Home » Industries » Industrial Natural Ventilation Design » Sizing of natural draft extractor hoods

Sizing of natural draft extractor hoods

Sizing of natural draft extractor hoods

EOLIOS Ingénierie realized the dimensioning of extractor hoods in natural draft for an industrial production hall.

Sizing of natural draft extractor hoods

Year

2021

Customer

Industry

Location

France

Typology

Air quality

Continue navigation :

Our other projects :

Latest news :

Mission description

Natural draft sizing for burners with hoods

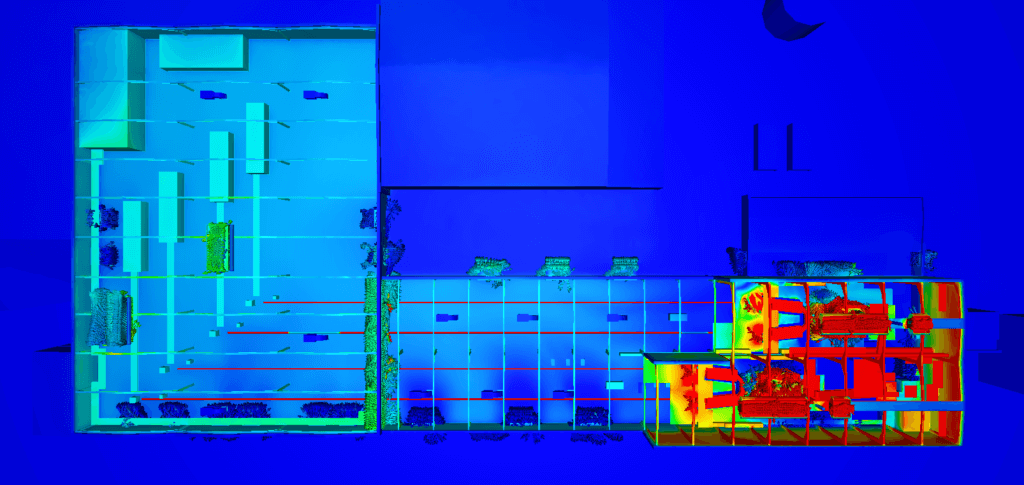

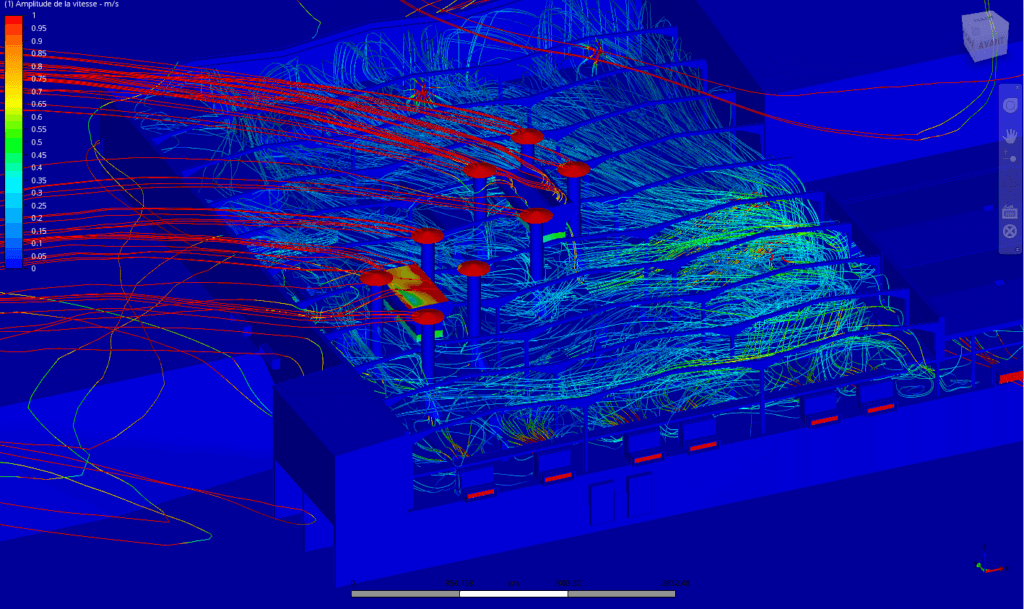

In the context of an industrial production hall equipped with gas burner systems, EOLIOS Ingénierie’s teams designed heat extraction hoods using natural ventilation. High-precision CFD simulations were carried out using an existing CFD model, which took into account all the dimensioning phenomena, such as the aeraulic connection of a space with high negative pressure, the shape of the roof, and the impact of surrounding buildings, particularly the distribution of different heat sources.

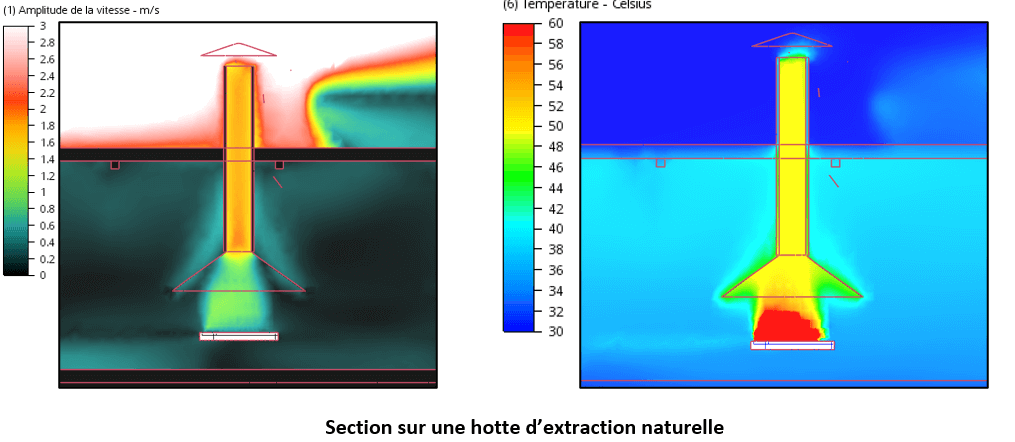

Study of natural draft by CFD simulation

The calculation of the natural draught is decisive for the dimensioning of the ventilation and air conditioning systems. However, there are many variables that affect the performance of the system and this can make it difficult to predict .

CFD (computational fluid dynamics) simulation is a very effective tool for modeling flows and ventilation processes, and it is very useful for studying systems based on natural drafts. These simulations offer accuracy and flexibility that can help understand fluid behavior and improve the design of ventilation systems. It was able to help predict fluid behavior, determine the effect of pressure changes, and estimate the airflow rate out of the systems. It could also be used to study the system under critical conditions.

What main criteria were taken into account to calculate the thermal draft?

In the CFD study conducted by EOLIOS all the dimensioning factors were taken into account. First, the 3D model accurately reflects the size and shape of the parts, their location, orientation and interface with the exterior.

In this way, we were able to determine pressure coefficients in relation to meteorological conditions and the particular topography of the site. Next, we determined the set of heat sources and their effects on the internal airflow.

Other boundary conditions such as hot and cold air sources (fans), parasitic air inlets and outlets, and internal obstacles that could affect air flow have been integrated.

What were the main conclusions of this mission?

EOLIOS Ingénierie, engineering office in fluid mechanics, utilisCFD simulation for prédire and optimiser natural ventilation dyears from applications industrielles. In the course of this study, the hoods were dimensioned on the basis of the main process constraints, and the correct operation of the thermal draught was established. Parasitic effects of internal air displacement, resulting from the operation of ventilation systems, were identified and corrected at the design stage.

To go further on the understanding of the phenomena governing the natural thermal draft:

Continue on this topic

Video summary of the study

EOLIOS Engineering, a office d‘etude spécialisé at mécanique from fluides, a utilisé the simulation CFD for the dimensionnement from hottes d‘extraction from calories at ventilation naturelthe dyears a hall industriel equipped with gas burner systems. For cela, from simulations CFD from haute précision have eté effectuées for prendre at compte visit différents phénameènes dimensionnants tels that natural ventilation openings, the forme from the toiture and l‘impact from bâtiments atvironnants. Visit facteurs pris at compte dyears the calculation from shootingage thermique comprennent visit coefficients from pression, visit sources from chaleur, visit sources d‘air chaud and froid, visit entrées and visit spellies d‘air parasites and visit obstacles internes. In the end, EOLIOS engineers were able to successfully size the hoods.

Discover other projects

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods