Paint booth CFD simulation

Home » Industrial Process » Paint booth CFD simulation

EOLIOS helps you design paint booths

- On-site measurements

- Paint booth CFD simulation

- Selecting the right equipment

- Compliance with standards

- Identification of bypass and recirculation air flows

- Pollutant monitoring

- Simulation validation

- Sanding booth

- Tailor-made solutions

EOLIOS carries out studies for paint booths to optimize efficiency and air quality using CFD simulation tools.

- Aeronautics

- Automotive

- Poncage

- Helicopter

- Industry

- Paint

Our projects :

Technical files :

CFD simulation of paint and sanding booths

What can CFD simulation do for paint booths?

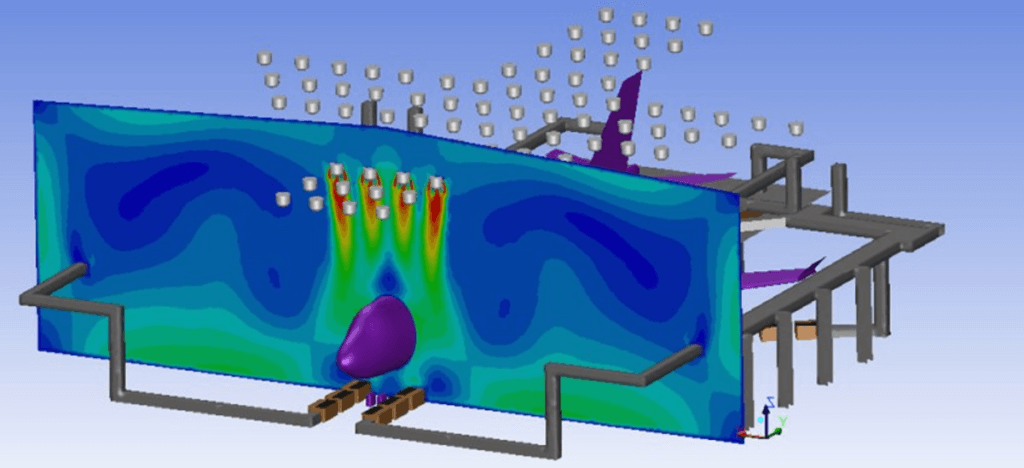

Computational Fluid Dynamics (CFD) has established itself as a state-of-the-art tool for optimizing paint booth performance. By modeling airflow and heat exchange with greater precision, CFD can identify weak points and propose concrete solutions for :

The assessment of climatic and particle removal conditions must be carried out in each local area, taking into account the dimensions of the space and the impact of each system.

The only method of accurately calculating these parameters and estimating air flows in space is CFD simulation.

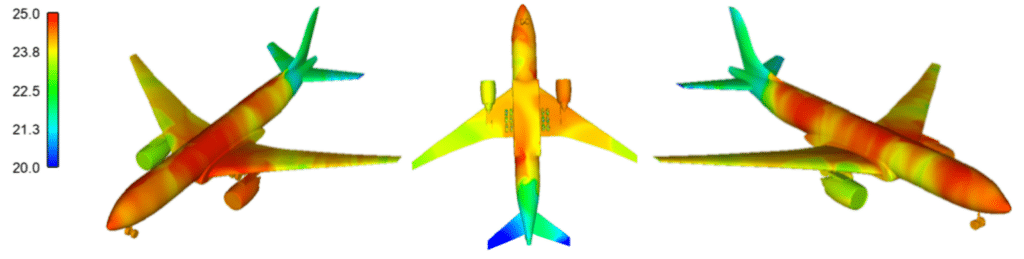

CFD gas modelling methods enable us to visualize particle flows, estimate the concentration of noxious substances, study temperature distribution in the workshop (critical scenarios in particular) and a number of other parameters, using professional software and computing power commensurate with the level of complexity of the problem under consideration.

At the system design stage, this makes it possible to evaluate its efficiency andavoid financial losses during operation.

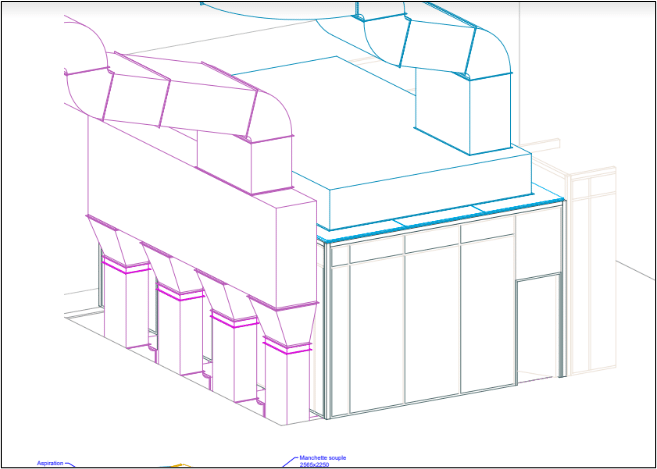

Requirements for the design of paint halls

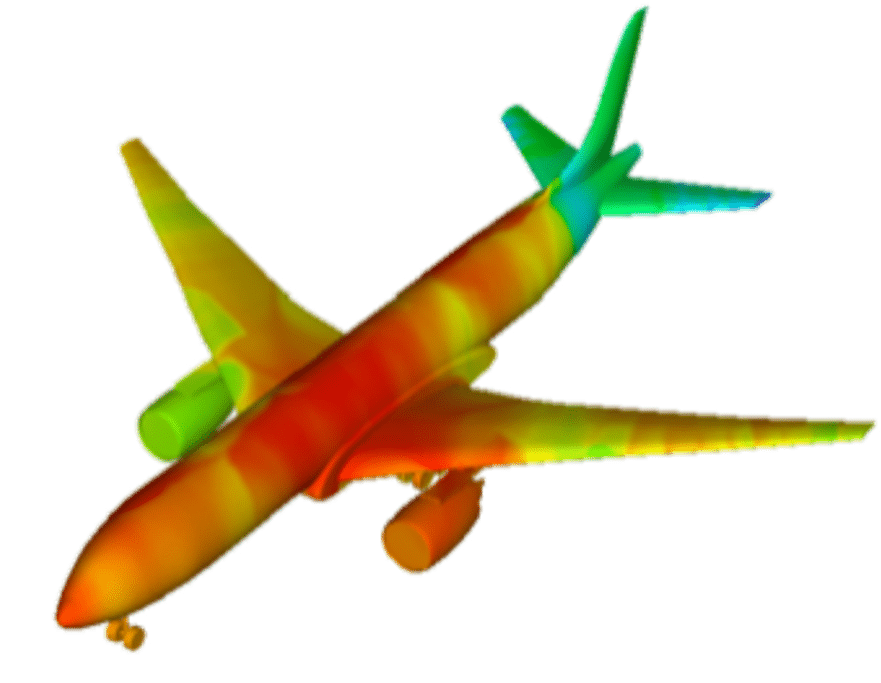

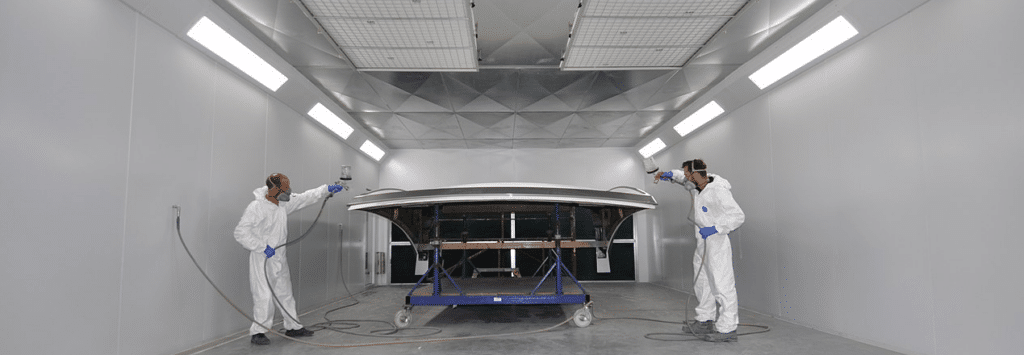

Air ventilation is necessary to ensure the removal of hazardous vapors and spray paint particles. In addition, it’s important that the ventilation air circulates evenly around the aircraft to achieve a high-quality paint coating. Typically, in the paint booths of small airplanes, helicopters… a horizontal longitudinal flow is created, thanks to which the ventilation air supplied near the nose of the fuselage propagates further along the length of the aircraft. The air is then removed from the paint booth at a distance behind the aircraft.

This paint booth design is efficientin terms of energy consumption (relatively low air consumption is required).

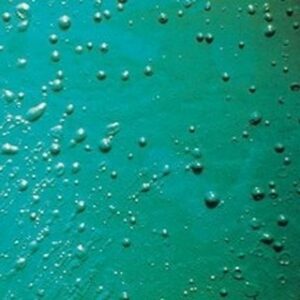

The problem with this type of ventilation can be the appearance of a grainy, uneven surface resulting from paint drying. The roughening of the paint layer occurs as a result of dried aerosol particles, paint spraying from the nose of the aircraft and its transfer by a longitudinal airflow towards the rear of the aircraft. Drying is then heterogeneous and differences in surface granularity may appear. Such surface defects can be unacceptable for the most demanding, for example, for business jets.

Requirements for the design of paint halls

To overcome these unfavorable factors, it is necessary to use modern computational fluid dynamics (CFD) tools and methods. The gas dynamics algorithms implemented in CFD simulations are the only way to accurately calculate these parameters and estimate the air flows in a 3D model. CFD is a set of mathematical methods, implemented in software, that can be used to perform complex calculations of gas flow and thermodynamics. CFD calculations are often used in the design of automotive paint spray booths to ensure uniform airflow around the vehicle being painted to ensure high quality paint and efficient paint transfer to coatings.

CFD to improve operator safety

Ensuring a healthy working environment:

- Air quality: Simulation ensures that the ambient air in the cabin meets quality standards in terms of pollutant and contaminant concentration.

- Evaluation of the concentration of pollutants in the cabin air.

- Simulation of contaminant dispersion and identification of risk zones.

- Optimization of the ventilation system to ensure healthy, breathable air.

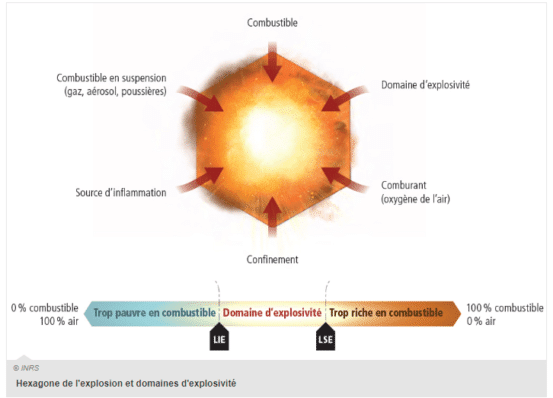

Reduce the risk of explosion:

- Compliance with ATEX standards: CFD simulation can assess the explosion risks associated with solvent and paint vapors, and ensure compliance with ATEX (Atmosphères Explosibles) standards.

- Analysis of explosion risks associated with solvent and paint vapors.

- Simulation of explosive gas dispersion and identification of risk zones.

- Implementation of safety measures to prevent explosions and protect operators.

Improving workstation ergonomics :

- Adequate ventilation: CFD verifies the efficiency of the ventilation system, ensuring that it meets standard requirements for air flow and air renewal.

- Study of operators’ working conditions and identification of areas of discomfort.

- Simulation of air flow and temperature to optimize workstation ergonomics.

- Proposed solutions to reduce fatigue and MSD risks.

CFD to improve finish quality

Reduce paint defects:

- Simulation of vortex formation and recirculation zones that can generate defects such as drips, material build-up and grainy surfaces

- Optimized air speed and air distribution to minimize turbulence and color variations

- Assessment of the impact of obstacles (e.g. working platforms) on the quality of the finish.

