Home » Data Center » Thermal study of technical premises » Technical premises – Data Center

Technical premises – Data Center

Thermal study of data center equipment rooms

In a context of ever-increasing demand for storage capacity and processing power, thermal management of data center equipment rooms is proving to be a major challenge. The aim of the study is to use CFD to propose customized and innovative solutions to ensure optimum performance, maximum energy efficiency and unrivalled reliability in these critical environments. The premises studied are a UPS room, an STS room and a transformer room, located in Meudon.

Locaux techniques - Data Center

Year

2024

Customer

NC

Location

France

Typology

Data Center

Continue navigation :

Our other projects :

Latest news :

Our expertise:

Using CFD for thermal optimization

Why carry out a CFD (Computational Fluid Dynamics) study?

In the world of data centers, thermal management plays a central role. Usually, hot and cold aisles are set up in data center halls to optimize cooling of servers and equipment. However, when it comes to technical premises, the situation is quite different. Each installation is unique, with its own constraints and configurations, making standardized cooling solutions often unsuitable.

In this context, CFD (Computational Fluid Dynamics) expertise plays a key role. In the absence of established measurements and ready-made solutions, it is essential to use advanced modeling tools to understand and optimize air circulation, heat dissipation and temperature distribution. Using CFD, an in-depth analysis of the infrastructure is carried out toidentify hot zones,optimize air flows and design appropriate cooling solutions for these technical rooms.

Modeling process for CFD study

To create a 3D model of a machine room for the CFD study, we used both floor plans and site visits. Firstly, detailed architectural drawings of the room were used to recover the dimensions and layout of the equipment. Then, during the site visit, more in-depth observations and precise measurements were made, and specific details such as cooling systems, ventilation grilles and obstacles were noted.

Using 3D modeling software, geometric models of the rooms were created, integrating equipment and room obstacles, while respecting their actual location. Finally, by assigning the appropriate physical properties to each element of the model, such as the thermal conductivity of materials, the heat output of machines and the performance of air-conditioning systems, CFD studies could be carried out.

Simulation results

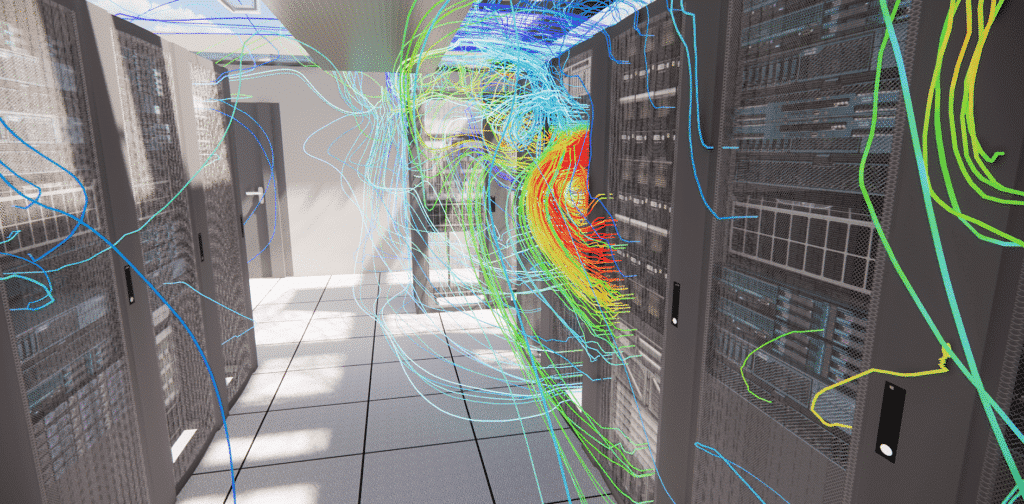

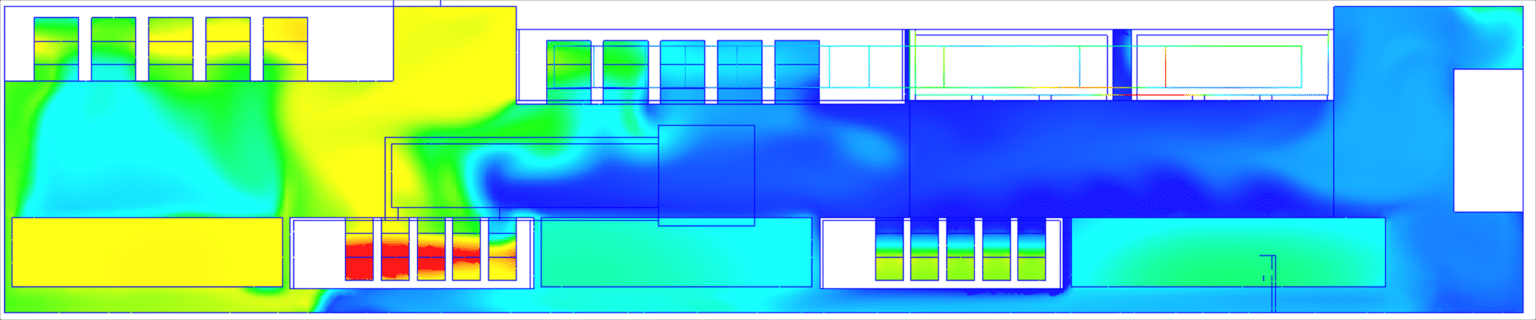

Detection of thermal anomalies and looping phenomena

During our simulations on the existing configuration of the technical rooms, excessively high temperatures were observed at the systems’ fresh air intakes. These high temperatures were mainly caused by looping phenomena, wherewarm air is recycled instead of being efficiently evacuated.

In addition, the presence of hot spots– areas where heat dissipation is insufficient – has been identified, which can lead to equipment overheating. A new design is therefore required to optimize air circulation, avoid looping phenomena and improve heat dissipation.

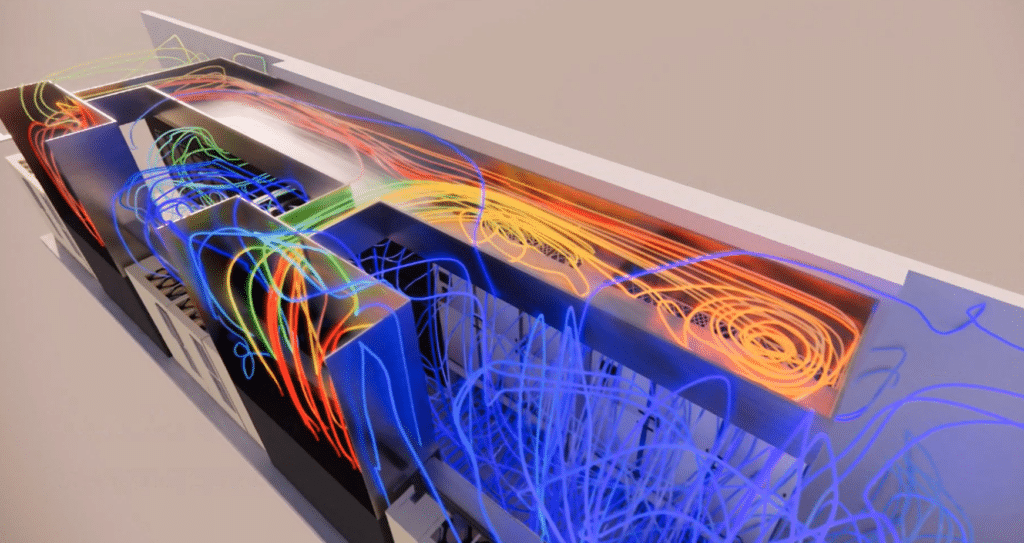

Tailor-made solutions for optimum thermal management

To avoid looping and reduce excessive temperatures, new designs have been proposed for each technical room. In the STS room, the heat rejects were sheathed to better channel and evacuate the heat.

In the UPS room, an integral hood between the upper and lower sections was installed to compartmentalize hot and cold air masses. In the transformer room, the air intakes of the CRAH (Computer Room Air Handler) units were raised to ensure better suction of heat-laden air.

These new designs were subjected to advanced CFD simulations to evaluate their effectiveness. The results obtained are very encouraging, as they clearly show that the new designs make it possible to avoid looping and reduce temperatures in the systems’ fresh air intakes. In fact, temperatures were lowered by 5°Cwhich greatly contributes to guaranteeing optimal operating conditions and reducing the risk of overheating in the data center’s technical rooms.

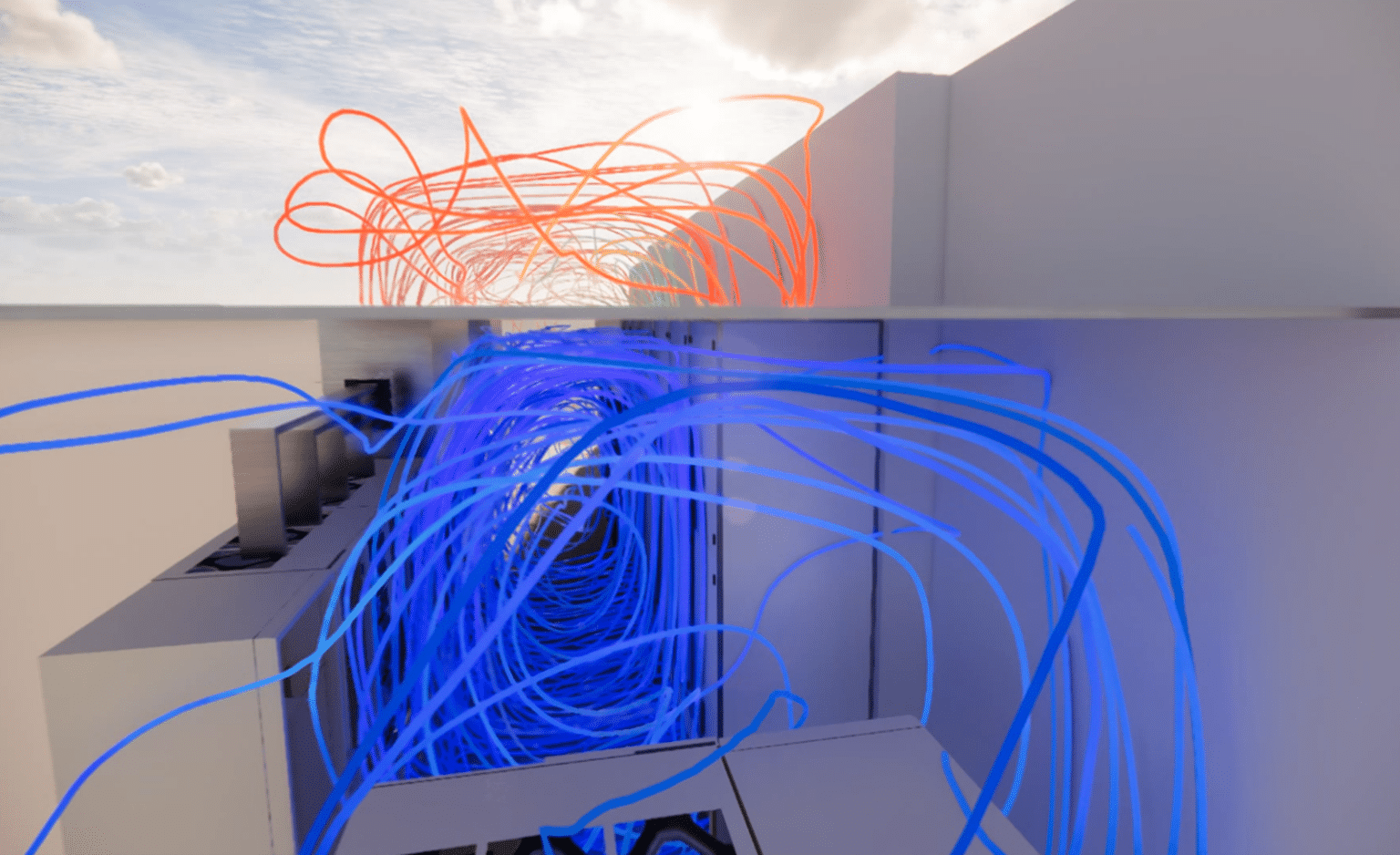

Detailed redundancy simulation: Maintaining temperature with CRAH off

A careful redundancy analysis was carried out in the technical rooms to ensure unrivalled reliability of the cooling systems. To this end, two CRAH (Computer Room Air Handler) units are installed in each room, operating in parallel for optimum operational redundancy. This approach maintains sufficient cooling capacity even in the event of failure of one of the units.

In order to validate the effectiveness of this redundancy, detailed simulations were carried out considering the deactivation of a CRAH unit. The results showed that even with a CRAH unit switched off, the temperature in the equipment rooms remained within a suitable range, with no risk of overheating. This demonstrates the effectiveness of the redundancy implemented.

At EOLIOS, the vital importance of redundancy in critical environments such as data centers is always taken into account.

OurCFD simulation expertise enables us to design robust and reliable cooling solutions, guaranteeing continuous equipment availability even in the event of a unit failure.

Continue on this topic

Video summary of the study

Video summary of the mission

Discover other projects

Data center study – Data Hall and UPS premises

Engineering smoke extraction in a data center

External & internal CFD – Data Center Hyperscale

CFD Optimization – Data Center

Data Center – DC28 – Internal

Pressure loss study – Generator – Data center

Data Center – PA 22 – External

Technical premises – Data Center

Cooling optimization – Data Center

Data Centers – DC15.1 & DC15.2 – External

Data Center – Paris

Data Center – GAZ NOVEC

Data center – DC25 – Internal

Data center – DC17 – Internal

Data Center – DC10 – Internal

Data center – DC25 & DC26 – External

Data center – D14 – External

Data center – DC17 – External

DC23 – External