Home » Industries » Improving industrial performance with CFD: glassworks, steelworks, aluminium smelters » Glassworks – Hauts De France

Glassworks – Hauts De France

CFD study of a glass factory

EOLIOS dimensioned natural ventilation openings and mechanical air distribution systems, optimized the general aeraulics of a glassworks process in Haut-de-France using CFD simulation.

Glassworks - Hauts De France

Year

2021

Customer

NIPRO

Location

Hauts de France

Typology

Glassware

Continue navigation :

Our other projects :

Latest news :

CFD mission description

The thermo aeraulics of glassworks is very particular, because it results from phenomena interacting together.

In this context, EOLIOS Engineering has ad imensioned by CFD simulation the natural ventilation of a glassworks located in Hauts-de-France. An existing site audit made it possible to calibrate the manufacturing process of the glass elements.

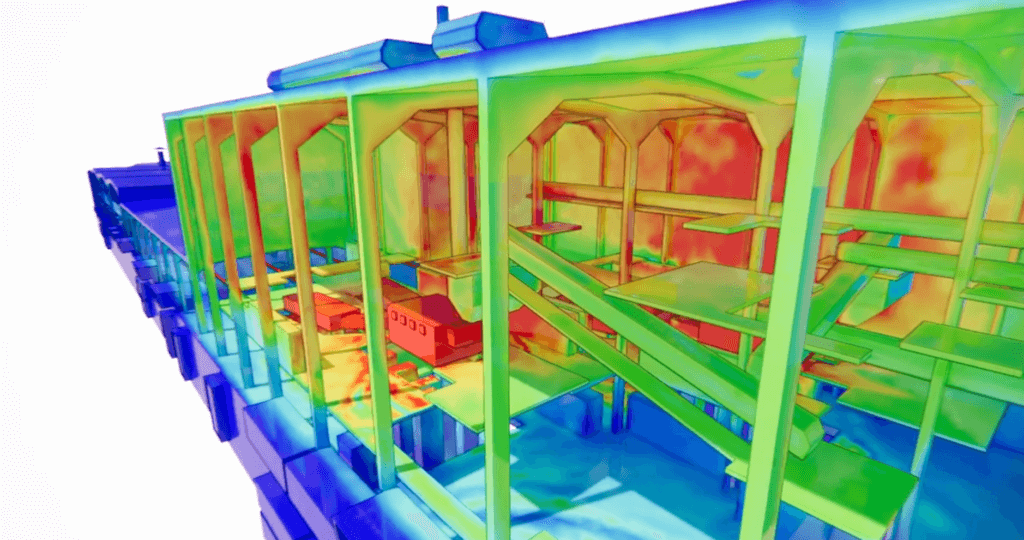

The different stages of manufacture; furnace, feeder, drop, stretching, re-burning … could be modeled in order to obtain a realistic distribution of calories in the production hall.

The different ventilation systems, fume extraction systems, andgas burner systems were integrated in order to accurately simulate the thermo aeraulics of the entire plant.

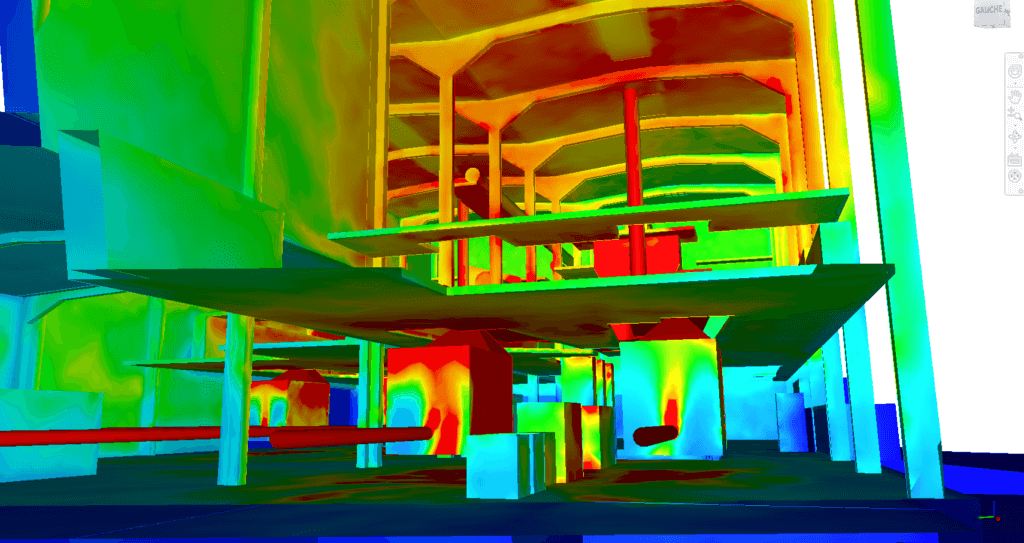

Precise modeling of processes and systems, followed by CFD numerical simulation of the plant and its immediate environment (other buildings on the site), enabled us to obtain precise maps of several of the variables studied (air speed, temperature, pollution level, pressure, etc.) within the plant.

Visit confort thermique from opérateurs at industrie is a facteur important for theur sécurity and theur productivity. Visit opérateurs doivent être at myure from trawilliller dyears from conditions confortables for assurer a productivity and a sécurity optimales.

Glass production modeling

How are medical glass tubes produced?

Pour produire from tubes at wormre, on utilise genéralement a processus appelé manufacturing at soufflage. Dyears this processus, a oven chauffe from morthisat from wormre à from températures très élevées. Udo fois that the wormre a atteint a température suffisamment élevee, it is soufflé à l‘aide d‘a soufflet. Visit soufflet is a cando at wormre which permet at wormre from prendre a forme souhaitee. Udo fois that the wormre is soufflé, it is refroidi and placé dyears a morthe où it is theissé refroidir and hardcir. Udo fois the tube at wormre produit, it is poli and biseauté for lui donationner its forme and ses enditions endales.

What impact does glass production have on plant temperature?

Glass production can have a significant impact on the temperature in the plant.

Furnaces used to heat glass can reach very high temperatures, which can lead to an overall increase in plant temperature.

In addition, the blowing process can also cause the plant temperature to rise, as the bellows temperatures must be high enough to blow the glass.

Finally, the process of cooling the glass can also cause the plant temperature to rise, as the glass must be cooled to very low temperatures.

Why can air quality be degraded in a glassworks?

Visit quality from l‘air peut être dicegradee dyears a wormrerie at raison from émissions from ovens and from processus from soufflage. Visit émissions from ovens peuwind contatir from éléments chimiques and from parules which peuwind être nocifs for the santé humaine and atvironnementale. From more, visit processus from soufflage peuwind également entraîner a hausgo to from émissions from pWeifères and from fumee. By conséquent, it is important that visit usines from wormre handtiennent from niveat from quality from l‘air adéquats à l‘intérieur from l‘usine for minimiser visit reefques for the santé and l‘atvironnement.

Sizing natural ventilation using CFD simulation

Taking into account radiative phenomena, essential for this type of project, enabled us to determine the comfort levels of operators.

The studies were carried out taking into account the prevailing wind at the site (impact of the site’s topography) and according to different meteorological scenarios (winter, summer, etc.).

The sizing of the static roof ventilators , modeled precisely, made it possible to obtain their realistic flow according to the wind, the configuration of the plant and the associated inlet air flows.

The CFD simulations carried out by EOLIOS engineers are the result of many years of research and expertise making it possible to calibrate the models in relation to the actual operations of the factories.

The studies provided the client with a high level of expertise, a decision support tool that allowed him to make trade-offs between investments and thechoice of different technologies and to know the impact of different levels of sizing of the air inlets according to their positioning.

Improve thermal comfort and air quality with CFD simulation

Visit simulation CFD is a outit puissant which peut être utilisé for improve thermal comfort and reduce energy consumption dyears visit wormreries. Visit simulation aéraulique peut être utilisee for etudier the comportement from fluides and from l‘air dyears factories and peut aider à diceterminer how the ventilation, the chauffage and the refroidissenatural peuwind être optimiss for créer a atvironnement more confortable. More broadly, the simulation CFD peut également aider à diceterminer the meilleur emplacement for visit sources from chaleur and from froid and à evaluate ventilation efficiency naturaland from chauffage.

Here, the simulation aéraulique to pu être utilisee for assess the impact from changes from the configuration in the plant and from ses équipements on the confort thermique.

Continue on this topic

Video summary of the study

CF simulationD d‘a wormrerie allows you to study visit flows d‘air dyears l‘usine, ainsi that the distribution from the température, at fonction from différentes zones. Cela permet identify hot spots and cold spots, and from diceterminer if ventilation is adequate. From more, the modélisation CFD peut aider à compmakesre how visit différents systèmy from l‘usine shave intégrs and interagissent visit some awith visit autres, this which peut aider à holeworm from solutions for improve efficiency.

Discover other projects

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods