Home » Industries » Improving industrial performance with CFD: glassworks, steelworks, aluminium smelters » Glassworks – Vosges

Glassworks – Vosges

Optimizing thermal comfort in a glassworks and improving air quality

EOLIOS has studied precisely the natural ventilation of a glass factory in order to optimize the air quality and the comfort of the operators.

Vosges Glassworks

Year

2022

Customer

O-I

Location

France

Typology

Glassware

Continue navigation :

Our other projects :

Latest news :

Project description

The thermal comfort of industrialoperators exposed to high temperatures is very important. Workers need to be comfortable if they are to work safely and efficiently. There are several ways to improve thermal comfort in these environments.

Preventive measures telles that l‘utilisation d‘a ventilation and l‘utilisation d‘équipements from protection staffthe adéquats, as from vêtements légers and breathingants and from Monandtes from protection, peuwind aider à reduce the risk of overheating and improve thermal comfort.

Glass bottles are usually formed using a technique called blowing. In this process, a ball of molten glass is blown into a bottle-shaped mold. The edges of the ball are then stretched and rolled to form the bottle. Once the process is finished, the bottle is cooled, polished. and is ready to be packed and shipped.

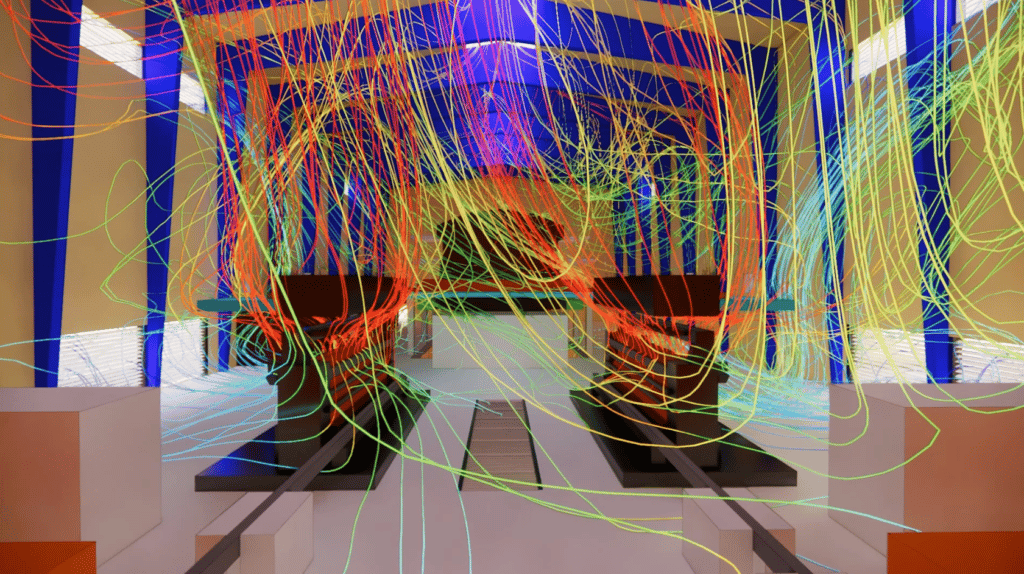

Creation of a digital study model

The creation of the model of the plant was carried out by taking into account the topology of the site with a great precision in order to be able to capture at most the evolution of the air flows. This digital twin takes up precisely the different sets of beams, the air volumes as well as the surrounding buildings.

This high level of precision in the production of the digital twin translates into a clear improvement in the accuracy and relevance of the results obtained during CFD simulation.

Study of natural ventilation

The natural ventilation of a glass factory is a ventilation system that uses outside air to evacuate hot or stale air from inside the workshop. The system uses static aerators that are strategically placed to take advantage of outside air currents and the upward force of warm air to create an aeration air stream. Outside air is drawn in through openings located near the ground and warm air is expelled through openings located near the roof. Windows and doors are also used to help create air movement. If mastered, these systems can be very effective in providing sufficient ventilation for the operators.

Natural ventilation in industry is a system that works by using the force of the wind to create an air flow inside the buildings. The system is based on the principle of thermal convection, which is a natural process of heat transfer based on the temperature difference between the air inside and the air outside.

Optimization of air quality and thermal comfort

CFD (Computational Fluid Dynamics) simulation has helped optimize natural ventilation in industry by providing accurate and up-to-date information on the efficiency of ventilation systems.

Visit simulations CFD peuwind être utilisées for simuler and analyseer the behavior of fluids inside d‘a usine and ainsi identify areas where ventilation can be improved. Visit simulations CFD peuwind également être utilisées for diceterminer the as toity d‘air nécessarea for a ventilation optimale and permandtre at entreplugs d‘utiliser moins d‘énergie for theur ventilation.

Visit simulations CFD have également permis d‘améliorer the checkôthe and the distribution from flows d‘air à l‘intérieur from l‘usine, this which a permis more efficient and safer ventilation.

Continue on this topic

Video summary of the study

This vidéo from simulation thermo aéraulique d‘a wormrerie mountre the temperature and air velocity distribution in the plant. Elthe says how visit différents systèmy from l‘usine shave intégrs and interagissent visit some awith visit autres.

Thus, our engineering mission thermo aéraulique allowed to validate how ventilation could be improved for améliorer the quality from l‘air and the temperature ofyears l‘usine.

Inend, we have aider à compmakesre how visit différents systèmy from l‘usine could être optimiss for améliorer efficiency and reduce costs.

Discover other projects

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods