Home » Industrial Process » Study of network load losses » Clinker loading facility

Clinker loading facility

Clinker loading facility

Year

2021

Customer

NC

Location

France

Typology

Dust study

Continue browsing :

Our other projects :

Latest news:

Description of the CFD expertise mission

What are the risks associated with dust?

In the production of cement, large amounts of fine and hazardous dust are produced and released. These noxious dusts are deposited on all surfaces of the plant, or are carried by the wind, representing a serious threat to the health of workers and problems of production efficiency.

Cement production in cement factories exposes cement manufacturers to skin and respiratory pathologies, some of which are of allergic origin, linked to the structure of fine alkaline and irritating powder which is spreads in the ambient air in the form of dust, and is deposited on all floors and various supports.

What is clinker?

The clinker is a matériat compoundé principalement from silicate, d‘aluminate and from ironrite from calcium, which is élaboré à shareir from matières premières telles that the calluscaire and l‘argisland, puis cuit à of températures très élevées. He is the principal constituentant from the plupart of betons and of deathiers, and is également utilisé for the manufacturing from briques and from youislands.

How is clinker stored and transported?

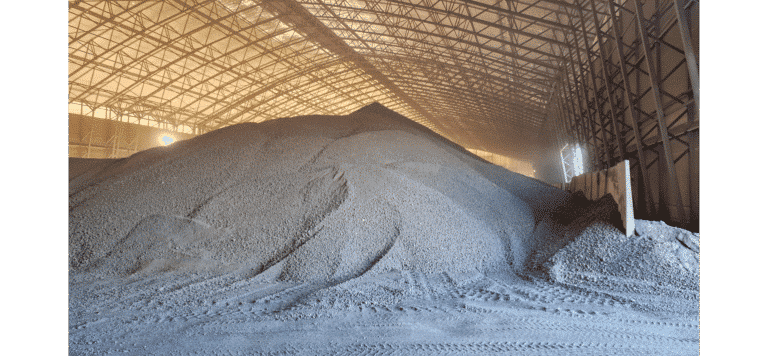

Clinker is stored in the open air in piles or heaps. Clinker is usually stored in piles in a warehouse using mechanical piling and tarping systems. Conveyor belt systems are used to transport the clinker into the warehouse and deposit it on the heap. Once the pile is formed, a mechanical tarp system is used to secure the pile and keep it in place. Protective slabs are also placed between the piles to reduce the risk of accidental movement or collapse of the piles.

The clinker is genéralement transporté by camions–trailers equipped with tipper, by ship and by train. The clinker is unloaded into the trucks using a forklift truck, equipped with a grab system and a crane. The bucket is placed under the clinker and the forklift lifts it and dumps it into the truck. Dust can occur, but clinker plants strive to use filtering and vacuum systems to minimize emissions.

Description of the CFD expertise mission

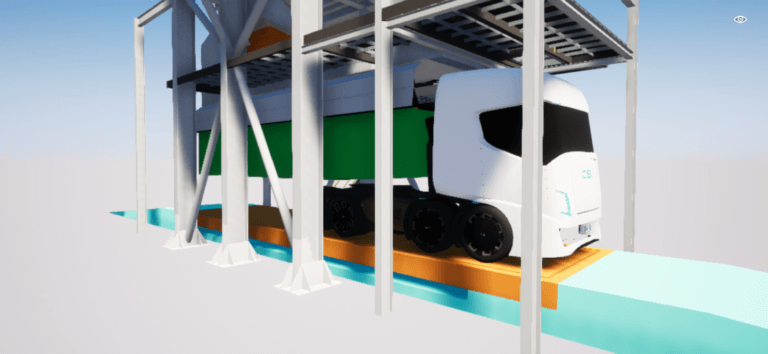

Custom design of a clinker dust extraction system:

The système must be conçu for capturer and éliminer the pYou can visitifères from clinker genérees by the loadement of camions. He is conçu for être installé on the site ou à nearimity, for capturer the pYou can visitifères à the source during the unloading beforeant that‘elles do contaminatedent l‘air and l‘invironmentnement. The clinker dust extraction system is optimized to provide an efficient and safe solution for the collection of fine and light dust generated by the clinker. It offers high filtration efficiency, high treatment capacity and a solution that limits energy consumption.

Methodology for sizing dust collection systems :

EOLIOS Engineering’s studies have made it possible to design a specific system for vacuuming Clinker dust when loading transport lorries.

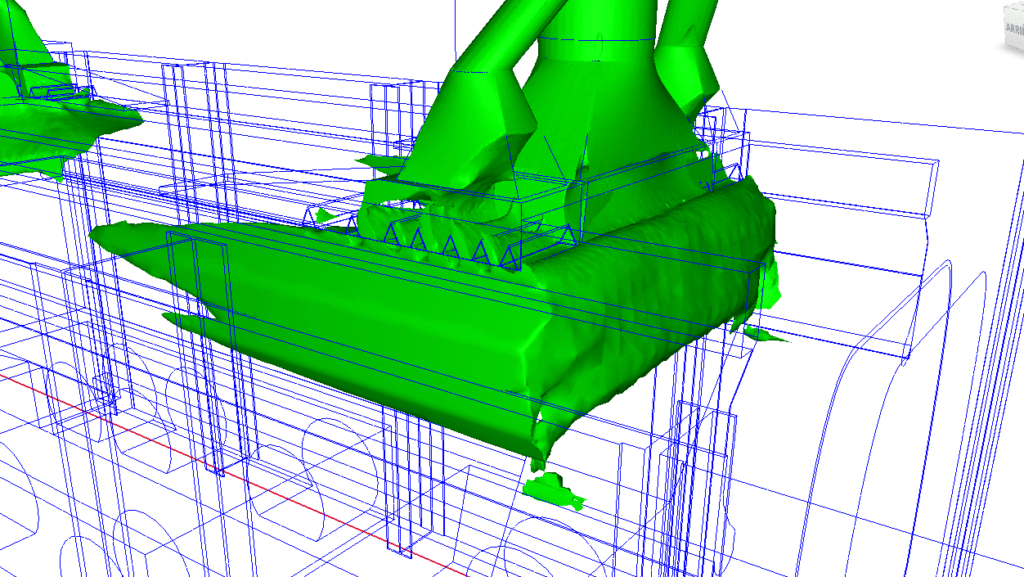

The objective was to simulate various prototypes in order to validate an aspiration concept (effective collection of dust without release into the environment.

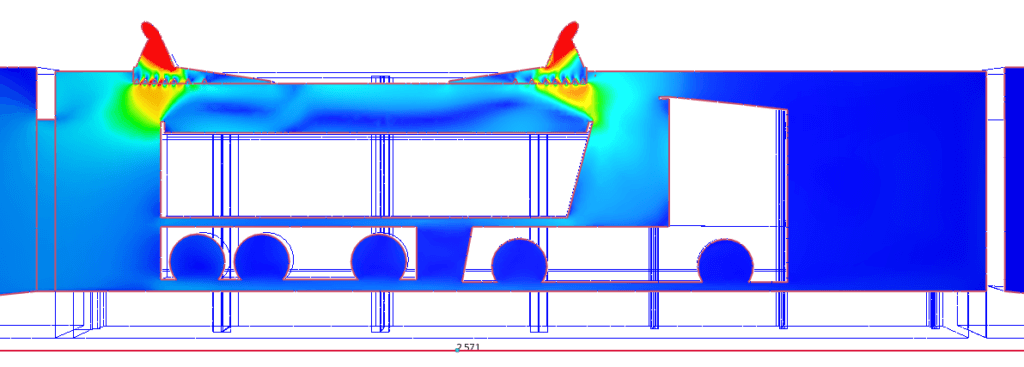

The studies made it possible to converge on the most efficient system, very markedly reducing the suction flow rates generally used for this type of systems (optimization of investment costs by reducing the capacity of the suction fans).

The theoretical concentration of expelled dust was studied as a function of different loading levels.

The pressure drops and the pressure levels were determined in order to calibrate the various regulating devices (valves, hatches, etc.).

Ultimately, these studies made it possible to improve the air quality of the site and limit the pollution generated by the release of fine dust into the environment. The optimization of the systems made it possible to significantly limit the client’s investment costs .

Continue with the same subject

Video summary of the study

Udo etude realisee by the méthode CFD a etudié the loadement from clinker entraînant a degagement from pYou can visitifera and the systèmy from captureation conçus for cela. The simulation numérique a eté utilisee for modéliser the comportement of parules from pYou can visitifera pendant the loadement and the deloadement, and for design and evaluate the role of capture systems. The rsultats have mountre that the système from captureation a reussi à reto reduce the dust level libéree dyears l‘atmosphera from 80%, this which reprsente a good rsultat in matiera from protection from l‘invironmentnement.