Home » Industrial Process » Generators » Generator sets – GE1

Generator sets – GE1

Study of air circulation conditions in premises

EOLIOS Ingénierie verified and optimized the design of a system to improve the air circulation of air coolers located on the roofs of technical rooms occupied by generators.

Groupes Electrogènes - GE1

Year

2021

Customer

ENERIA

Location

France

Typology

Groupes Electrogènes

Continue navigation :

Our other projects :

Latest news :

Description of the CFD study

The purpose of the assignment was to study the cooling system of a data center consisting of a complex of 4 generators.

The challenge of such a project is to control the specific thermo-aerodynamic phenomena induced by the various manufacturing stages at very high temperatures.

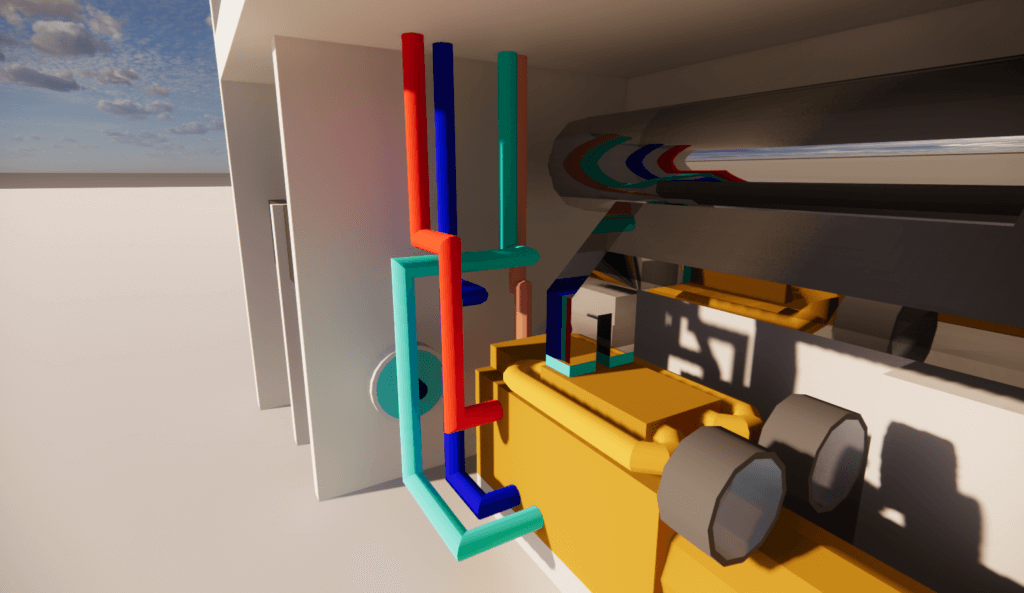

CFD thermo-aerodynamic studies will be carried out to study the different aeraulic and thermal principles governing the configuration of the systems.

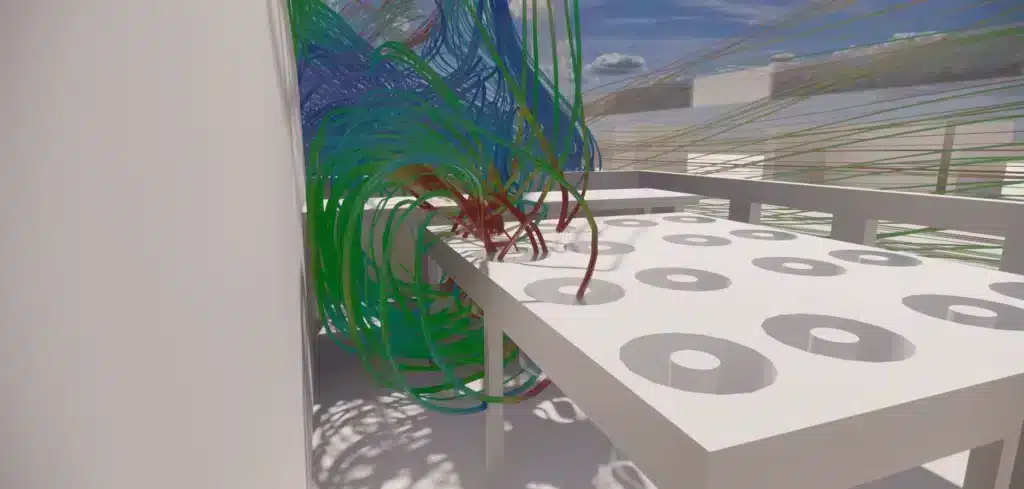

This analysis examines the exhaust plume from a series of generators in connection with rooftop systems for a data center.

The aim is to determine whether the exhaust from the systems can contaminate the supply air for the various pieces of equipment, and their impact on adjacent buildings.

This involves using CFD numerical calculations to simulate the thermo-aerodynamic behavior of the various phenomena taking place outside the model and inside the generator technical rooms.

Radiant wall temperatures, thermal draught from motor gas processes, wind pressure, internal resistance to vertical airflow; location and flow resistance characteristics of envelope openings; local terrain and immediate impact of building structure on wind; and the presence of mechanical systems stirring air around processes were all incorporated into the simulation.

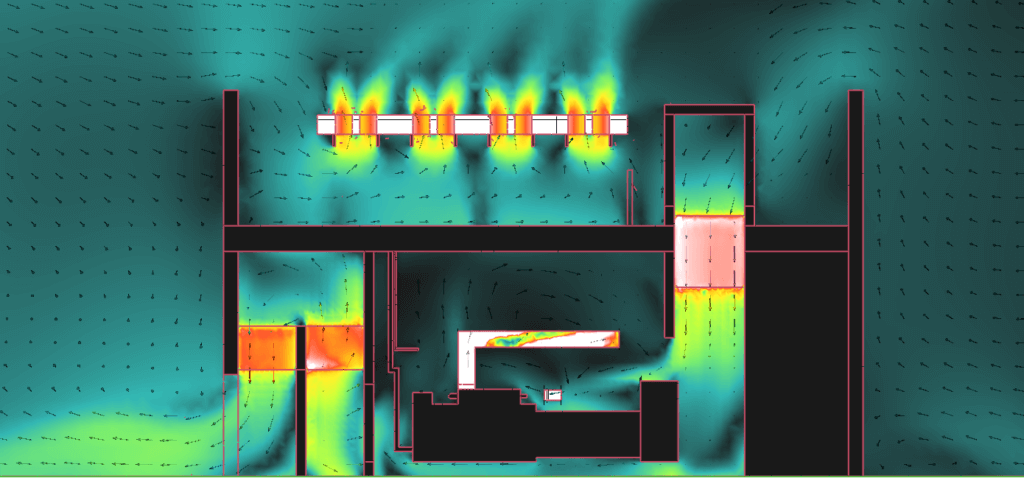

The results of the initial studies indicated that the looping and heat extraction were not optimal for rooftop systems.

The presence of an opaque gable favours the recirculation of air extracted from the air coolers to the suction zones.

This looping phenomenon leads to an increase in the system discharge temperature, which in turn leads to an increase in the return temperature.

Optimization solutions not presented here have been implemented.

Continue on this topic

Video summary of the study

Discover other projects

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Sizing – Chimney – Laboratory

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Stratification of a thermal storage tank

Generator sets – GE1

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy