Accueil » Smoke control » The objectives of smoke control

The objectives of smoke control

Continue navigation :

Our latest news :

Read more :

Our projects :

Our areas of expertise :

The danger of fumes

Dangers for people

Since the 1980’s, it is known that 80% of the deaths caused by a fire are due to the inhalation of toxic fumes. We can distinguish 3 main dangers. Hazards related to opacity, toxicity and temperature.

Opacity Hazards:

One of the special features of smoke is its opacity. However, when a person is caught in a fire and visibility is reduced to less than 4 meters, it becomes virtually impossible for them to find their way around and find the emergency exits.

In a state of panic, the occupant loses his bearings and acts as if trapped in a confined space, losing all sense of orientation. If the person is not removed quickly from this atmosphere, the situation can quickly become fatal.

Loss of visibility at the start of a fire

Toxicity Hazards:

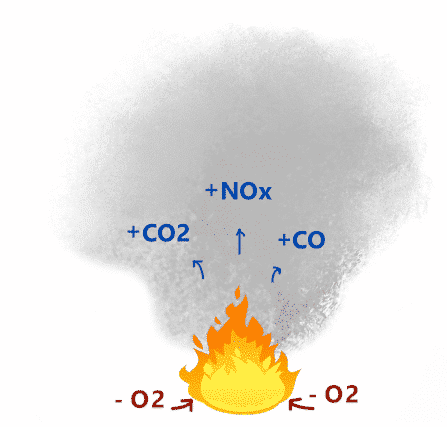

A fire releases around 140 hazardous compounds, some of them highly concentrated, which can be fatal even after a short exposure. Victims must be rescued within 30 minutes of the fire. Toxic gases fall into two categories: asphyxiating gases (such as cyanides and carbon oxides), which depress the central nervous system, and irritating gases (such as chlorine and its derivatives), which damage the respiratory mucosa. Among the most dangerous compounds for human beings we find :

- Carbon dioxide

- Carbon monoxide

- Nitrogen oxides

In the event of fire, there is a significant reduction in the amount of oxygen available in the air, which can cause syncope or even death if the oxygen concentration falls below 6%. The fumes released by the fire also contain toxic compounds that can cause rapid poisoning. A person who finds himself in a smoky environment will cough, but this can make the situation worse by increasing his exposure to toxic substances.

In addition, the reduction in the amount of oxygen in the air can lead to impaired motor coordination and difficulty in moving, which can put the victim in mortal danger if not evacuated quickly. So it’s crucial to take precautions to prevent fires, and to know what to do in an emergency.

Temperature-related hazards:

In a fire, temperatures can rise rapidly to levels lethal to the pulmonary alveoli above 120°C, causing death within minutes. However, the fumes produced have a very low density, which causes them to rise towards the ceiling and accumulate in layers with decreasing temperatures (a phenomenon known as “stratification”).

Given the phenomena of convection and stratification, we recommend moving closer to the ground during a fire, where temperatures are lower, concentrations of toxic compounds are lower and oxygen levels are higher. In short, it is advisable to get close to the ground to maximize the chances of survival in the event of a fire.

Hazards to property

Smoke plays an important role in the spread of fires because of its characteristics. During a fire, combustible materials are exposed to high temperatures in hot, oxygen-depleted environments, such as smoke or the interior of the flame. As a result, the materials decompose, producing combustible gases that fuel the flames – a phenomenon known as pyrolysis.

Fumes are also corrosive, containing compounds such as hydrochloric acid, which are hazardous to building structures and property in the fire zone.

The roles and objectives of smoke control

Smoke control to save lives: crucial issues in the event of fire

In short, the greatest threat to a person caught in a fire is smoke poisoning. It is therefore crucial to evacuate the smoke from the affected building, which is accomplished through smoke extraction. During a fire, the smoke and heat produced remain trapped inside the building, which can prevent the occupants from safely exiting. The purpose of smoke extraction is to evacuate a portion of the smoke from the fire to create an area of free air below the smoke layer.

Video of a fire in a theater

Smoke extraction has many benefits: it facilitates occupant evacuation by maintaining visibility and fresh air; it limits the spread of fire by evacuating hot gases and particles; it enables firefighters to gain access to the scene of the fire; and it helps reduce the risk of building collapse by limiting the rise in temperature.

The constraints of smoke control

Smoke extraction optimization: Limit volumes and control smoke stratification

In order to meet the objectives set out above, a number of constraints must be met to ensure effective smoke extraction. The first constraint is to limit the volumes to be cleared of smoke by compartmentalizing with fire-resistant walls and doors to reduce fire propagation.

For example, large sales areas that cannot be compartmentalized will be reduced by creating containment screens to channel fumes to evacuation systems.

Videodetection of smoke propagation in high spaces

In addition, it will be necessary to respect the stratification phenomenon by avoiding creating turbulence that could send hot fumes back to the ground. Blowing speeds should never exceed 5 m/s. For an efficient scavenging, the fresh air intakes should be located at the bottom and the smoke exhausts at the top, avoiding any dead zone where a smoke plug could stagnate.

Finally, it will also be important to comply with thermal regulations to guarantee optimum thermal comfort without having to resort to permanent openings to the outside.

The constraints of smoke control

There are two main principles for smoke control:

- sweeping

- the hierarchy of pressures.

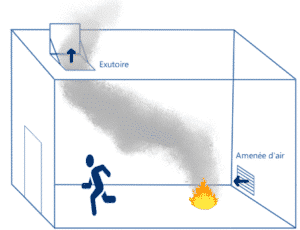

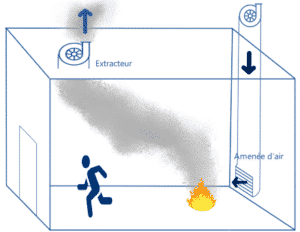

Sweeping consists of circulating fresh air in the lower part of the volume to be cleared of smoke, and extracting the fumes in the upper part. This can be done naturally or mechanically depending on the type of drainage.

Pressure hierarchies, on the other hand, involve establishing a lower pressure in the affected volume than in adjacent rooms, to create an equilibrium that prevents smoke propagation. This method is often used in high-rise buildings and requires mechanical smoke extraction.

The different modes of smoke extraction

Natural smoke control

This is the most common type, using smoke vents or remotely controlled openings in the facade to evacuate smoke, and doors or openings to bring in air. The controls must act simultaneously on the exhaust and supply air.

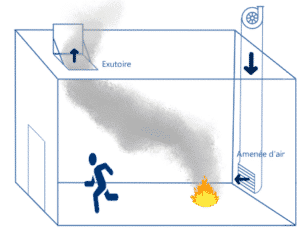

Mechanical/natural smoke control

This configuration is less frequent, and requires the use of a fan for air supply when the volume to be cleared is semi-buried or otherwise difficult to access. Air inlets must have an air velocity of less than 5 m/s, and smoke exhaust must be from roof-mounted outlets.

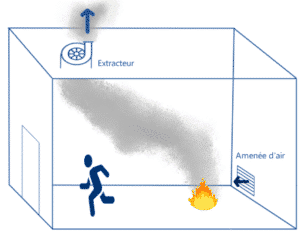

Natural/mechanical smoke control

Here, extraction is provided by one or more fans, while air supply is provided by remote-controlled doors or openings, as with natural smoke extraction. The dimensions of the air inlets are calculated taking into account the total extraction flow.

Mechanical/mechanical smoke control

This type of smoke extraction requires both supply and exhaust fans. Air velocity at the supply ports must not exceed 5 m/s to avoid destratification of the fumes. To respect the pressure hierarchy, the supply air flow rate must be lower than the extract air flow rate, generally 0.6 times the extract air flow rate.

The concept of smoke control engineering

The decree of March 22, 2004 introduced smoke ventilation engineering, which is used when the strict application of regulations is not possible, such as in buildings classified as historical monuments, where certain modifications are impossible.

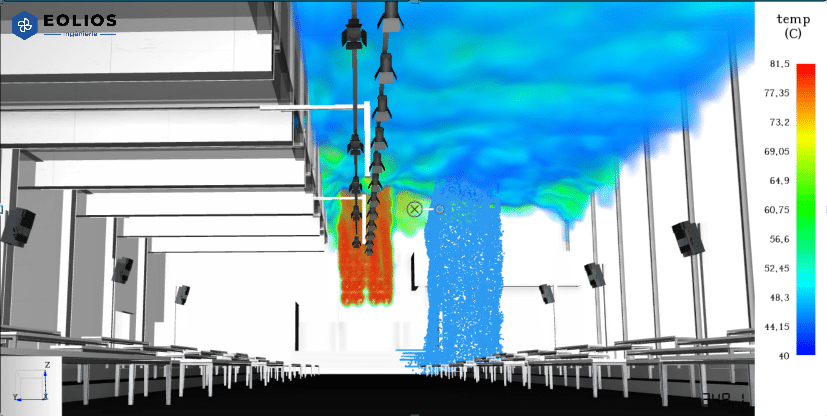

The aim of this approach is to simulate the evolution of smoke during a fire and its control by natural and/or mechanical smoke extraction systems.

Example of smoke control engineering

Engineering studies must be performed by organizations recognized as competent by the Ministry of the Interior. These studies must include a comprehensive presentation of the assumptions made, simulations showing satisfactory smoke control, and a presentation of the results and conclusions regarding the effectiveness of the recommended smoke control systems.

In 2017, the Guide de bonnes pratiques pour les études d’ingénierie du désenfumage was published by the Central Laboratory of the Paris Prefecture. This guide clarifies the roles and responsibilities of the players involved, harmonizes definitions, formalizes the smoke control engineering process, defines imposed fire scenarios, harmonizes predefined acceptability criteria and establishes the various on-site smoke control test methods.

Examples of CFD simulation applications

Brandschutztechnik

Find out more

Smoke extraction in underground parking lots

Find out more

Sprinkler: how does a sprinkler system work?

Find out more

Fire safety engineering

Find out more

Data center fire safety: Automatic Gas Extinguishing Systems (IEAG)

Find out more

File: applying IT263 – smoke extraction from atriums

Find out more

File: applying IT246

Find out more

The ESSOC law for fire safety

Find out more

Dynamic modeling of the evacuation of people

Find out more