CFD simulation: An alternative to wind tunnel testing

Accueil » Air & Wind » CFD simulation: An alternative to wind tunnel testing

Obsolete Wind Tunnel Tests? The Rise of CFD Simulation

Discover how CFD (Computational Fluid Dynamics) simulation is revolutionizing aerodynamic analysis, offering an efficient and cost-effective alternative to traditional wind tunnel testing. Explore its benefits, applications and new perspectives for modern engineering.

- A passionate team

- Exclusive estates

- All sectors

- Dozens of projects completed

- Proven expertise

- International projects

Our projects :

CFD: an alternative to wind tunnel testing

Wind tunnel tests

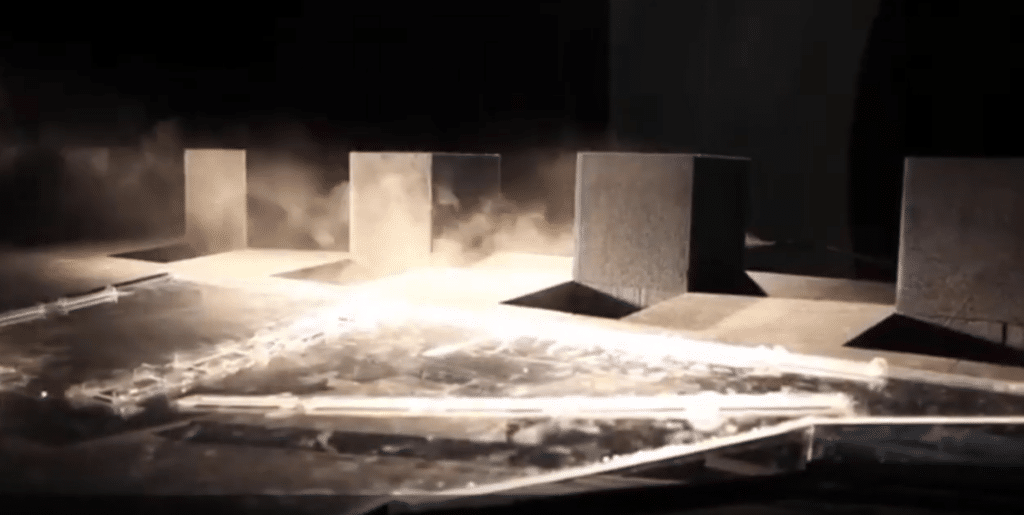

Wind tunnel testing has been widely used for industrial and research applications over the past five decades.

Wind tunnel testing requires expensive equipment and sophisticated instrumentation to measure a range of field variables. range of field variables (wind speed, pressure loads, turbulence intensity, etc.).

Its main limitation lies in the fact that such measurements are only obtained at a few precise points in the test section, which considerably restricts overall understanding of evolutionary or transient processes complex unsteady phenomena (such as vortex shredding, turbulent wakes and thermal stratification).

The different stages of a wind tunnel test

A wind tunnel test is an aerodynamic test carried out in a wind tunnel to study the behavior of an object exposed to an air flow simulating real-life conditions.

Here are the main stages of a wind tunnel test:

1. Defining the objective: Before carrying out a wind tunnel test, it is important to clearly define the objective of the test.

This could be studying the drag of a vehicle, optimizing the lift of an aircraft wing, or assessing the stability of a building in the wind.

2. Model design: A reduced-scale model of the object to be studied is usually made, so that it can be tested in the wind tunnel.

The model can be made from a variety of materials, such as plastic, wood or even 3D printing.

3. Installing the model in the wind tunnel: Once the model is ready, it is positioned in the wind tunnel so as to be exposed to the air flow.

Brackets and measuring systems are used to hold the model in place and collect relevant data during the test.

4. Setting test conditions: Before starting the test, the test conditions must be set, such as wind speed, temperature and pressure.

These conditions are generally determined according to the specific technical specifications of the test object.

5. Data collection: During the test, various measurements and observations are made to assess the object’s behavior in the airflow.

These may include measuring the force exerted on the object (drag, lift), visualizing airflows using visualization techniques (smoke, particles), or measuring pressures on the object’s surface.

6. Analysis of results: Once the data have been collected, they are analyzed to draw conclusions about the aerodynamic behavior of the object.

The results of the wind tunnel test are often presented in the form of technical reports, graphs or visuals to communicate the conclusions of the study and any recommendations for optimizing the tested object.

CFD: a toolbox type evolution

Numerical modeling of wind tunnel tests

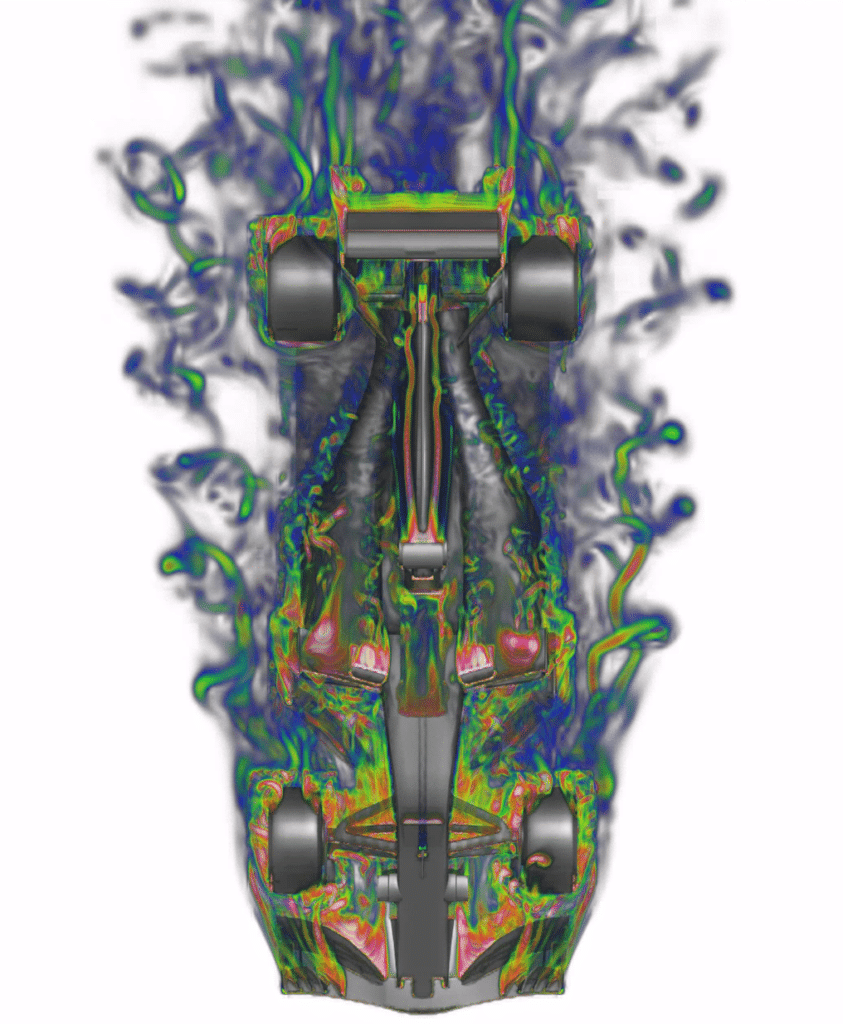

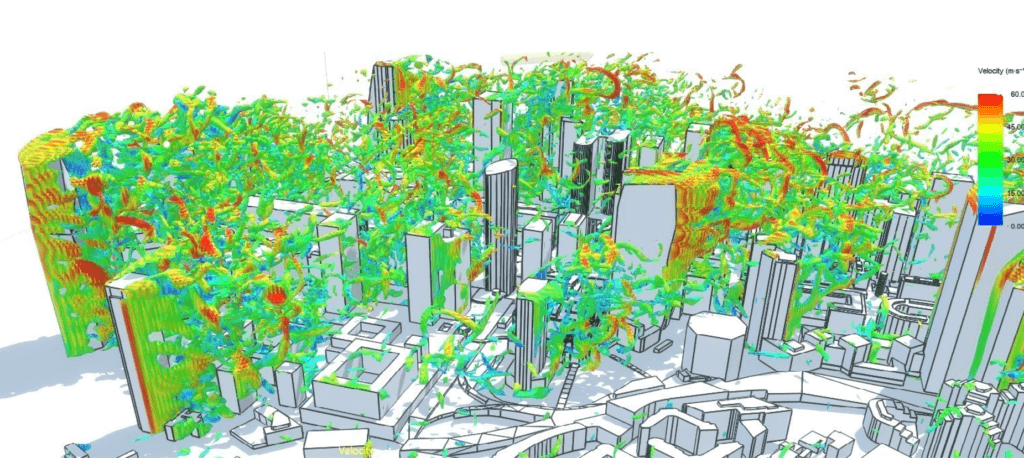

CFD offers many advantages over wind tunnel testing. In addition to generating full-scale simulations (rather than the reduced-scale models used for many physical simulations), it also provides complementary data and enables wind speeds for a given wind to be compared simultaneously between two points.

