Home » Data Center » External CFD simulation for data center » Data center – DC17 – External

Data center – DC17 – External

Study of aeraulic phenomena in a data center

EOLIOS Ingénierie provided an overview of the thermo-aeraulic conditions of the various phenomena that take place at the ventilation outlet. The study of the thermal plume of the datacenters is essential to avoid any overheating of the servers.

Project

Data center - DC17 - External

Year

2022

Customer

NC

Location

France

Typology

Data Center - External

Continue navigation :

Our other projects :

Latest news :

Mission description

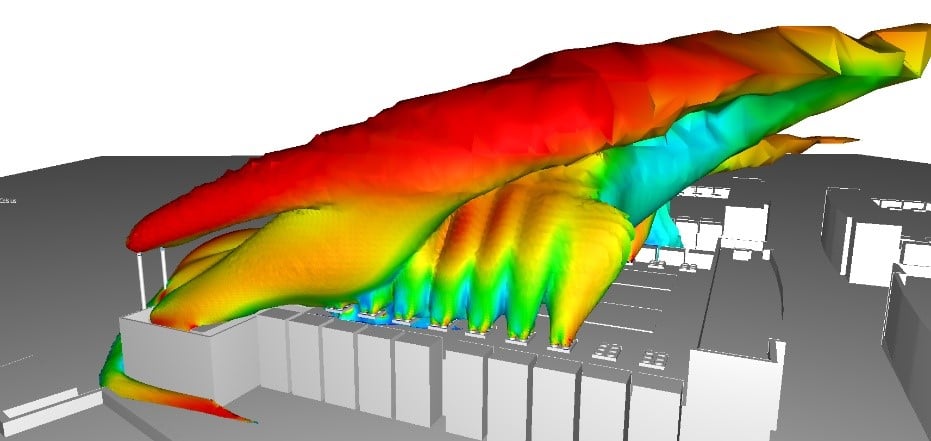

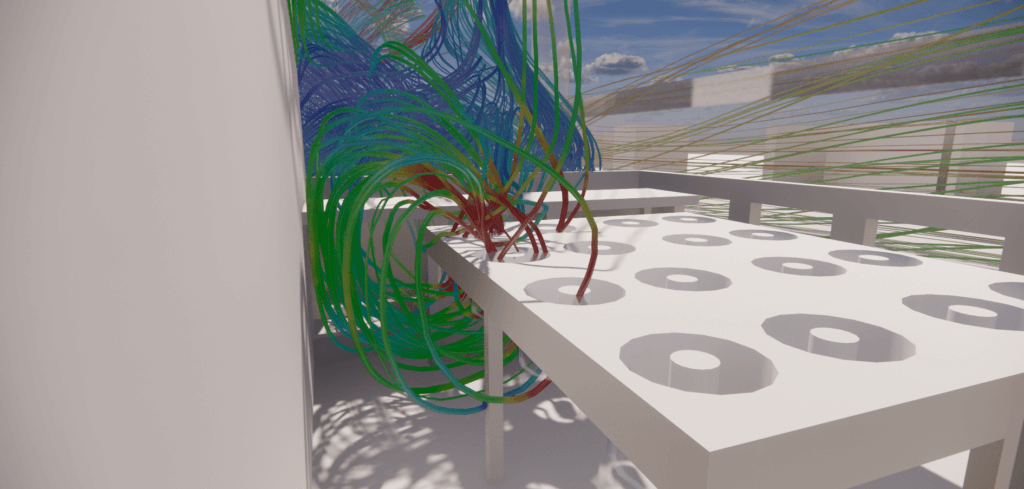

The challenge of this project was to control the particular thermo-aeraulic phenomena induced by the discharge from the coolers, as well as the evolution of the various thermal plumes. The CFD studies have made it possible to visualize the different thermo-aeraulic phenomena according to different wind orientations, which has allowed the optimization of the HVAC treatment systems.

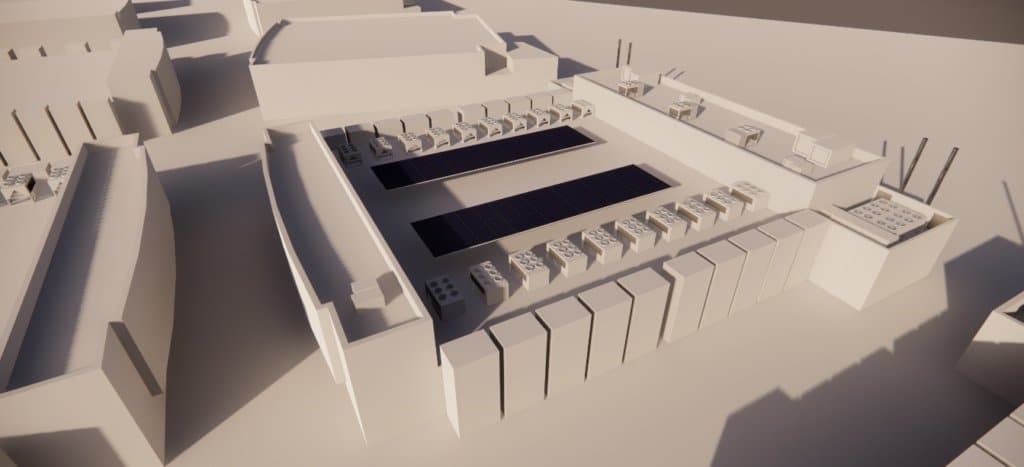

Creating a digital twin

The digital twin of the data center studied in CFD takes up the air volumes, all the generators, the external air coolers and the walls in contact with the outside. All HVAC systems are modeled. The digital twin also includes the surrounding buildings which have been carefully modeled in order to obtain the most precise evolution of thermal plumes according to different wind orientations and thus to quickly identify potential thermal problems. By analyzing these results from a global or local perspective, we can propose solutions that fit the different problems identified.

All the generating sets were modeled in CFD from the digital twin . Motors, chimneys, calorie extraction fans, equipment systems and electrical cabinets are taken into account in the study. The refinement of the CFD resolution makes it possible to benefit from a distribution of complex temperatures but representative of reality . Certain specific phenomena were identified during the study, which led to design work to resolve these issues.

Design readjustment

CFD simulations have made it possible to represent areas of high temperatures at all points in space . This advantage of simulation has thus allowed us to know precisely the loop zones between the air expelled by the air coolers and the air that they breathe back. The results obtained allowed us to conclude that the thermo-aeraulic dynamics of the original design could cause overheating of the cooling system . In addition, these results made it possible to review the original design and implement appropriate solutions .

Why use CFDs?

By using a CFD study, it is possible to analyze, check and correct, if necessary, potential errors during the design. This fast, precise method reduces design time and ensures concrete and safe results . Integrating a CFD study during its design stage means calling on professionals to ensure that no problems arise in the future.

Continue on this topic

Video summary of the study

Play Video

Discover other projects

Engineering smoke extraction in a data center

External & internal CFD – Data Center Hyperscale

CFD Optimization – Data Center

Data Center – DC28 – Internal

Pressure loss study – Generator – Data center

Data Center – PA 22 – External

Technical premises – Data Center

Cooling optimization – Data Center

Data Centers – DC15.1 & DC15.2 – External

Data Center – Paris

Data Center – GAZ NOVEC

Data center – DC25 – Internal

Data center – DC17 – Internal

Data Center – DC10 – Internal

Data center – DC25 & DC26 – External

Data center – D14 – External

Data center – DC17 – External

DC23 – External