Home » Cooling towers – ICPE

Cooling towers – ICPE

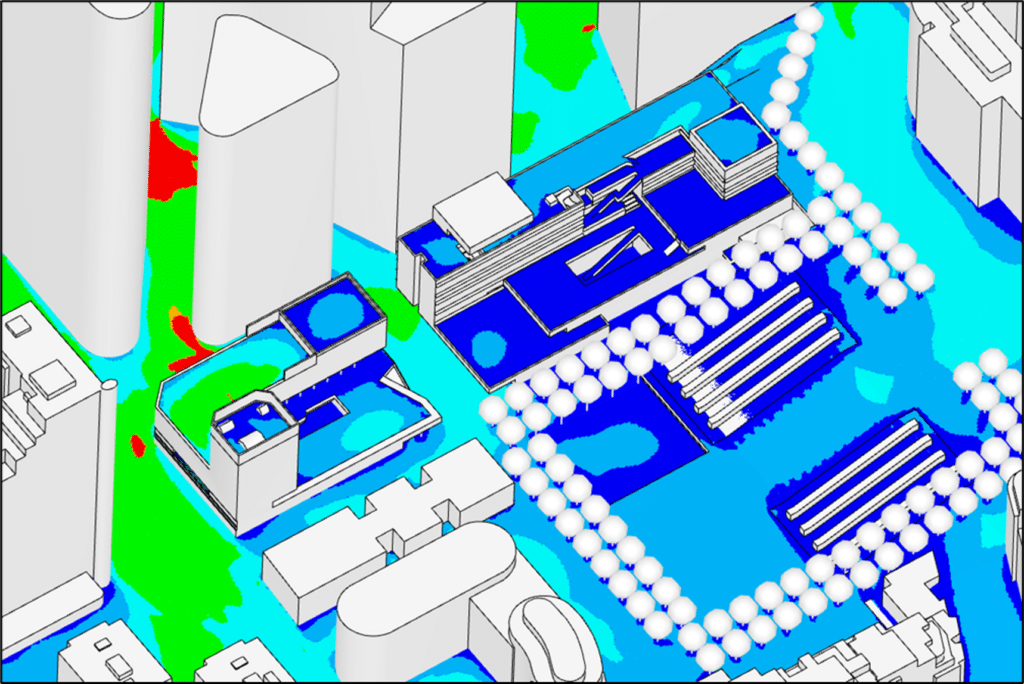

Thermal-air analysis of an office roof

The study focuses on cooling towers located on the roof of an office building. These cooling systems are essential for the air-conditioning of people and technical rooms in IT areas. That’s why we need them to work optimally. During this study, the principle of system looping was studied and solutions recommended to remedy it.

Studies of cooling towers as part of an ICPE project

Year

2024

Customer

SETEC

Location

France

Typology

Air & Wind

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

Study of ICPE office cooling towers

Office cooling

The study carried out by EOLIOS concerns the sizing and implementation of cooling towers (TAR) on the roofs of ICPE (Installations Classées Protection de l’Environnement) offices.

Air-cooled cooling towers are an efficient solution for buildings with high heat dissipation requirements. They use outside air to cool water, offering an energy-efficient alternative to traditional air-conditioning systems. Thanks to their lower energy consumption, they also help to reduce environmental impact.

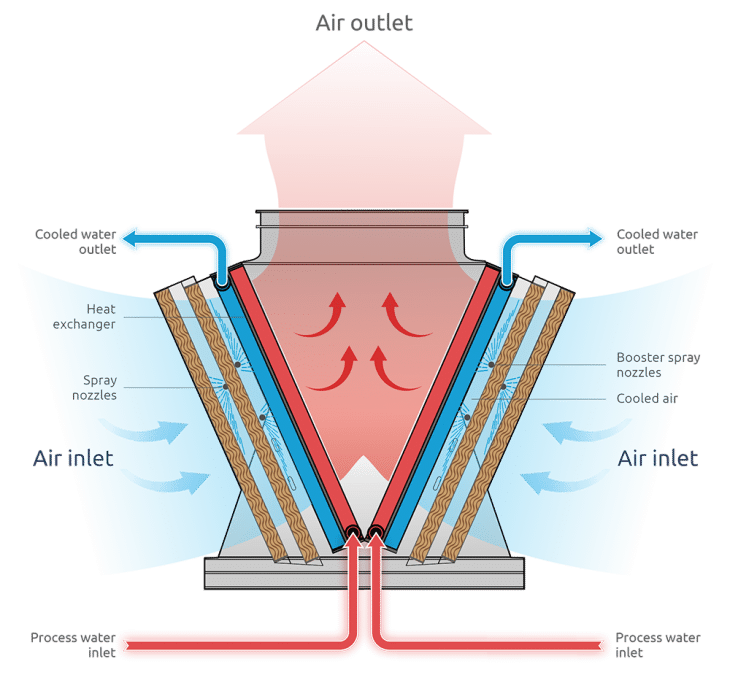

Cooling towers: Operating principle

Air-cooled cooling towers are cooling systems that useambient air to dissipate heat. They operate on the principle of water evaporation. A cooling tower generally consists of a tower-like structure containing panels or padding. Hot water from the cooling systems is pumped to the top of the tower, where it is distributed evenly over the panels or padding. At the same time,fans draw outside air into the tower. When the air comes into contact with the water spread over the panels or padding, it partially evaporates, triggering heat exchange. This evaporation of water absorbs heat from the air, cooling the water circulating in the tower.

The now moisture-laden air escapes from the tower via fans at the top. The cooled water, meanwhile, is collected in a tank at the bottom of the tower, then pumped back to the cooling system. This process takes place continuously, ensuring efficient cooling and the maintenance of a stable temperature inside the building. The main objective is to ensure efficient cooling of the offices by validating the sizing and layout of the TAR systems on the roof. The aim is also toimprove the overall performance and energy efficiency of the RACs in order to minimize energy consumption. Theaim of this study is to validate the sizing and implementation of TAR systems on the building’s roof. To this end, three parameters will be used: temperatures, velocities and humidities around the TARs.

