White Paper: Using CFD for Data Centers

Home » Data Center » White Paper: Using CFD for Data Centers

Virtualization: thermal density on the rise

Ramping up digital infrastructures: Virtualization and AI

Global demand for digital infrastructure is growing exponentially, driven by the rise of the cloud, AI, IoT and data-intensive applications. In this context, data centers play an essential role: they house the servers, storage equipment and networks that enable information to be processed and distributed.

At the same time, the thermal load on data centers has risen sharply. The miniaturization of equipment, the massive virtualization of servers and the multiplication of AI applications are generating far more heat per unit than was previously the case. Whereas a cooling capacity of 5 kW per rack used to be sufficient, today many servers exceed 10 kW per rack, and some installations reach up to 45 kW.

In this context of thermal intensification, control of air flow and cooling becomes critical, and a central question arises:

"Is the air conditioning system capable of handling 100% of the thermal load, including in degraded conditions?"

Economic and material consequences

Thermal challenges in data centers can have significant and multidimensional consequences. Poor heat management can lead to a significant increase in operating costs, linked to energy consumption and corrective maintenance.

It can also shorten the lifespan of IT equipment, as electronic components are sensitive to temperature variations and repeated overheating. This increases the risk of sudden hardware failures or service interruptions, which can impact business continuity and generate high costs for operations.

Finally, these thermal problems can limit the ability to increase IT workloads, blocking expansion projects and infrastructure ramp-up.

Conventional thermal calculation methods, based on simplified formulas or Excel spreadsheets, are not sufficient to anticipate the behavior of systems under critical conditions, such as air conditioning failure, power cuts or rack maintenance, making these risks even more difficult to control.

To meet these challenges, CFD (Computational Fluid Dynamics) digital simulation has become a strategic tool. It enables us to accurately model air flows, pressure, thermal distribution and cooling configurations, and toanticipate the most critical scenarios. This approach makes it possible to design and operate more reliable and optimized data centers, preventing any risk of overheating or malfunction.

Thermal challenges in data centers

Temperature control in a data center is a complex exercise resulting from multiple interactions: building architecture, IT load density, airflow dynamics, cooling technologies and operational developments.

Densification of IT workloads

Modern servers, particularly those designed for intensive computing applications such asArtificial Intelligence (AI) or High-Performance Computing (HPC), can dissipate several tens of kilowatts per rack. This high equipment density generates a significant thermal load in data centers, requiring particularly high-performance cooling systems with a considerably reduced margin for error. As power increases, so do the risks of hot spots and hot air recirculation .

Server densification requires not only precise dimensioning of cooling systems, but also active airflow management and rigorous thermal control to guarantee a stable, safe environment for equipment.

Formation of hot spots

Hot spots are areas where the temperature exceeds the thresholds recommended by ASHRAE standards, and can occur as a result of poor airflow distribution,physical obstacles, rack positioning, poorly calibrated cooling units, load variations or layout modifications, such as the addition of extra servers or racks.

Even in centers with low thermal loads, these thermal imbalances have a direct impact on equipment reliability and service life. Electronic components, such as processors and memory, are sensitive to temperature variations, and can see their performance and longevity reduced. Moreover, locally high temperatures increase the risk of sudden hardware failure, which can lead to costly downtime.

Often invisible without specialized tools, these hot spots require interventions that are difficult to predict. CFD (Computational Fluid Dynamics) simulation is a key tool for detecting, anticipating and preventing these critical zones, by optimizing air circulation and thermal management of data centers.

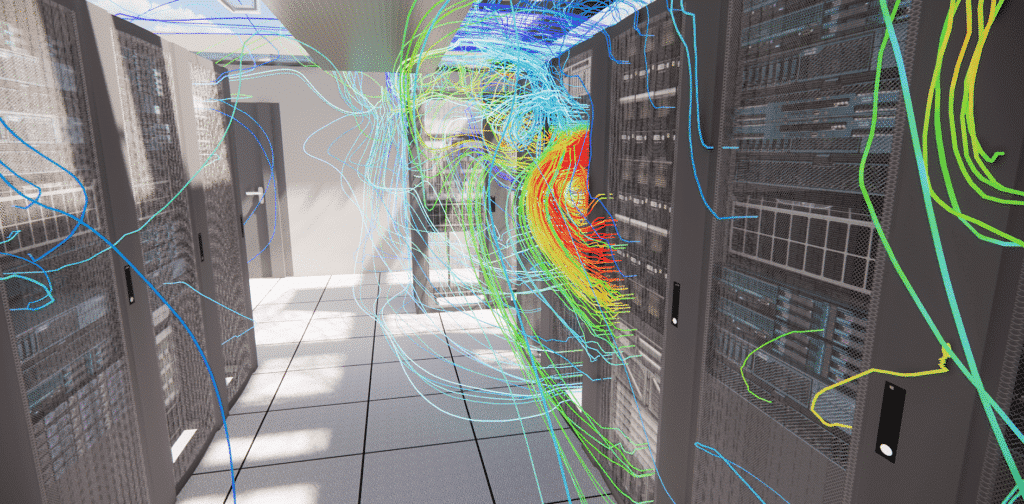

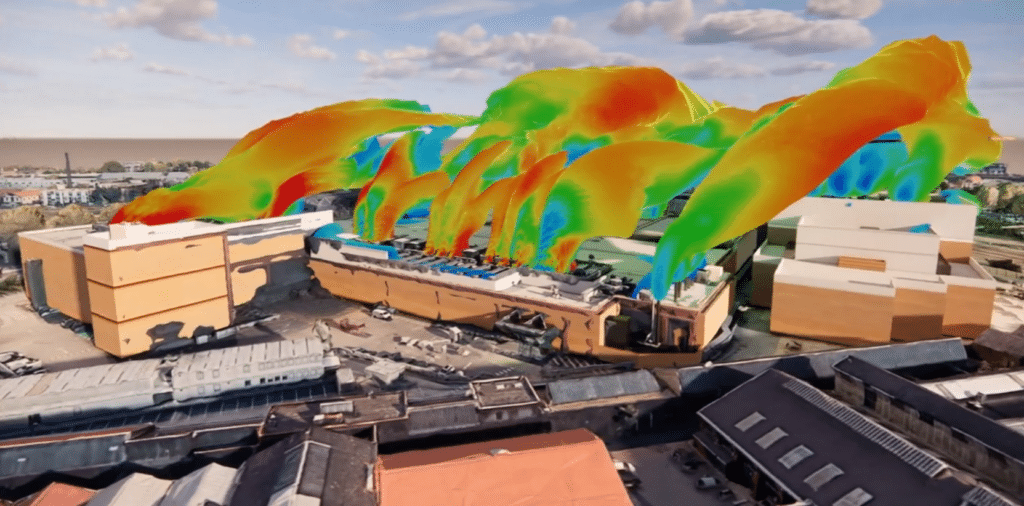

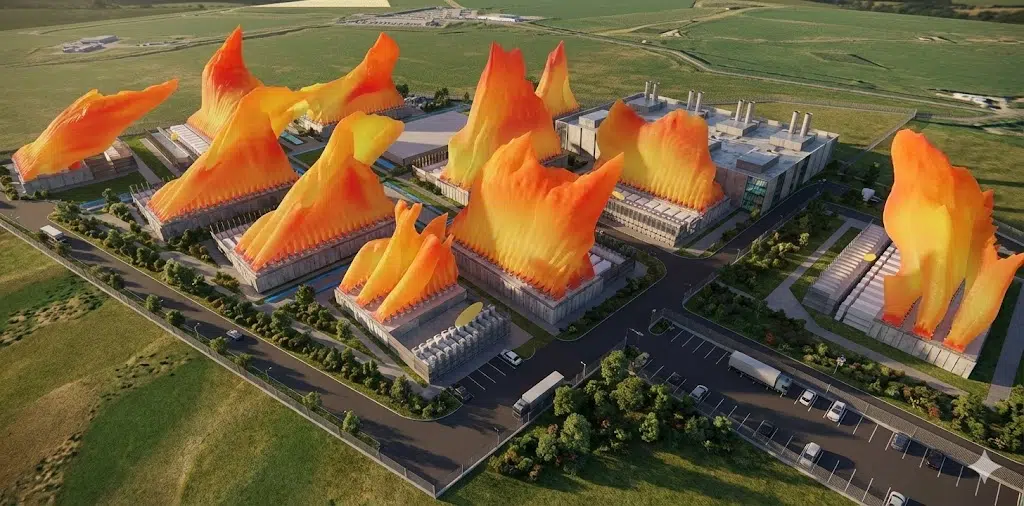

CFD simulation - Hot spots in aisles

Hot air recirculation

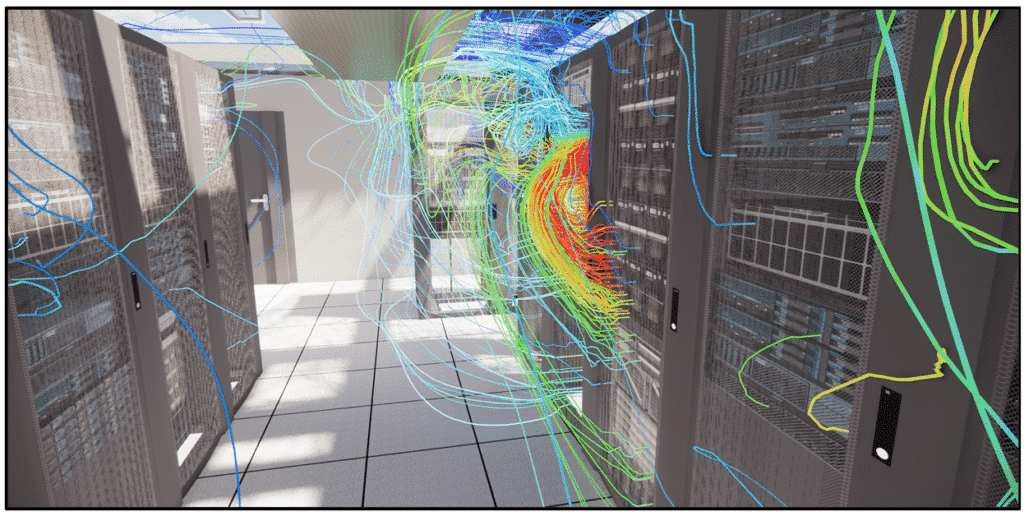

Air recirculation in a data center refers to the phenomenon wherebyhot air exhausted by servers returns to the cold aisle before it has been properly cooled. This phenomenon disrupts the expected heat flow and can have significant consequences on the operation and efficiency of the cooling system.

When the hot air mixes with the cold air from the cold aisle, the temperature at the cabinet inlet rises. Servers then receive air that has already warmed up, whichreduces cooling efficiency and can cause significant thermal variations. This lack of cooling also increases the risk of hot spots, which can compromise equipment reliability and service life.

Recirculation also leads to over-consumption of air-conditioning units. Systems have to supply more cold air to compensate for the mixed flow, which increases energy consumption and reduces overall data center efficiency.

There are several reasons for this phenomenon. Poorly sealed aisles, such as the absence of brushes or blanking panels in bays, allow hot air to escape to the cold aisle. Poorly designed confinement, such as open or partially partitioned cold or hot aisles, also encourages the return of warm air. Lastly, insufficient air flow, not allowing hot air to be expelled efficiently, contributes to increased recirculation.

CFD simulation - Hot air recirculation on systems

Faced with uncertainty or the risk of hot spots, many operators choose to overcool the room. As a result, HVAC units run at a higher power than is actually needed, increasing PUE (Power Usage Effectiveness) and energy costs, sometimes significantly. The challenge is to cool exactly what’s needed, where it’s needed, without waste. Thus, rigorous management of aisle architecture, combined with appropriate airflow sizing, is essential to limit recirculation and maintain optimal cooling conditions in a data center.

Temperature and humidity control

Temperature and humidity are essential factors in ensuring the reliable, long-term operation of a data center. Too high a temperature accelerates wear and tear on electronic components, reduces the efficiency of storage systems and increases the risk of breakdowns. Conversely, too much humidity can cause condensation on circuits, leading to short circuits and data loss. Conversely, humidity that is too low encourages static electricity, which candamage sensitive components.

Humidity control is therefore a key element in the protection of digital infrastructures. It has a direct impact on equipment safety, server durability and the stability of critical data storage systems. In high-density computing environments, such as centers hosting servers for artificial intelligence or high-performance computing, precise temperature and humidity management becomes even more critical. The slightest imbalance can amplify the risk of overheating, hot air recirculation or hardware failure, impacting both service continuity and energy consumption.

Fine-tuning these parameters not only helps prevent incidents, but also optimizes the center’s energy efficiency, avoiding excessive or poorly-targeted cooling that consumes energy unnecessarily without any real benefit for equipment protection.

Starting fires

Data centers present specific fire hazards due to the high concentration of electrical and electronic equipment and high-power electrical supplies. A hardware failure, short-circuit, local overheating or power supply fault can quickly lead to a fire. Although the materials used generally comply with safety standards, the combustion of electronic components generates dense, toxic and corrosive fumes, representing a major hazard for people and equipment.

In addition to the risk of fire spreading, the rapid accumulation of hot smoke can severely impair visibility, complicate rescue operations and cause a rapid rise in ambient temperature. In a confined environment such as a data center, these phenomena can occur in a matter of minutes, making the control of air flows and the sizing of smoke extraction systems particularly critical.

In this context, numerical simulation using CFD is an essential tool for analyzing and anticipating building behavior in a fire situation. It can be used to model smoke propagation, temperature evolution and the influence of aeraulic flows generated by ventilation or smoke extraction systems. In particular, CFD can be used toassess the efficiency of smoke extraction systems,identify areas where smokestagnates and check that escape routes remain passable.

The main objective of these simulations is to guarantee acceptable intervention conditions for the emergency services, by ensuring sufficient visibility and temperatures compatible with their intervention. CFD thus makes it possible to verify that smoke extraction activation effectively limits smoke accumulation, encourages smoke evacuation to the outside, and maintains controlled thermal conditions throughout the intervention. These analyses contribute to enhancing safety, limiting material damage and validating the compliance of installations with fire safety requirements.

CFD simulation: an indispensable tool

What is CFD simulation?

Computational Fluid Dynamics(CFD) is a numerical simulation method for modeling fluid behavior and associated thermal phenomena. Using specialized software, the engineer builds a three-dimensional model of the object under study, defines boundary conditions, chooses the relevant physical models (convection, conduction, radiation, heat transfer, flow dynamics, etc.) and selects a calculation method.

A phase of iterations follows: based on the results obtained, the model is adjusted to better represent actual physical phenomena. The aim of CFD modeling is to understand, analyze and optimize the thermal and fluidic behavior of a system, in order to provide a reliable solution to the design or operating problems identified.

Simulation results are a decision-making tool: they can be used to improve the initial design of a plant, identify bottlenecks andoptimize operational performance.

A tool for understanding and visualizing

Thermal management is crucial in data centers. A rapid rise in temperature due to cooling failure can lead to simultaneous equipment failures, threatening service continuity. Unlike traditional spot measurements, CFD offers a global, predictive view, enabling problems tobe anticipated before they occur.

