Designing your data center’s digital twin

Home » Data Center » Designing your data center’s digital twin

Creating digital twins of data centers

Expertise in creating digital twins for data centers

At EOLIOS, our dual expertise in CFD (Computational Fluid Dynamics) modeling and in-depth understanding of digital infrastructures enables us to create faithful, usable digital twins of existing or planned data centers. These virtual models enable us toanticipate the actual behavior of facilities under a wide variety of conditions,optimize their thermal and energy performance, and reinforce their resilience in the face of operating hazards.

We support operators, infrastructure engineers, contracting authorities and specialized design offices in the design, operation and modernization of data centers. Our approach combines field observation, technical data collection and digital simulation to provide concrete decision-making tools. To ensure the reliability of technical choices, validate design or upgrade hypotheses, and achieve ambitious energy performance targets, the creation of digital twins in support of CFD is a major asset.

- 3D aeraulic modeling of data hall air flows

- Validation of thermal design in the project phase

- Simulation of external wind conditions on the building

- Optimizing the layout of IT racks and equipment

- Assessing resilience to failure scenarios

- Support for the modernization of existing halls

- Simulation of the impact of adding high-density racks

- Estimated gains from operating changes

- Support for certification or monitoring of performance indicators (PUE, DCIE)

Digital twins offer data center operators a powerful tool for better understanding, controlling and optimizing their facilities. Thanks to CFD simulation, EOLIOS supports its customers in the fine modeling of their existing or planned data centers, in order to validate their energy performance, anticipate changes and guarantee high operational resilience.

Validate the high energy performance of your data center

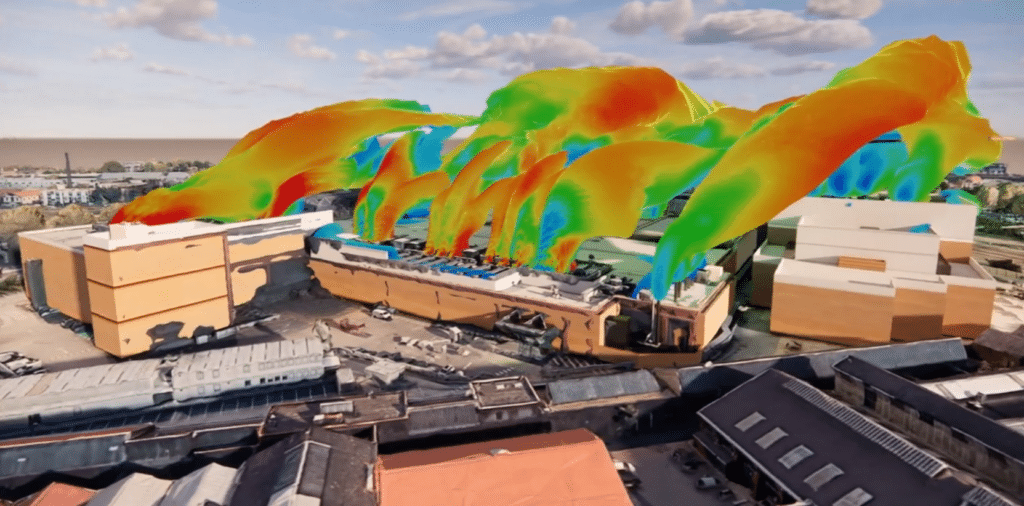

Evaluating design in the face of external conditions

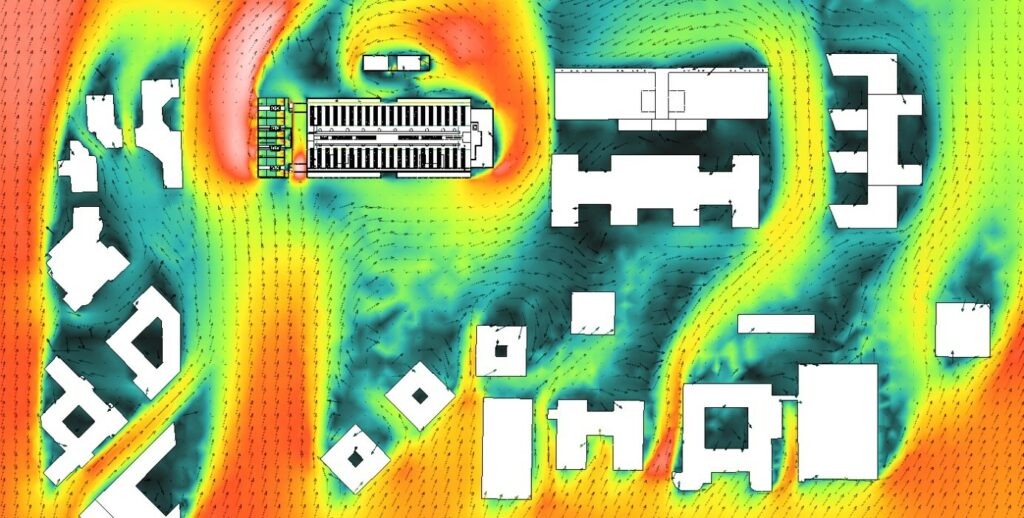

The energy performance of a data center depends as much on its architecture as its layout. Thanks to the creation of a complete digital twin, it is possible to accurately simulate the wind and temperature conditions to which the building will be exposed throughout the year.

Our models take into account the specific features of the local environment: topography, vegetation, neighbouring buildings, ground roughness, prevailing wind regimes…

This analysis enables us toassess the interaction between external air flows and data center structures, in order toidentify risks of hot air recirculation, thermal stagnation zones or overpressure effects on ventilation equipment.

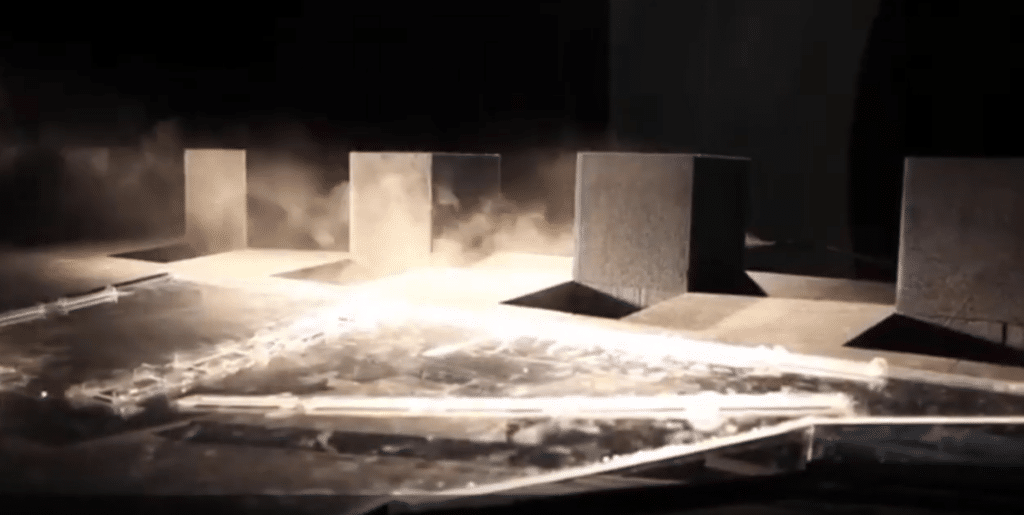

Study of wind behavior around a data center

These simulations are particularly useful for rooftop data centers or those located in dense urban areas, where masking effects and vortices can seriously disrupt the operation of free cooling or heat exchangers. They can be used to test the building’s robustness in the face of extreme climatic conditions (gusts, heat waves, thermal inversions), with a view to building resilience.

