Generators

Accueil » Industrial Process » Generators

EOLIOS takes care of your generators:

- Pressure loss study

- Sizing natural ventilation

- Study of NOx diffusion

- Impact of extreme weather conditions

- Study of critical failure scenarios

- Identification of bypass and recirculation air flows

- Improved air distribution and cooling efficiency

- Precise dimensioning of grating layout

- Optimizing placement and control of air handling systems

- A passionate team

Continue navigation :

Our latest news :

Our projects :

Our areas of expertise :

How can CFD simulation be used for generator rooms?

Ventilation systems for different uses

Generator sets dissipate heat during the production of electrical energy, and a sufficiently ventilated space is required to keep the temperature within the operating threshold.

Heat is removed from the genset by inducing a flow of air through a ventilation system around the engine.

Generator rooms therefore require appropriate ventilation.

These diesel or gas engines may be used to propel boats, or to generate electricity, and are exposed to variable climatic conditions: from the cold extremes of the Arctic to the heat of the tropics.

These engines must therefore continue to operate in all environments.

Ventilation of these machine rooms is of vital importance, enabling :

- Supply combustion air to engines

- Provide engines with fresh air to extract unwanted heat

- Maintain room temperature within a sufficient range to ensure that personnel can work in the machine room and that components do not overheat.

Typically, the airflow through the machine room is calculated using the average ambient temperature, and does not take into account any extreme climatic conditions that may be associated with it.

We study generator ventilation systems in their final operating conditions.

We support the manufacturers of these units by providing advice on the amount of air required for combustion and advising on the air flow rate required to accommodate engine cooling.

We offer assistance on the global ventilation of these machine rooms, the study of the impact of the rejections on the systems in the vicinity and the calculation of the pressure losses of the acoustic systems.

What are the steps involved in a CFD simulation applied to the study of systems?

CFD simulations enable a thermal analysis of equipment rooms that cannot easily be carried out by experimentation.

To create a computer model, first of all, the geometry of the building is slightly simplified.

This involves removing gaps and small edges that would result in too many finite elements being generated during mesh generation.

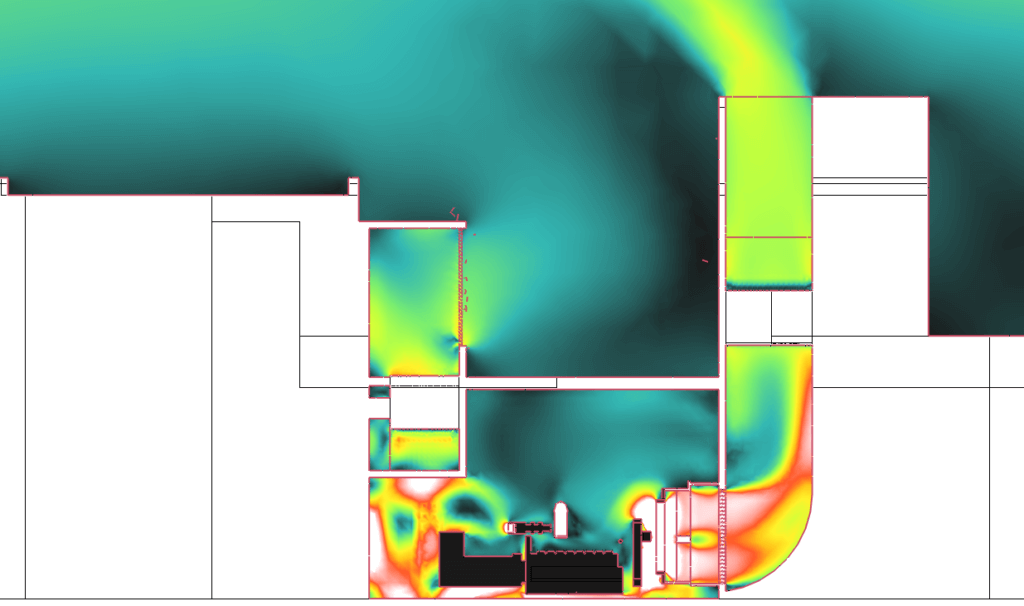

The model is then used to establish global thermal profiles for certain extreme climates.

The main objective is to carry out analyses of air inlets and outlets.

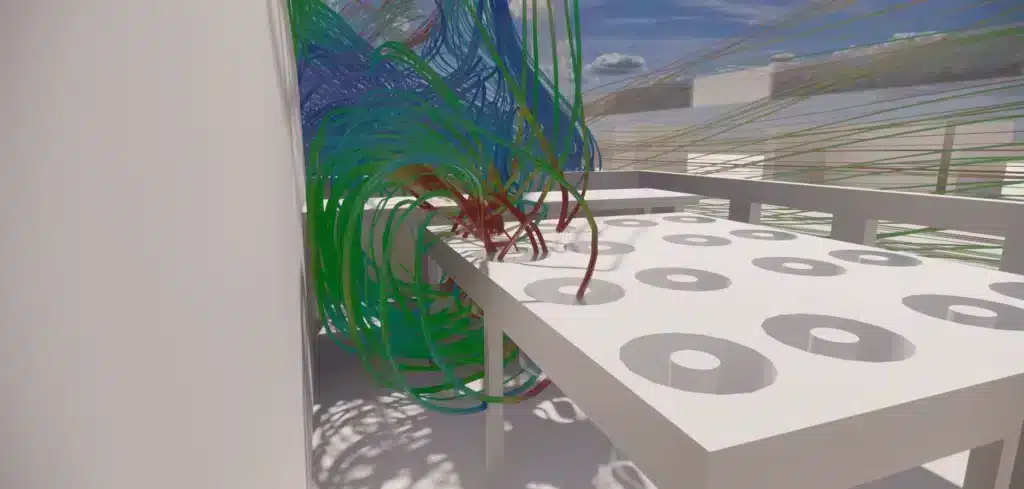

These are generally channelled to direct the flow around operating parts, to improve the efficiency of the generator engine (Genset).

It is then possible to compare several variants precisely andobtain a large amount of information: pressure, maximum intake temperature, air displacement, pollutant displacement…

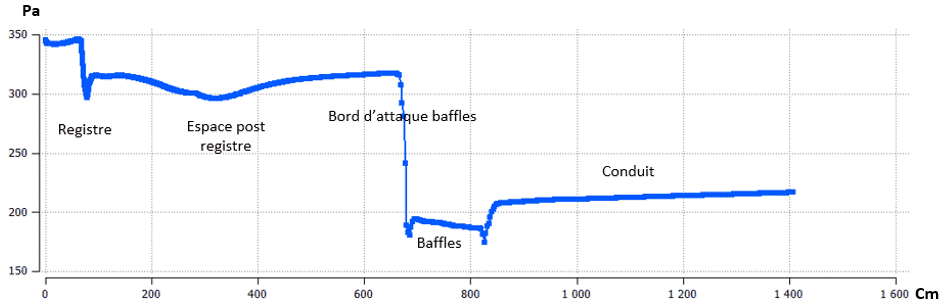

Calculation of pressure losses using CFD simulation and sizing of generator fans

We carry out pressure loss studies for acoustic baffles and dimensioning of fans.

As a function of air speeds, pressure losses become exponential.

The diesel engine and the generator are the various elements that disrupt fan flows.

Louvers and acoustic baffles near and upstream of the exhaust are a major source of pressure drop for fans.

Minor flow resistance comes from battery banks, fuel tanks, intake pipes and the engine exhaust stack.

In addition to the flow inside the room, another flow must be taken into account: wind flow over the building. This is due to the possibility of wind blowing over the generator room, which can lead to a higher pressure drop and, above all, recirculate overheated exhaust gases to the engine inlet.

The louvers and acoustic baffles near the exhaust and upstream are a major source of pressure loss for fans. Minor flow resistance comes from battery banks, fuel tanks, intake pipes and the engine exhaust stack.

In addition to the flow inside the room, another flow must be taken into account: wind flow over the building. This is due to the possibility of wind blowing over the generator room, which can lead to a higher pressure drop and, above all, recirculate overheated exhaust gases to the engine inlet.

Diesel exhaust contamination of HVAC systems

We study the diffusion of Nox and other pollutants that can degrade new office air.

Generators are one of the best ways of coping with power cuts.

It is, however, a double-edged solution.

The engine of this equipment emits pollutants to produce electricity.

These include carbon dioxide, sulfur and nitrogen oxides.

In general, gensets run on gasoline, gas or diesel.

They can therefore pollute the surrounding atmosphere, especially if used intensively during a power failure.

Our analyses can include the monitoring of exhaust gas dispersion.

We study the dissipation of pollutants from generator discharges and check that there is no direct recirculation to my hygienic air intake systems (AHUs) in nearby premises.

CFD plume studies for an extreme scenario