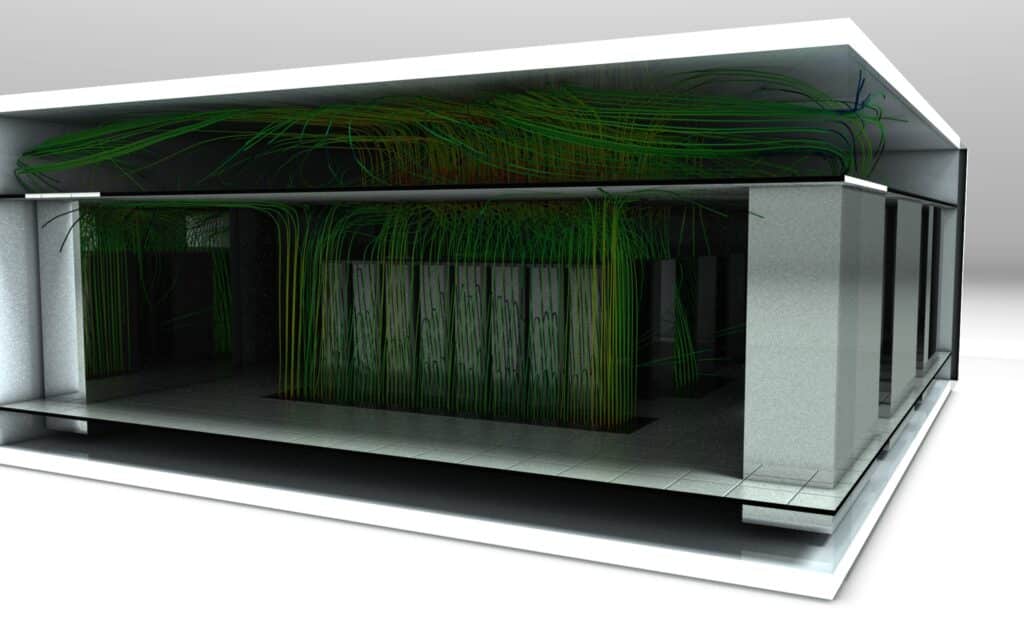

- Visualizing the invisible

CFD makes visible and quantifiable aeraulic and thermal phenomenathat cannot be observed directly by the naked eye. In particular, it highlights air flow trajectories, hot air recirculation zones, temperature gradients, localized overheating zones, as well as the effects of turbulence and pressure variations. This three-dimensional visualization capability is particularly relevant in the context of data centers, where flows are highly complex and large-scale physical prototyping is unrealistic, if not impossible. CFD thus provides a detailed understanding of the thermal behavior of the premises, enablingmalfunctions to be anticipated before any modifications or on-site implementation.

- A predictive and optimizing tool

CFD provides engineers with a decision-support tool enabling them toevaluate and compare different configurations virtually, before implementing them on site. In particular, it enables them toanticipate the impact of adding or increasing IT loads, analyze the effectiveness of hot and cold aisle containment strategies, and predict the system’s aeraulic and thermal behavior in degraded situations, such as the failure of a cooling unit. This approach guarantees validation of technical solutions without interrupting service, while limiting operational risks and avoiding the additional costs associated with unsuitable design choices or retrospective corrections.

- Cost reduction and energy efficiency

CFD simulation is a major lever for the technical and economic optimization of data centers. It enables us to precisely target actual cooling requirements and avoid oversizing equipment, thus reducing unnecessary investment in additional infrastructure. By optimizing the distribution of air flows and the efficiency of cooling systems, it also contributes to a significant reduction in the energy consumption of HVAC installations, while limiting over-cooling phenomena. In many cases, this fine-tuning enablesIT capacity to be increased without the need for major new infrastructures.

Typical CFD applications in data centers

CFD can be used to simulate a wide range of critical scenarios:

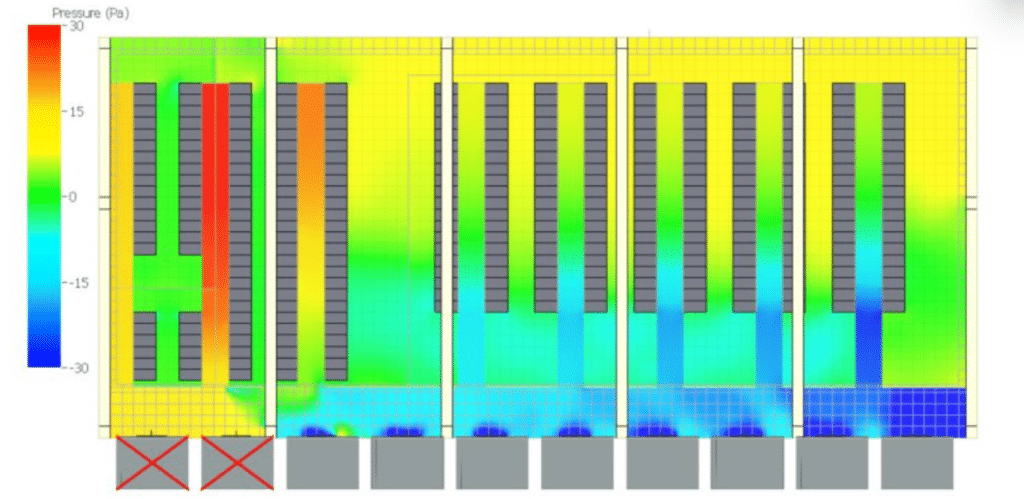

- Air distribution in cold and hot aisles,

- Pressure under raised floor,

- Temperature around the systems,

- Performance of CRAC/CRAH units,

- Containment effectiveness,

- Impact of a cooling unit failure

- Consequence of load variation

- Comparison of different cooling configurations

These analyses enable informed decisions on data center design and operation, offering a level of precision unattainable by thermal probes alone or by empirical experience.

CFD software for data centers

The market offers a variety of software for simulating flows and thermodynamic phenomena: ANSYS, Autodesk CFD, XFlow, OpenFOAM, Phoenics, FlowVision, STAR-CD, TileFlow, Sigma6Room, Gas Dynamics Tool, etc.

Some tools, such as TileFlow or Sigma6, integrate specific libraries for data centers (fans, air conditioning units, perforated tiles, IT equipment), simplifying modeling for less experienced engineers. Nevertheless, the quality of the analyses depends heavily onthe expertise of the CFD specialist, capable of correctly fitting the models and rigorously interpreting the results.

CFD study process

Data collection

Data collection is the initial and decisive phase of any CFD study, as it directly conditions the reliability and relevance of future numerical simulations.

This stage is largely based on theanalysis of technical information, such as layout plans, equipment characteristics, airflow diagrams, dissipated power and nominal operating data. This information is used to characterize air velocities, pressure levels, temperature fields and flow rates, as well as to identify obstacles, preferential flow paths or potential leakage zones.

This analysis phase is essential for establishing a coherent modeling basis, correctly defining assumptions and parameterizing boundary conditions, while highlighting the first critical points likely to impact the system’s thermal and aeraulic performance.

3D model creation

The creation of a three-dimensional model is a key stage in the CFD study, as it enables the data center to be faithfully represented in the form of a digital twin that can be used for calculations. This 3D model is created using computer-aided design (CAD) tools, and incorporates all the geometric elements that influence airflow and heat transfer.

The size and volume of the room are precisely defined, as are the layout of computer racks and telecom cabinets, in order to reproduce actual air circulation paths. The technical floor is modeled, taking into account its height and the position and perforation rate of the slabs, which determine how cold air is injected. Air-conditioning equipment is integrated with its functional characteristics, including air flow rates, speeds and directions, as well as fan type and discharge orientation. Obstacles likely to disrupt the flow, such as cable trays or ancillary structures, are also taken into account.

This detailed modelingavoids the simplifying assumptions or oversizing commonly used in the absence of CFD, and provides a realistic basis for accurately predicting the thermal and aeraulic conditions of the data center, thus reducing the risk of sub-optimal design.

Boundary conditions

Boundary conditions in Computational Fluid Dynamics (CFD) are a fundamental element of modeling, as they mathematically translate the interaction between the computational domain and its physical environment. They define, at the boundaries of the meshed domain, the imposed values or functional relationships of conserved quantities such as velocity, pressure, temperature or heat flow.

Depending on the physical nature of the problem, different types of boundary conditions are applied: Dirichlet-type conditions imposing a fixed value (e.g. velocity or temperature), Neumann-type conditions imposing a gradient or flow, or mixed conditions combining the two. Flow inlets and outlets are generally characterized by velocity, mass flow or pressure profiles, while solid walls can be modeled as adherent (non-slip condition), isothermal or adiabatic. Turbulence models also require specific conditions for turbulent quantities, consistent with the expected flow regime.

The choice and rigorous implementation of these conditions are essential to ensure numerical stability, solution convergence and physical representativeness of the results, as any inconsistencies can lead to significant errors or unphysical solutions.

