Home » Smoke control » Smoke control engineering (ISI) » ISI – Offices – Grand Army

ISI – Offices – Grand Army

Study of smoke evacuation in the event of a potential office fire

In the context of a new development, the aim of this smoke extraction study is to determine whether the installation of a new partitioning system can safely and optimally evacuate smoke and combustion products from the building in the event of a fire.

Office building - Paris - Grande Armée

Year

2023

Customer

NC

Location

Paris

Typology

Smoke control engineering

Continue navigation :

Our other projects :

Latest news :

Technical files :

Project description

In the event of a fire in a building, smoke will develop and spread. This can cause obstruction of escape routes and emergency exits due to heat, smoke fumes and poor visibility. The aim of the project is to use the French Labour Code to ensure proper smoke extraction from the compartments, by placing full-height obstacles and complying with LCPP TAC and TMSP standards.

Smoke control engineering

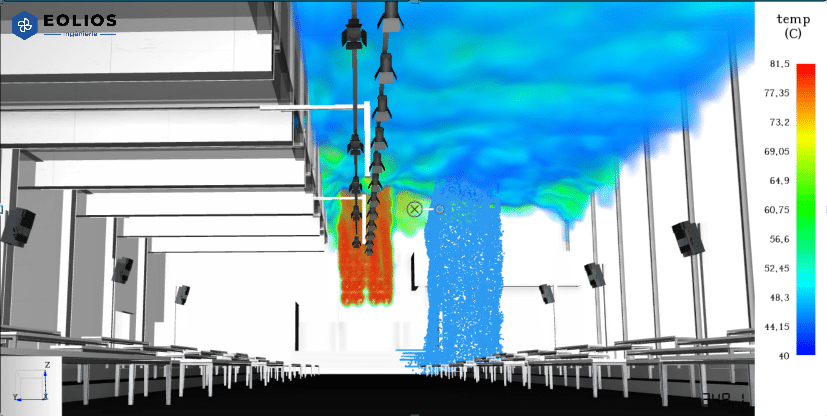

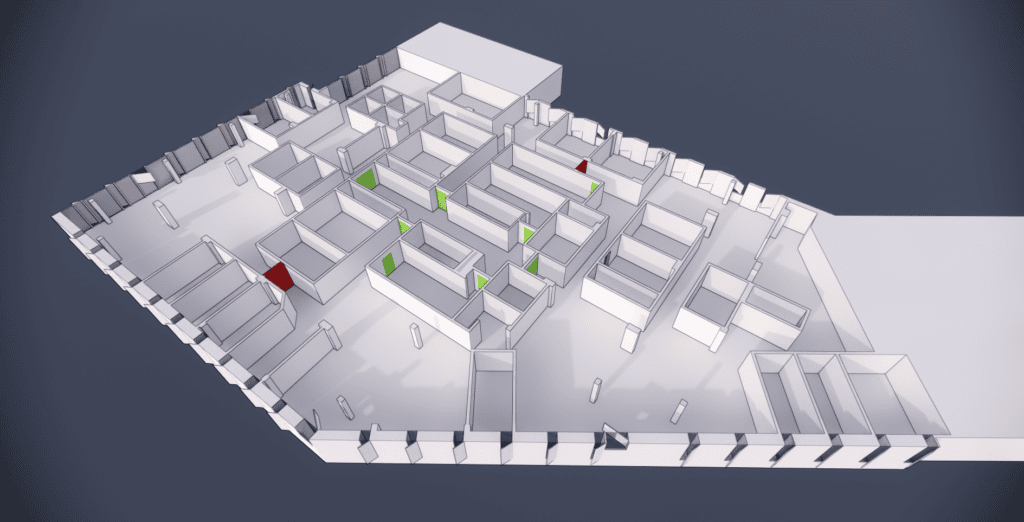

3D modeling of spaces for the study of natural smoke ventilation

Since the purpose of the model is smoke extraction, particular care must be taken with interconnections between different areas of the building (e.g. staircases, walkways, doors, etc.), and with all elements that may interfere with the passage of smoke (e.g. transoms, doors, etc.).

Obviously, the reproduction of the geometry is subject to the constraints of the software used.

Our studies are based on modelling the building at a scale of around 10 cm.

All spaces in direct aeraulic communication with each other must be modelled, as the smoke extraction study covers all these spaces.

In this framework, we integrate all the parts in aeraulic connection in order not to constrain the area of study by an effect of scale too reduced. We will work independently by compartments.

Modeling of the smoke extraction system

The consideration of the smoke extraction system is obviously particularly important. This modeling involves two steps, which are detailed below:

- geometric consideration of the openings

- Air flow rate of the openings

In this context, we’re modeling the smoke vents and their joinery to scale. The CFD fluid mechanics engineering allows to automatically calculate the flow rates according to the prevailing wind and the temperature rise in the compartments (fluid mechanics). There are no fixed flow requirements at windows that face the outside environment. The sashes are scrupulously modeled from the architectural plans; this sash typology must be respected for the conclusions of these studies to remain valid.

Position of the fireplaces in smoke extraction engineering

EOLIOS engineers can simulate different types of fire depending on the study location – in our case, a classic office fire was modeled.

Here, the project aims to ensure that smoke extraction systems are adequately sized to meet protection objectives, by selecting representative scenarios and positioning them according to specific constraints. The homes are then positioned in accordance with different constraints:

- Maximize the smoke path between the fireplace and the nearest outlet

- Maximize detection time

- Delaying the discovery of fire

- Blocking the use of an emergency exit or clearance

- Promote the accumulation of heat and smoke in a specific area

Methodology

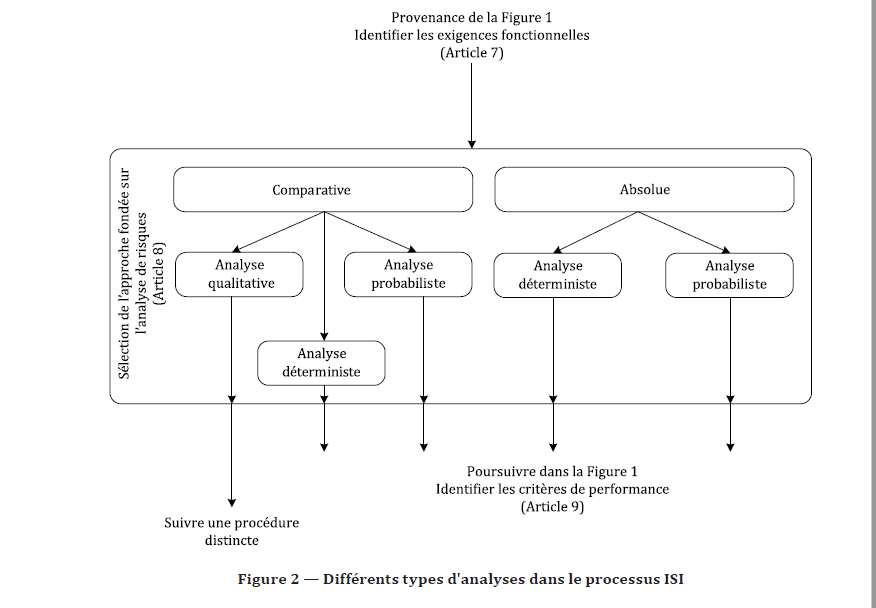

Deterministic analysis according to ISO 23932

Our engineers were chosen for their cutting-edge expertise in smoke control. This renovation project aims to create new internal partitions based on an open space, i.e. an open space without closed spaces.

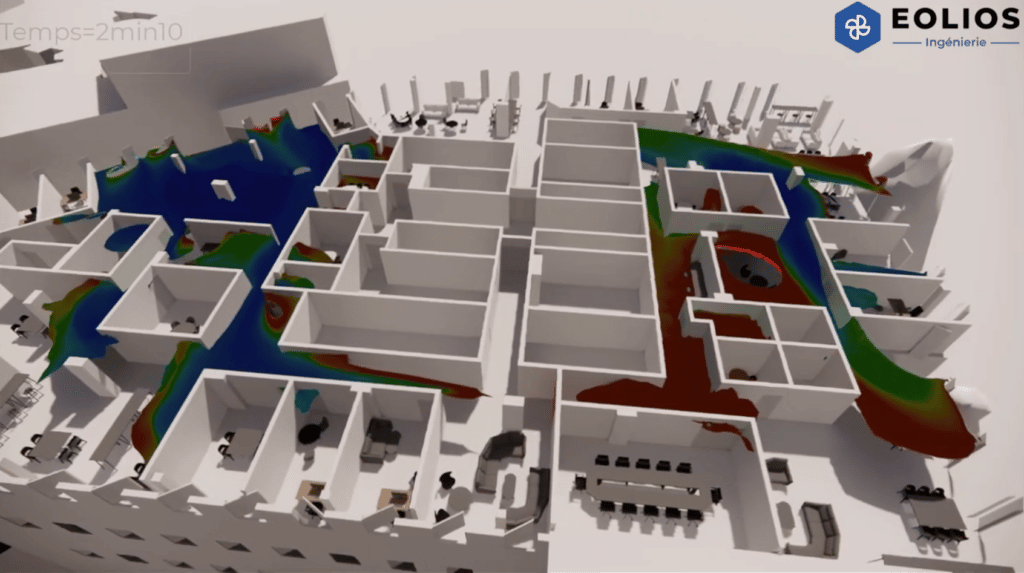

It is important to know that smoke moves with the air movement generated by the fire. In the event of a fire, the heat produced by the fire will create a suction air stream which will then carry smoke to the ceiling and through the room. Depending on the wind, a slight imbalance occurs, which in the long run causes the smoke to flow towards the openings on the opposite side.

According to the ISO 23932 standard, the smoke extraction study was based on a deterministic risk analysis.

Study scenario

It was necessary to apply a standardized method to identify a manageable group of design fire scenarios for analysis. Different methods can be used depending on the risk analysis approach. Stakeholder consultation is necessary to ensure that all appropriate scenarios are considered => the proposed study was structured around 3 deterministic (adverse) scenarios per compartment.

Conclusions of the study

In our different scenarios, the smoke could rush into the corridors, causing faster disruption to the clearances, or it could develop by lurking under the ceiling, moving more usually towards the opposite façade.

The EOLIOS engineers had to contribute their knowledge in order to validate a new design proposed by the project owner, which would guarantee an aesthetically pleasing and optimized evacuation of the staff who would be present in the premises in the future.

Continue on this topic

Video summary of the study

Discover other projects

Engineering smoke extraction in a data center

Smoke control engineering – Restaurant area – Type N

Fire engineering – Fashion show

Losses – CNIT

Smoke control engineering – Theater

Data Center – GAZ NOVEC

Smoke extraction – CHU

ISI – Offices – Grand Army

Smoke extraction plenum – AF1

Smoke extraction plenum – AF2