Accueil » Climatic engineering » Climatic engineering of high rise premises » HVAC – Medical equipment warehouse

HVAC – Medical equipment warehouse

Temperature control of a medical equipment warehouse for Bio-Rad, Mitry-Mory

The medical innovation company Bio-Rad called on us to maintain a precise temperature in their refrigerated hall for storing medical products. Uniform, precise temperature maintenance in the storage area helps preserve the quality of sensitive products, comply with regulations, andensure the long-term stability and efficacy of medical products.

The aim of the study is therefore to use numerical simulation methods (CFD) to analyze the hall’s thermoaerulic conditions, and to develop technical solutions for maintaining temperatures within specific target values.

HVAC for a medical equipment warehouse

Year

2024

Customer

IPSEN

Location

Mitry Mory

Typology

HVAC - Laboratory

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

Studies carried out for large storage buildings for temperature-sensitive materials

The importance of a CFD study for maintaining a homogeneous temperature in a warehouse

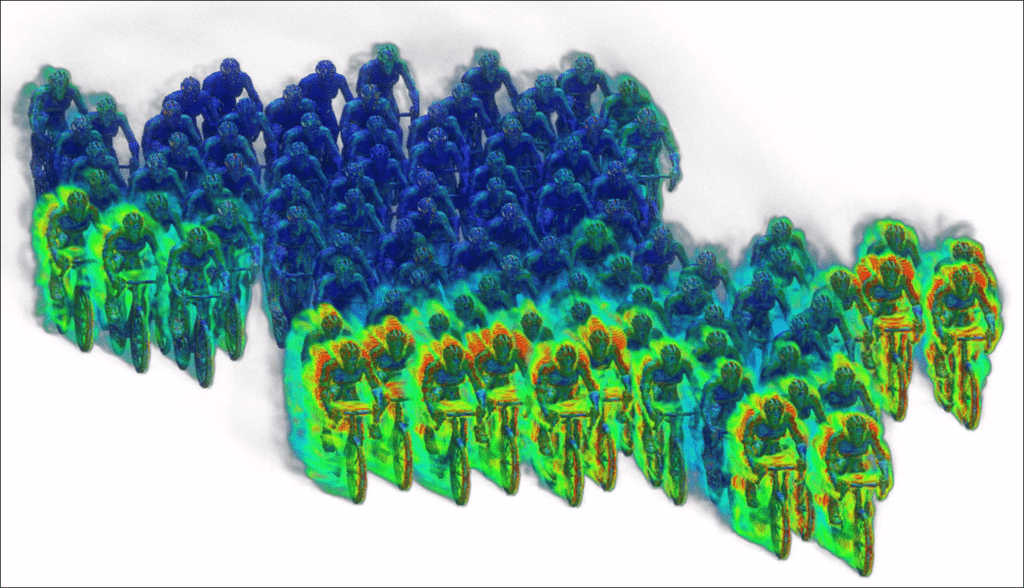

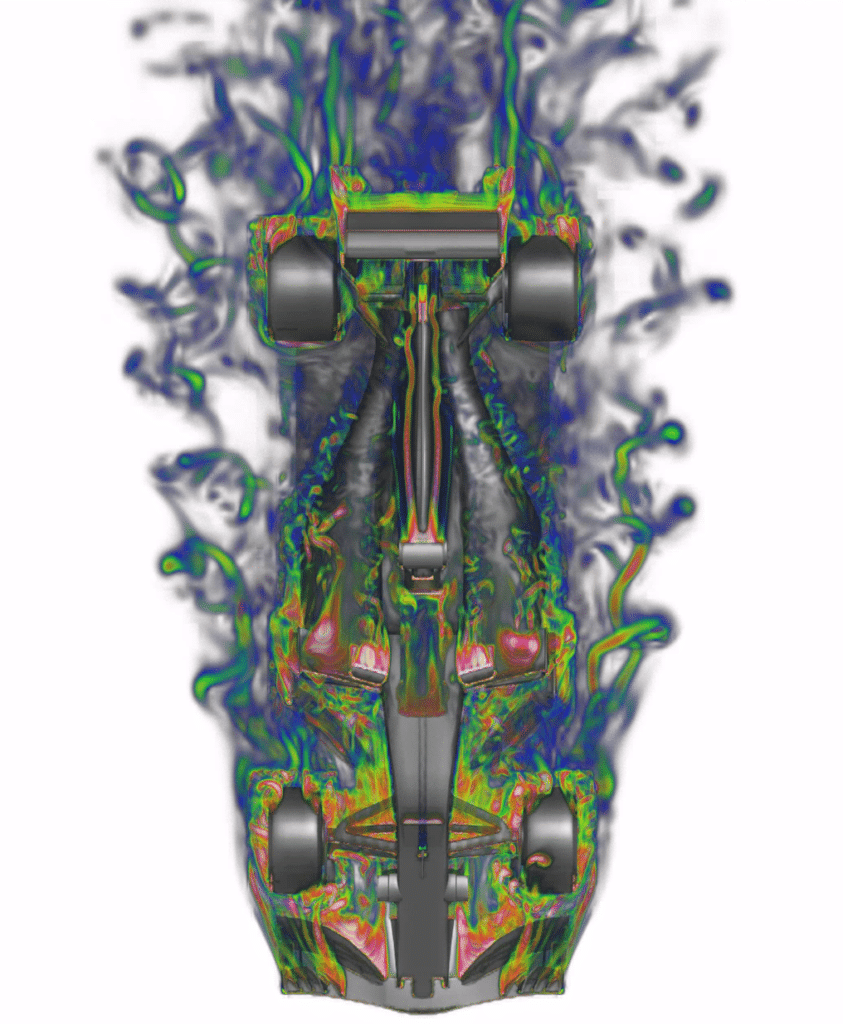

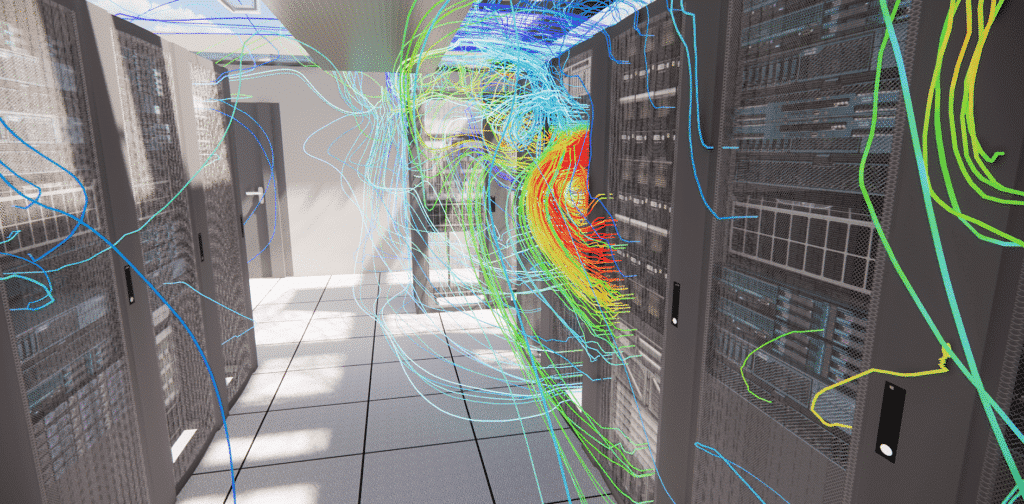

In order to maintain a homogeneous temperature in the warehouse, it is crucial to carry out a CFD (Computational Fluid Dynamics) study. This approach makes it possible to simulate and visualize air flows and heat exchanges inside the warehouse at any point in the space.

By fully understanding these heat flows, it becomes possible to determine how temperature propagates and varies in space, helping to identify any areas outside the target range, as well as the causes of these problems. Once these problems have been detected, appropriate adjustments can be made to ensure the right, uniform temperature throughout the warehouse.

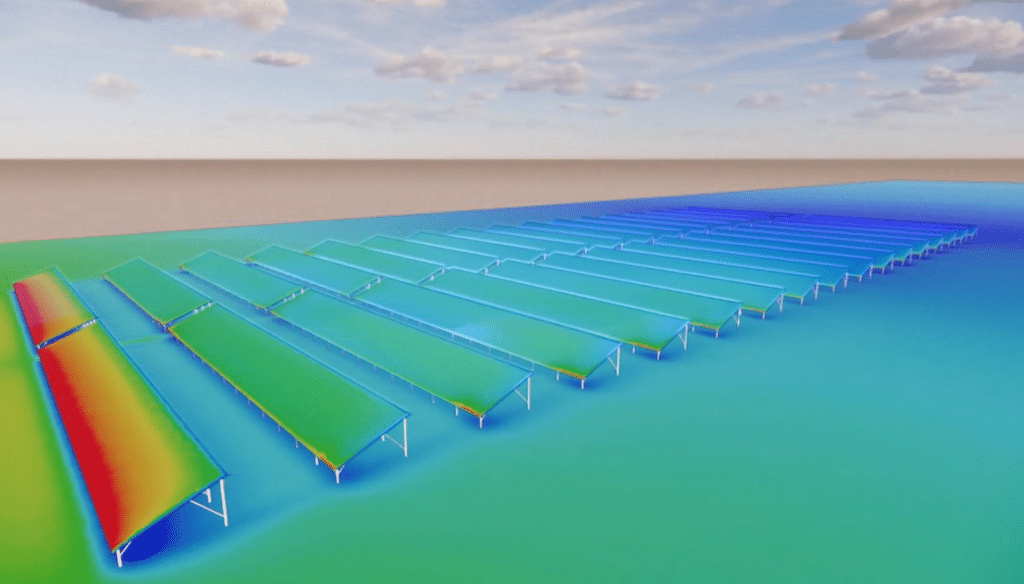

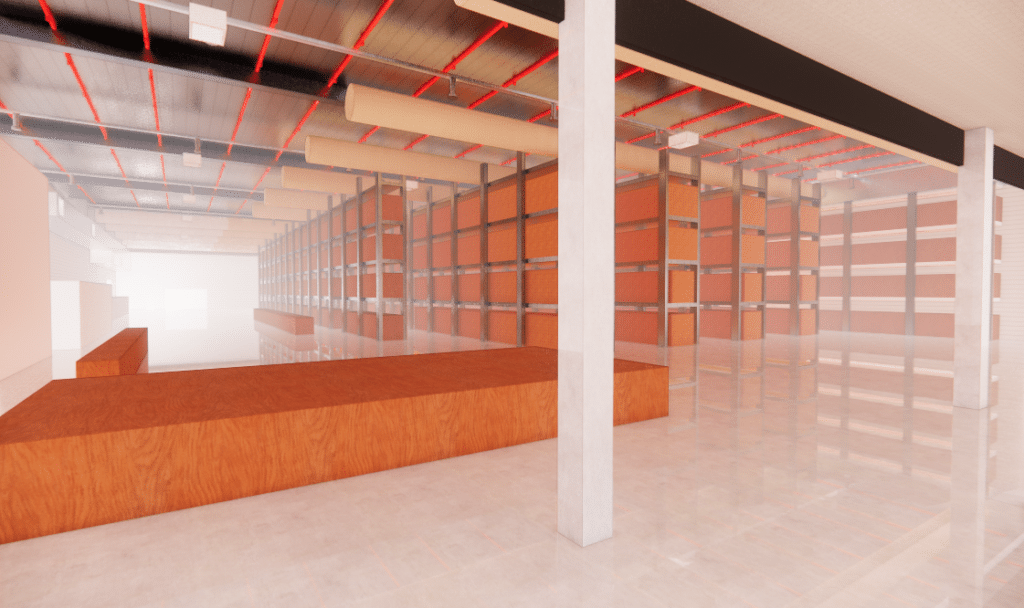

3D warehouse modeling

To carry out this CFD study, a precise 3D model of the entire warehouse is designed by our engineers. Next, a numerical simulation of air movements and temperatures is carried out, taking into account all the parameters inside and outside the system, as well as all the physical phenomena involved, particularly heat exchange with the outside, through walls and openings.

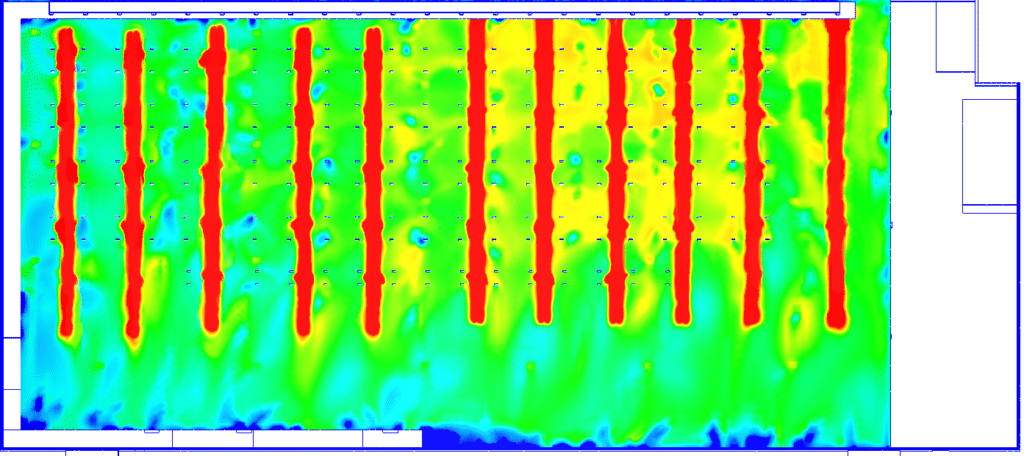

The effects of air stratification

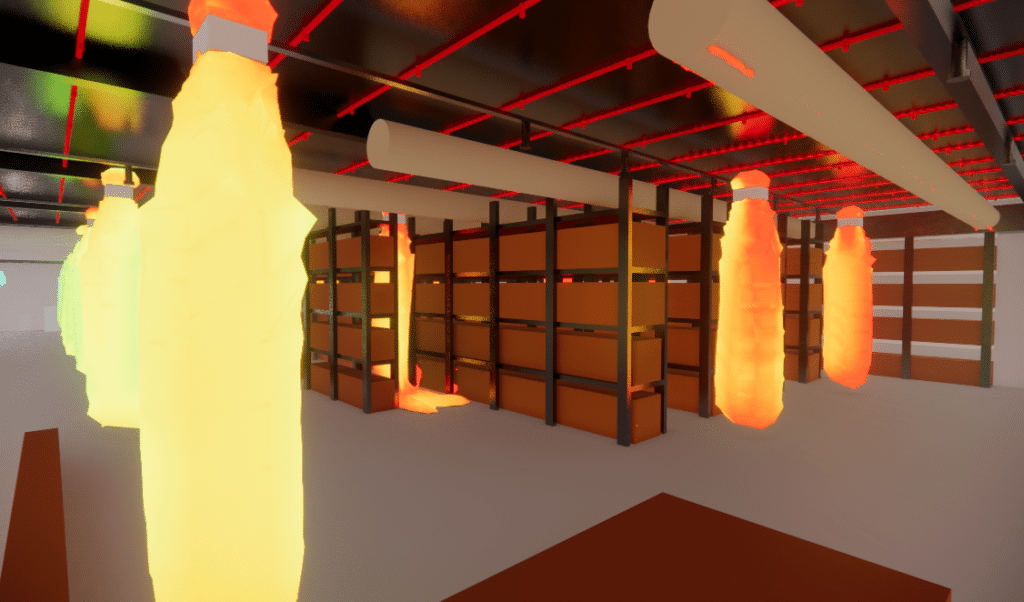

An air stratification study is essential for a thermoaerulic analysis of a building with high ceilings. Due to the difference in air density as a function of temperature, stratification occurs naturally, with warm air accumulating in the upper parts of the building and cold air remaining at ground level.

This air stratification can lead to a number of problems. Firstly, it can cause significant temperature variations between different areas of a building, making some parts too hot or too cold. This can affect occupant comfort and lead to excessive energy consumption to maintain an even temperature. Secondly, air stratification can also result in poor distribution of fresh and stale air, leading to poor indoor air quality. Contaminants can accumulate in the lower parts of the building, with harmful consequences for the health of occupants.

To remedy these problems, the use of destratification systems is essential. Destratifiers are devices used to disrupt air stratification by actively mixing warm and cold air layers.

They reduce temperature differences between different areas of the building, ensuring greater thermal comfort for occupants. In addition, destratifiers provide better ventilation and therefore reduce the risks associated with the presence of contaminants in the lower parts of the building.