Mesh

Mathematical simulation of airflow and heat transfer processes involves numerically solving a set of non-linear, second-order partial differential equations.

Since the numerical model of spaces is made up of an infinite number of points, it is impossible to solve the partial differential equations, even numerically. The structure is therefore broken down into a finite number of points, resulting in a decomposition of the geometry into simple shapes. All these nodes and elements constitute the model mesh.

The software performs a complete topological interrogation of the analysis geometry and determines the size and mesh distribution on each edge, surface and in the model volume. Geometric curvature, gradients and proximity to neighboring geometry are taken into account when assigning element sizes and distributing the mesh. The mesh is then systematically refined by the engineers in charge of studies in specific, high-gradient zones.

The mesh is automatically generated according to the model geometry and boundary conditions using algorithms(Petrov-Garlerkin 5-type advection method) defining the optimal convergence solution.

The mesh produced is of the hybrid type. The elements of this type of mesh are generated without any constraints on their arrangement, enabling complex geometry to be generated while maintaining good element quality. The mesh generated combines a mixture of elements of different types, tetrahedral, prismatic or pyramidal in 3D. It combines the advantages of structured and unstructured meshes.

In each of these volumes, the conservation equations are expressed as algebraic equations. This set of finite volumes is referred to as the mesh.

Analysis and optimization

Analyzing and optimizing the results is the final phase of the CFD study, transforming the numerical data into concrete levers for improving the system.

Calculation results can be visualized in a variety of ways, including heat maps, velocity fields, vertical or horizontal cross-sections, and animations showing airflow trajectories and interactions. These representations make it easier to identify critical areas, such as hot spots, unwanted recirculation , flow imbalances or losses in ventilation efficiency.

Based on these analyses, corrective actions can be proposed, such as reorganizing equipment, adjusting airflow rates and directions, modifying the layout of perforated tiles or optimizing the positioning of air-conditioning systems. Simulation scenarios can be iterated to compare different configurations and converge on a solution offering optimal, reliable thermal and aeraulic operation in line with the data center’s operating requirements.

Summary

CFD simulation software enables the precise representation of fluid flow, whether liquid or gaseous, as well as all associated physical phenomena, particularly heat transfer. Based on thermodynamic modeling, these tools offerin-depth analysis of air and heat behavior, making it possible to design high-performance systems as well asfine-tune existing installations, particularly in complex environments such as data centers.

Without the use of CFD, reliable assessment of temperature and airflow distribution in a computer room would remain largely approximate. These quantities are the result of theinteraction of numerous parameters, such as the heat load dissipated by IT equipment, the layout and performance of air-conditioning units, heat transfer fluid temperatures, the height and configuration of the technical floor, the layout of supply and return grilles, and the type and characteristics of fans.

By simultaneously integrating all these factors, CFD simulation has become an indispensable tool for understanding, anticipating and controlling the thermal and aeraulic behavior of a data center, while securing design choices and improving overall energy efficiency.

Find out more:

Our specific solutions for data centers :

CFD engineering for data centers

Find out more

Thermal storage study

Find out more

External CFD simulation for data center

Find out more

Data Center Fire Simulation

Find out more

Thermal study of technical premises

Find out more

Urban heat island impact study for data centers

Find out more

Audit, diagnosis and 3D modeling of existing data centers

Find out more

Designing your data center’s digital twin

Find out more

Energy optimization and PUE calculation for data centers

Find out more

Commissioning: study and CFD modeling of load benches

Find out more

Data center engineering

Initially created in France, EOLIOS Ingénierie is the benchmark thermal and aeraulic simulation consultancy for data centers in Europe and worldwide. The company supports operators, designers and project owners at every stage in the life of a data center: design, optimization, renovation or extension.

By combining cutting-edge scientific expertise, state-of-the-art simulation tools and in-depth knowledge of the data center ecosystem, EOLIOS Ingénierie is a trusted partner for ensuring the availability, security and energy performance of IT infrastructures, while anticipating sustainability issues.

EOLIOS

PARIS – LONDON – MILAN – MUNICH – MADRID – WARSAW – CASABLANCA – UNITED ARAB EMIRATES – USA