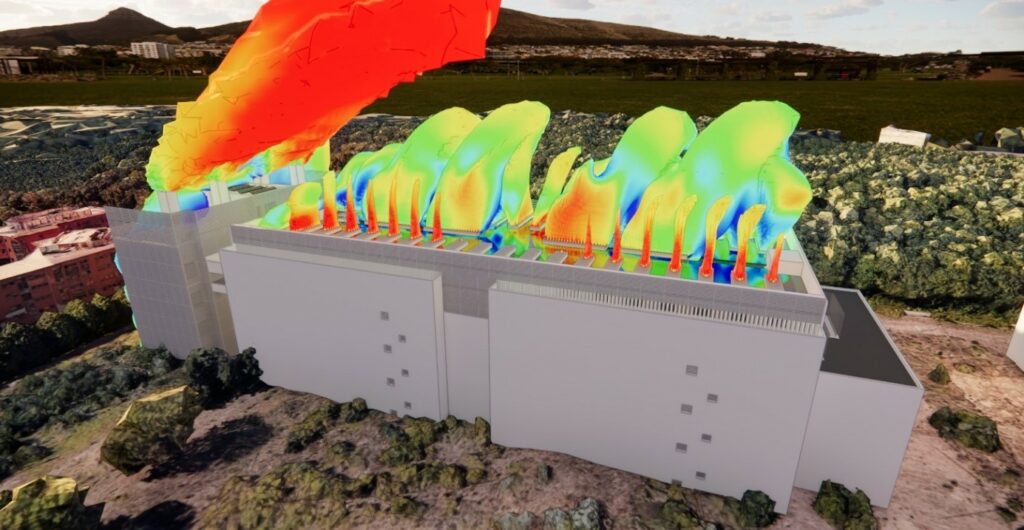

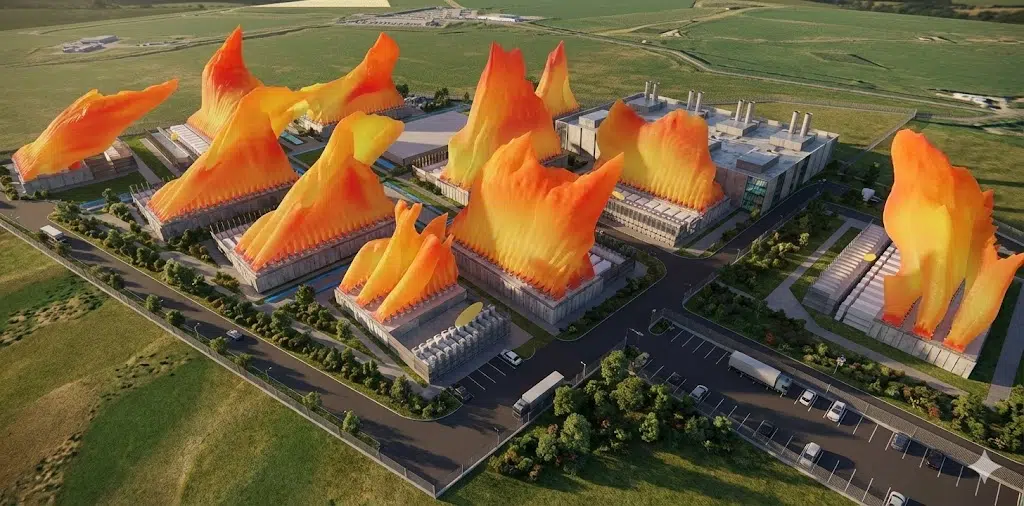

Study of thermal plumes in a data center

Check the efficiency of cooling systems

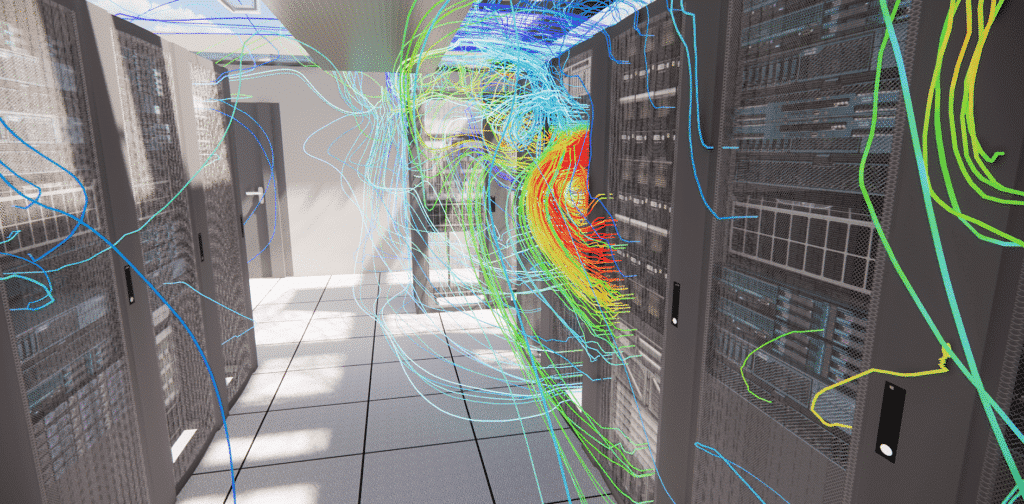

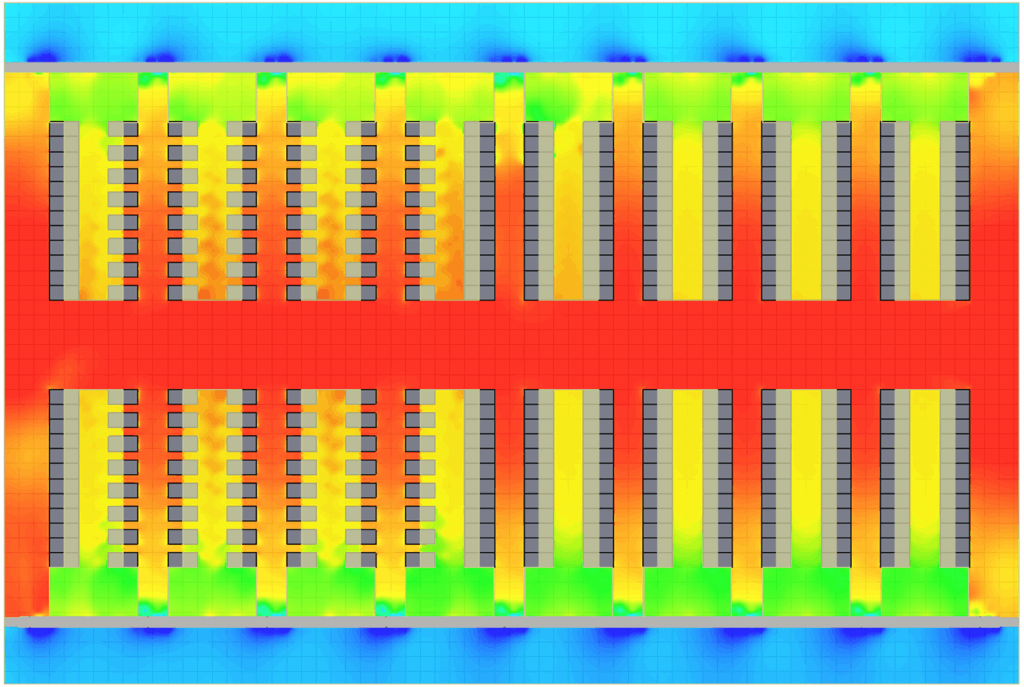

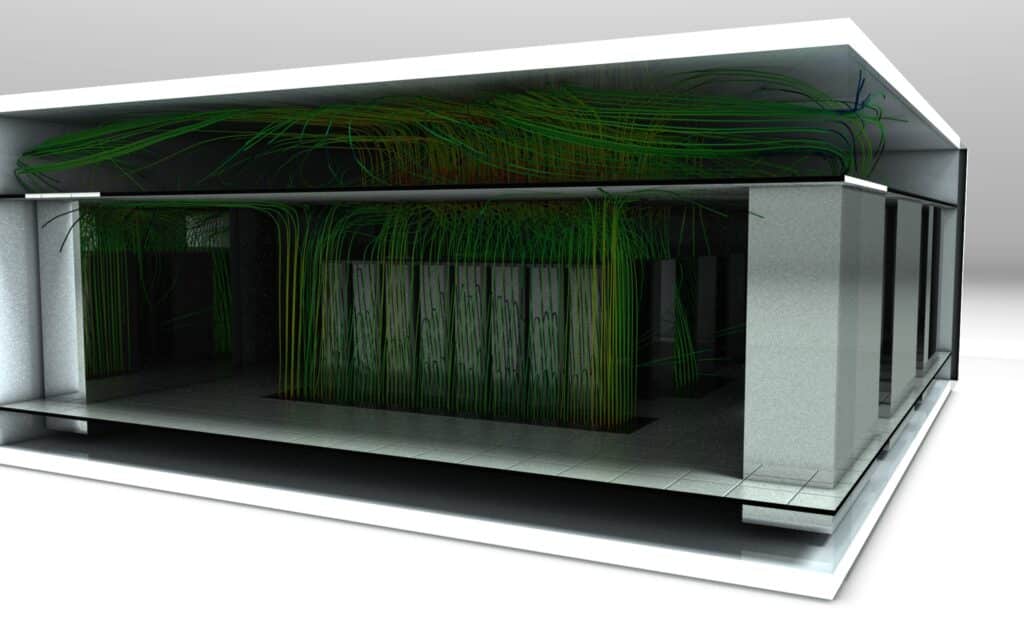

Beyond the envelope, it’s the internal efficiency of the cooling system that determines the data center’s power consumption. By modeling all the installations in a digital twin, from the layout of the racks and confined aisles to the AHUs, plenums and technical ducts, we are able to simulate the overall aeraulic and thermal behavior of the facility. This modeling takes into account actual airflows, heat gains per rack, pressure drops and existing control systems.

These simulations make it possible to test different operating configurations: partial load, peak activity, ramp-up scenario, even partial loss of redundancy. The aim is toverify compliance with admissible temperatures,avoid overheating zones, quantify containment performance (hot aisle / cold aisle), andidentify any imbalances between aisles.

These analyses are essential to validate that theoretical energy performance promises are kept under real operating conditions. They also help maximize energy efficiency (PUE) without compromising operational safety.

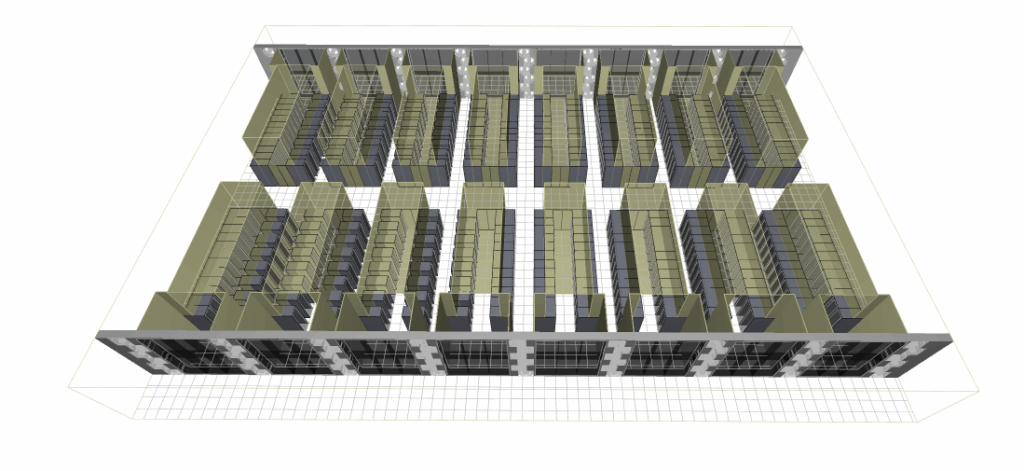

Digital twin of data hall

Modernizing infrastructures with digital twins

Continuously improve data center performance

Data centers are living systems. They are constantly evolving to adapt to demand, integrate new technologies or respond to maintenance constraints. In this context, the digital twin is a strategic management tool, capable of anticipating the impact of a change on the site’s thermal and aeraulic behavior.

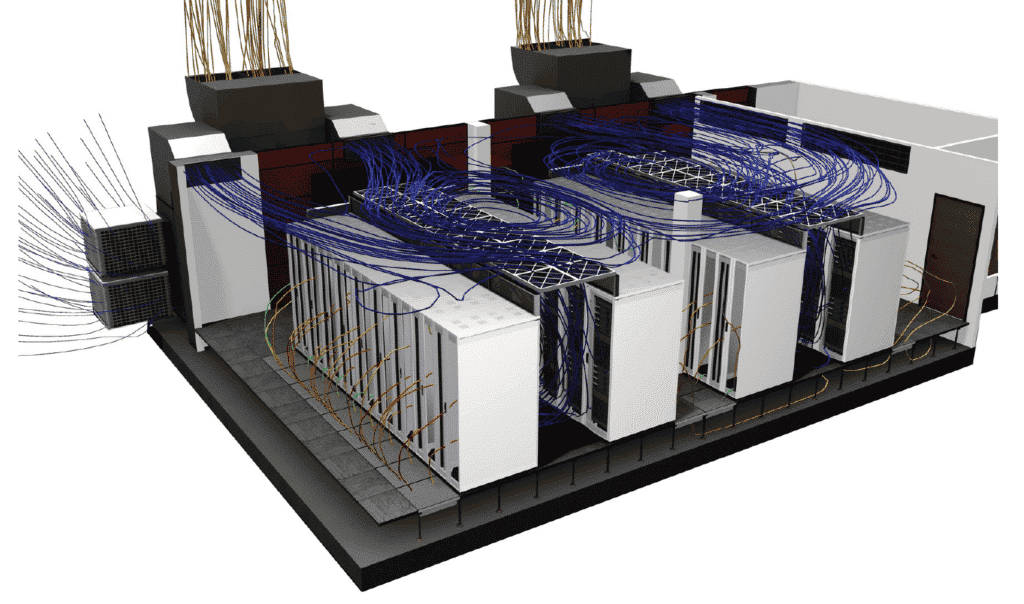

Based on an accurate, constantly updated CFD model, it is possible to quickly test the effect of a modification: addition of a rack, reversal of aisle feed direction, relocation of an AHU, change of control setpoint, and so on. These simulations facilitate decision-making by objectivizing the real consequences on air flows, critical temperatures or power consumption. They also helpidentify inefficiencies that were previously difficult to see, such as recurrent hot air recirculation or pressure imbalances between zones.

Digital twin of data hall

Optimize technical choices during the project phase

In a modernization project, every technical choice has an impact on the overall performance of the data center. The digital twin makes it possible to objectively simulate and compare several design variants, well before the work is actually carried out. Whether you’re considering replacing a chiller, optimizing a duct network, or adding aisle containment, CFD simulations enable you toaccurately assess the energy, thermal and operationalbenefits associated with each scenario.

This method helps toavoid costly or inefficientdesign errors, by highlighting the weak points of certain options or unforeseen interactions between systems. It also encourages more fluid dialogue between the various project stakeholders (project owner, operator, design office, integrators), thanks to clear visualizations and shared indicators.

