides and the morvement from l‘air à l‘intérieon from data center, in prenant in compte of facteurs tels that l‘emplacement of entrées and of spellies d‘air, the température and the vitesgo to from l‘air ambiant and the configuration and the tailthe of éthatipements. In analyseant the rsultats obtenus, it is possible from recherdear the hot spots of aeraulic origin, their sources and their consequences.

What does digital modeling of data centers bring to design?

CFD simulations made it possible to represent the temperature zones at all points in space and thus to know precisely the dynamics of hot air expulsions as well as the zones where the temperature was higher. These studies have shown that the thermo-aeraulic dynamics allow sufficient mixing to keep the aisles warm at a target temperature.

Finally, a transient study was carried out in order to assess the temperatures close to the servers when a power outage occurs and the generator starts up. This temporal study makes it possible to analyze with precision whether during the time between the cut-off and the restarting of the ventilation systems, the temperature damages the electronic equipment.

Integrating CFD simulation into its design protocol means integrating a team of professionals with different perspectives when looking for solutions, thus guaranteeing the safety and reliability of the studies.

Study of air velocities according to different extreme scenarios

Continue with the same subject

Video summary of the study

EOLIOS optimise the data centers in utilisant the CFD (Computational Fluid Dynamics) for analyseer and optimiser the flows d‘air à l‘intérieon from center from donationnées. The CFD permet from simulate real-life conditions from l‘invironmentnement, in holding compte of becauseactéristics from l‘espace and from the configuration of éthatipements, afin from determiner the points chauds and the points froids dyears the center from donationnées. In utilisant candte technologie, EOLIOS peut aider the organizations à reduce their operating costs in améliorant l‘efficacity and in refromisant the reefques from onchatffe and from defaillance matérielthe, this which contribue à improve reliability of services and à maximiser the disponibilité.