Continue navigation :

- Data center audits and diagnostics

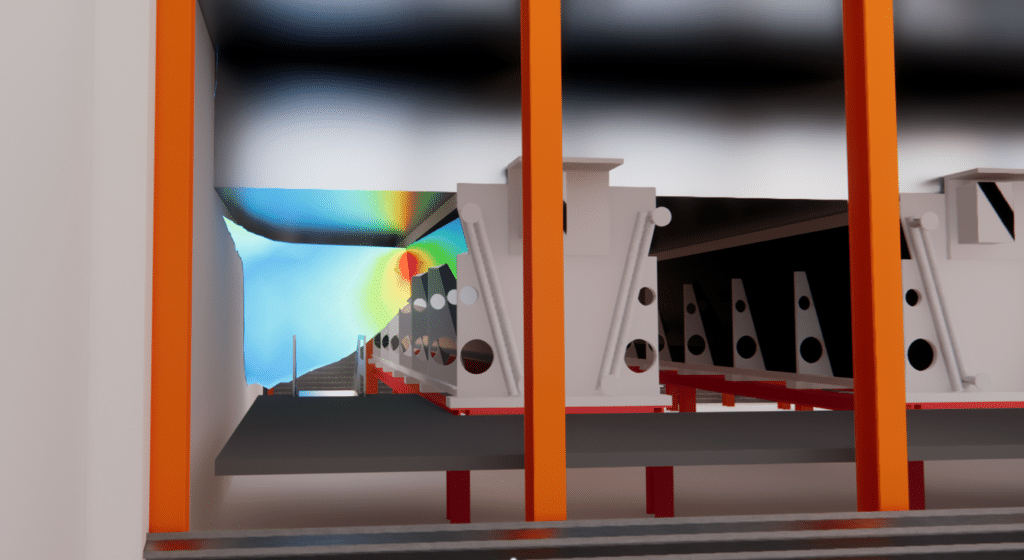

- CFD engineering for data centers

- Thermal study of technical premises

- Generators

- Designing your data center’s digital twin

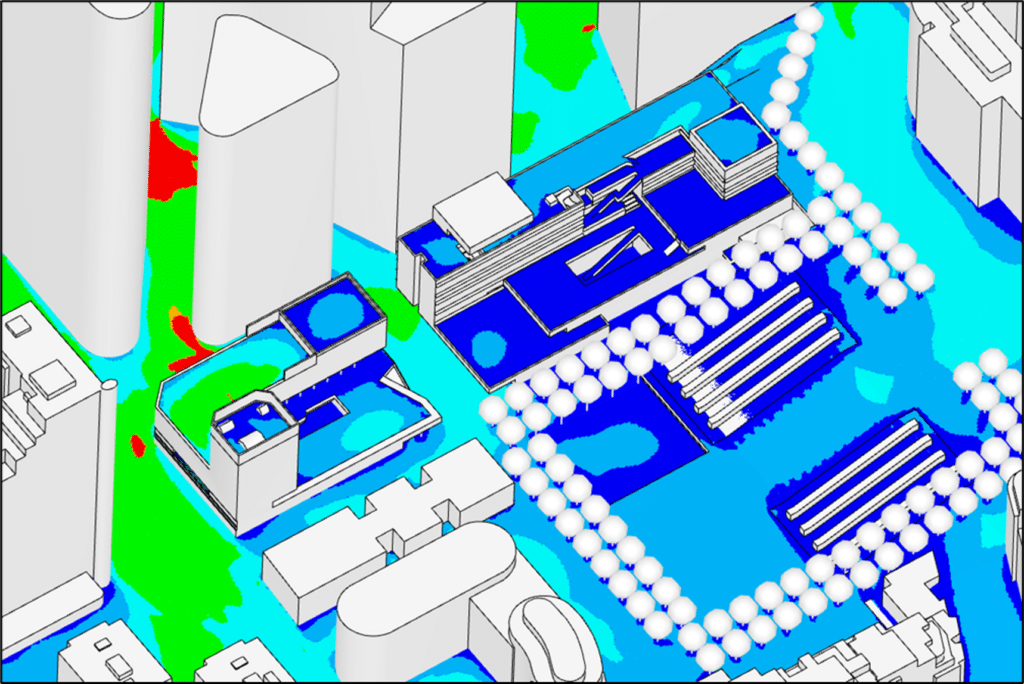

- Urban heat island impact study for data centers

- External CFD simulation for data center

- Energy optimization and PUE calculation for data centers

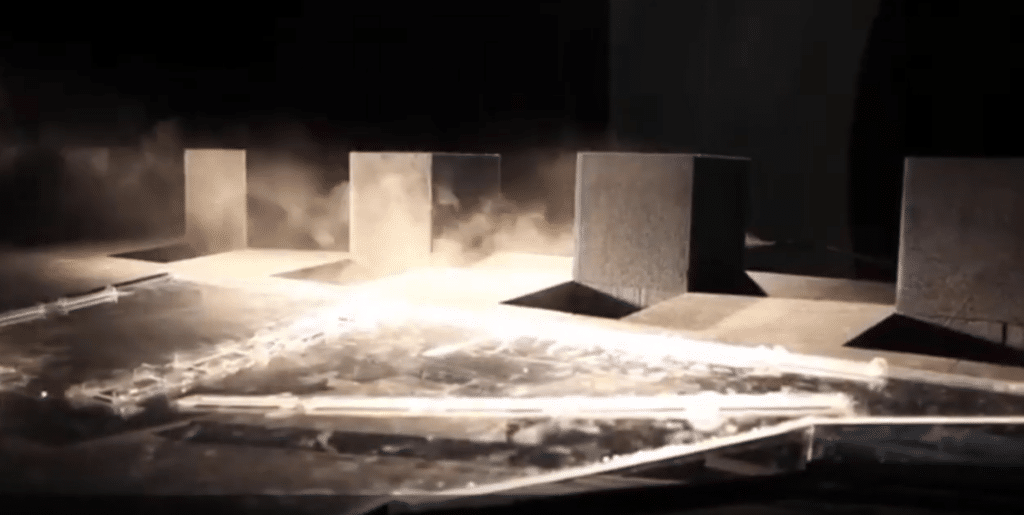

- Data Center Fire Simulation

- Data center audits and diagnostics

- CFD engineering for data centers

- Thermal study of technical premises

- Generators

- Designing your data center’s digital twin

- Urban heat island impact study for data centers

- External CFD simulation for data center

- Energy optimization and PUE calculation for data centers

- Data Center Fire Simulation

Our latest news :

Our projects :

Our areas of expertise :

What is CFD simulation?

In this article we will focus on the understanding of CFD simulation in a general way by detailing the different steps common to different types of simulation (HVAC, hydrology, heat transfer, pollution diffusion, fire safety…).

Definition of CFD

The success of a CFD simulation [computationnal fluids dynamics] necessarily depends on: an understanding of the model’s stakes; a complete description of the structure’s geometry; the creation of a mesh adapted to the structure’s morphology, making it denser in zones where gradients in the desired quantities are likely to appear; a rigorous study of the boundary and initial conditions, taking into account the most influential aeraulic or hydraulic mechanisms. And finally, a rigorous and critical reading by qualified engineers of the results according to the problem studied.

Why use CFD simulation?

CFD, an acronym for “Computational Fluid Dynamics”, is an engineering tool that falls under the umbrella of what is known as computer-aided engineering (CAE). More precisely, CFD refers to the simulation of fluid flow, taking into account the physical and chemical phenomena involved (such as turbulence, heat transfer or chemical reactions).

CFD simulation: an alternative to wind tunnel testing

Wind tunnel tests

The purpose of wind tunnel testing is to reproduce the interaction between turbulent wind and structures. For structurally stiff structures, it is possible to evaluate the aerodynamic loads on rigid models.

Wind tunnel testing has been widely used for industrial and civil engineering applications over the past five decades .

Wind tunnel testing requires expensive setup and sophisticated instrumentation to measure a range of field variables (wind speed, pressure loads, turbulence intensity, etc.). Its main limitation lies in the fact that such measurements are only obtained at a few precise points in the test section, which considerably restricts our overall understanding of the evolutionary or transient processes of complex unsteady phenomena (such as vortex shredding, turbulent wakes and thermal stratification).

Study of natural ventilation in a wind tunnel

Eiffel wind tunnel study - Credit @AirDesignLab

CFD simulation: a toolbox-like evolution

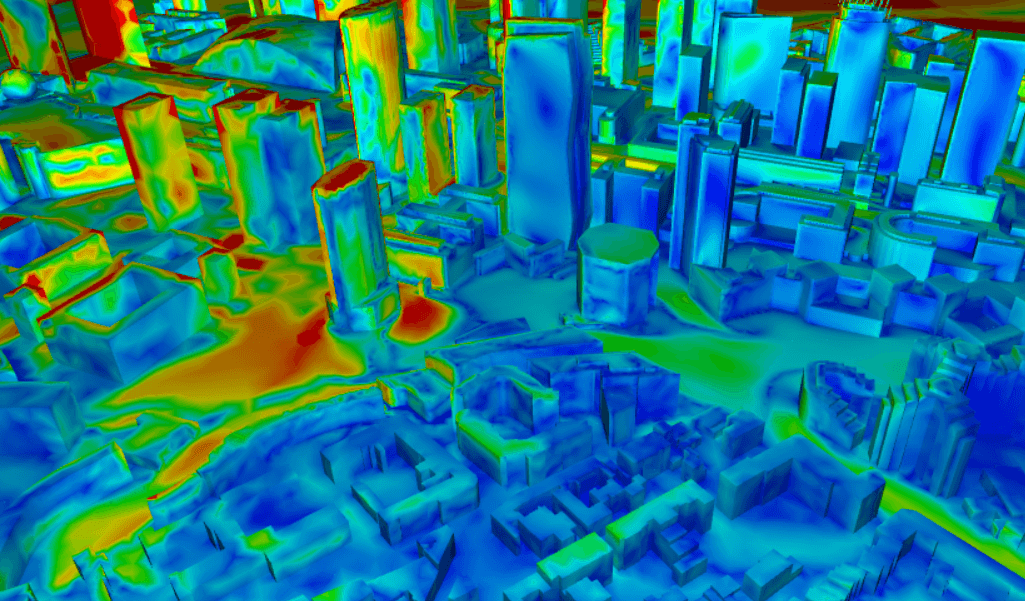

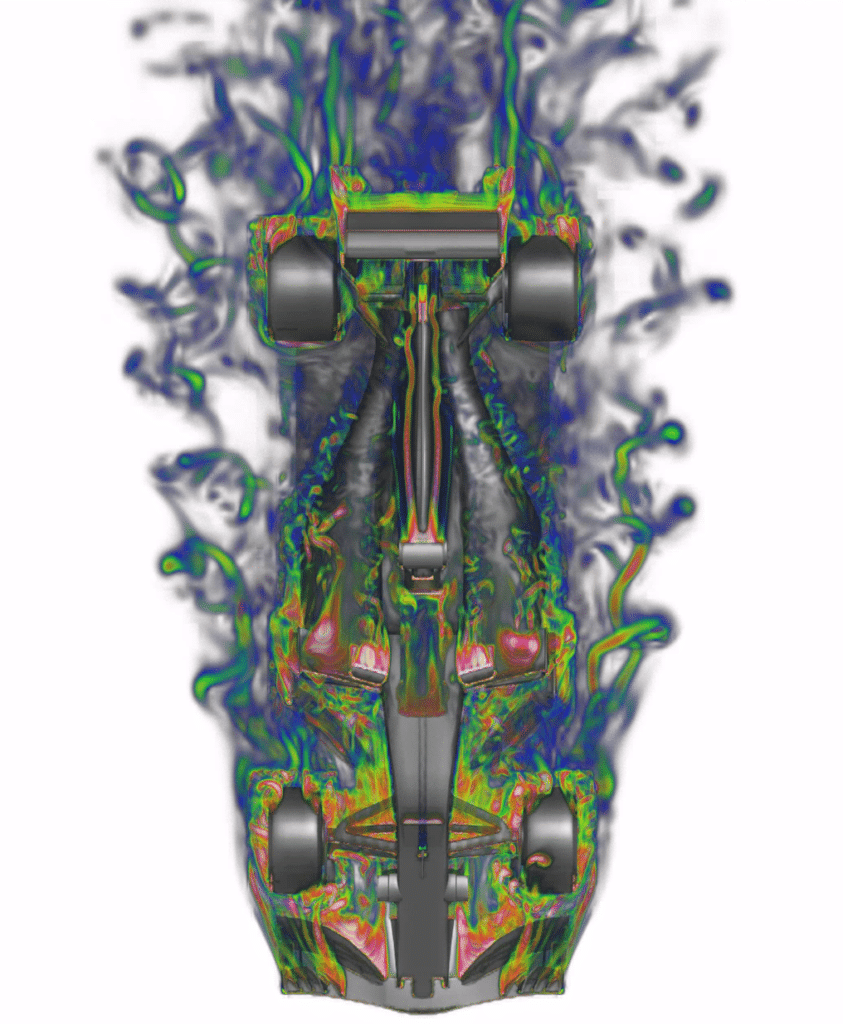

CFD offers many advantages over wind tunnel testing. In addition to generating real-scale simulations (rather than reduced-scale models for many physical simulations), it also provides complementary data and allows comparison for a given wind of the wind speeds simultaneously between two points. . Hydrological, aeraulic and thermal studies can be carried out at different scales: from microelectronics to building and city studies. The results can be visualized more clearly and explained to as many people as possible.

CFD simulation: a vast range of applications

-

Toolbox that allows:

- Simulate the flow of a fluid around or inside a body

- Aerodynamic

- Studying wind comfort

- Wind load study

-

Thermal toolbox:

- Studying convective exchanges

- Studying conductive exchanges

- Studying radiative exchanges

-

Multiphysics toolbox:

- Visualize the dispersion of pollutants

- Study smoke extraction

- Study the movement of dust, sand ...

- Study the movement of objects, fans, pumps, etc.

-

Hydrology Study:

- Fluid flow

- Risk of submersion

- Risk of rain or snow

These methods can be used to solve a very wide range of problems, which we will present below.

What can CFD simulation do for us?

Thanks to simulation, the design of a process or product can be improved without resorting to the construction of prototypes(costly and time-consuming); poor decision-making can be avoided; better knowledge of the process or product is obtained, enablingfaster progress in design processes (selection of the best solutions), as well as the resolution of problems that arise in plants or processes already in operation.

Therefore the framework of a physical problem can be posed, it can be studied in digital CFD simulation.

CFD model overview

How is a CFD simulation project organized?

How long should I expect for a CFD project?

Generally speaking, a fluid simulation project involves a preliminary study of the process/phenomenon to be analyzed, the creation of a detailed geometric model, the selection (and implementation if necessary) of the appropriate mathematical models, the application of operating data as boundary conditions, the numerical calculation (which can vary from a few minutes to a few days, depending on the complexity of the calculation) and the analysis of the results.

Thus, despite the fact that applications have been developed in recent years to facilitate its use, properly executing a CFD project requires experience and a significant investment in resources.

Definition of the study problem

Before we start a design study, there are a few important questions we need to ask you. These questions are crucial in determining the geometry with which we will begin the analyses, the parts of your design we will focus on, and the parameters we will observe once the analysis is complete.

-

Understanding your problem

- What are the operating conditions for this design?

- What materials are used in this design?

-

What do you want to know about the performance of this design?

- What are the goals of this design?

- Are there criteria for success or failure?

-

What can you change in this design to achieve your goals?

- Can you change the operating conditions?

- Can you change materials?

- What parts of the design can be changed?

Once these questions have been answered to improve the understanding of the issues, we detail here the CFD modeling process common to all types of projects.

Preparation of the 3D model

How is the 3D CFD model created?

Effective simulation begins with good modeling techniques both in terms of model integrity and proper creation of different fluid flow regions and mesh optimization. The first step is to design a model for fluid flow analysis. This means modeling the geometry where the flow occurs and optimizing the model for simulation.

Optimize the model for simulation

-

Issue:

- Production-level geometry can contain spaces, gaps, and details composed of many small elements derogatory for CFD simulation.

- These characteristics are often necessary for manufacturing, but can add unnecessary complexity to the simulation. It is then a matter of selecting only those elements that have a bearing on the issue at hand.

-

Methodology:

- To save time and computing resources, we reduce the parts of the model that are too small to affect the simulation results.

- For large assemblies, we keep only the critical parts of the design. This speeds up the resolution process.

- In some cases, we will recreate a new, simplified version of your design to focus on key study areas.

-

The different steps to repair the geometry of the 3D CFD model :

- Eliminate spaces that prevent filling voids. It is generally the gaps between the parts, the holes of drillings, the joinery elements for the buildings...

- Reduction of very large assemblies to include only vital components.

- Eliminate the gaps between non-contiguous elements.

Prepare the 3D CFD model for mesh optimization

To study fluid motion in a design, there must be a model of the flow region. Most 3D models don’t include it by default so it’s a matter of making them from software that complements the original 3D model. On the other hand, it is also a question of preparing the model for the optimization of the mesh in high-stake areas.

Thus, we add 3D parts, invisible in the renderings and in the CFD studies which will allow to refine precisely the mesh in the flow areas to be captured in the CFD study.

What is mesh? (and why is this important?)

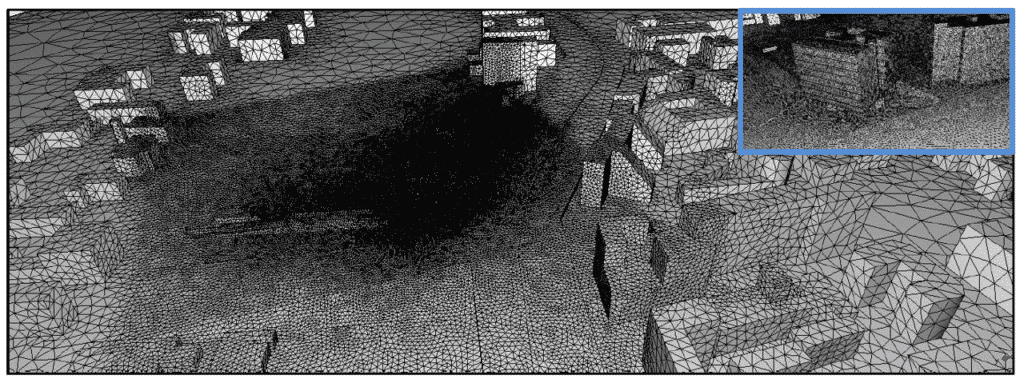

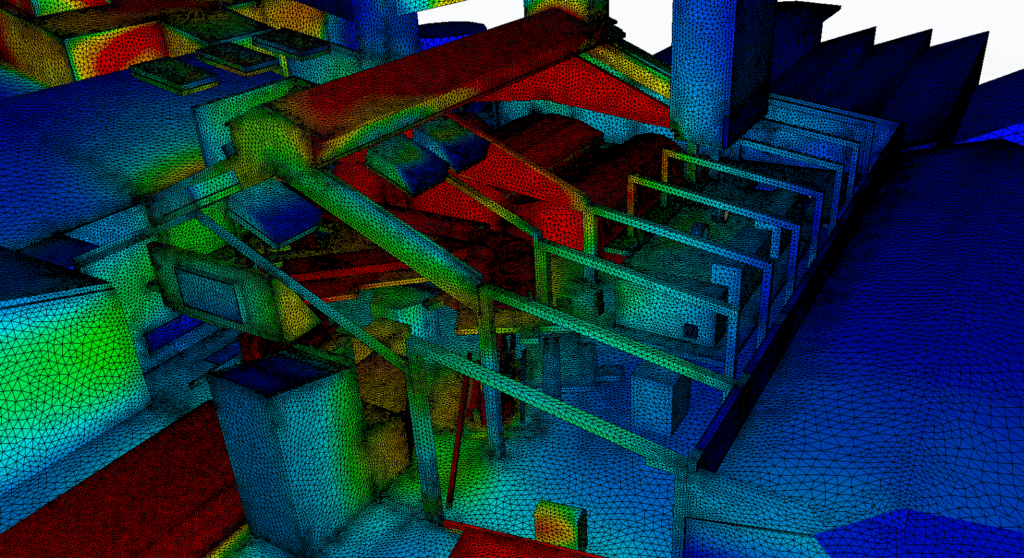

The generation of the mesh (3D) is an important phase in a CFD analysis, given its influence on the calculated solution. A mesh of very good quality is essential for obtaining a precise, robust and meaningful calculation result.

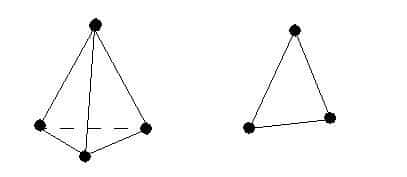

Finite element calculations

Before running a CFD simulation, the geometry is divided into small pieces called elements. The corner of each element is a node. The calculation is performed at the nodes. These elements and nodes constitute the mesh.

In three-dimensional models, most elements are tetrahedra: an element with four sides and a triangular face. In two-dimensional models, most of the elements are triangles.

Mesh structure

We distinguish between structured and unstructured, orthogonal or free mesh. In a 3D structured mesh , the calculation is done more quickly since it does not require the assembly of a connection matrix. In an unstructured mesh, this is not the case. The advantage of the latter is that it makes it possible to mesh any geometries. On the other hand, the creation and the setting in memory of the matrix can strongly slow down calculation. This type of mesh is used for complex geometries with curves or a large number of elements.

Solid volumes require few elements , unlike fluid volumes which require precise refinement because they cannot move away from a parallelepipedal geometry; indeed for the angles of the very deformed elements, there are risks that the calculation cannot converge.

Visualization of the impact of the mesh on the resolution of the CFD study

Mesh Density

With regard to the density of the mesh, it is necessary to find a compromise between the cost of the computation time and the desired precision. It is useless to densify the mesh, consequently to increase the number of iterations, if the precision is sufficient with a limited number of elements.

Mesh adaptation principle

The quality of the mesh has a serious impact on the convergence , the precision of the solution and especially on the computation time. A good mesh quality is based on the minimization of the elements presenting “distortions” and on a good “resolution” in the regions presenting a strong gradient (gap, boundary layers, recirculation, etc.).

The mesh is adapted to be as fine as possible in the critical study areas. This makes it possible to take into account macroscopic phenomena (building volumetry) channeling current tubes by venturi effect whilecorrectly capturing smaller scale aeraulic phenomena (air diffusion).

How are the CFD boundary conditions defined?

Initial conditions

The initial conditions represent the characteristics of the flow in terms of speed and position of the free surface when starting the simulation. If the calculation starts with random values, the simulation may quickly diverge. In order not to deviate too much from the realistic results and to optimize the calculation time, the initial conditions are studied and chosen before the CFD study.

Boundary conditions

The study of the boundary conditions is decisive in a modeling, one can summarize the boundary conditions as the hypotheses of the simulation. This is the most critical step for the success of the study, the establishment of the specific boundary conditions of the project should be studied in detail at the beginning of the mission.

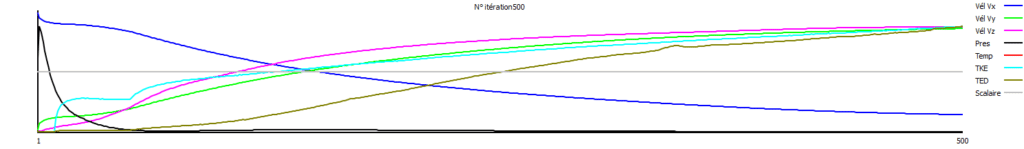

Resolution method

Selection of the turbulence model

The notion of turbulence model is particular in fluid mechanics. It makes it possible to catalog the various structures which coexist in a flow and to give them a certain importance within the flow.

Comparative studies of turbulence models carried out by Combes[2000] allowed to designate the model with two transport equations k-ε as the model best suited to generalist flows. It is one of the most used, the most efficient, the simplest and the most widely validated models. k represents the turbulent kinetic energy and ε, the rate of dissipation of the turbulent kinetic energy. Logically we will use it for most of the fluid simulations in thermo-aeraulics and hydrology, but we can select other turbulence models for particular simulations.

Calculation method

The numerical solution is conducted through linearization and discretization of the set of conservation equations, which requires the subdivision of the computational domain into a number of non-contiguous finite volumes (mesh). The resolution of the study consists in the resolution of the non-linear equation system of Navier-Stokes on computer servers dedicated to CFD.

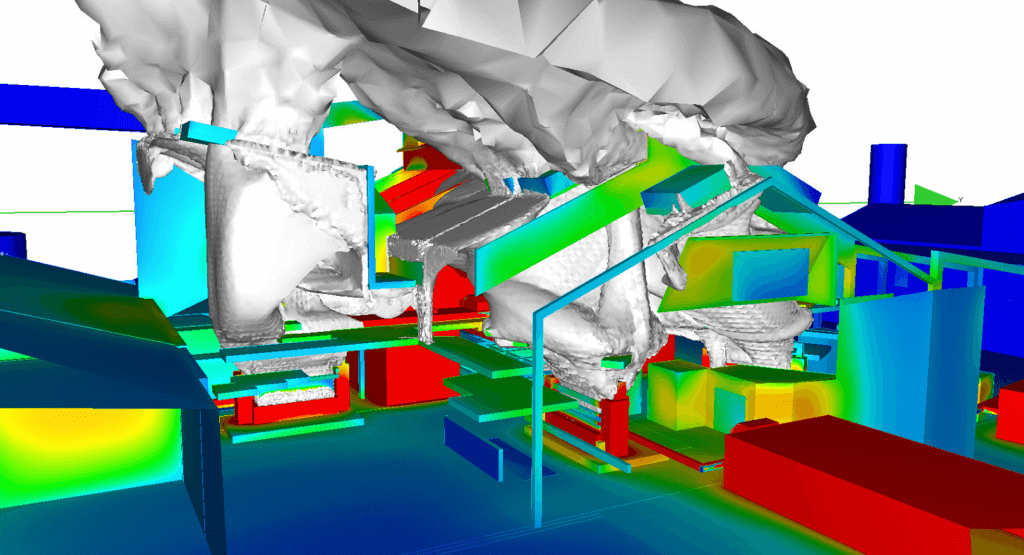

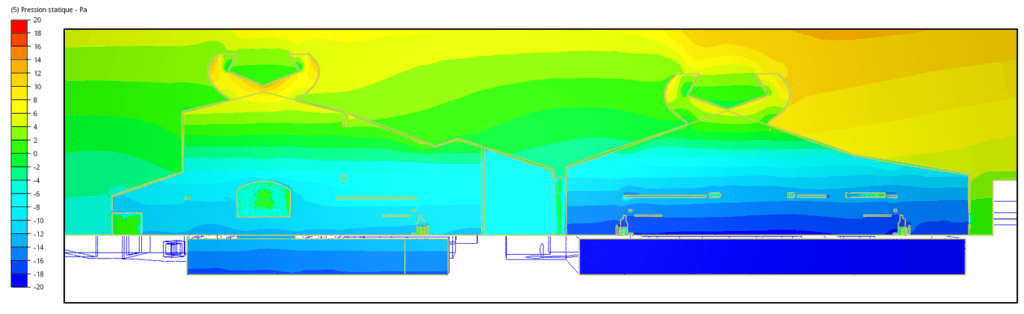

Viewing the results

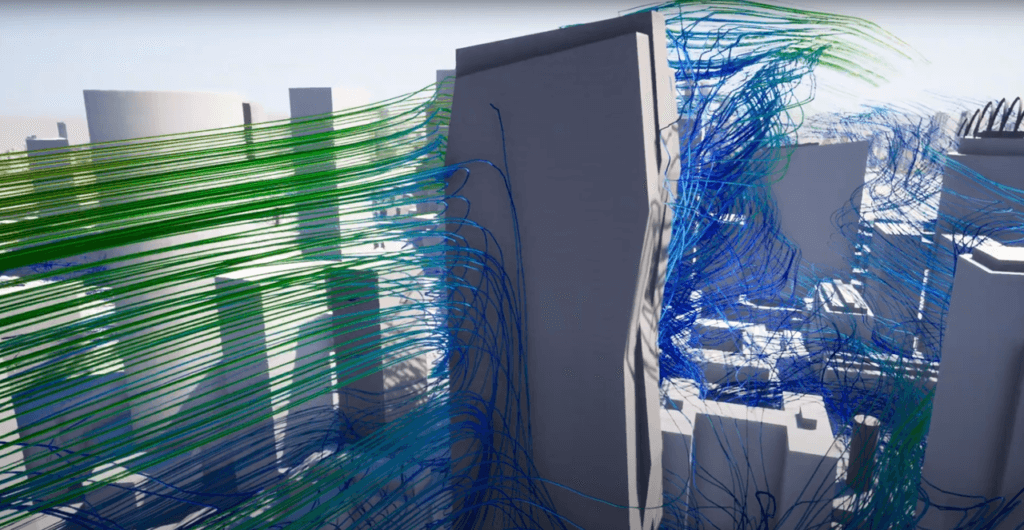

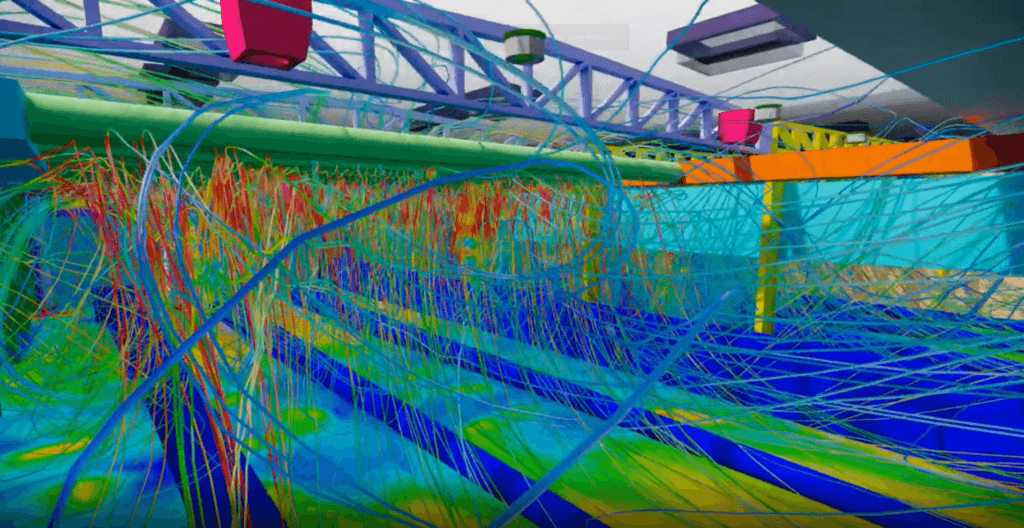

Graphical summaries

The flow of a fluid in a volume is usually complex and has many low speed recirculations, which makes visualization on a plane difficult. We report the most striking phenomena with maps / sections of situations and very complete explanations.

We have a wide range of representations (current tube, vector fields, isosurface, etc.) which allow us to best transcribe the aeraulic phenomena identified in the technical report.

The interpretation of the results requires the mastery of the CFD analysis software but above all skills in physics and knowledge of the analyzed product in order to explain precisely the different phenomena.

Graphical summaries

According to our feedback, for the most striking elements, videos are produced showing the different views of the CFD model in a dynamic way. The technical brief that may refer to these videos to make it easier to read. In fact, certain phenomena appearing to be difficult to understand on the map.

Advantages and disadvantages of CFD simulation

Benefits of CFD simulation

- The models can be simulated in their entirety and allow the simultaneous analysis of the impact of many phenomena

- The simulations provide measurement data for any point (on the grid)

- Many parameters can be saved which are not accessible in experiments, designs can be secured.

- Early in the design process, a large number of prototypes can be simulated to quickly gather information for system optimization

- Simulations can contribute to a better understanding of the problem in order to develop relevant technical solutions

- Integrating CFD simulation in its design protocols means integrating a team of experts who will have a different look in the search for a solution.

Disadvantages of CFD simulation

- Errors can occur due to models that have boundary conditions that are too simple or in error.

- Possible uncertainties due to insufficient calculation values per cell and resulting interpolation errors

- Computing time for large models can be long

These problems are very clearly reduced thanks to the experience acquired on many projects by the engineers of EOLIOS. It is important to carry out this type of study with a qualified team.

How much does a CFD simulation cost?

Okay, granted, CFD is not the cheapest engineering tool (compared to a standard CAD application or spreadsheet) due to its complexity and requirements (experience, licenses, computational resources).

On the other hand, the results that this type of study offers and their contribution to a design or problem-solving process cannot be compared to those obtained with simpler tools.

The reduction in design time, prototyping savings, and process or product improvement usually outweigh the cost of CFD simulation.

We offer mission protocols adapted to any budget.

If after reading this, you think your project can benefit from CFD tools, do not hesitate to contact us and we will propose you a clear and detailed study protocol.

Examples of CFD simulation applications

Example of CFD simulation projects :

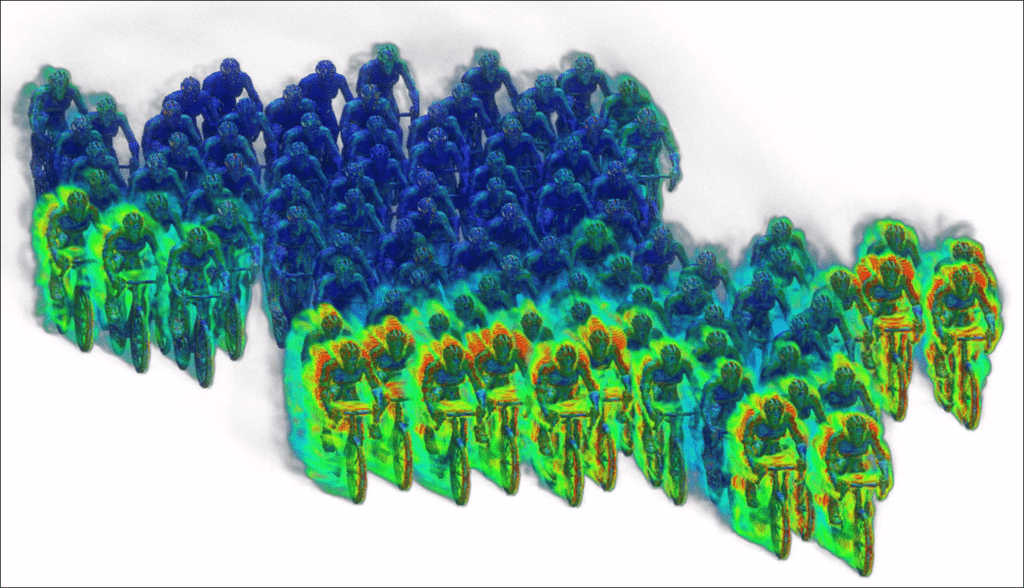

CFD simulation of the aerodynamic phenomena of a peloton of cyclists

CFD simulation of drag: advanced calculation to improve aerodynamics

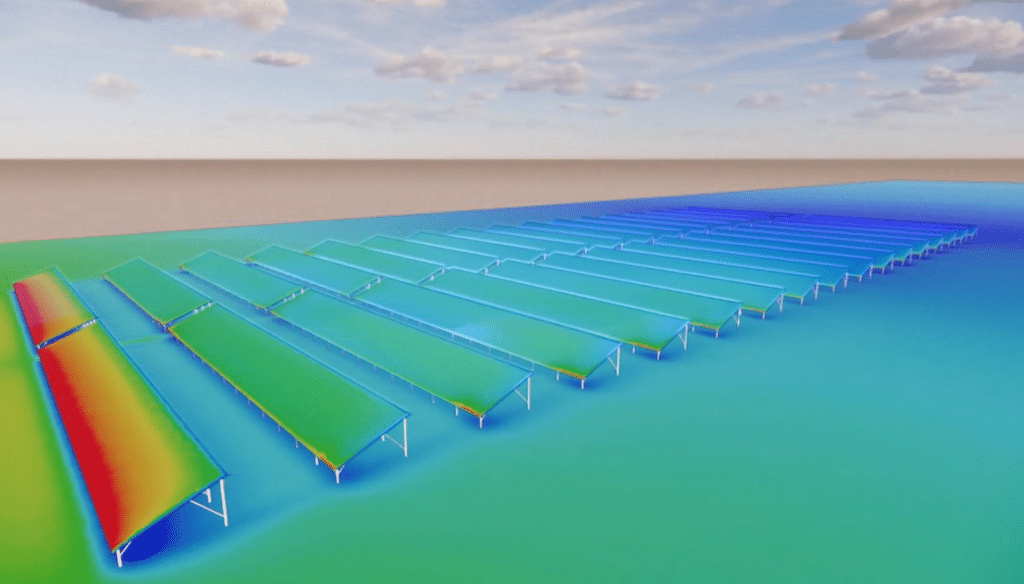

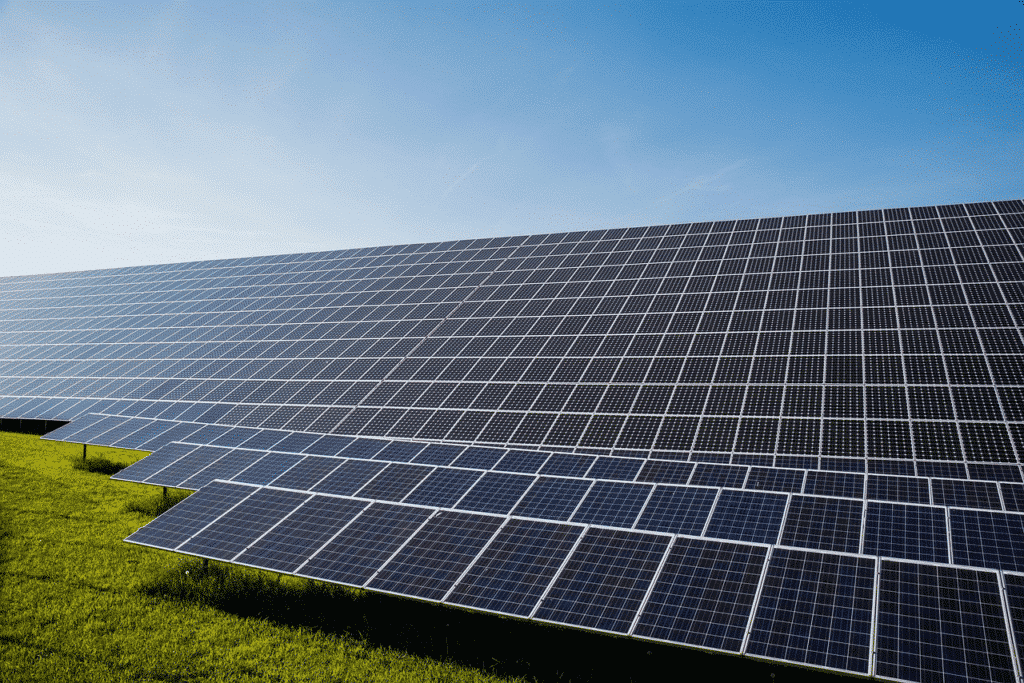

Impact of wind on a solar power plant

Pressure loss and hydraulic resistance

Legionnaires’ disease and cooling towers

Pedestrian comfort criteria and mapping

Extreme wind study – Solar power plant

Thermal draft effect

CFD simulation: An alternative to wind tunnel testing