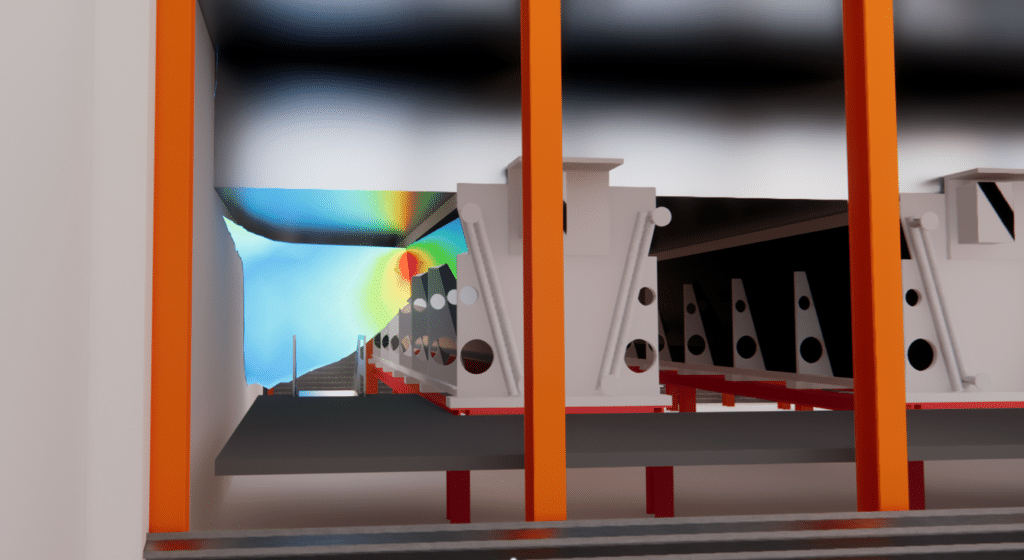

Numerical simulation of conditions around TARs

Modeling the ICPE building

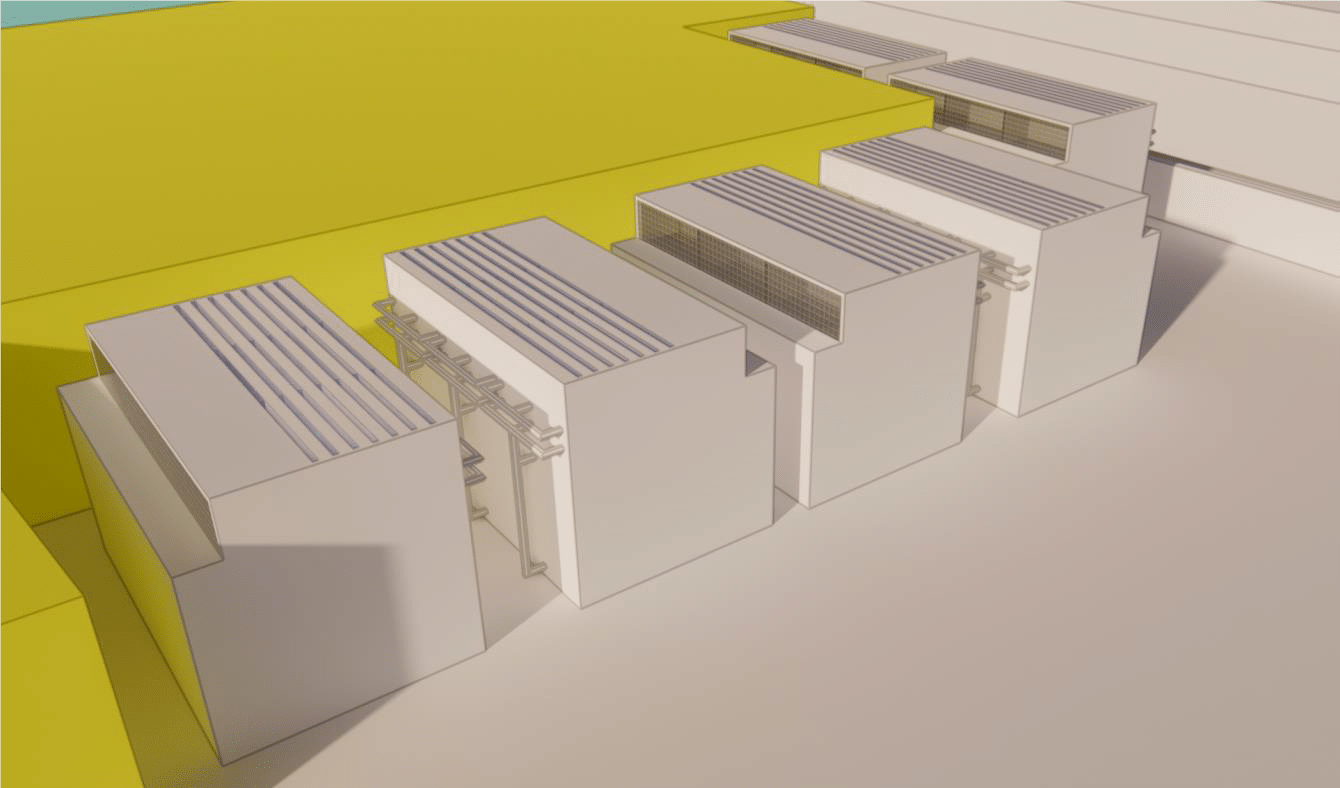

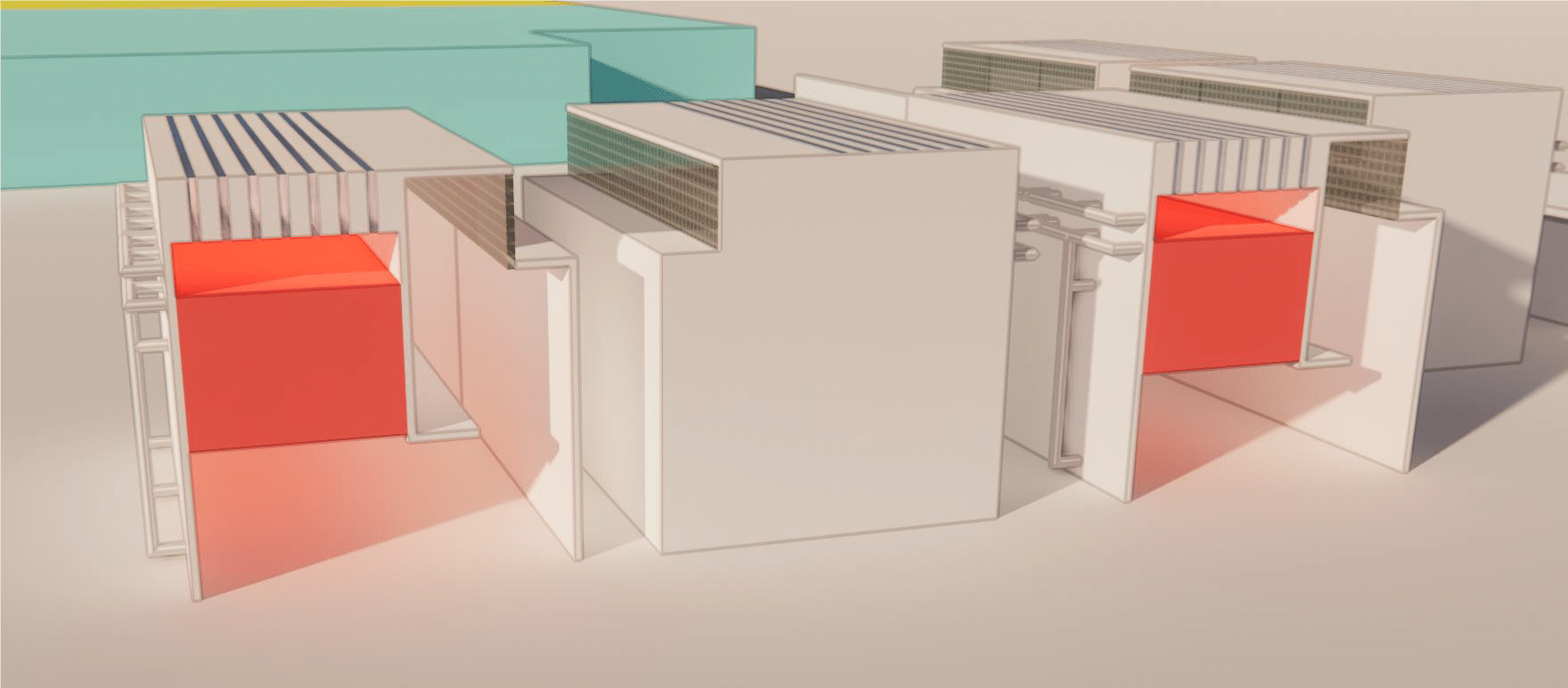

The study was carried out using CFD simulation. This method can be used to model and analyze fluid flows into and out of TARs. As part of this study, a 3D model of the building concerned was developed. This model provides a detailed representation of the building’s structure and its surroundings within a 400-meter radius. It is based on a sectional drawing of the project and a 3D model supplied.

By taking into account the surrounding buildings, we can provide a more accurate picture of the wind’s evolution on site. As the site is densely populated with infrastructure, these constitute