Isosurface velocity at 1m/s

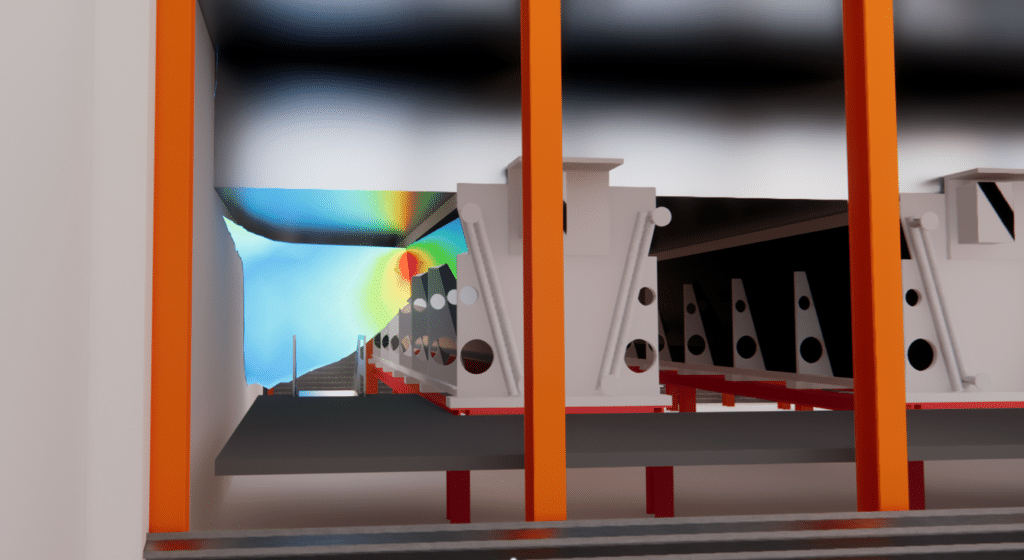

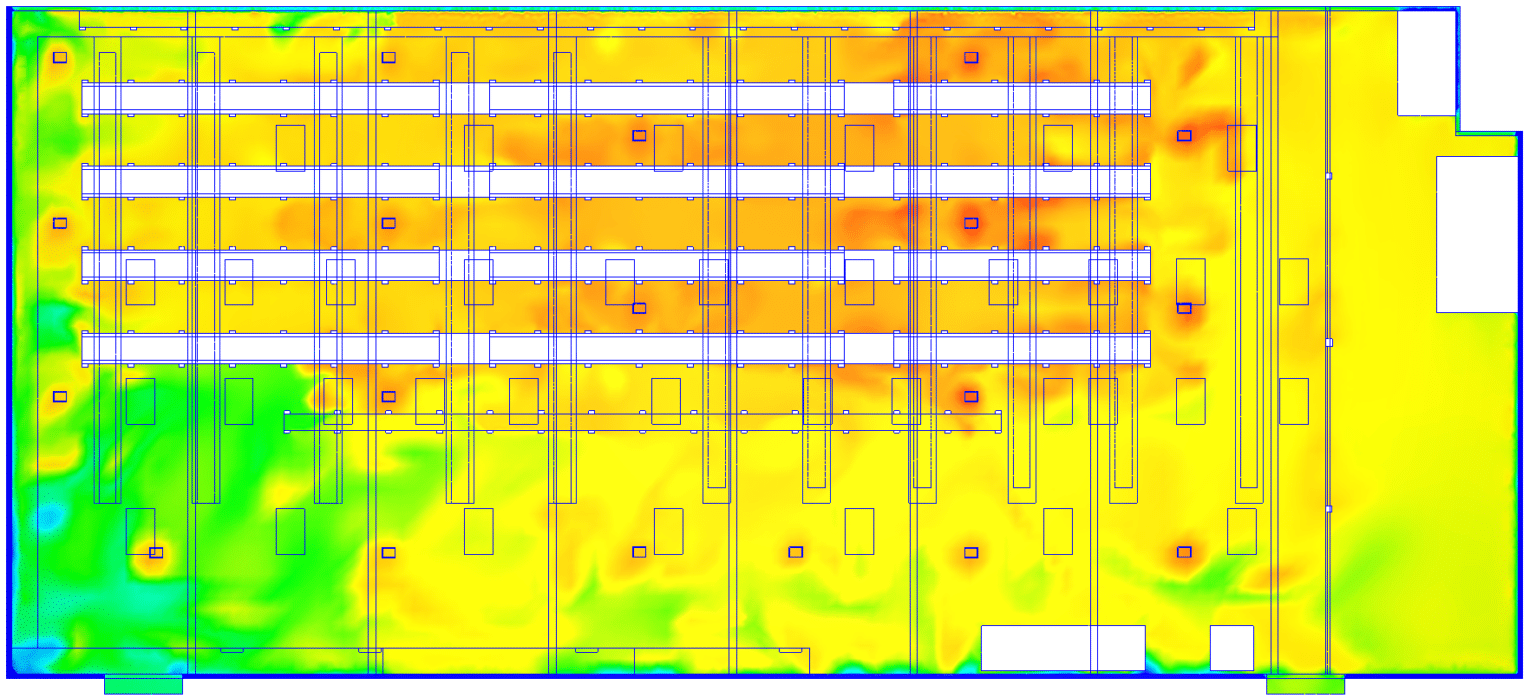

Redundancy study for climate control systems

Redundancy of climate control systems is of crucial importance in buildings storing temperature-sensitive materials such as medical equipment. Redundancy refers to the presence of two or more systems capable of performing the same function. In the context of climate control systems, this means having multiple, independent air-conditioning devices to maintain the desired temperature conditions.

The importance of redundancy lies in the increased reliability and resilience it offers. If one system fails, the others can take over to maintain the required environmental conditions. This avoids temperature variations that could damage sensitive equipment. What’s more, it reduces the risk of losing valuable and costly equipment, and also contributes to regulatory compliance.

Using a CFD study, it is possible to check whether the redundancy of climate control systems is sufficient to maintain stable environmental conditions throughout the building. This type of study can be used to simulate different situations, such as a system failure or additional thermal loads, to check whether back-up systems are capable of maintaining the required temperature conditions. By identifying areas of poor performance and optimizing redundancy systems, it is possible to guarantee total resilience in the event of failure.

Thermoaerulic study of the warehouse

Precise characterization of the system under study

To be able to analyze the above-mentioned issues in detail, EOLIOS mobilized its engineers on site to carry out various surveys and observations. First of all, a precise survey of the building’s layout was carried out to enable complete 3D modeling of the environment.

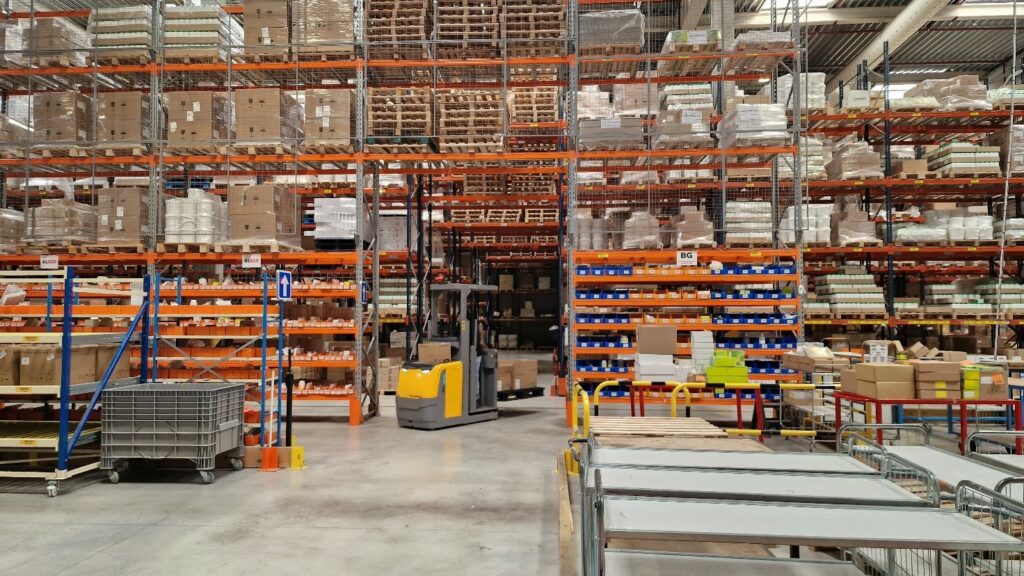

Particular attention has been paid to the layout of the storage racks, as their arrangement can have a significant impact on air circulation and temperature distribution in the warehouse. This modeling will enable precise modelling of thermal and aeraulic flows, as well as interactions between the various elements present in the storage hall.

