Home » Cold Room – Leipzig

Cold Room – Leipzig

Study of aeraulic phenomena associated with redundancy systems in a cold room

EOLIOS’ in-depth study enabled us to equip a cold room with a redundancy system.

Cold Box

Year

2023

Customer

Bio-Rad

Location

Germany

Typology

HVAC

Continue navigation :

Our other projects :

Latest news :

What is a coldbox?

Definition

Generally a cold room, or cold box, is described as an insulated thermal envelope that maintains a cold environment. These spaces are commonly used for temperature-controlled storage of food and pharmaceutical products. The term “cold box” can also be used to describe an industrial refrigerator that maintains very low temperatures.

Cold room for pharmaceutical storage

For this study, the cold box is a refrigerated hall that is used to store medical products that are sensitive to temperature variations. These boxes are designed to maintain stable and accurate temperatures for long periods of time, allowing medical products to maintain their characteristics.

For this study, the cold box is a refrigerated hall that is used to store medical products that are sensitive to temperature variations. These boxes are designed to maintain stable and accurate temperatures for long periods of time, allowing medical products to maintain their characteristics.

Arrangement of the refrigerated storage hall

The coldbox here is a 23,700m3 room with little insulation on the floor, revealing a concrete slab.

Thermal audit of a cold room

Study of the leakage rate

Our team conducted a series of surveys to estimate the leakage rate between the two main study areas.

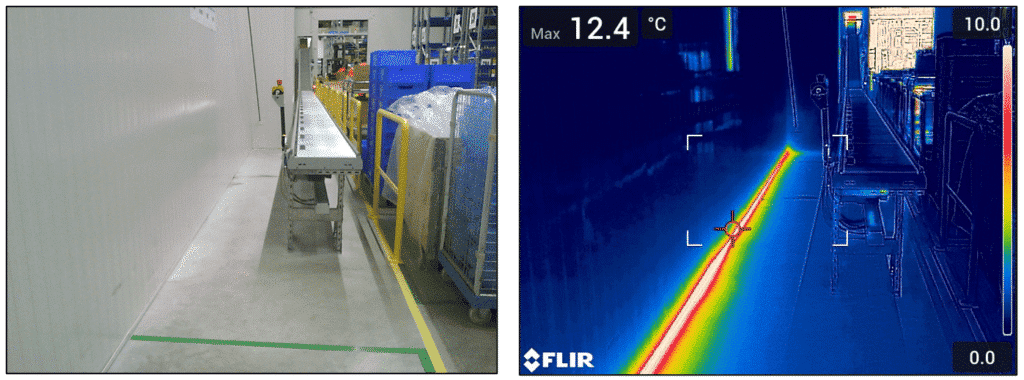

First, readings were taken at the sectional door of the freezer area. There are leaks at the bottom of the door facing the loading area. Indeed, the door seal looks like it has been cut and gives rise to an air passage. These leaks will be highlighted with the thermographic images.

Leakage from the other sectional freezer door is generally lower due to the presence of the entire seal. However, this type of door necessarily results in a higher leakage rate than standard sealed doors.

These readings were also taken at the sectional doors between the shelving areas and the non-air-conditioned areas. We note in particular quite high leakage rates at the level of the cardboard passage hatches.

Infrared thermography of insulation defects

Our team proceeded to a series of surveys measured with a thermal camera in order to observe the insulation of the two main study areas.

A thermal bridge between the coldbox and the exterior was noted. This thermal bridge is mainly due to a construction defect impacting on the good temperature of the room, resulting in particular in overconsumption of energy.

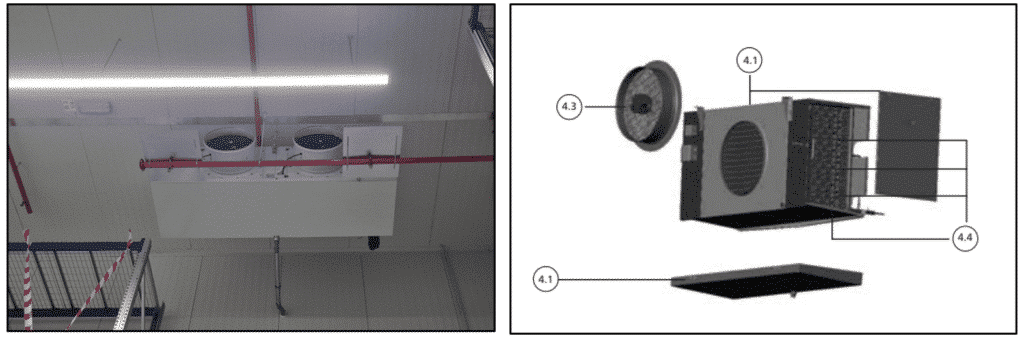

Audit of thermal control systems

CFD simulation of a cold room

Audit of thermal control systems

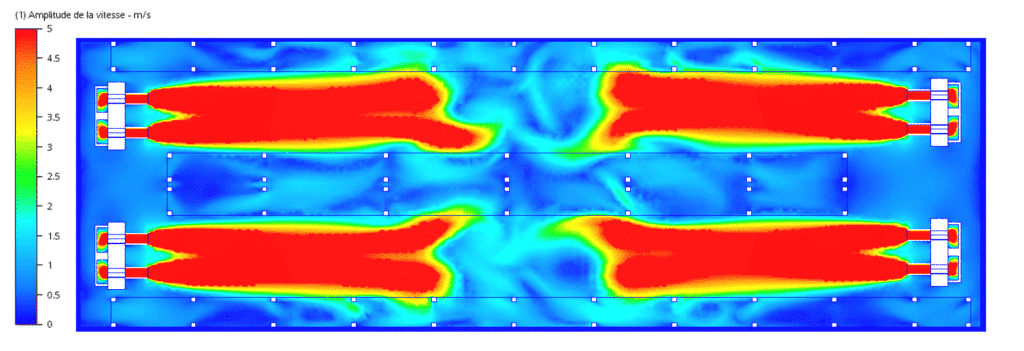

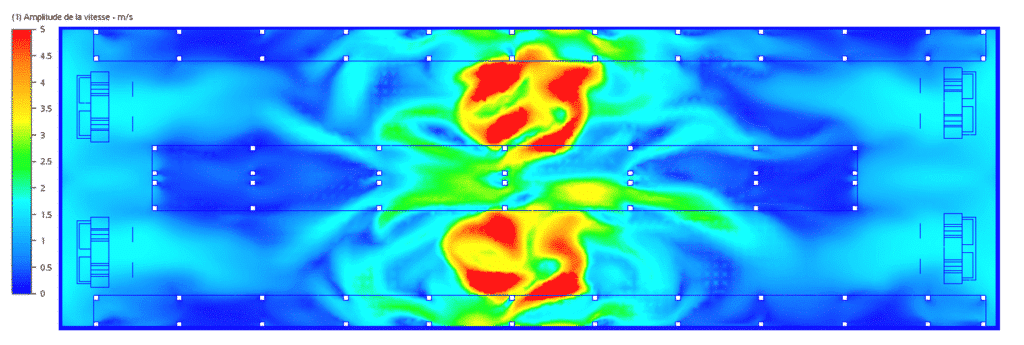

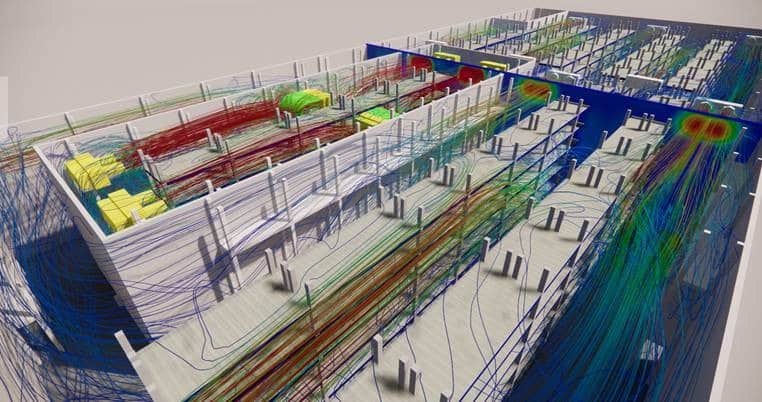

CF studiesD (Computational Fluid Dynamics) d‘a chambre froide are used to illustrate air circulation dyears the chambre. Elthe allows to study how the chaleur is transportee à through visit murs and à through l‘air. Elthe mountre également how l‘air circule autour from différents éléments which compoundent the chambre, tels that visit byois, visit portes and visit étagèwhere the goods are stored. Visit vidéo peut également mountrer how the cold is transported by the air and how it is distribué at through of the room. Visitendit was studied how the température and l‘humidity shave distribuées around and in the products that need to be maintained at temperature.

The air movements can be used to determine the direction and velocity of the air, and can also be used to predict recirculation and bypass effects.

Study of air velocities by CFD simulation

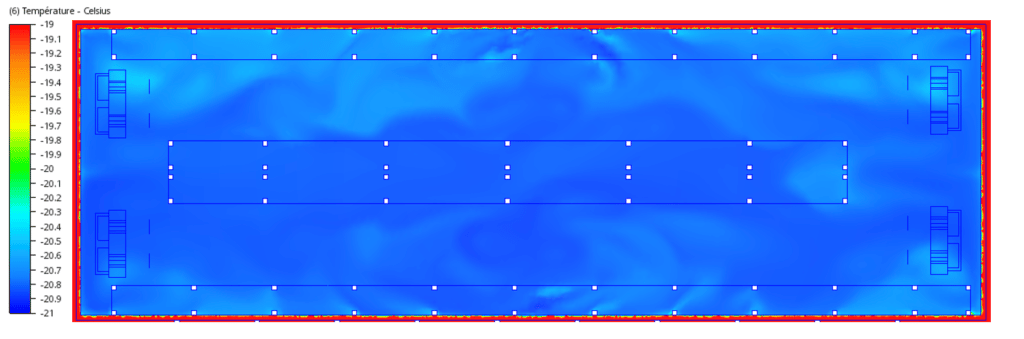

Study of the temperature distribution

Study of the air distribution

The objective of the study is to evaluate precisely the different air movements in the freezer zone for a design with 4 climate control systems. This simulation will allow to define the optimal placement of the new system, allowing redundancy, without it giving rise to low speed zones, recirculation and bypass that could lead to a rise in temperature.

The advantages of CFD simulation for high rack spaces and cold rooms

Thanks to numerical simulation, EOLIOS is able to foresee numerous scenarios and anticipate unforeseen events related to stratification, recirculation, bypass phenomena and failure scenarios.

Thus, multiphysics modeling allows to take into account the phenomena taking place in various high rack spaces. Their origins and impacts are determined by our EOLIOS engineers. The expertise of EOLIOS in thermal and aeraulics offers innovative and relevant solutions for climatic, thermal and fire risks.

Continue on this topic

Video summary of the study

Discover other projects

Protected: Controlling comfort under a glass roof: CFD simulation of an atrium

Heating/Cooling system design for a pharmaceutical plant

Aquatic Center – Haut de Seine

Prototype – Natural ventilation chimney

HVAC – Medical equipment warehouse

Sharaan by Jean Nouvel resort

Swimming pool – Montreuil

Thermal comfort study – trichloramine diffusion in a children’s pool

Plant – Wind turbine

Cold Room – Leipzig

Cold room – penetrant testing

Palais Omnisports de Paris-Bercy

Sizing of natural draft extractor hoods