Accueil » Laboratoires » Laboratories – White Rooms » Cleanroom aeraulics

Cleanroom aeraulics

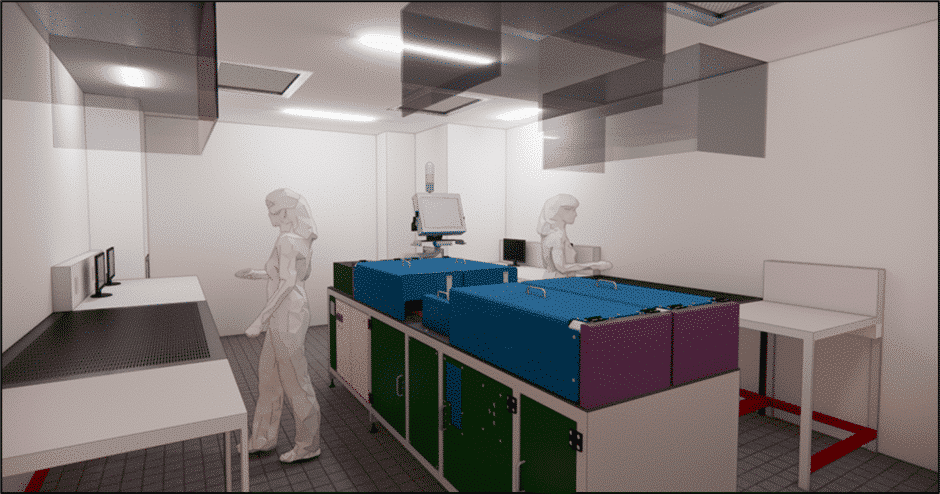

CFD study of air flows to check cleanliness of a cleanroom

EOLIOS’ in-depth study determined the air flows in the cleanroom to verify its cleanliness.

Cleanroom aeraulics

Year

2023

Customer

Dalkia - Ipsen

Location

France

Typology

Laboratory

Continue navigation :

Our other projects :

Latest news :

What is a cleanroom?

A cleanroom is a highly controlled space specially designed for various applications, such as scientific research, manufacturing, electronics, pharmaceuticals and the aerospace industry. Its main objective is to maintain an extremely high level of cleanliness by rigorously controlling the concentration of airborne particles. Other essential parameters such as temperature, humidity and pressure are also closely monitored and regulated.

Cleanrooms are specifically designed to prevent contamination of sensitive products or ongoing processes. They are used to protect products, equipment or materials that are sensitive to particles, bacteria, micro-organisms, dust or any other type of contamination that could impair their quality or performance.

To guarantee compliance with required cleanliness standards, cleanrooms are equipped with advanced air filtration and air flow control systems. What’s more, they feature smooth, easy-to-clean surfaces. Rigorous procedures also govern the entry and exit of personnel in these areas. To minimize any contamination of the environment, workers accessing these areas are often required to wear special clothing including overalls, gloves, masks and overshoes.

EOLIOS helps you comply with cleanliness standards andoptimize thermo-aerodynamics in cleanrooms thanks to CFD simulation.

Cleanroom standards

Cleanroom standards are set to guarantee a precise level of purity in terms of airborne particle concentration. The standard most commonly used to classify cleanrooms isISO 14644, which establishes cleanliness levels based on the number of particles per unit volume of air. Classifications range from ISO 1 (cleanest) to ISO 9 (least clean).

These standards apply mainly to the concentration of airborne particles. When a cleanroom is designed and operated, rigorous maintenance, cleaning and monitoring procedures are put in place to ensure that the required levels of cleanliness are maintained at all times.

Limiting contamination

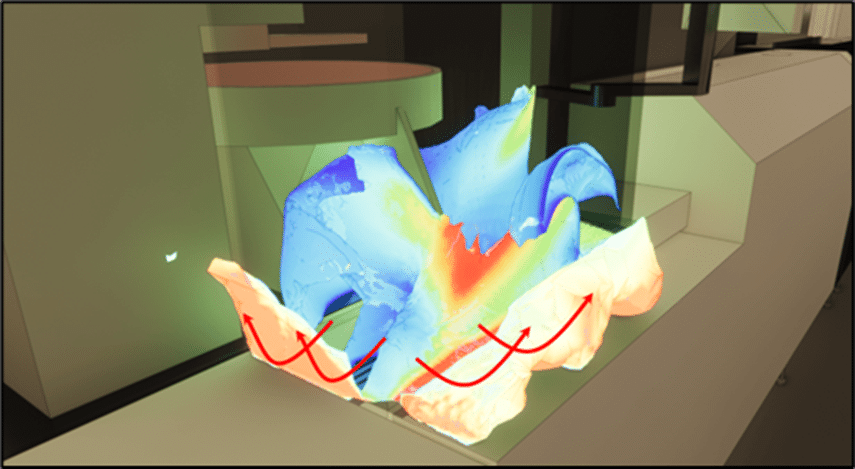

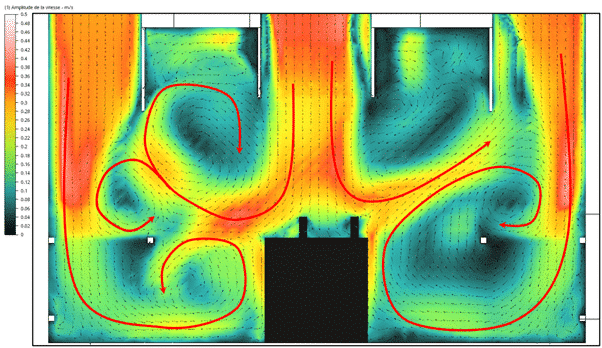

There are many ways of limiting contamination in cleanrooms. First of all, the presence of laminar flow ensures linear, turbulence-free airflow. A steady stream of air flows through the cleanroom in a single direction. It is also necessary to limit the flow of air from the ground into the breathing zones. This can contaminate products or processes, but also cleanroom users who may inhale pollutants.

The use of baffles is essential in a cleanroom, so it’s very important to know how to size them. These air deflectors ensure more precise aeraulics in the room and are compatible with improved air quality. Their main objective is to maintain a uniform, directional airflow in the cleanroom, to minimize the dispersion of particles and contaminants in the ambient air.

Different types of blowing/recovery

Before starting the simulation, it is necessary to identify all the supply/exhaust systems and record their flow rates, so that they can be modeled correctly.

FFU blower

Air filtration units (FFUs) are usually installed in grilles or ceilings and blow a stream of filtered air through the built-in filter. The fan inside the unit creates positive pressure, pushing filtered air into the room and keeping outside contaminants out.

Air handling unit filter blowing

CTA(Centrale de Traitement d’Air) filter blowers are ventilation and air-conditioning systems that distribute, filter, heat, cool and control the humidity of ambient air. This type of ventilation is used in many fields toimprove indoor air quality, maintain comfortable conditions and ensure healthy, productive working environments.

CTA takeover

AHU covers refer to devices or ducts that collect and recycle contaminated air, containing particles, pollutants or odors, present in an area. The air is then returned to the AHU to be filtered and conditioned again, before being redistributed into the interior space via air ducts and supply grilles to ensure adequate, uniform ventilation.

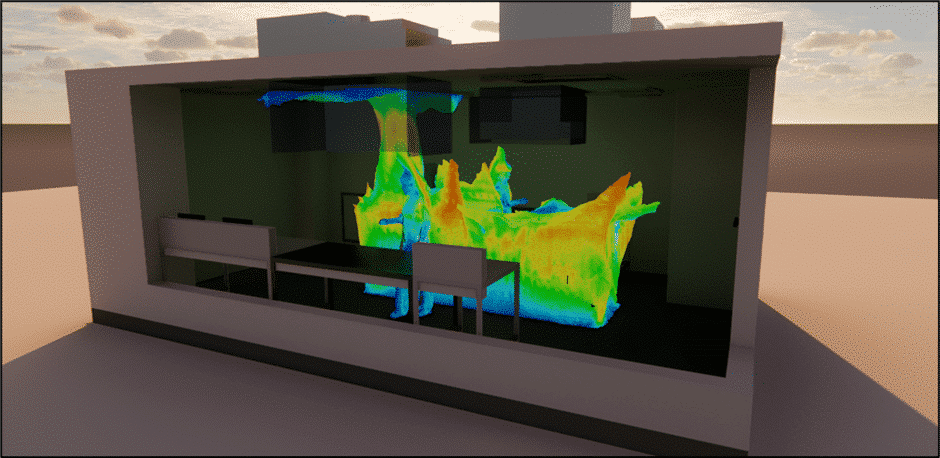

Laminar flow recovery

Laminar flow recovery is a specific ventilation system designed to maintain a high level of air cleanliness and precise control of airborne particles. The principle is based on the creation of a regular, unidirectional flow of air that crosses the cleanroom space linearly and without turbulence. This laminar flow is generally directed from ceiling to floor.

CFD simulation of cleanroom aeraulics

CFD simulation plays an important role in keeping cleanrooms clean. It provides an in-depth understanding of air movement, particle distribution and contaminant dispersion.

Air velocity and air temperature studies are carried out within the hall to determine whether the flow rates present are adequate and whether the ventilation systems allow pollutants to be evacuated.

EOLIOS supports you ...

EOLIOS is able to model airflow in a cleanroom, taking into account ventilation systems, filters and equipment. In this way, we can guarantee adequate air flow and even air distribution to minimize stagnation zones where contamination could accumulate. Critical areas – those with the greatest risk of contamination – can be identified by studying air flows, hot spots and recirculation zones. Filter efficiency can also be assessed using CFD, by simulating particle filtration and identifying areas where contaminated air could leak.

As a result, our team is able to validate or invalidate the performance of ventilation systems present in a cleanroom. This ensures that the required levels of cleanliness are achieved and maintained to the specified standards.

Video summary of the study

Discover other projects

HVAC – Medical equipment warehouse

VOC treatment process improvement

Cleanroom aeraulics

Pharmaceutical Laboratory – Dust

Qualification of fume cupboards – Laboratory

Study of a clean room