Study of network load losses

Home » Industrial Process » Study of network load losses

EOLIOS calculates and optimizes the pressure drops of your networks

We carry out pressure loss studies for networks and complex systems.

- Design, analysis, optimization

- Speed evolution

- Stationary or transient study

- Optimization of the installation

- Laminar or turbulent flow

- Sizing vacuum systems

- International projects

- Fan selection

- A passionate team

- Pressure loss study

Continue navigation :

Our latest news :

Our projects :

Our areas of expertise :

Technical file :

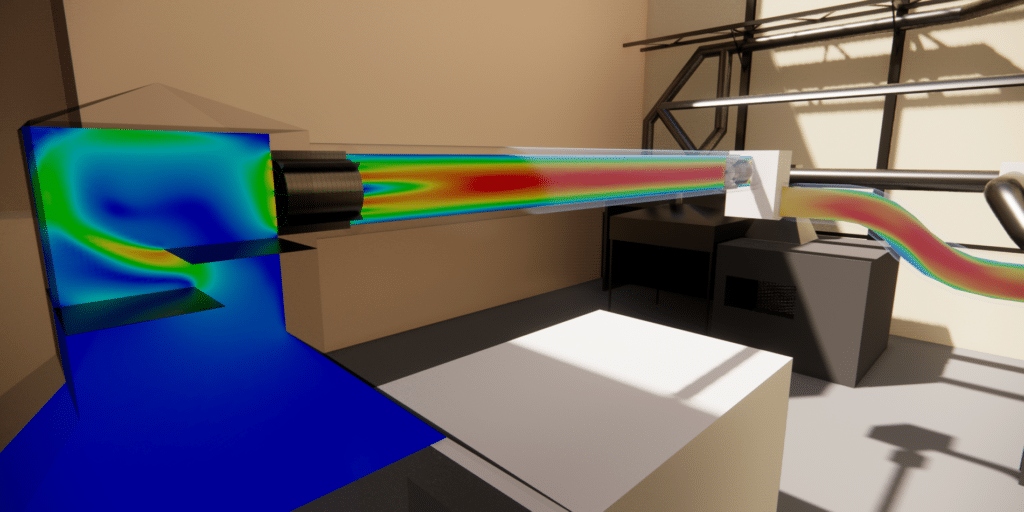

EOLIOS expertise: CFD head loss analysis

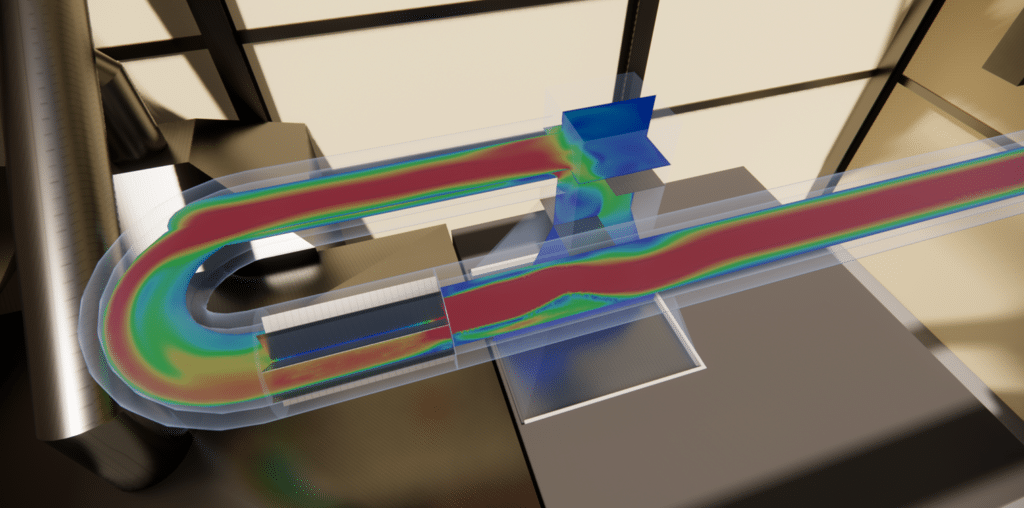

At EOLIOS, our commitment to managing and optimizing pressure losses in industrial fluid systems is rooted in a deep understanding of multi-scale aeraulics. Industrial plants often feature complex fluid transport circuits that include geometric singularities such as elbows, cross-sectional changes and other regulating devices.

These disruptive elements significantly modify fluid flow, leading to complex phenomena such as phase separation,flow instability and changes in flow regime.

These disturbances, if left unchecked, considerably complicate the assessment of pressure losses, making systems less efficient and more costly to operate. EOLIOS, thanks to its cutting-edge expertise and the use of sophisticated computational fluid dynamics (CFD) techniques, is a key player in providing comprehensive analyses and tailor-made solutions that maximize energy efficiency, reduce costs and extend the life of your facilities.

Controlling pressure losses through in-depth understanding

Pressure losses, defined as the decrease in pressure of a fluid as it passes through a system, are mainly the result of complex, multi-factorial interactions between the fluid and the pipe walls. They fall into two main categories: linear, or regular, losses, and singular losses.

Linear losses result from continuous friction between fluid and walls, amplified by fluid viscosity and pipe material roughness. They vary according to the flow profile, which can be laminar, transient or turbulent, with each type of flow modifying the ratio of inertial and viscous forces.

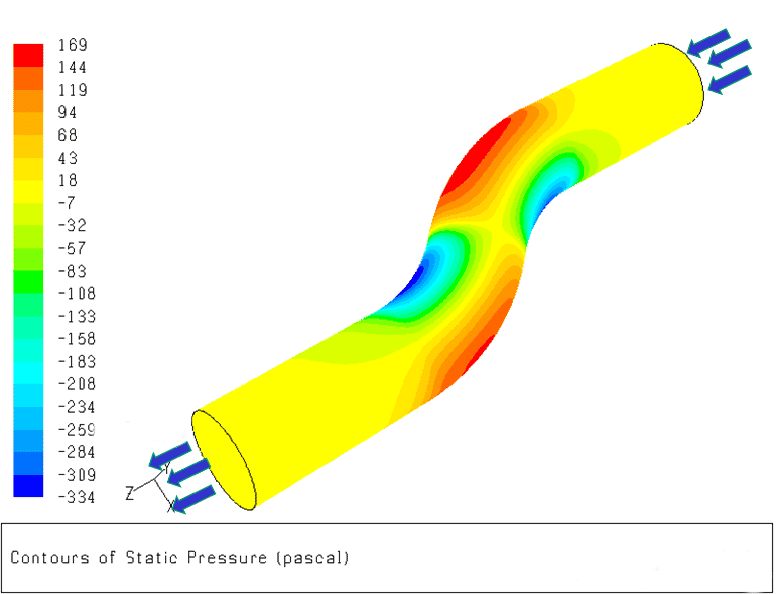

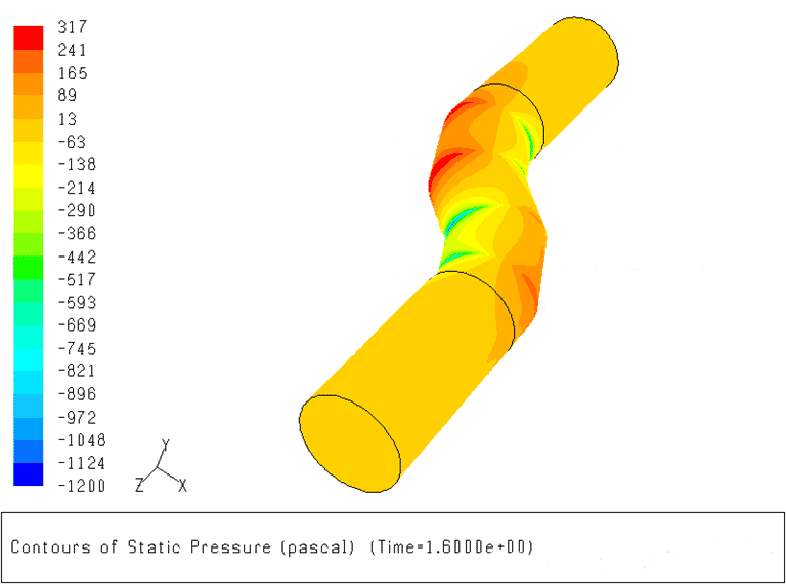

On the other hand, singular losses arise from disturbances caused by structural singularities such as elbows, fittings, baffles, and internal equipment like expansion boxes or heat exchangers.

These elements not only introduce immediate variations in pressure transfer, but are also likely to create vortex phenomena that exacerbate overall energy losses. EOLIOS focuses on thedetailed analysis of these phenomena using CFD to provide insights and practical solutions aimed at minimizing the impact of these losses on overall system efficiency.

Advanced CFD simulation and modeling for fluid systems

CFD simulation is an essential pillar of our methodological approach to understanding and controlling pressure losses. By developing

By faithfully capturing fluid-structure interactions, we can identify critical points where pressure losses and potential inefficiencies are concentrated. This ability to

Precise CFD methods for calculating head losses

Computational Fluid Dynamics (CFD) head loss calculation is a meticulous process, requiring precise modeling and rigorous analysis to capture the complexity of fluid-structure interactions within industrial systems. As a first step, detailed three-dimensional modeling of the infrastructure is created, taking into account every aspect of the system: network geometry, material properties, and boundary conditions – such as inlet and outlet velocities and initial pressures.

These initial models are used to define the simulation environment, which faithfully reproduces actual operating conditions. Using

These equations take into account the conservation of mass, momentum and energy, enabling pressure, velocity and direction to be calculated at each point of the mesh.

Pressure losses in the system are then determined by analyzing the pressure gradients across the network sections. By assessing the

These calculations provide a rich and nuanced picture of internal dynamics, facilitating a clear breakdown of linear and singular pressure losses. Integrating the results not only enables

EOLIOS uses these proven methods to guide the design and implementation of strategic operational improvements, ensuring greater efficiency and sustainability at all levels of theinfrastructure studied.

Strategies for optimizing fluid networks to reduce pressure losses

In the industrial fluid network environment, each installation requires a tailored approach that takes into account its unique characteristics and specific performance imperatives. EOLIOS works alongside your teams to develop optimization recommendations that focus on minimizing pressure losses while maximizing operational efficiency.

This customization approach can include modifying the geometric dimensions of the ducts, changing materials to optimize wall roughness, and integrating innovative technologies that promote smoother, more stable flow.

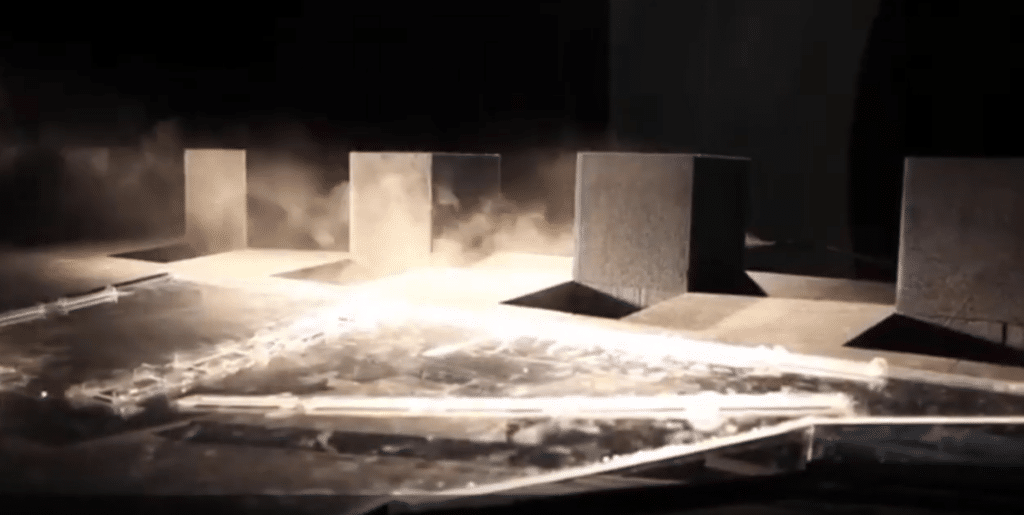

Application example for pressure loss studies

We analyze current configurations to assess opportunities for improvement, and implement refined structural adjustments designed to increase energy efficiency and reduce costs. This solution-oriented approach not only guarantees immediate reductions in inefficiencies, but also lays a solid foundation for sustainable development and enhanced operational performance over the long term, aiming to future-proof your infrastructure while optimizing return on investment.

Innovative solutions for today's industrial challenges

In a fast-changing industrial world, EOLIOS keeps its finger on the pulse of technological innovation and growing sustainability requirements. We integrate these new technologies into our solutions to offer an appropriate response to today’s challenges.

Cutting-edge CFD simulations, combined with in-depth expertise in multi-scale aeraulics, enable us to reconfigure your infrastructures so that they meet not only today’s efficiency expectations, but also the future imperatives of environmental compliance. Theconstant adjustment of our know-how in the face of industrial evolution enables us to transform challenges into opportunities for performance and sustainability, ensuring that your systems are ready to meet current and anticipated challenges in an increasingly demanding sector.