Home » Smoke control » Smoke control engineering (ISI) » Smoke control engineering – Theater

Smoke control engineering – Theater

Smoke control engineering

Year

2023

Customer

NC

Location

France

Typology

Smoke control engineering

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

In a few words

EOLIOS Ingénierie’s in-depth expertise in fluid mechanics enabled it to carry out a rigorous study to ensure safety within the site in the event of fire.

The primary aim of our study was to analyze potential fire hazards and evaluate existing safety measures. Based on the results obtained, we identified the areas at risk and the additional measures to be put in place to ensure optimum protection.

We used advanced modeling methods to simulate fire behavior in different scenarios. This enabled us to assess the extent of potential damage and determine the areas of impact.

On the basis of this information, we have recommended the installation of fire detection and fire-fighting systems adapted to the specific features of the site. We also recommended improvements to ventilation and smoke evacuation, to optimize occupant safety.

We worked closely with the company’s teams to implement these recommendations.

Fire safety in theaters: the importance of rapid evacuation

Theaters are performance venues that seat between 30 and 700 spectators, depending on their size. It is therefore essential to plan for the sudden evacuation of large numbers of people in the event of problems such as fires. In the event of fire, smoke will rise and spread. This can lead to blocked escape routes due to heat, smoke and poor visibility.

Computational Fluid Dynamics (CFD) ensures that escape routes are kept clear and smoke extraction systems are designed efficiently to help save lives and fight fire or its spread. The aim of our smoke ventilation study is to model smoke propagation in order tooptimize the evacuation of smoke, combustion products and people from the theater in the best possible conditions in the event of a fire.

Simulation of the wind around the building

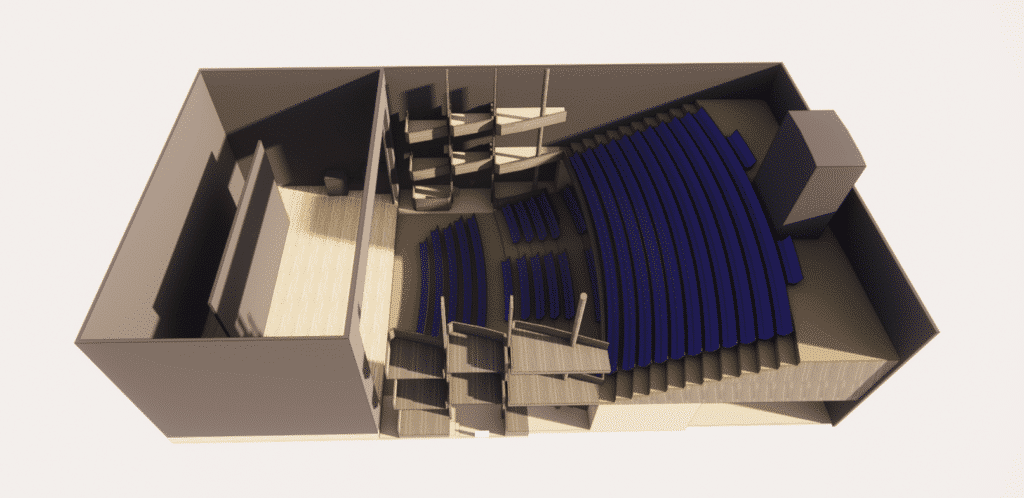

The entire site was reproduced using 3D software by our EOLIOS engineers. This model is based on the 3D model of the building and its systems.

3D model of the theater studied in smoke control engineering

This modeling is then used to run the CFD simulation for each scenario.

As the aim is not to overload the model with inappropriate details in order to maximize calculation power for the sensitive areas of the study within the volume, the volumetry is carried out in such a way as to take into account all elements having an impact on the volume’s aeraulics.

Creation of a digital study model

Defining heat flow: challenges in fire modeling

Software can be used to study fluids, but cannot predict the ignition of combustible objects or the way in which they burn (energy and effluents produced). Consequently, the combustion phenomenon has not been modeled in this study. The fire is modeled using a volumetric heat model, which takes into account only the thermal and toxic effects of combustion, in a volume defined as the zone in which combustion occurs.

It is then the user’s responsibility to choose themodel’s input data carefully. Combustion is a reaction that releases heat. This quantity of heat per unit of time, known as heat output or fire power, is not constant over time (small flames, then bright flames, then gradual extinction), which makes it complex to define. Preliminary studies are therefore being carried out to determine thetemporal evolution of heat output and the emission rates of combustion products, which will then be used as input data. EOLIOS has a database for defining fume generation conditions for the most common materials.

Smoke control engineering theater model -Flame velocities

Modeling combustion phenomena: focus on heat and toxic effects

Scenarios considered

It’s very difficult to predict the precise position of a future fire. This is why several studies are being carried out with different scenarios. The locations of the fireplaces studied are taken from the most unfavorable cases in order to best size the smoke extraction systems. These unfavorable cases satisfy several constraints:

- Maximize the smoke path between the fireplace and the nearest outlet

- Maximize detection time

- Delaying the discovery of fire

- Blocking the use of an emergency exit or escape route

- Encourage the accumulation of heat and smoke in a specific area

The model development phase focuses on defining the essential parameters of each fire scenario. These parameters are :

- Focus position

- Characterizing the focus

- Building components, systems and measures affecting fire development and spread

These different scenarios are designed to ensure that smoke extraction systems are adequately sized to meet protection objectives. It is therefore possible to determine the ideal location of emergency exits, fire doors and smoke extraction systems by observing the path taken by smoke in the theater.

Fire evacuation: theatrical challenges in the face of smoke

CFD simulation of the model

Smoke extraction engineering studies show gas diffusion in space and time. It is coupled with multiphysics modelling that takes into account phenomena arising from smoke formation. EOLIOS’ expertise in thermal and aeraulic engineering offers innovative and relevant solutions for climatic and fire risks. The implementation of CFD simulations requires the involvement of experts in fluid mechanics, thermal engineering and numerical simulations.

EOLIOS engineers specializing in thermo-aerodynamics and fluid mechanics work closely with other EOLIOS engineers specializing in fire risk and systems.

For our study, a CFD simulation is carried out for each scenario considered. Boundary conditions must first be determined in order to solve the model’s partial differential equations. An appropriate mesh is then automatically generated from the model geometry, but can be made finer where greater precision is required.

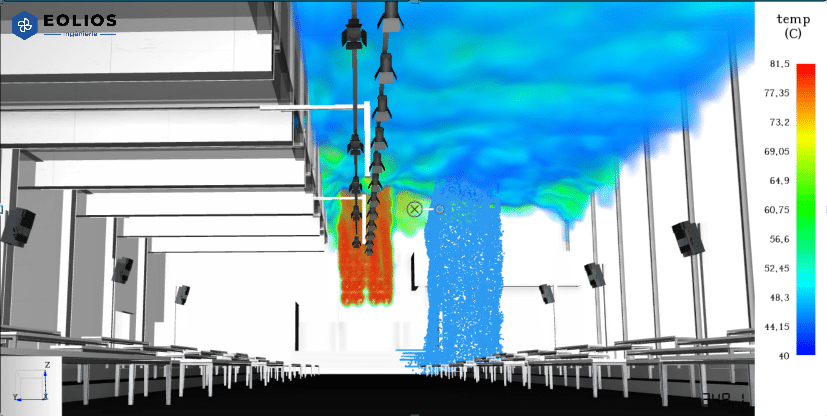

3D model of the theater in smoke control engineering - Temperatures

With the various simulations, we can study the movement of heat and smoke, which follow the movement of air generated by the fire. It is necessary to determine the length of time during which the various accesses to the emergency exits would have been obstructed by smoke, preventing evacuation in full or in part under good conditions.

Wind power potential study

The results provide an insight into the thermal conditions and heat flow to which people may be subjected during evacuation, and firefighters during their response. A solution for upgrading existing smoke extraction systems can then be worked out. EOLIOS offers a new system that takes into account personal safety, applicable regulations and environmental conditions. Proposals for the layout of the site, such as the location of emergency exits and fire doors, are also made in view of the speed at which smoke spreads through the spaces, the temperatures inside the theater and the visibility of smoke, which is the greatest distance at which an object can be seen.

Video summary of the study

A CFD (Computational Fluid Dynamics) simulation of a fire on a theater stage produces several important results. Here are some of the key results that can be expected from such a simulation:

1. Heat propagation: CFD simulation shows how the heat generated by the fire propagates in the environment. This helps to understand areas of high temperature and to predict how it might affect the theater structure, scenic elements and spectators.

2. Smoke movement : The simulation also shows how the smoke generated by the fire moves through space. This can help identify areas where smoke could accumulate, becoming potentially dangerous for people in the theater.

3. Air flow velocity and direction: CFD simulation is used to study air movements, in particular the velocity and direction of air flows generated by the fire. This helps to understand how fire can affect air circulation in the theater, and to assess the risk of smoke inhalation for occupants.

4. Concentration of combustion products: CFD simulation can also be used to calculate the concentration of combustion products, such as toxic gases, in different areas of the theater. This makes it possible to identify the areas where the concentration of these products is highest, helping to take appropriate safety measures to protect occupants.

5. Evaluation of escape routes: Knowing the spread of fire, smoke and combustion products, CFD simulation can evaluate the effectiveness of existing escape routes in the theater. This helps to identify any problems in the initial design, and to suggest improvements for safer evacuation in the event of fire.

In short, a CFD simulation of a fire on a theater stage can be used to visualize the spread of fire, smoke and combustion products, assess the risks for occupants and identify the safety measures required to ensure rapid, safe evacuation.

Discover other projects

Smoke control engineering – Restaurant area – Type N

Fire engineering – Fashion show

Losses – CNIT

Smoke control engineering – Theater

Data Center – GAZ NOVEC

Smoke extraction – CHU

ISI – Offices – Grand Army

Smoke extraction plenum – AF1

Smoke extraction plenum – AF2