a large number of aeraulic masks, greatly influencing the evolution of the air. The study building has been accurately modeled. The ARTs on the roof were modelled according to the data sheets supplied by the customer. There are 6 TARs on the roof.

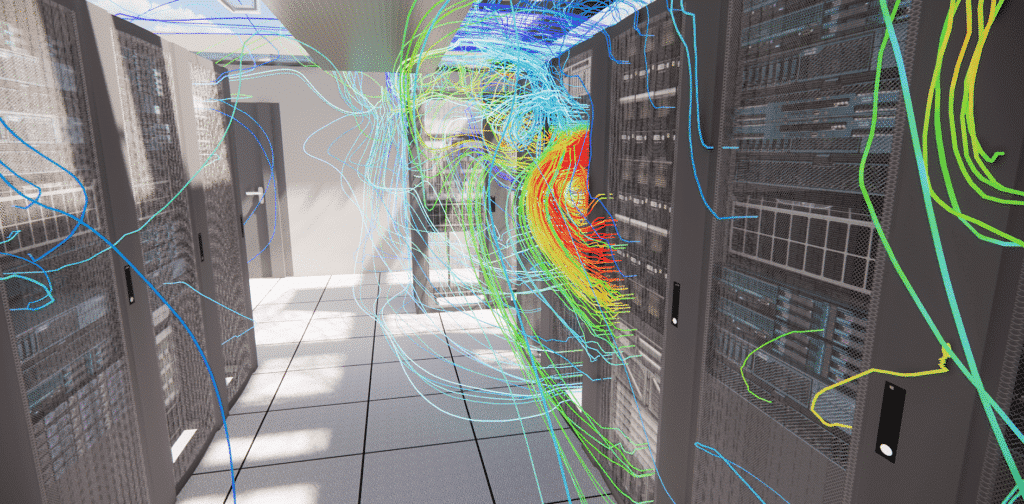

CFD simulation: an accurate tool for analyzing TAR environmental conditions

CFD simulation provides precise, detailed results, taking into account many factors such as building geometry, environmental conditions and the properties of the materials used. Thanks to CFD simulation,EOLIOS engineers can provide technical solutions and recommendations adapted to this project. This enables customers to make informed decisions and optimize the sizing and installation of RATs on the building’s roof.