Finally, this approach provides a rational basis for prioritizing investments and quantifying the expected gains, with a view to achieving a return on energy investment (ROI).

Supporting the deployment of high-density racks

Make informed decisions before work begins

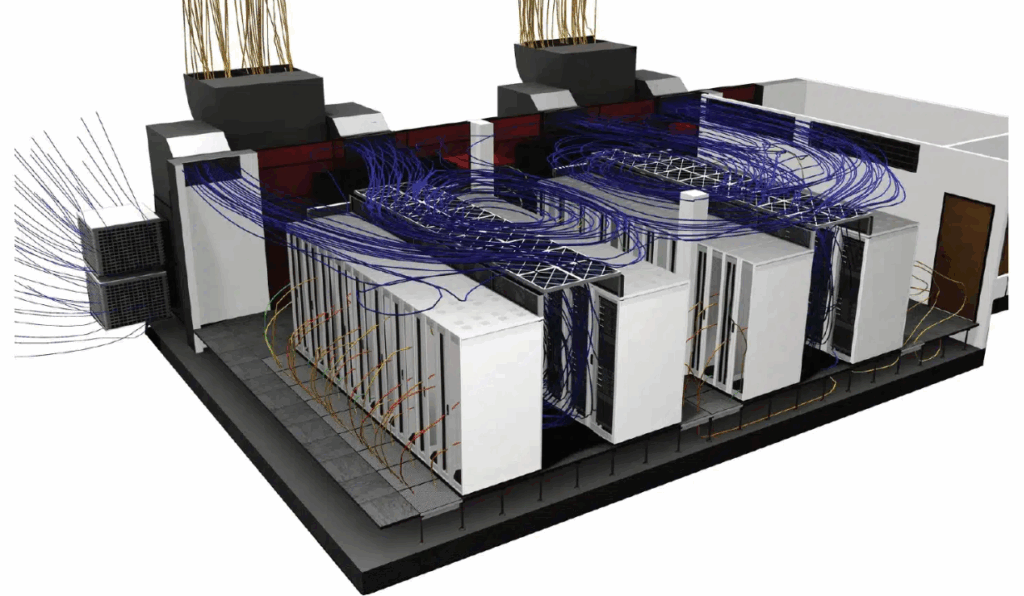

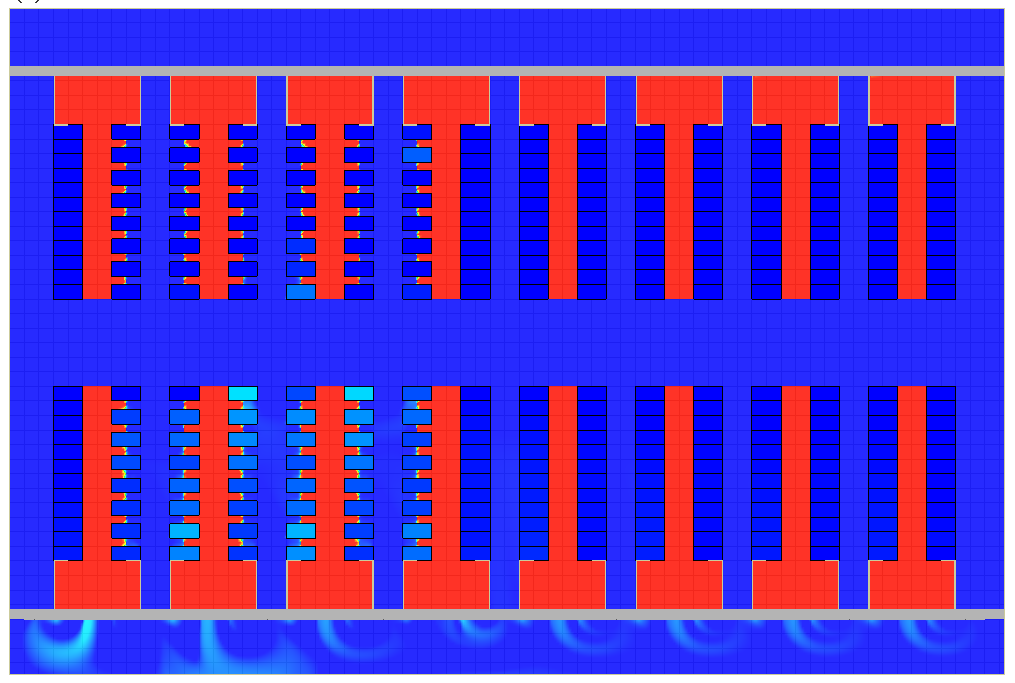

The rise of supercomputing, mission-critical applications and artificial intelligence has led to a growing concentration of power in computer racks. These new high-density configurations, often exceeding 20 kW per rack, require precise control of thermal and aeraulic distribution. Before any physical modifications are made, the digital twin makes it possible to virtually test the impact of these localized loads on the immediate environment.

By integrating equipment heat dissipation data, room geometry, containment devices and cooling system capacities, CFD simulations provide a detailed mapping of inlet temperatures, thermal gradients and air velocities. This approach enablesupstream detection of areas likely to exceed warning thresholds or disrupt flows.

Depending on the results, corrective measures can be incorporated into the project, such as adding perforated slabs, changing the direction of air discharge, localized reinforcement of air conditioning or reorganization of cooling priorities.

Example of digital simulation in a data hall

Simulate load ramp-up

One of the major advantages of the digital twin is its ability to dynamically simulate progressive evolution scenarios. As part of a high-density rack deployment, it becomes possible tostudy the impact of a progressiveload increase on one or more areas of the data hall. This approach makes it possible to validate the resilience of installations without the need for a costly or risky test phase.

By comparing several growth stages (e.g. 10 kW → 15 kW → 22 kW per rack), engineers can identify critical thresholds beyond which thermal instabilities or drops in efficiency appear. This not only enables them to plan investments more effectively, but also to distribute the load more evenly across the site, in line with local cooling capacities.

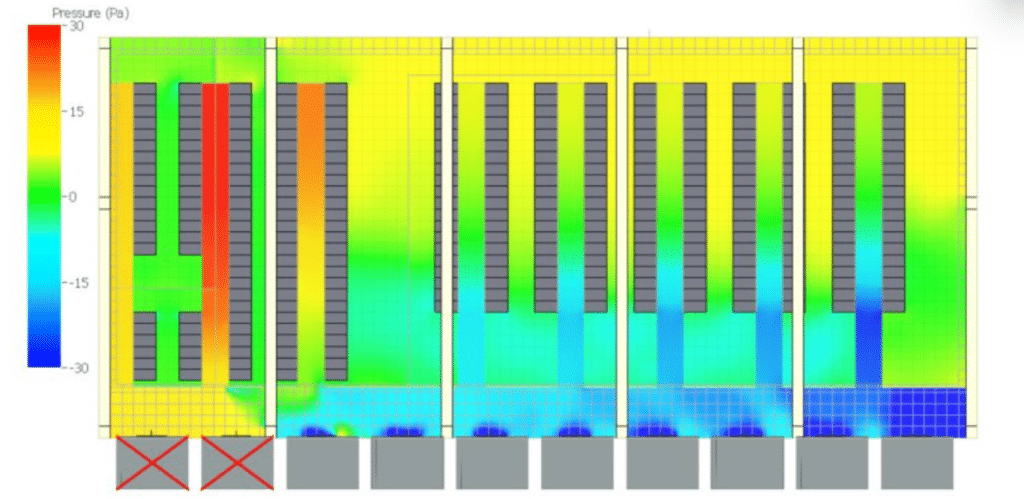

Results can be visualized in the form ofthermal animations, pressure maps orenergy efficiency indicators (local PUE, ΔT air inlet/outlet temperature). These deliverables facilitate communication between technical teams, operations managers and strategic management.

Example of a data hall pressure map

Anticipating and managing failure scenarios

Simulate breakdowns and degraded cases

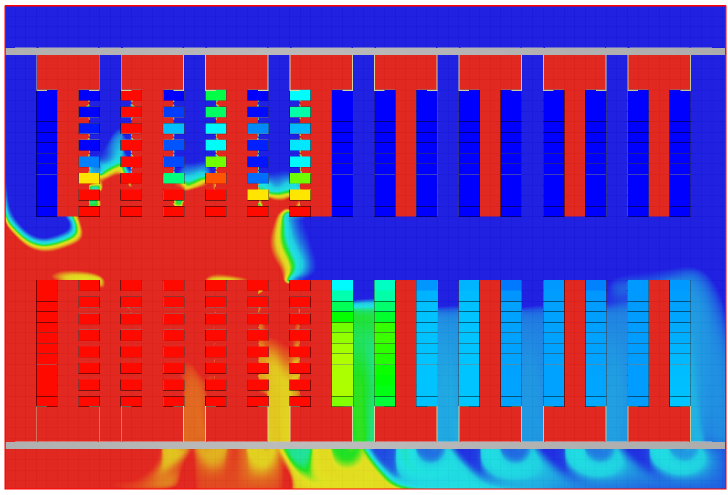

In a data center, every second of failure can have a critical impact on hosted services. The digital twin makes it possible toassess the robustness of the infrastructure in the face of a wide range of degraded scenarios – without ever disrupting actual site operation.

By finely modeling sensitive equipment (refrigeration units, air-handling cabinets, control devices), EOLIOS simulates targeted failures: loss of a refrigeration production unit, stoppage of a row of CRAH units, blower failure on an aisle, power supply failure in a critical zone, etc. These simulations enable us to observe temperature trajectories, pressure gradients, stagnation zones or uncontrolled recirculation in real time. These simulations enablereal-time observation of temperature trajectories, pressure gradients, stagnation zones or uncontrolled recirculation.

Temperature rise times are estimated according to different load scenarios, enabling risks to be prioritized, realistic alert thresholds to be defined, and the effectiveness of corrective measures provided for in the DRP (Disaster Recovery Plan) to be tested.

Temperature plan for studying scenarios with and without data hall failure

Guaranteeing service continuity

Simulations in degraded mode enable us to validate design assumptions in terms of redundancy and resilience. The digital twin becomes a genuine internal certification tool for the site’s ability to absorb an incident without service interruption.

Emergency configurations, such as N+1 mode operation, 2N redundancy and automatic changeover of blowing circuits, can be tested under simulated conditions, without mobilizing equipment or disrupting ongoing operations. These virtual tests help to optimize contingency plans and secure future operation or maintenance operations.

They are also invaluable in changing contexts: extending a data hall, commissioning a new cooling unit, reallocating technical areas, etc. The digital twin ensures continuity in service quality, while facilitating the traceability of technical choices.

Fire simulation in a data hall

Improving data center energy efficiency

Test the impact of modifications on overall performance

Energy optimization is not just a matter of designing an efficient data center in the initial phase, but of continually adapting its operation to real-life operating conditions. Thanks to a faithful digital twin, every modification envisaged can be tested virtually to assess its thermal, energy and operational effects.

In this way, the addition of a containment wall, the modification of a supply air setpoint or the punctual shutdown of a fan in a redundant configuration can be precisely simulated. The digital twin makes it possible tovisualize actual air flows, anticipate potential malfunctions and calculate the energy savings associated with each scenario.

This approach ensures that every technical decision, no matter how small, makes a real contribution to improving the overall energy efficiency of the site.

Identify levers for improvement

The richness of the digital twin also lies in its ability to cross-reference multiple sources of information: in-situ temperature readings, IT load profiles, air handling unit utilization rates, and so on. This systemic approach makes it possible toidentify oversized or poorly-operated equipment, locate unwanted recirculation and pinpoint areas of heat loss invisible to the naked eye.

EOLIOS uses this data to propose concrete areas for optimization: redeployment of air flows, ventilation rebalancing, adaptation of control strategies, elimination of hot spots, etc. Based on clear visualizations and performance comparisons, these targeted actions contribute to a measurable improvement in the site’s PUE (Power Usage Effectiveness).

Improving data center energy efficiency

Faced with increasing IT workloads, rapidly evolving technologies and growing demands in terms of energy performance, data center operators must now rely on powerful tools to secure their decisions. The digital twin is a strategic solution: it can simulate, anticipate and optimize the actual behavior of installations in a controlled virtual environment.

At EOLIOS, we apply the power of CFD simulation to the operation and continuous improvement of digital infrastructures. By combining rigorous field audits with advanced modeling of airflow and heat transfer, we provide our customers with a clear, usable vision of their data center,both now and in the future. Our work enables us tosupport design hypotheses,accompany configuration upgrades (modernization, high density), simulate critical scenarios and reduce the energy footprint of installations.

Find out more:

Our specific solutions for data centers :

CFD engineering for data centers

Find out more

Thermal storage study

Find out more

External CFD simulation for data center

Find out more

Data Center Fire Simulation

Find out more

Thermal study of technical premises

Find out more

Urban heat island impact study for data centers

Find out more

Audit, diagnosis and 3D modeling of existing data centers

Find out more

Designing your data center’s digital twin

Find out more

Energy optimization and PUE calculation for data centers

Find out more

Commissioning: study and CFD modeling of load benches

Find out more

Data center engineering

Initially created in France, EOLIOS Ingénierie is the benchmark thermal and aeraulic simulation consultancy for data centers in Europe and worldwide. The company supports operators, designers and project owners at every stage in the life of a data center: design, optimization, renovation or extension.

By combining cutting-edge scientific expertise, state-of-the-art simulation tools and in-depth knowledge of the data center ecosystem, EOLIOS Ingénierie is a trusted partner for ensuring the availability, security and energy performance of IT infrastructures, while anticipating sustainability issues.

EOLIOS

PARIS – LONDON – MILAN – MUNICH – MADRID – WARSAW – CASABLANCA – UNITED ARAB EMIRATES – USA