Hydrological, aeraulic and thermal studies can be carried out at different scales: from microelectronics to building and city studies.

Results can be visualized more clearly and explained to a wider audience.

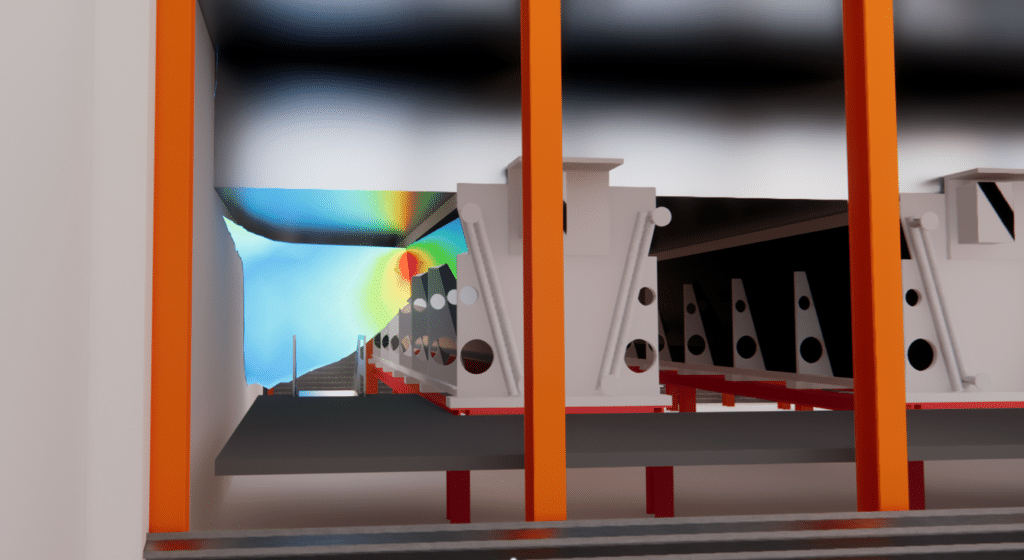

CFD simulation of a metro moving through a station

CFD: a very wide range of applications

- Simulate the flow of a fluid around or inside a body

- Studying wind comfort

- Wind load study

- Studying convective exchanges

- Studying conductive exchanges

- Studying radiative exchanges

- Visualize the dispersion of pollutants

- Study smoke extraction

- Study the movement of dust, sand …

- Study the movement of objects, fans, etc.

- Fluid flow

- Risk of submersion

- Risk of rain or snow

These methods make it possible to solve a very wide range of problems that we will present here.