3D model of TARs

Results of the thermo-aerodynamic study

Influence of wind on the building

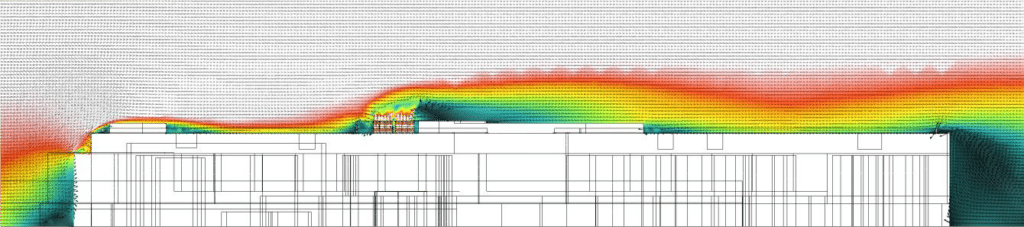

Wind is an extremely changeable phenomenon, both in terms of direction and speed. While maximum wind speed values are essential for structural stability calculations, average wind speed and direction values are more appropriate for thermo-aerodynamic studies. In our study, the wind is considered to be constant with a direction perpendicular to the site.

Initial results show that the wind has a strong influence on the air currents around the building, creating three zones of disturbance: at the front of the building, at the rear and further out in the wake of the building. TAR discharges are directed upwards and follow the wind. An upstream wall limits air flow to the TARs, creating low-velocity zones upstream and downstream.

TAR looping: A challenge for optimal cooling

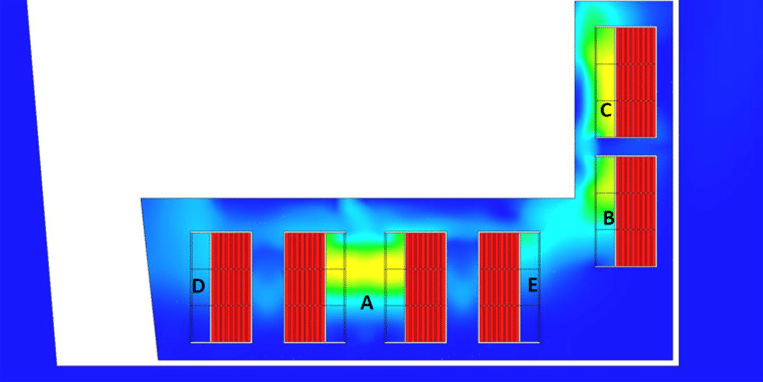

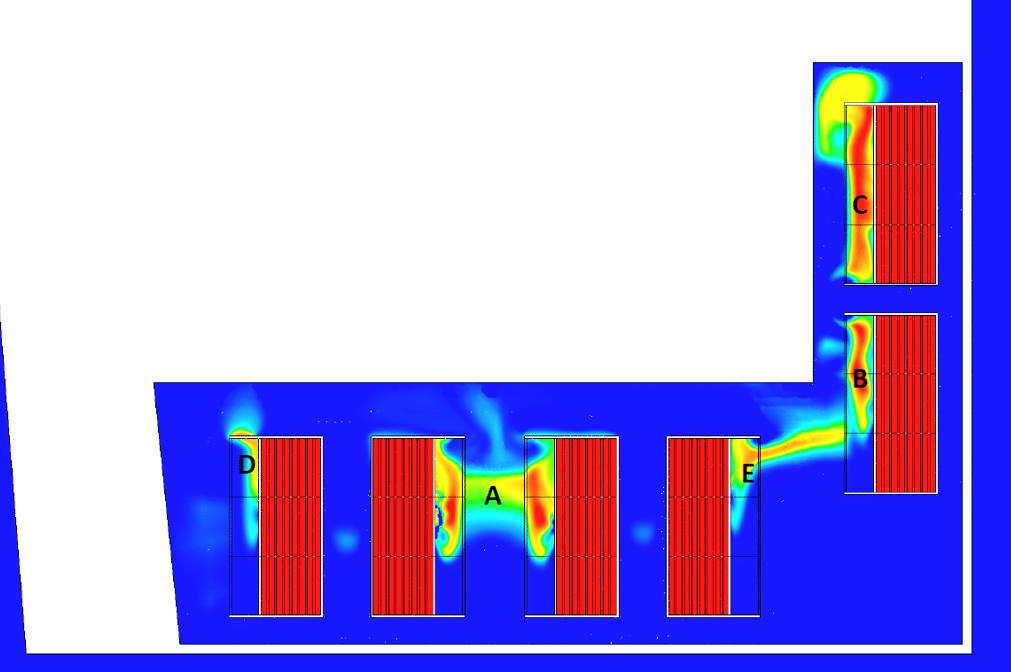

The temperature results show variations at the air inlets of the TARs. The looping phenomenon affecting these units is clearly visible, particularly with the two central (A) and two right-hand (B and C) TARs, which draw in air at a higher temperature than the surrounding air, as do the TARs on the sides (D and E).

TARs in position A encounter a zone where the temperature is higher, due to a reduction in the supply of fresh air caused by the proximity of suction points. Between the TARs in positions B and E, a similar phenomenon is observed at a slightly lower temperature, thanks to the greater distance between these units. In particular, TARs in position B and especially C, due to their proximity to the walls of the rooms where the air intakes are located, capture air at a significantly higher temperature than the ambient air. These TARs are confined between two walls, which reduces fresh air intake. This analysis underlines the importance of optimizing the design of air inlets to ensure an adequate supply of fresh air and avoid overheating problems.

The drawing shows the humidity conditions at the TAR air inlets. Note the looping phenomenon, where several TARs (A, B, C, D and E) draw in air with high humidity levels. The central TAR (A) and those on the right (B and C) attract particularly humid air, while those on the sides (D and E) also capture humid air, albeit to a lesser extent. This looping pattern for humidity corresponds to that observed for temperatures, and is due to similar factors. Higher humidity levels are also observed between TARs in A, as well as between those in B and E.

Simulation shows that ARTs expel humid air, which is then sucked back in, creating a looping phenomenon. This problem is exacerbated when the air inlets of one TAR face another TAR or an obstacle such as a wall. This prevents access to fresh air at room temperature and moderate humidity. As a result, TARs tend to draw in air from higher up, which is warmer and more humid.

Theextent of looping and theeffect of obstacles on moisture evacuation are detrimental to system efficiency. The current layout of ventilation systems on the roof seems inadequate. These observations highlight the need for design review and modifications to improve TAR performance and ensure optimum efficiency.

Improving TAR efficiency: EOLIOS recommendations to limit looping

Following these observations, EOLIOSproposes various solutions to reduce the looping of the TARs.

One of the key proposals, based on the results of the study, would be toinstall ventelles in place of the acoustic wall around the TARs. The aim of this measure is to mitigate the aeraulic masking effect created by the acoustic wall, which limits the intake of fresh air and creates areas of low air velocity at the bottom of the TARs. The louvers will improve airflow, bringing in fresh air more efficiently and reducing air stagnation problems.

Should the installation of vents prove insufficient, and the systems continue to loop back on themselves, we recommend the installation of horizontal hoods at the level of the systems’ discharges, to limit the downward flow of plumes towards the intake.

If it proves too complicated to install a full horizontal hood, one option is toinstall several horizontal hoods at the TAR intake.

The installation of vertical hoods at TAR outlets would also make it possible to increase the distance between the discharge and the TAR intake, and thus limit looping effects. This solution will still be less effective than a horizontal cowling.

This study demonstrates theimportance of using CFD simulation to understand and optimize TAR performance. Thanks to this method, we were able to analyze in detail the air flows, temperatures and humidity around the TARs, revealing areas of disturbance and phenomena such as airflow looping. CFD simulation offers advantages such as accurate results, cost and time savings, and a better understanding of the factors that influence TAR operation. Using this knowledge, recommendations such as the installation of louvers in place of walls have been formulated to promote a better supply of fresh air and improve TAR performance.

Reduce the spread of legionella with CFD

Studying the spread of legionellosis in evaporative cooling plants such as ARTs is essential to prevent the transmission of this potentially fatal respiratory disease. Legionella bacteria, responsible for Legionnaires’ disease, thrive in warm water environments such as water treatment plants.

When bacteria-contaminated water is sprayed into the air by TAR fans, it creates a moist plume that may contain infected droplets. When these droplets are inhaled by people in the vicinity of TARs, they can cause respiratory infections, including legionellosis.

CFD studies play a crucial role in understanding and managing the spread of legionellosis. CFD studies can be used to visualize airflow and the dispersion of wet plumes generated by TARs. Thanks to the results of CFD simulations, it is possible to identify areas at risk and take measures to prevent the spread of Legionella. These measures can include adapting ART design, modifying fan operation, adjusting water spray parameters, or implementing more efficient water monitoring and treatment systems. CFD studies thus help to improve the safety and reliability of evaporative cooling plants, by minimizing the risk of legionella spreading. They enable us to assess the effectiveness of preventive measures put in place, and to optimize the design and operation of ARTs in order to reduce risks to public health.

Continue on this topic

Video summary of the study

Summary of the study

The study carried out by EOLIOS concerns the sizing and implementation of cooling towers (TAR) on the roofs of ICPE offices. ARTs are cooling systems that use outside air to dissipate heat, offering a more energy-efficient alternative to traditional air-conditioning systems. The study uses CFD simulation to model and analyze fluid flows into and out of TARs.

The results of the study highlight the influence of wind on air currents around the building, and show the phenomenon of TAR looping, which affects the temperature and humidity of the air drawn in.

These results enable us to optimize the sizing and layout of the air handling units to ensure efficient cooling of the offices.

Video summary of the mission

Discover other projects

Wind impacts on high-rise buildings: Tours Olympiades in Paris

Comfort – Rooftop of a palace – Casablanca

Tour Liberté – La Défense

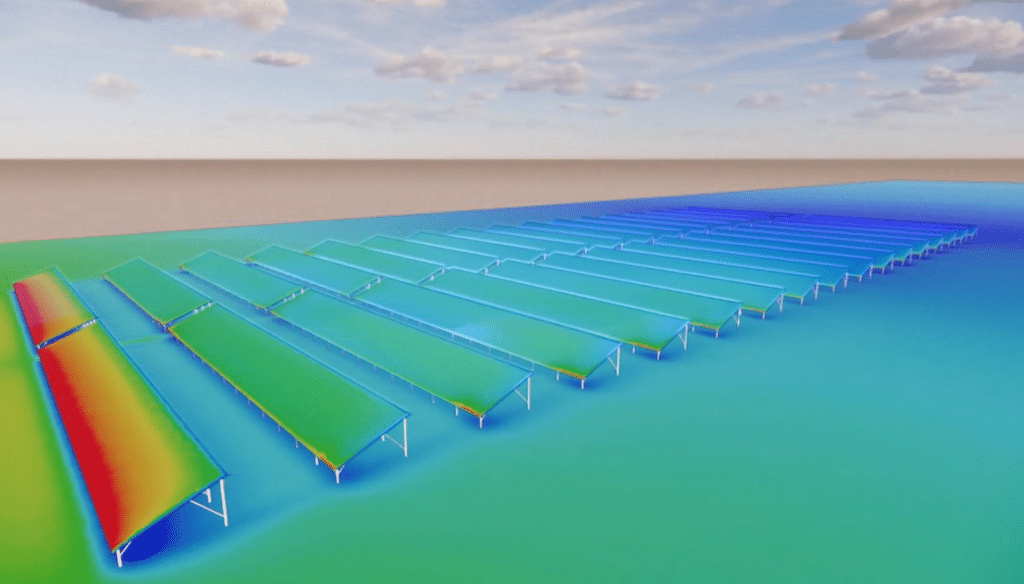

Impact of wind on a solar power plant

Cooling towers – ICPE

Pedestrian comfort study – La Défense

Confort au Vent – PSG training center

Wind study – La Défense

Fine particle capture in a metro station

Sharaan by Jean Nouvel resort

Air coolers – Critical study – Heat wave

Fine dust measurements

Balenciaga – Wind potential