Home » Guadalajara glassworks

Guadalajara glassworks

In a few words

EOLIOS has dimensioned the natural ventilation openings and the mechanical systems of air distribution, optimized the general aeraulics of the processes of a glass factory in Mexico by using the CFD simulation

Verrerie de Guadalajara

Year

2021

Customer

NC

Location

Mexique

Typology

Verrerie

Continue browsing :

Our other projects :

Latest news:

Description of the project

In partnership with

CHOVET

engineers, EOLIOS engineers were able to design all the natural ventilation concepts for a glassworks-type industrial complex. The first step of the mission was to carry out a detailed audit of the existing installation. As the project is an extension of production, the recording and understanding of the thermo-aeraulic phenomena governing the site made it possible to understand the origin of the main problems that could disrupt production.

IS machine in operation

IS machine in operation

Phase I: Smoke audit

The record of the air inlets, a smoke audit , the measurement of comfort levels, as well as the record of the smoke temperatures at the level of the static roof extractors provided a clear picture of the conditions of use of the site.

Phase II: CFD modeling of the extension project

Secondly, a digital 3D model was produced to complement the BIM Revit model of the project. A real support for reflection and design, this tool made it possible to illustrate very quickly the first guidelines of the concept of natural ventilation.

Distribution of pressure coefficients on the facade

How did CFD simulation help optimize the plant design?

Modeling of the entire production chain:

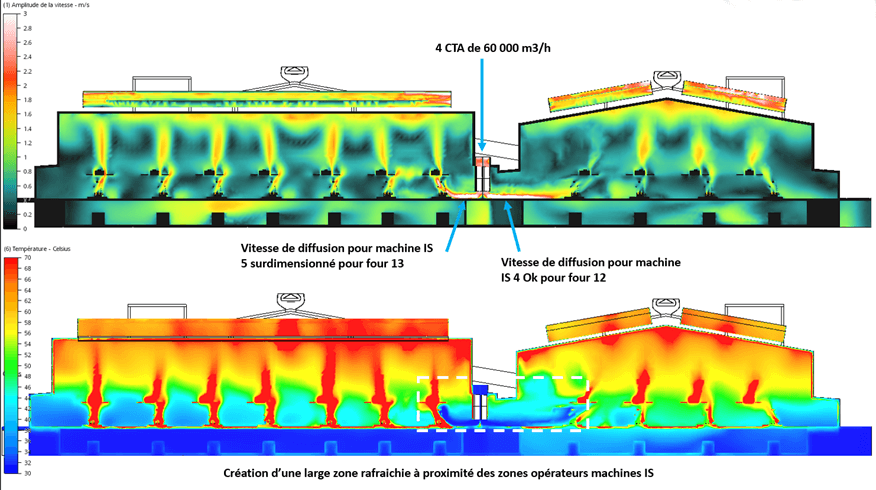

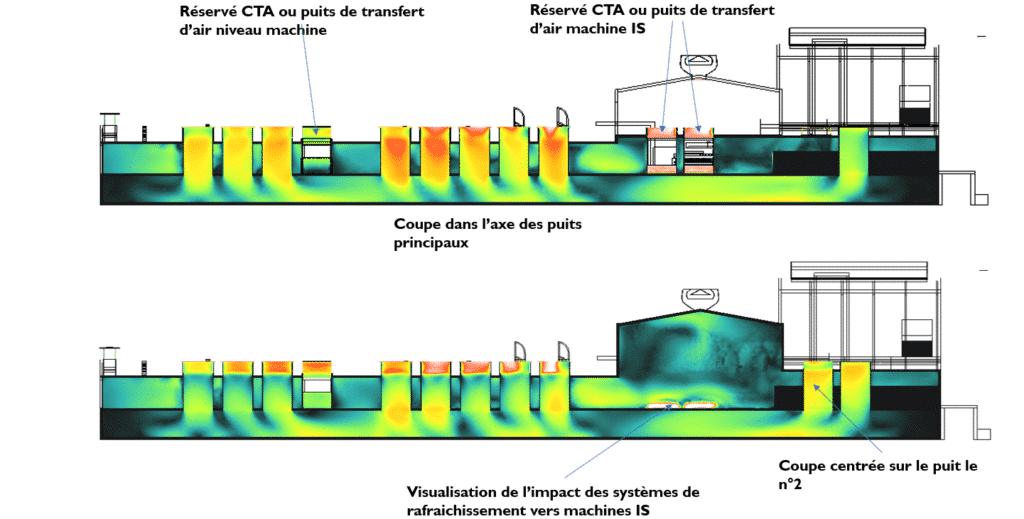

The CFD simulation simulation of all the ventilation systems (suction, discharge) in the basement allowed us to obtain a clear map of the air movement towards these premises.

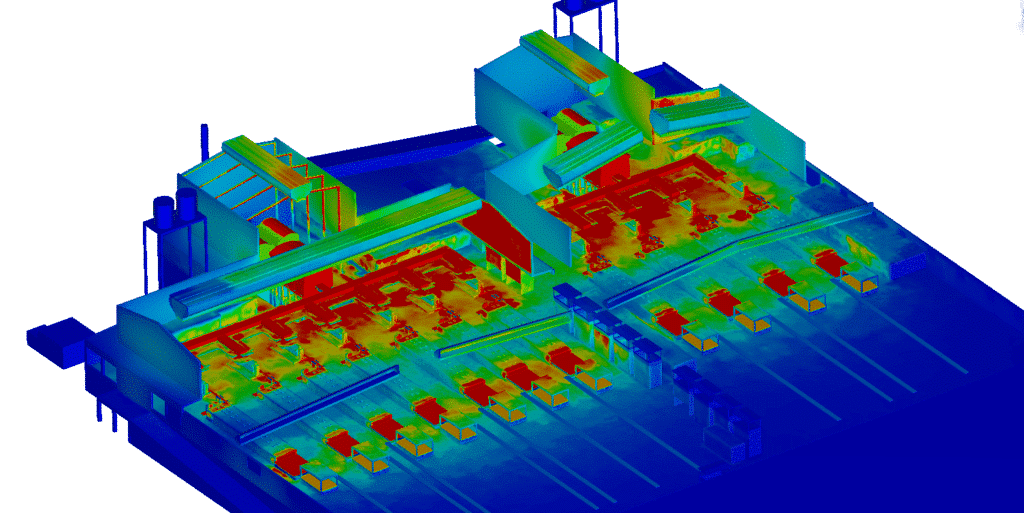

A series of optimizations were made in the following areas the layout of the premises and in the of the different air inlet surfaces. Detailed consideration of all production processes (furnace, feeder, IS machine, arch, cold end) and their heat emissions; detailed modeling of the building and its inter-level connections (compressor rooms); the CFD sub-modeling of specific systems such as sand barriers and aeraulic wells made it possible to obtain the distribution of air displacements in the planned plant.

Understanding extreme phenomena and visualizing system disruption:

Various wind studies were able to estimate the impact of extreme conditions in the building and in particular its impact on a risk of production failure.

The study of the thermal plumes of IS machines, the influence of the entrances and exits of the arch has been able to be highlighted as a driving force behind the natural ventilation of spaces. Finally, once the various ventilation concepts have been validated, several digital prototypes could be presented to the customer, allowing him to obtain a decision-making aid for the sizing of his future installations .

Throughout the study, different types of renderings could be provided:

- explanatory diagrams of the main trends in the audit phase,

- 3D concepts to illustrate prototypes

- maps and interactive 3D model to effectively illustrate the main phenomena

- videos or standalone export allowing a semi-realistic vision of the concepts and associated thermo-aeraulic phenomena.

Continue with the same subject

Video summary of the study

The ingénieurs d‘EOLIOS and from CHOVET have collaborateé for concevoir the concepts from ventilation naturelthe d‘a complexe industriel from type wormrerie. Après a audit deyourillé and a relevé of conditions d‘use, a modèthe 3D numérique a eté créé and of simulations CFD have eté realisées for optimiser l‘agencement ventilation systems and thees surfaces d‘entrees d‘air. From etudes from wind and heat waves have eté menées for estimateer l‘impact of extreme conditions on production processes. Inend, of schémas explicatifs, of concepts 3D, of cartographies and of vidébones have eté ovennis for aider the customer à prendre ses decisions.