Examples of CFD simulation applications

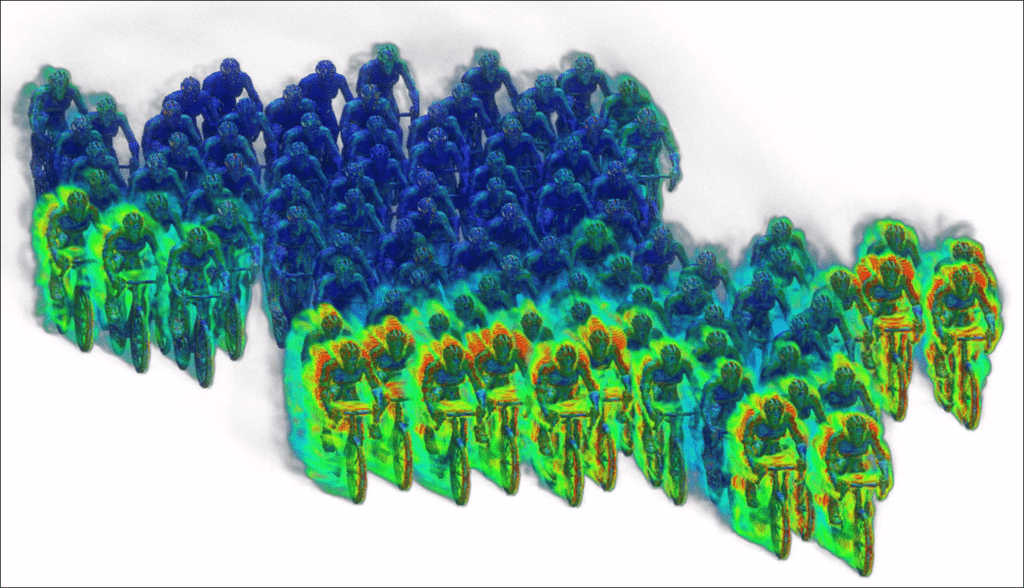

CFD simulation of the aerodynamic phenomena of a peloton of cyclists

CFD simulation of drag: advanced calculation to improve aerodynamics

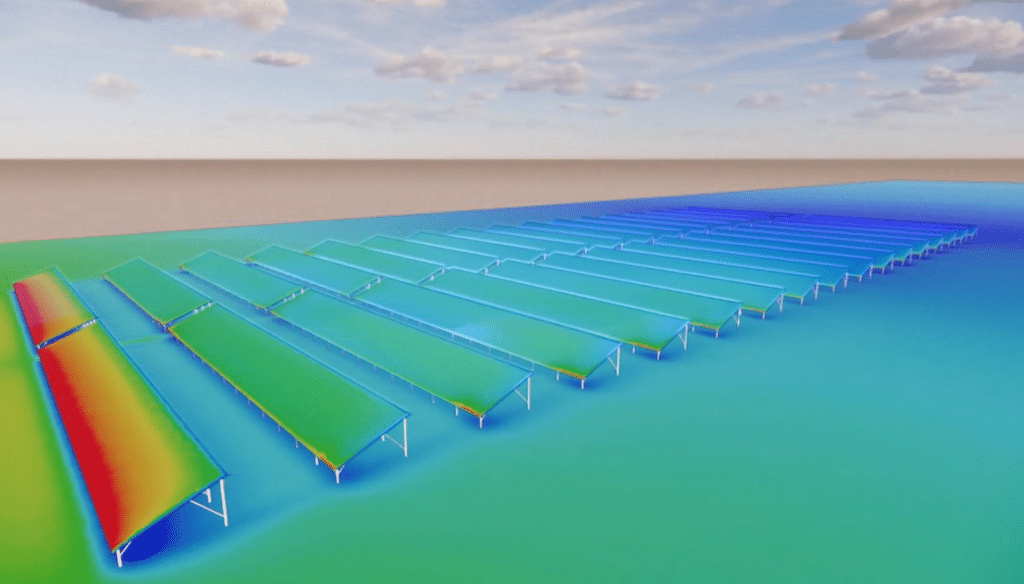

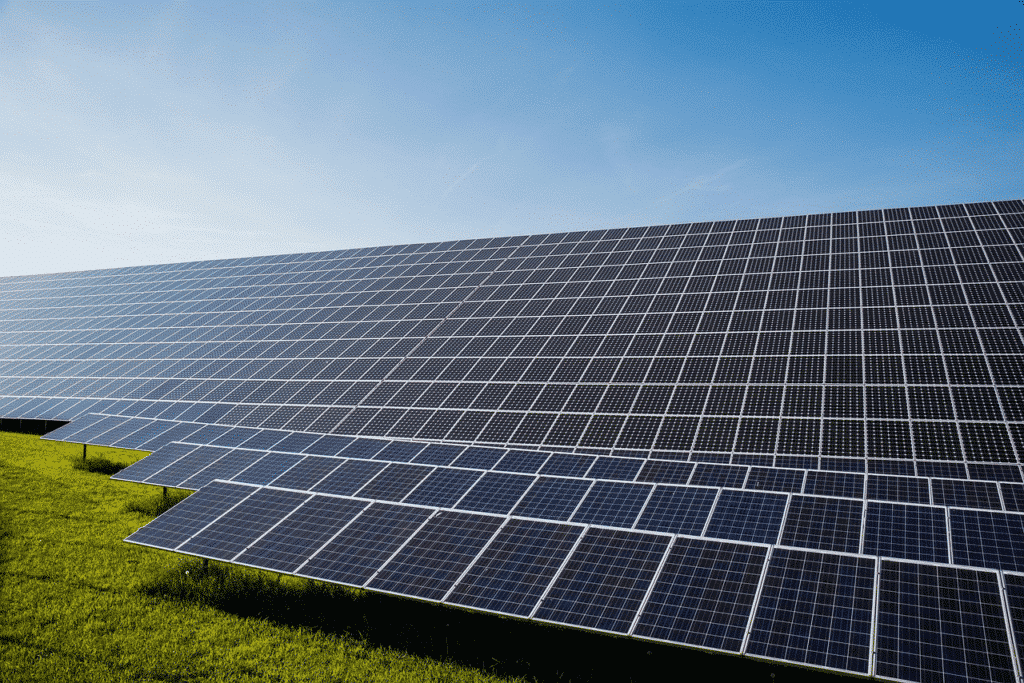

Impact of wind on a solar power plant

Pressure loss and hydraulic resistance

Legionnaires’ disease and cooling towers

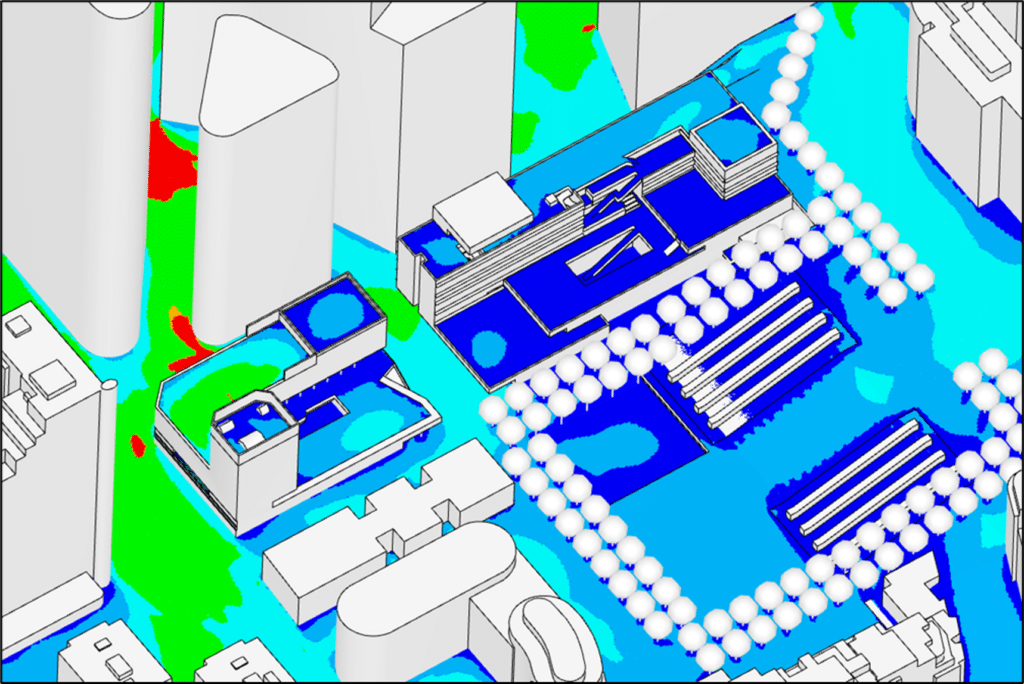

Pedestrian comfort criteria and mapping

Extreme wind study – Solar power plant

Thermal draft effect

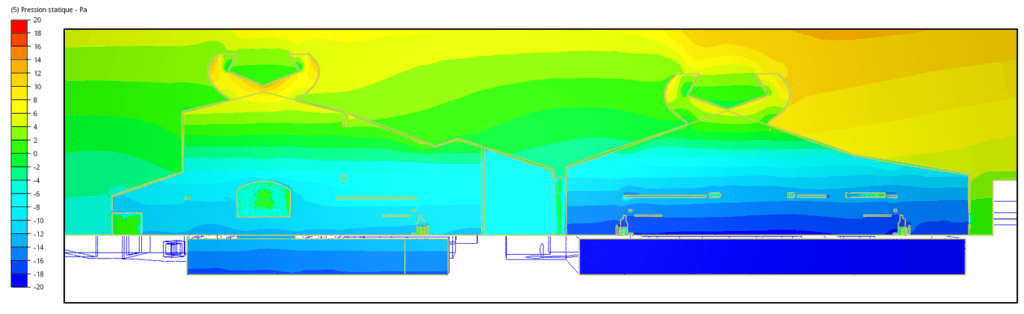

Pressure study