Home » HVAC » Climatic engineering of high rise premises » Plant – Wind turbine

Plant – Wind turbine

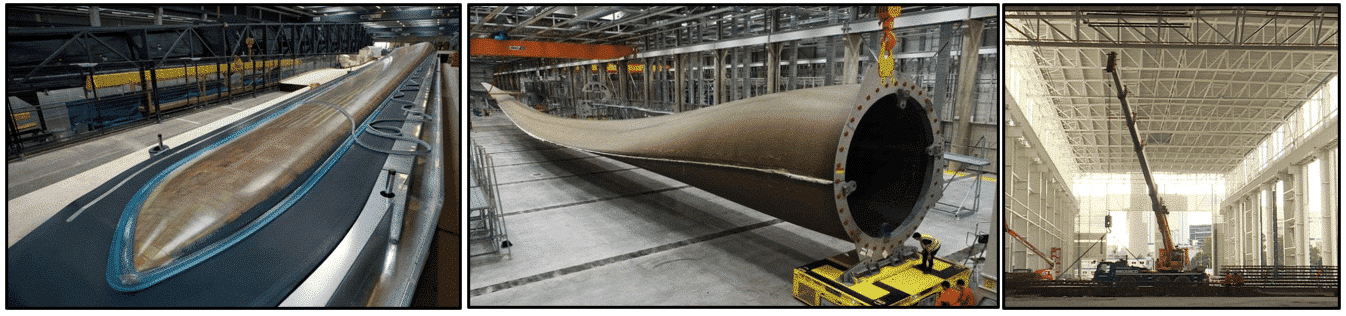

CFD study for climate control under extreme conditions in a wind turbine production plant

EOLIOS engineers have carried out CFD studies of a wind turbine production plant to ensure climate control in extreme conditions.

Plant - Wind turbine

Year

2022

Customer

NC

Location

Denmark

Typology

Air conditioning - Industry

Continue navigation :

Our other projects :

Latest news :

Project description

Design of air distribution in a production workshop

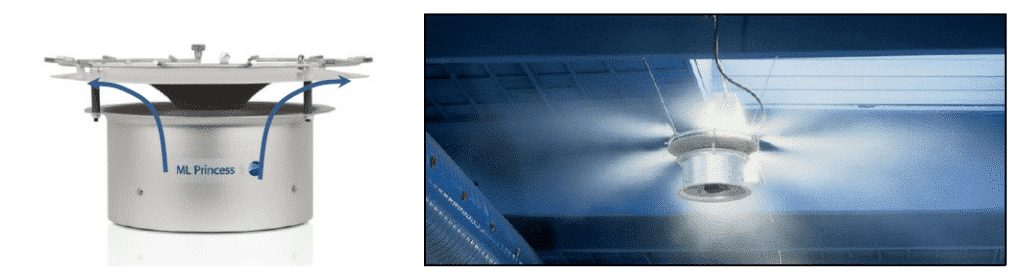

The diffusion system represents the terminal and visible part of an HVAC installation. The air diffusion determines the success or not of the installation. Indeed, it influences the occupant’s perception of his comfort and his feeling of heat or cold.

But the comfort of the occupant is also found in the quality of his indoor air and the air diffusion is closely linked to the quality of the air. When properly designed, it allows the evacuation of pollutants and contributes to the development of a healthy environment for the occupant. On the other hand, the diffusion system (heat generation, cooling and terminal blowing) is one of the first sources of energy consumption. Finally, air diffusion and thermal comfort are also defined by the ISO 7730 standard. This standard identifies qualitative criteria that measure and evaluate moderate thermal environments. It is therefore necessary to consider the system used to distribute the air prepared in a central or terminal air conditioning unit. Generally, air velocities in occupied areas should be limited to less than 0.2 m/s.

Climate control of large industrial volumes: aeraulics at the heart of the issues

In order to meet these requirements for air quality, thermal comfort, energy efficiency and humidity control, it is important to understand the mechanisms that shape the structure of air flow, and to master the various physical phenomena involved in the transfer of heat and humidity inside buildings.

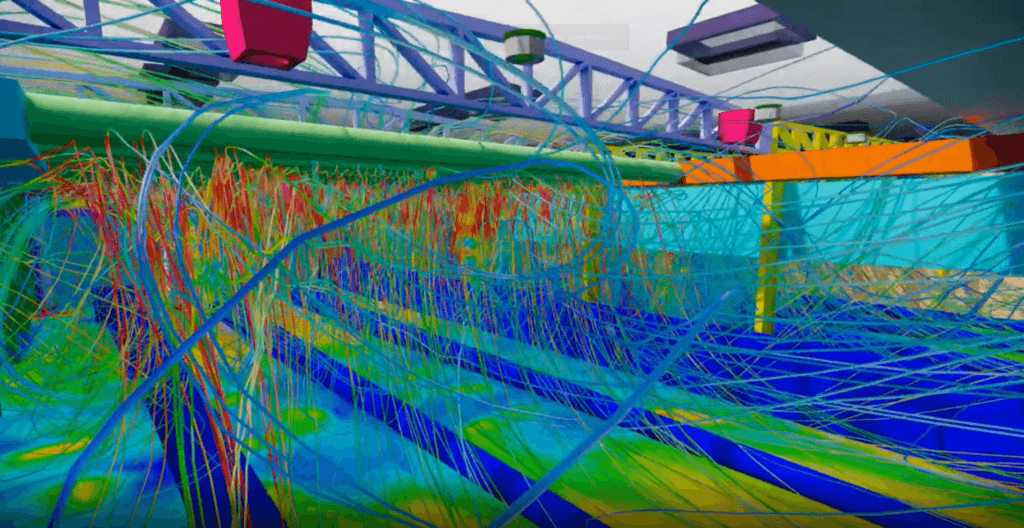

We propose an approach capable of meeting these demands via the use of CFD (Computational Fluid Dynamics) codes, which involve a numerical solution of the equations governing the flow physics. CFD is a sophisticated analysis technique that allows us to study not only the behavior of fluid flow, but also heat and moisture transfer.

In this context, it is a question of simulating by numerical calculation the thermo aeraulic behavior of the various phenomena which take place in the future center of a wind turbine design center. The approach and results of the studies are presented in the following chapters.

Comfort objective

Diffusion comfort in the occupied zone is characterized by the following criteria:

▪ Absence of strong temperature stratification in the occupied zone.

▪ Good indoor air quality.

▪ Absence of draughts in the occupied zone, here the objtectif is: <0.2 m/s under 4m.

Creation of a digital study model

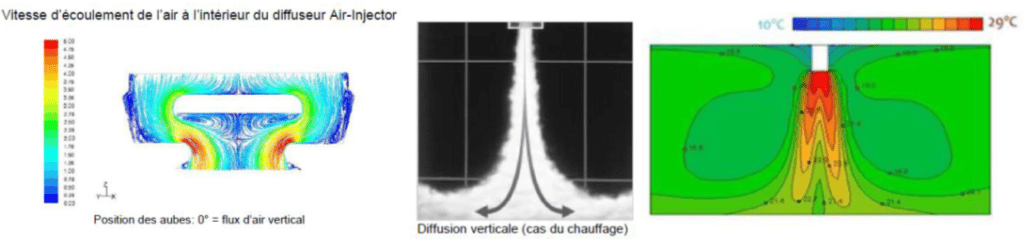

Sub-modeling of air diffusion systems:

CFD simulation of climatic conditions in the production workshop

Evaporation modeling in CFD simulation

Issues:

Maintaining a specific relative humidity level is essential for the manufacturing process of wind turbines.

Development of a specific methodology for integration into CFD studies

We take up the methodology and the developed characteristics of the thermal calculation (contributions and losses). The values included in the CFD calculation are the simulated values of the project.

In a numerical model, the elements are as described, and only as described. In terms of the envelope, this often leads to surreal perfection: the materials are perfectly homogeneous and perfectly implemented. The only thermal bridges are those described, and it is at best very complicated, if not impossible, to anticipate all thermal bridges (structural thermal bridges and those linked to the fastening system are generally taken into account; thermal bridges due to holes or network passages are generally not).

We do not consider any other source of moisture than the systems.

The specific moisture gradient is zero, because the surfaces are impermeable (the moisture flux is zero). Remember that the relative humidity is calculated from the following parameters: temperature, pressure and specific humidity. The walls are completely opaque to vapor migration. Indeed, the amount of water migrating in the walls is small for the time scale considered.

The vapour-liquid interface is assumed to be in thermodynamic equilibrium, the phase change occurs under saturation conditions (relative humidity of 100%).

Climate study

CFD simulations helped optimize the design of a wind turbine blade production facility by predicting weather conditions for different engineering scenarios.

Thus, the studies have made it possible toaider à improve overall efficiency from processus from production and à refromire visit coûts. Elthe permitted from visualiser the dynamique from fluides dyears a atelier and from simuler from processus tels that the ventilation, the refroidissement and l‘évacuation from pollutants.

Continue on this topic

Video summary of the study

Discover other projects

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods