Industrial natural ventilation

Accueil » Expertise » Industries » Industrial natural ventilation

The engineering of natural ventilation is based on specific phenomena that can be controlled:

- Sizing of static aerators

- Ventilation shaft design

- Improved comfort

- Sizing of filtration systems

- Pollutant extraction

- Evacuation of water mists

Continue browsing :

Our latest news:

Our projects :

Our fields of intervention :

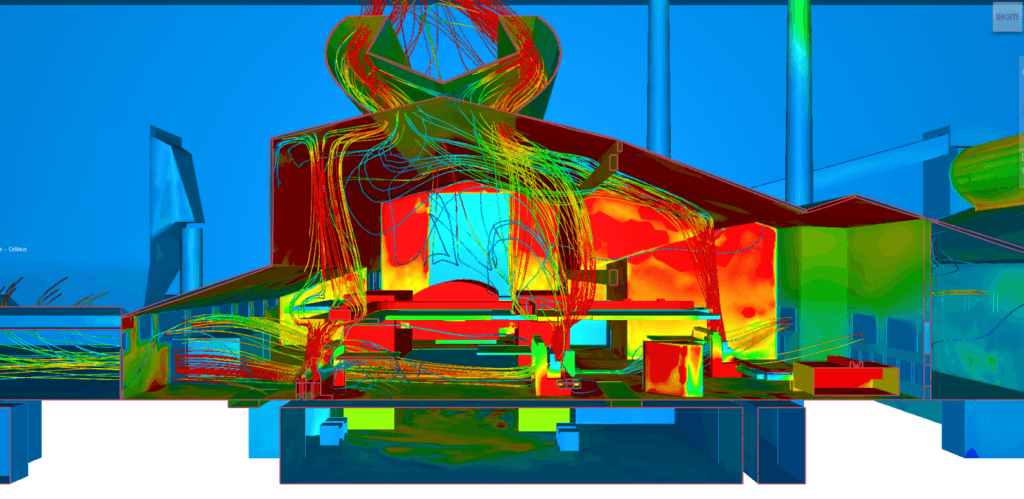

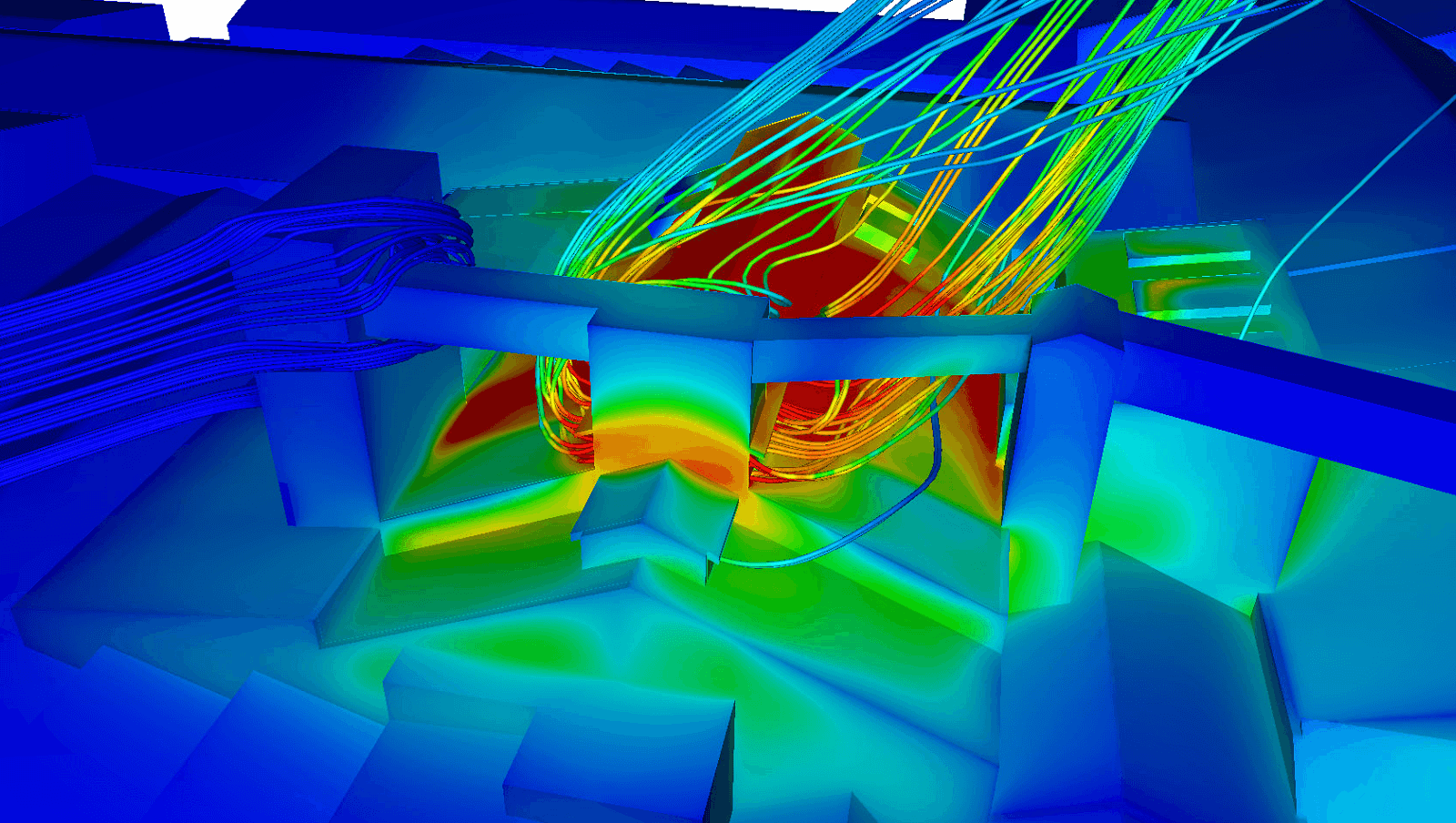

Design of natural ventilation in glassworks

In industrial facilities with large heat sources, such as glass and steel plants, natural ventilation uses the heat gains from the production process itself to create sufficient motive power.

Ventilation of a plant containing furnaces operating at the extremely high temperatures required for glass production is a major technical problem. Even the best insulated furnaces give off large amounts of heat inside the facility, resulting in very high heat gains to the indoor air.

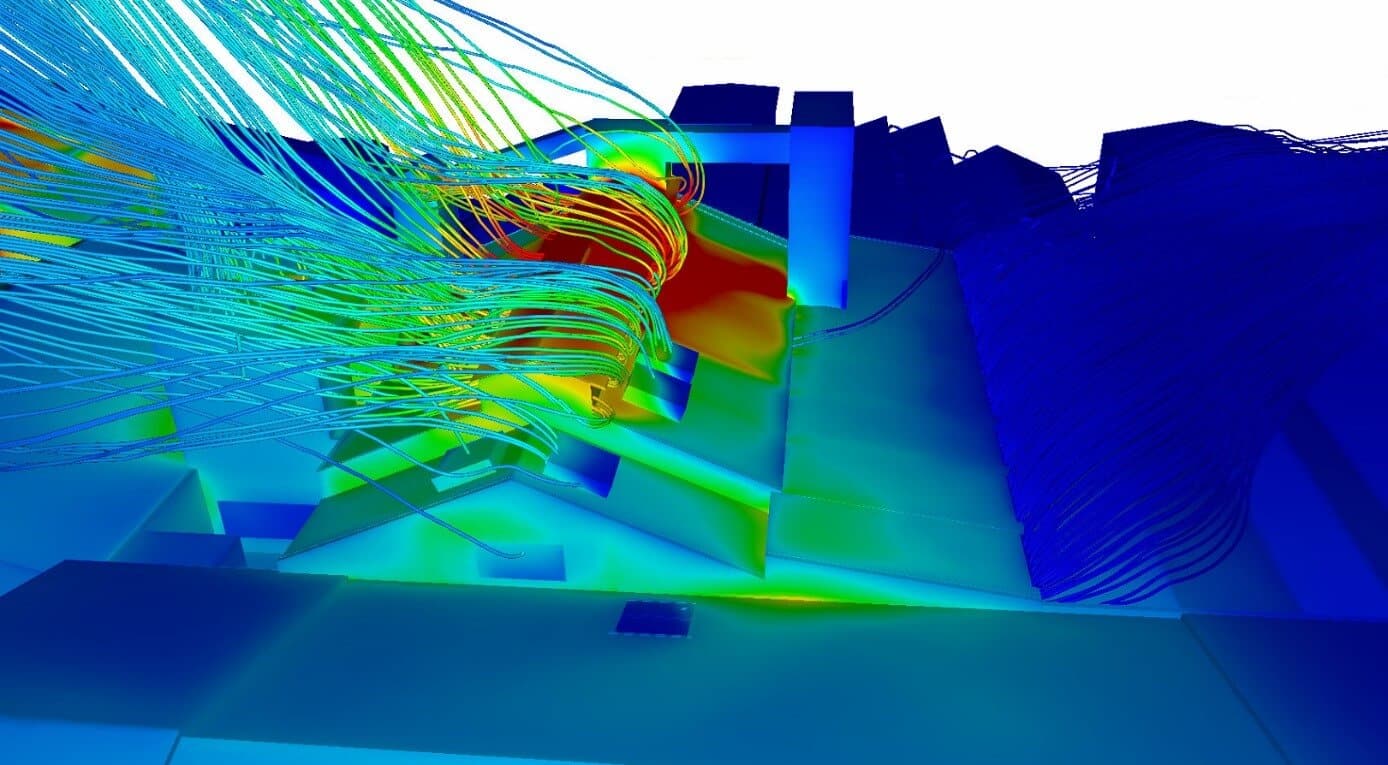

Sizing of static natural ventilation aerators

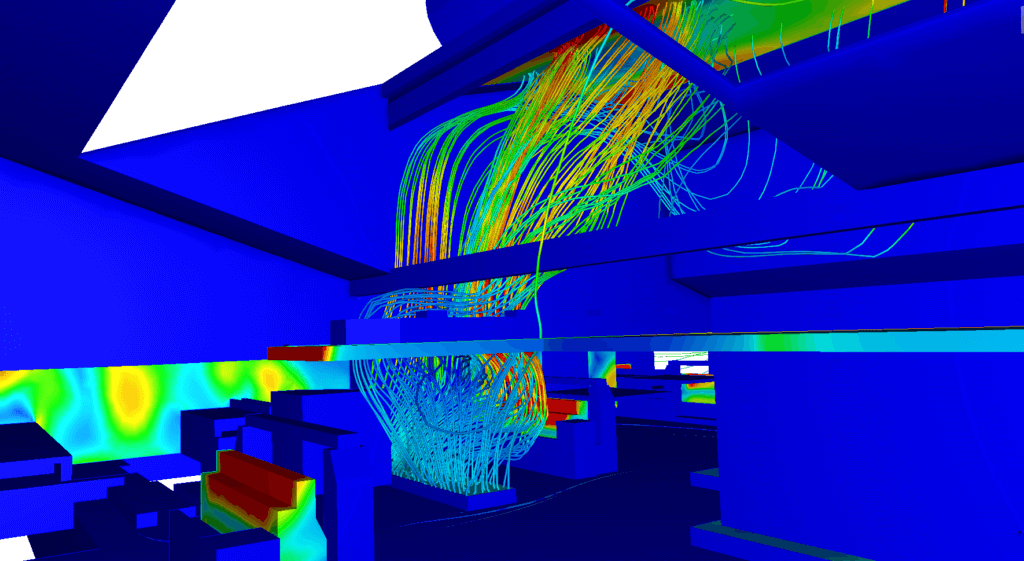

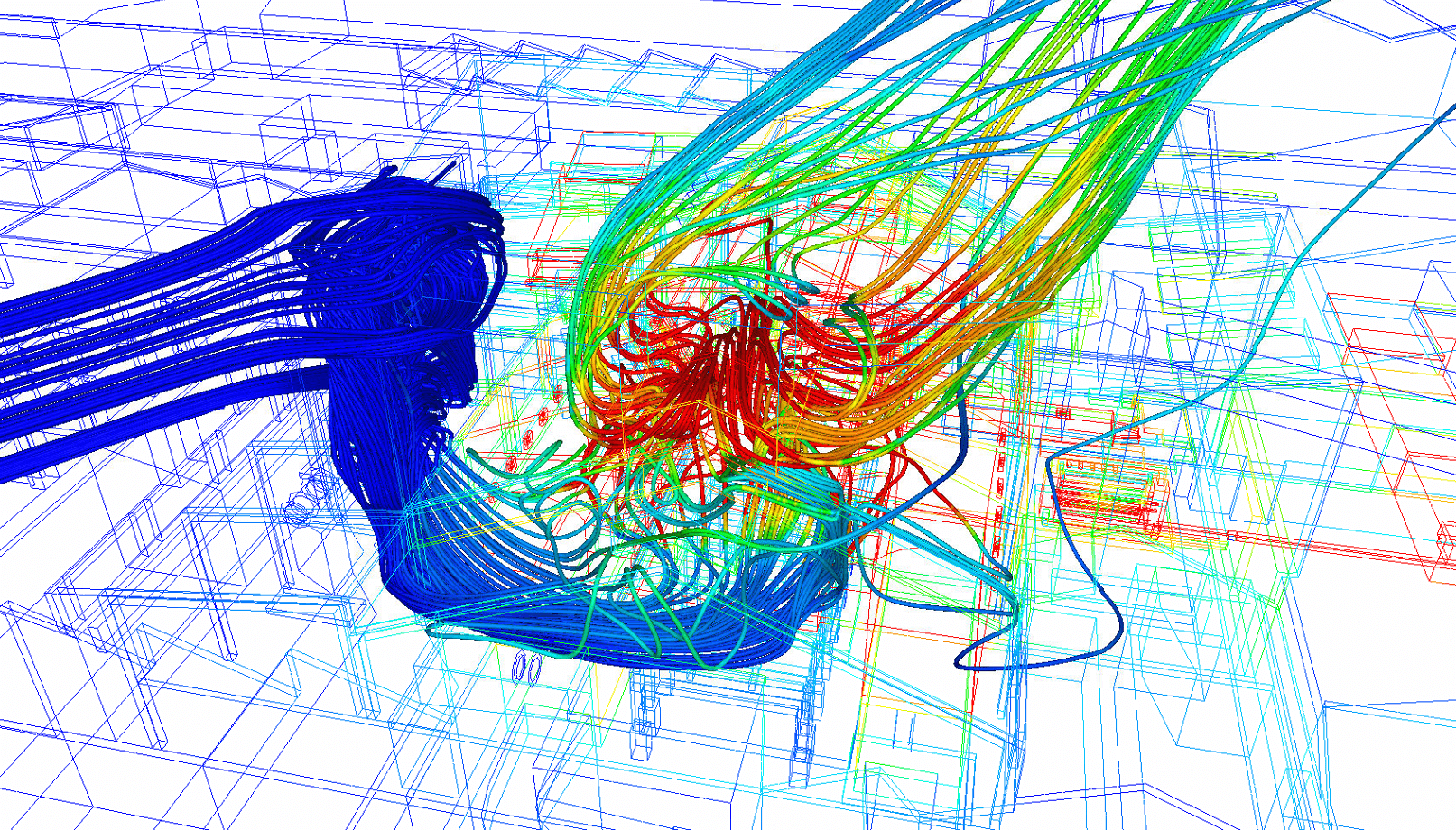

We are studying the principle of the neutral pressure plane in order to optimize natural ventilation.

Automatic natural ventilation

Modern natural ventilation systems operate automatically on both the exhaust air vents and the air inlets of the dampers with air supply. Thus, this operation allows to maintain a specific temperature under the roof and to minimize the

pressure

of negative air on the first floor of the building. The principle of minimizing negative pressure requires a sufficiently large number of air inlets.

Optimization of operator comfort

Natural ventilation is often associated with the thermo-aerodynamic discomfort of the operators because it is rarely controlled.

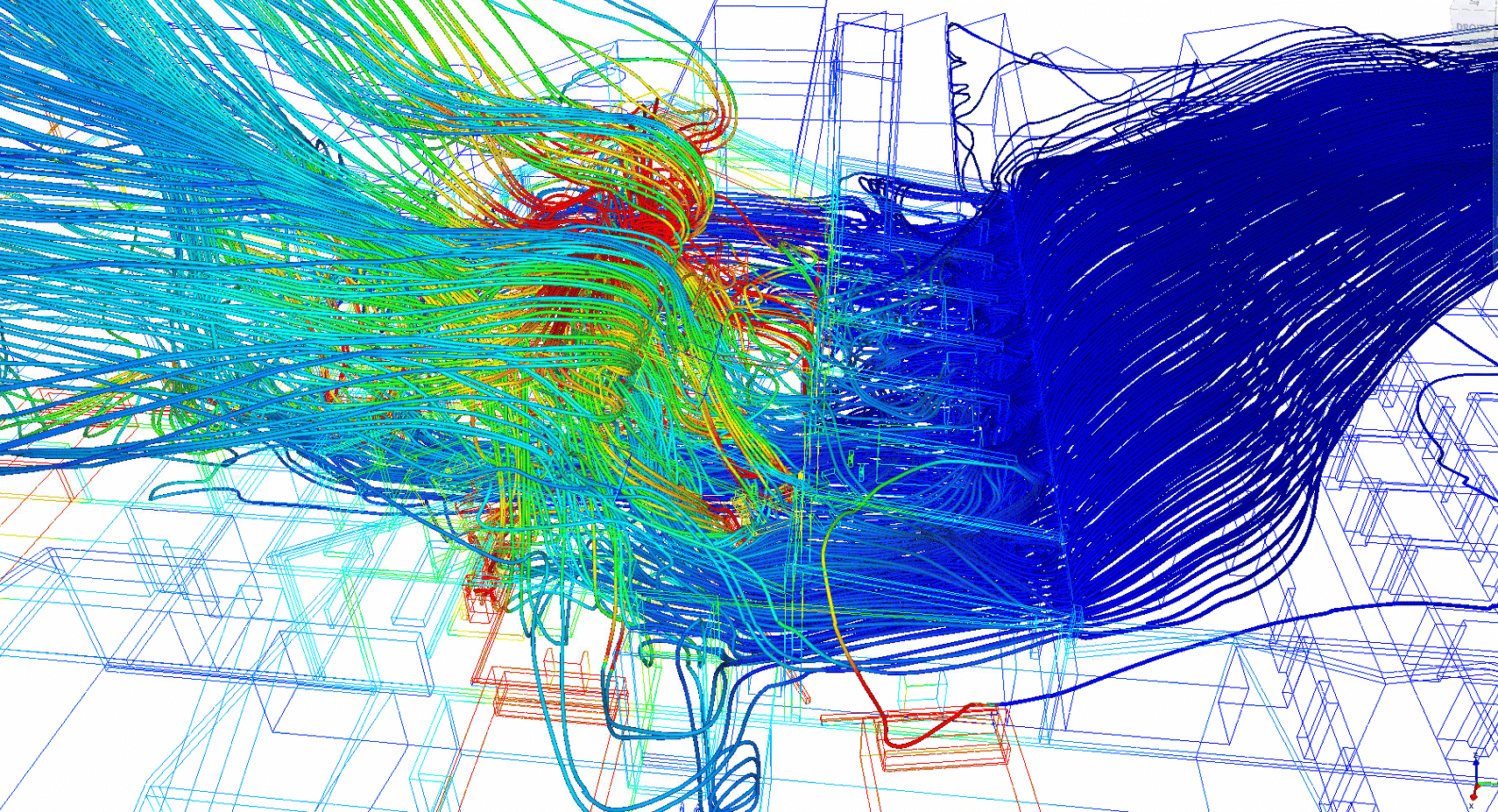

Pollutant extraction

Monitoring indoor air quality

air quality

Indoor air quality monitoring is important for the health and safety of employees. Invisible pollutants such as carbon monoxide, fumes toxic to traffic. And other harmful chemicals can cause health problems. As well as lower organizational productivity.

CFD modeling is a tool versatile to solve engineering problems related to analysis of the propagation of various impurities and particles in the air. The CFD modeling allows to reproduce the air movement taking into account the heat and mass transfer, taking into account the transfer of gaseous impurities and their dispersion, as well as the transfer of mechanical particles in suspension.