Reservoir rupture: wave effect

Accueil » Expertise » Industrial Process » Reservoir rupture: wave effect

EOLIOS improves safety for outdoor liquid storage

- Liquid storage

- Retention devices

- Modeling overflow and wave effects

- Study of critical failure scenarios

- Preventive measures.

- Impact study

- Spreading area

- Retention devices

- Tailor-made solution design

Our Data Center projects :

Preventing accidents : How EOLIOS uses digital simulation to make outdoor liquid storage safer

CFD simulation: improving safety for outdoor liquid storage

Outdoor liquid storage is common practice in many industries. However, it presents a potential risk in terms of corrosion and tank tearing.

Corrosion, whether caused by the liquid itself or by ambient humidity, can build up over the years and lead to structural failure.

In the field of fluid mechanics, EOLIOS is recognized for its expertise in numerical simulation. Thanks to this advanced technology, we are able to model the wave generated by a product leak and assist manufacturers in sizing retention devices. This precise analysis capability makes it possible to determine the amount of liquid spilled and the surface area, which is essential for ensuring the safety of industrial facilities.

Modelling the effects of waves generated by a product leak

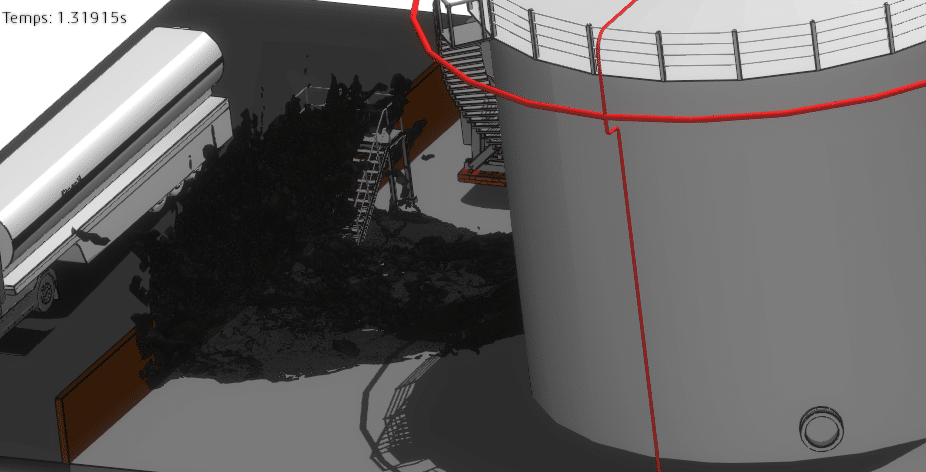

When a product leak occurs, a wave is generated and propagates through the liquid contained in the tank. This wave can have a significant impact on retention devices. Using advanced numerical simulation tools, EOLIOS is able to accurately model the propagation of this wave, taking into account the properties of the liquid and the reservoir.

"Objective: to determine the consequences of excessive overflow in the event of a product leak.

Modeling the wave makes it possible to accurately determine the amount of liquid spilled in the event of a leak. This information is crucial for manufacturers, enabling them to correctly size retention devices such as retention basins or cofferdams. Excessive overflow can lead to environmental pollution and adverse consequences for worker health and safety.

The simulation takes into account several parameters, such as gravity, liquid density, pressure and reservoir size, as well as environmental conditions such as terrain topography and the presence of obstacles. These parameters are integrated into complex mathematical equations that are solved numerically to obtain an accurate representation of the liquid flow.

Visualization of spreading area :

In addition to estimating the amount of liquid spilled, our simulation also visualizes the extent of the area contaminated by the liquid. This information is essential for assessing potential damage and the necessary intervention measures.

Thanks to our numerical modelling, we are able to accurately represent the spreading surface of the liquid. This enables professionals to visually assess the extent of potential damage and plan interventions accordingly.

Visualizing the spreading area can also help identify areas at risk and take preventive measures to minimize the consequences of any product spillage.

"Is your data center protected against the failure of its climate systems during a heat wave? "

Sizing retention devices

Sizing retention systems is a critical step in the design of industrial facilities. Prolonged overflow can lead to significant and costly damage, both in material and environmental terms. It is therefore essential to determine the spreading area needed to effectively contain the liquid in the event of a leak.

One of the main objectives of our simulation is to accurately estimate the amount of liquid that will be overfilled when a reservoir ruptures. This information is crucial for assessing potential risks and sizing retention basins.

In fact, by simulating the flow of liquid, we can accurately determine the quantity of liquid that will end up outside the tank. This estimate takes into account parameters such as leakage rate, head and distance traveled by the liquid.

This information is essential for manufacturers, enabling them to optimize the size of their retention basins. By knowing the quantity of liquid likely to be overflowing, they can determine the necessary capacity of retention basins to limit environmental impacts and associated costs.

Optimizing industrial plant safety

The safety of industrial installations is a major concern for manufacturers. Proper risk management, particularly in terms of liquid storage, is essential to prevent accidents and spills. Appropriate design of retention devices is a key element of risk management.

Using the results of wave modelling, EOLIOS is able to assist manufacturers in sizing retention devices. We take into account various parameters, such as liquid viscosity, leak rate, tank geometry and environmental constraints. With this information, we can recommend the ideal spreading surface to minimize the risk of uncontrolled spillage.

By working with EOLIOS, manufacturers can be confident that their facilities are designed to minimize the risk of reservoir failure. Thanks to our expertise in numerical simulation, we can provide precise and reliable recommendations for sizing retention systems. This reduces the costs associated with material and environmental damage, and enhances worker safety.

EOLIOS: Assistance in modelling liquid waves to enhance the safety of industrial facilities

Our expertise

Outdoor liquid storage presents potential risks in terms of corrosion and tank tearing. Modeling the wave generated by a product leak and sizing retention devices are therefore crucial steps in the design of industrial plants.

Thanks to its expertise in numerical simulation, EOLIOS is able to assist manufacturers in these critical areas. By providing precise recommendations in terms of the quantity of liquid to be spilled and the area to be spread, we help to increase the safety of industrial facilities, reduce the risk of uncontrolled spills and minimize the harmful consequences for the environment and workers’ health.

Each case is unique and requires a tailored approach. At EOLIOS, we don’t subscribe to the idea of ready-made solutions. We understand that each situation has its own set of challenges and variables, requiring creative thinking and careful planning to arrive at a reliable and effective solution. Our fluid mechanics experts work closely with each customer to develop customized solutions to meet specific needs.

Modeling the wave generated by a reservoir leak is a valuable tool for assessing potential risks and taking appropriate preventive measures. Thanks to our expertise in numerical simulation, we are able to provide precise data on the quantity of liquid spilled and the spreading surface, enabling manufacturers to optimally size retention basins and plan interventions in the event of a product spill.

For more information on our liquid wave modeling services or to discuss your specific requirements, please contact us. Our team of experts will be happy to help you.