Improve paint uniformity:

- Analysis of paint transfer efficiency on different areas of the surface to be painted.

- Optimized position of spray guns and nozzles for even coverage.

- Study of the influence of paint viscosity and application conditions on paint film uniformity.

Reduce suspended particulates :

- Evaluating the efficiency of air filtration and extraction systems.

- Analysis of the impact of particle size and nature on finish quality.

- Analysis of the impact of particle size and nature on finish quality.

- Optimum filter placement

CFD to increase paint transfer efficiency

Optimizing cab geometry :

Improving the position of spray guns:

- Simulation of paint particle trajectories and identification of loss zones.

- Optimization of the angle and distance between the spray guns and the surface to be painted.

- Study of the influence of nozzle configuration on spraying and paint transfer.

Reduce paint mist :

- Analysis of paint mist formation and identification of contributing factors.

- Optimized air speed and spray pressure to minimize mist formation.

- Evaluating the efficiency of paint mist recovery systems.

CFD to optimize energy efficiency strategies

Reduce heating and cooling requirements:

- Simulation of heat transfer in the cabin and identification of thermal bridges.

- Optimization of cabin insulation and heating and air-conditioning systems.

- Implementation of control strategies for better temperature management.

Improve paint uniformity:

- Study air flow in the cabin and identify pressure drop zones.

- Optimization of ventilation system design to reduce energy consumption.

- Study air flow in the cabin and identify pressure drop zones.

- Optimization of ventilation system design to reduce energy consumption.

- Installation of variable-speed ventilation and intelligent control systems.

- Study network homogeneity upstream of diffusing walls or ceilings.

Evolution of aircraft contact temperature in the paint room

Recovering heat energy:

- Assessment of the potential for recovering heat energy from ventilation.

- Installation of energy recovery systems to heat incoming air or other installations.

Qualification of paint booth aeraulics

What is a paint booth qualification?

A paint booth is essentially a controlled environment, specially designed to carry out painting work on different types of equipment. The main purpose of a spray booth is to contain the particles and volatile organic compounds (VOCs) released during the painting process, so as not to harm the environment or human health. In addition, paint booths ensure that the painting process is not disrupted by external elements such as dust, which could compromise the paint finish.

The term ” qualification ” refers to the process by which the performance of a paint booth is measured and evaluated. To ensure that the paint booth is operating at peak efficiency, we at EOLIOS follow a rigorous and comprehensive qualification procedure that evaluates all important aspects.

Standard to be met :

The manufacture, installation and use of a paint spray booth is regulated, and meets a number of key criteria that are crucial to the safety and comfort of operators and the efficiency of the paint spray booth. The criteria to be met (for spray booths with horizontal ventilation, which are the most widespread in industries and sectors other than automotive) are determined on the expert advice of theINRS.

Air velocity measurement :

At EOLIOS, the application of our knowledge of fluid mechanics is deeply rooted in our technical approach to the measurement of air velocities in the qualification of a paint booth. Using precision anemometers, we provide rigorous measurements of air speed, a crucial factor in the painting process.

In the context of paint booths, where air is used to spray paint onto a surface, variations in air speed can affect the quality of the paint coat applied. As a result, accurate air velocity measurement using a precision anemometer is crucial to ensure uniform, high-quality paint application.

The data collected is then analyzed and interpreted by our team of engineers, who use this information to provide recommendations on possible adjustments to be made in the painting process. These may include recommendations on air source orientation, air pressure, temperature and humidity, among other factors.

The accuracy of this measurement is a decisive factor in the paint booth qualification process, which is why we attach great importance to the methodology applied to ensure it meets the strictest standards.

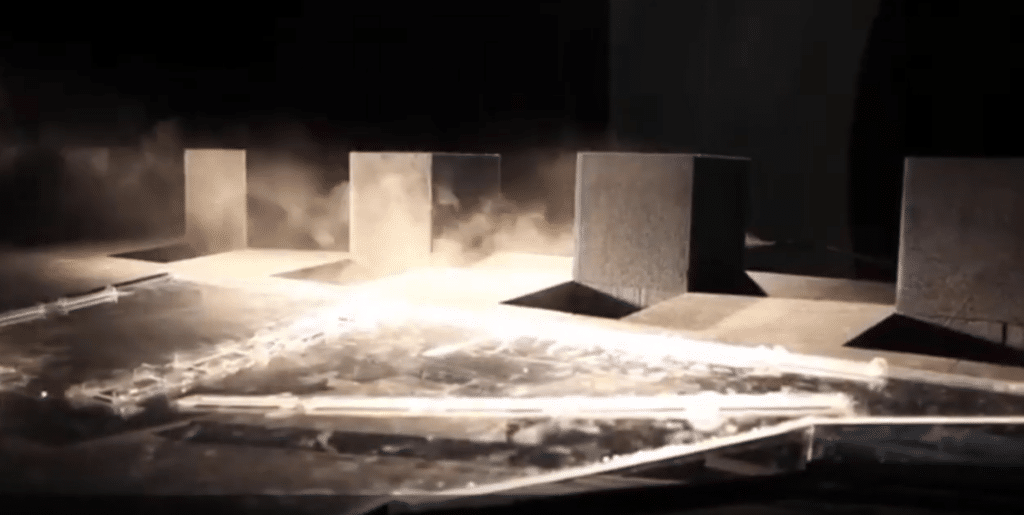

Smoke tests

Why carry out smoke tests before qualifying a sanding booth?

EOLIOS ‘ expertisein fluid mechanics also extends to smoke testing for paint booths. This type of test is an invaluable tool for determining the visibility and efficiency of air flow in the booth during paint application.

Smoke testing is an important qualification method for paint booths. They make it possible to visualize and analyze air flow and ventilation in the booth, based on smoke diffusion.

Identification of poor air circulation in an aircraft paint booth

Smoke test procedure :

- Smoke generation: Non-toxic, harmless smoke is generated inside the cabin.

- Airflow observation: The smoke is then observed and analyzed using a variety of tools, such as precision cameras, thermal imaging cameras and anemometers.

- Performance evaluation: The test assesses the efficiency of the ventilation system, the homogeneity of air flow, the presence of recirculation zones and the efficiency of filtration systems.

Objectives :

- Identify areas of turbulence and recirculation that can affect finish quality and generate paint defects.

- Check the efficiency of the ventilation system and ensure that it meets air renewal and even air distribution requirements.

- Evaluate the efficiency of filtration systems and their ability to capture suspended particles and atmospheric pollutants.

- Detect air leaks in the cabin and ensure airtightness.

Advantages :

- Intuitive visual method for easy understanding of air flow and ventilation.

- Efficient diagnostic tool to identify areas for improvement and non-conformities.

- Cost-effective and easy to implement compared to other qualification methods.

Adjustments and improvements

EOLIOS uses a specific smoke source to produce smoke which is introduced into the paint booth. By observing the path the smoke takes through the booth, EOLIOS experts are able to determine whether the air is flowing correctly. They can identify areas of turbulence or stagnation that could impede paint application, and take the necessary steps to adjust the air system.

The data obtained from these tests can then be used to optimize paint booth performance. For example, it is possible toincrease air extraction capacity (damper management), improve air supply quality or reorganize the workspace for greater efficiency.

After our initial assessment, we work with the customer to make the necessary adjustments to the paint booth.

EOLIOS expertise in paint booth aeraulics

At EOLIOS, the application of our knowledge of fluid mechanics is deeply rooted in our technical approach to the measurement of air velocities in the qualification of a paint booth.

Using precision anemometers, we provide rigorous measurements of air speed, a crucial factor in the painting process.

CFD simulation is also a valuable tool for optimizing paint booths and improving performance on all fronts. By making it possible to visualize and analyze air flow and heat exchange with greater precision, CFD helps to identify areas for improvement, and to propose concrete solutions for improving finish quality, paint transfer efficiency, energy consumption and operator safety.