Climatic engineering of high rise premises

Our projects :

How does the airflow in refrigerated high-bay warehouses work?

Why study the aeraulics of high-rise warehouses?

Refrigerated high-bay warehouses are a type of warehouse that features a cooling system to maintain constant, appropriate temperatures for the products stored. This type of warehouse is often used to store temperature-sensitive products, such as foodstuffs, medicines and pharmaceuticals.

The cooling system can be sized for a stand-alone cold store or a system integrated into the warehouse itself. Refrigerated high-bay warehouses are designed to store large quantities of products safely, without compromising quality or freshness.

Example of a study for the climatic control of a high-rise workshop

Thermal stratification, a recurring problem in high-rise warehouses?

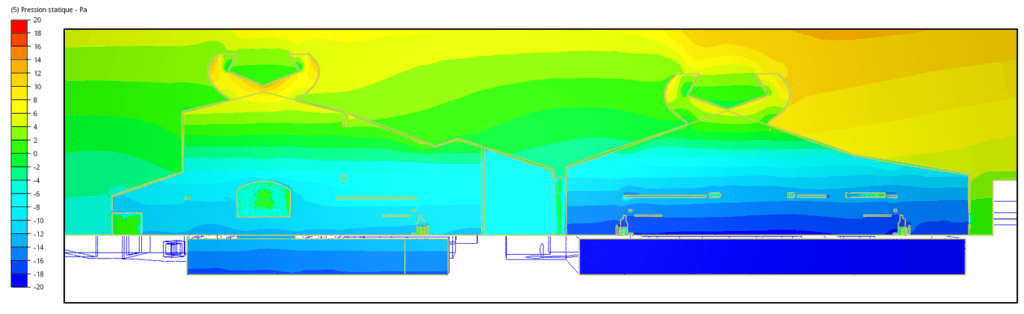

Thermal stratification is a common problem in high-rise warehouses. This physical phenomenon occurs when layers of air at different temperatures separate and do not mix, creating zones of inhomogeneous temperatures at different levels of the warehouse. This can lead to poor temperature distribution, making it difficult to maintain a uniform temperature, and can result in loss of stored products.

Thermal stratification also makes it more difficult to optimize the energy efficiency of climate control systems, resulting in additional costs for companies. It is therefore important to work to minimize thermal stratification in high-rise warehouses, using strategies such as installing ventilation units, designing an optimal cooling system and controlling warm air intakes.

Case of the cold rooms of storage of the pharmaceutical laboratories ?

These high-bay warehouses often hold tens or hundreds of millions of items. To ensure product quality, temperature monitoring systems in the pharmaceutical industry are very strict. Temperature variations can render entire batches obsolete and cause considerable economic damage.

Due to the geometric nature of this type of premises, with heights sometimes exceeding 20 meters, vertical temperature differences can develop if the ventilation and air-conditioning technology does not take adequate countermeasures. For both cooling in summer and heating in winter, this leads to difficulties when it comes to the type and positioning of ventilation technology, as well as the sizing and type of heating and cooling. The blocking of air flows by shelves and stored goods can have an adverse effect on air circulation, resulting in hot or cold zones in summer or winter.

In this context, safeguarding the temperature requirement for all outdoor climatic conditions and all operating situations is of great importance. The flow simulation in connection with the thermal building simulation is an important instrument to support the planning.

Why use CFD simulation to study high shelving areas?

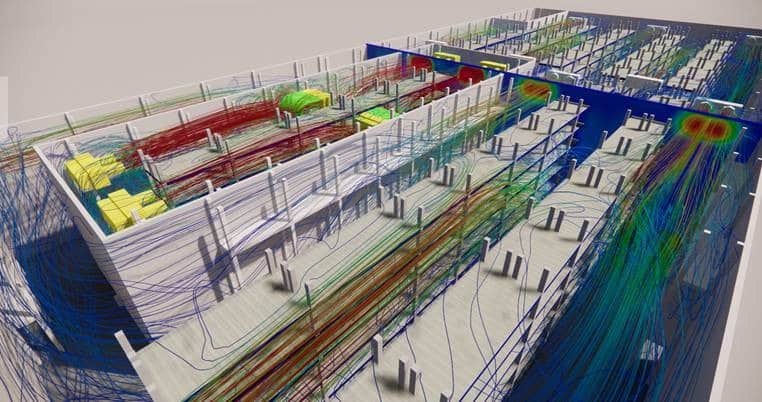

CFD simulation can be used to predict thermal and climatic conditions, including air circulation and temperature distribution, inside existing or planned high-bay areas.

This can help to understand potential problem areas and identify them so that action can be taken to correct them quickly and cost-effectively. In addition, CFD simulation can be used to assess the efficiency of cooling and air-conditioning systems in high-bay areas, and determine whether adjustments are needed to maintain the right conditions for the products stored.

Finally, CFD simulation can be used to assess the potential consequences of adding new equipment in high-bay areas, as well as when implementing redundancy systems. Indeed, systems that are too close to each other can interfere with each other and bypass effects or dead zones can appear. To assess the potential consequences of modifications, such as temperature and humidity, CFD simulation is the most appropriate tool for minimizing the risks to your products.

EOLIOS, a CFD consultancy specializing in the design of high-rise halls, offers its technical expertise in the understanding and modeling of thermo-aerothermal exchanges, in order to analyze the problems you may face and propose appropriate solutions.

Is the installation of redundancy systems necessary?

What is system redundancy?

In thermal engineering, the term “system redundancy” refers to the duplication of systems to ensure that, should one or more systems fail, the others in place can compensate for the lost power.

Indeed, as explained above, controlling climatic conditions is a decisive factor in guaranteeing the conformity of stored products and avoiding any loss of merchandise. However, the implementation of such systems is not necessarily easy. Indeed, it’s sometimes difficult to install new systems without one disrupting another.

Why use CFD simulation to size your system redundancy?

Using CFD (Computational Fluid Dynamics) simulation to dimension the redundancy of your systems can offer many advantages. Firstly, CFD simulation enables us to test different redundancy scenarios without taking any real risks with the existing system. This can help identify the best redundancy strategies in terms of reliability, cost and performance. In addition, CFD simulation can be used to predict system performance under real-life conditions, which can be difficult to do without a computer model.

Finally, CFD simulation can help avoid costly errors in system design by providing accurate data on expected performance.

Climate control: on the same subject

Thermal draft effect

Find out more