Storage racks - Passage under radiation

Next, the layout of the existing ventilation system was also carefully examined. The engineers have evaluated existing ventilation systemsidentifying any weak points or areas where improvements can be made. Finally, a study of meteorological conditions in the area was carried out to determine the most unfavorable the most unfavorable outside temperatures for to be taken into account.

Temperature and air velocity measurements were also taken at various strategic points in the building, in order to validate our numerical results experimentally.

The different situations studied with CFD

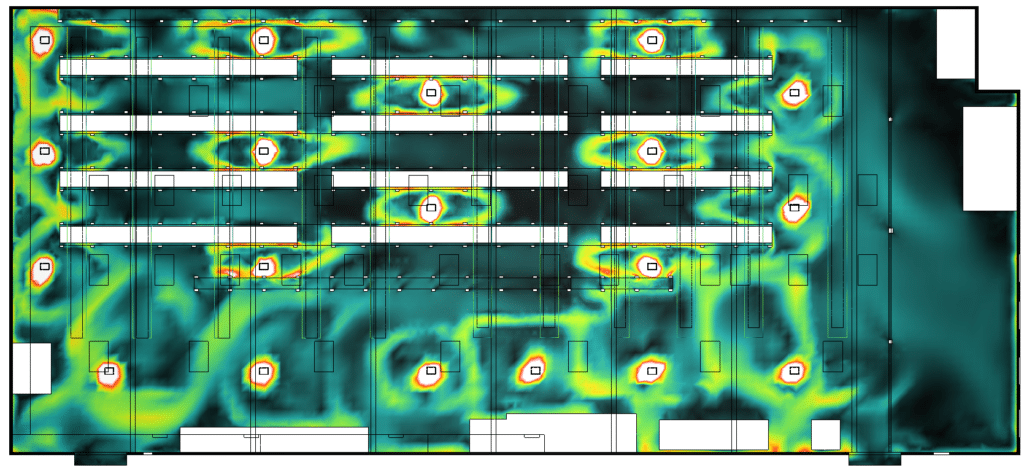

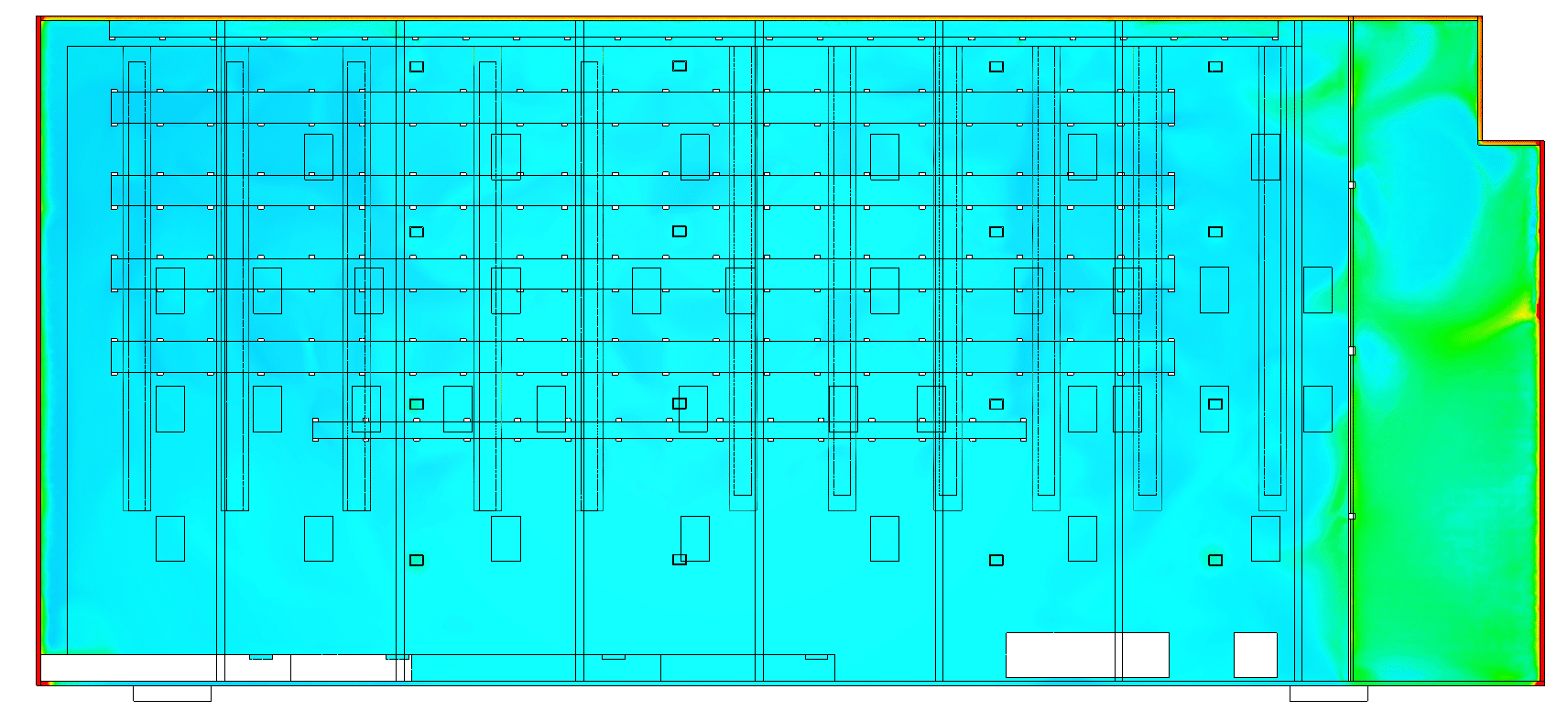

Temperature map - Duct outlet

Two situations were studied, one corresponding to the maximum outdoor temperatures reached in summer and the other to the minimum temperatures reached in winter. The simulations carried out in the summer scenario showed that the current air-conditioning system was sufficient to cope with high temperatures, with all points in the room within the target temperature range, and that activation of the destratifiers was not necessary in this context.

However, simulations carried out in the winter scenario revealed that, despite a certain degree of temperature homogeneity, some zones were outside the target range. Precise technical solutions for the layout of the space and ventilation systems (supply temperature, destratification system, redundancy) were then proposed and sized to be the least expensive possible, while effectively maintaining the temperature of the storage area under the most extreme conditions, in order to guarantee the quality and reliability of the medical products stored there all year round.

Continue on this topic

Video summary of the study

Summary of the study

Medical innovation company Bio-Rad called on us to maintain a precise temperature in their refrigerated warehouse in Mitry-Mory. Our aim was to use numerical simulation methods (CFD) to analyze the hall’s thermo-aerodynamic conditions and develop technical solutions to keep temperatures within specific target values.

We carried out precise surveys of the building layout and complete 3D modeling of the environment, taking into account the layout of the storage racks. A thorough assessment of the existing ventilation was carried out, identifying weak points and areas requiring improvement.

Simulations in the summer scenario showed that the current air conditioning system was sufficient to cope with high temperatures. However, in the winter scenario, some areas fell outside the target range. We therefore proposed and dimensioned precise technical solutions, such as adjustments to space planning and ventilation systems, to effectively maintain temperatures throughout the warehouse.

Our CFD study enables us to guarantee the quality and reliability of medical product storage all year round, by ensuring that temperatures are maintained at a uniform level in line with regulations.

Video summary of the mission

Discover other projects

Heating/Cooling system design for a pharmaceutical plant

Aquatic Center – Haut de Seine

Prototype – Natural ventilation chimney

HVAC – Medical equipment warehouse

Sharaan by Jean Nouvel resort

Swimming pool – Montreuil

Thermal comfort study – trichloramine diffusion in a children’s pool

Plant – Wind turbine

Cold Room – Leipzig

Cold room – penetrant testing

Palais Omnisports de Paris-Bercy

Sizing of natural draft extractor hoods