Sprinkler: how does a sprinkler system work?

Accueil » Smoke control » Sprinkler: how does a sprinkler system work?

Definition: what is a sprinkler?

Sprinklers are automatic extinguishing devices used to protect buildings against fire. In this document, we explain how they work, how to install them and their advantages in terms of fire safety. You’ll also learn about the standards and regulations surrounding the use of sprinklers, as well as best practices for ensuring their effectiveness.

Our fire safety projects :

Sprinkler systems: the key to fire safety

How sprinklers work

The sprinkler outlet nozzle is designed to distribute the water or extinguishing agent evenly over the surrounding area. This allows the fire to be effectively controlled and suppressed. This early release mechanism enables sprinklers toact quickly to control and extinguish incipient fires.

By acting in the early stages of a fire, sprinklers can prevent the rapid spread of flames, limiting the damage caused by fire and smoke. It’s important to note that not all sprinklers are triggered at the same time. Each sprinkler is independent and is activated only when it detects a sufficiently high temperature at its location. This means that only the necessary sprinklers are activated, minimizing water damage and enabling better fire control.

Different types of sprinkler heads

There are several types of sprinkler heads, each with its own specific characteristics and applications. Here are some of the most commonly used types:

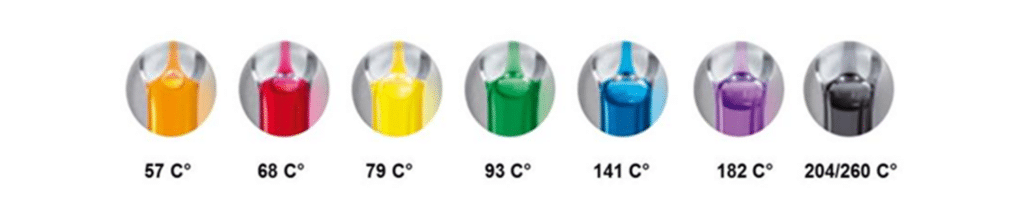

- Standard sprinkler head: This is the most common type of sprinkler head. It generally consists of a glass bulb containing a heat-sensing liquid. When the temperature reaches the preset threshold, the bulb shatters, allowing the water or chemical extinguishing agent to spread.

- Fused sprinkler head: This type of sprinkler head uses a thermal fuse that melts at a specific temperature. When the fuse melts, it releases the sprinkler valve, allowing the water or extinguishing agent to flow.

- Pre-action sprinkler heads: These sprinkler heads are used in environments where the risk of nuisance tripping is high, such as computer rooms or areas sensitive to water damage. Before the sprinkler valve opens, pre-action detection, such as a fire detection system or smoke detector, must be activated.

- Quick-activation sprinkler head: This type of sprinkler head is designed to react even more quickly to heat. It is often used in environments where rapid fire propagation is a high risk, such as warehouses or industrial facilities.

- Water mist sprinkler heads: These sprinkler heads use water mist technology rather than a traditional water jet. They disperse fine droplets of water, enabling heat to be absorbed more quickly and the fire to be suppressed more effectively. They are often used in areas where asset protection is paramount, such as archives or museums.

These different types of sprinkler heads offer solutions for a variety of fire safety situations and requirements. Selecting the right type of sprinkler head will depend on factors such as fire risk, building environment and current regulations. It’s important to consult a professional specializing in sprinkler systems to determine the most appropriate type of sprinkler head for each specific case.

Sprinkler head arrangements: Essential considerations for optimum installation

Sprinkler heads can be installed in different arrangements to suit the specific needs of each building. Here are some of the most common arrangements:

-

Hanging arrangement: Hanging sprinkler heads are fixed to the ceiling, suspended from a threaded rod or hook. They are mainly used when the ceiling is the main point of installation. When a fire is detected, they are triggered, allowing the water or extinguishing agent to flow downwards and spread over the fire area.

-

Standing arrangement: Standing sprinkler heads are fixed to the floor or the bottom of walls, projecting the jet of water or extinguishing agent upwards into the area to be protected. They are often used in areas where there is a risk of obstruction from hanging heads, such as plant rooms or areas where vibrations are frequent.

-

Recessed or semi-recessed layout: In this layout, sprinkler heads are integrated into ceilings or walls. They are set to be flush with the ceiling or wall surface, making them less visible and more aesthetically pleasing. These arrangements are generally used in buildings where aesthetic appearance is paramount.

-

Wall-mounted: Sprinkler heads can also be mounted directly on walls, often close to the ceiling. This arrangement is often used in places where the ceiling is unsuitable for hanging or standing installation.

The choice of sprinkler head layout depends on factors such as building type, architectural constraints, current regulations and aesthetic considerations.

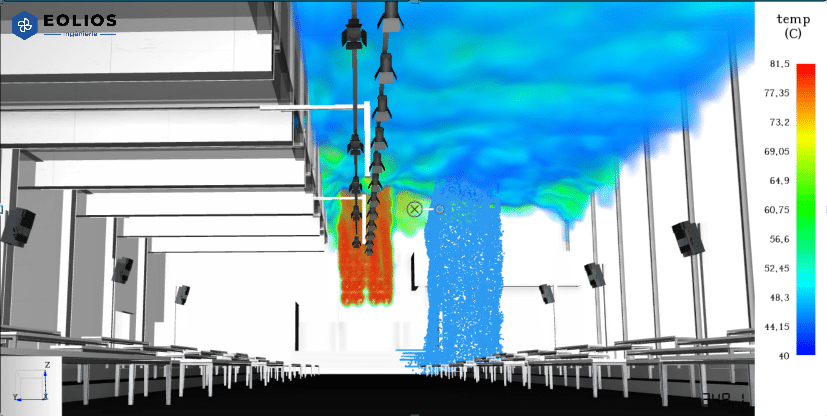

Modeling the triggering of a sprinkler head when threshold temperatures are reached

French regulations on sprinkler installations

Construction and Housing Code

France’s Code de la Construction et de l’Habitation (CCH) is the main reference for sprinkler regulations. These regulations set out fire safety requirements for different types of building.

According to the CCH, certain establishments open to the public (ERP) in categories J, M, N and group U must be equipped with fire protection systems, including sprinklers. ERP in these categories include, for example, hotels, auditoriums, sports facilities, shopping centers, restaurants and educational establishments. In addition, certain categories of industrial and commercial buildings must also be equipped with sprinkler systems to ensure the safety of those present and the protection of property. These fire protection requirements are determined by the classification of the building and its specific use. The CCH sets minimum standards for fire safety in the buildings concerned, ensuring that adequate measures are taken to prevent, detect and fight fires.

Standard NF S61-932

The NF S61-932 standard is a key document for sprinkler installations in France. It supplements the directives of the French Code de la Construction et de l’Habitation (CCH ) by providing specific technical requirements for the design, installation and maintenance of sprinkler systems. This standard covers several important aspects to ensure the proper operation of sprinkler systems.

It includes the classification of risks according to the activities present in the building. This classification is used to determine the protective measures required, including the type of sprinkler system to be used. For example, risks may vary according to the type of materials or products present in the building.

Standard NF S61-932 also specifies the water flow rates required for effective fire suppression. These water flows are calculated on the basis of various factors, such as building surface area, height, risk classification and so on.

Sprinkler head spacing is another aspect covered by the standard. It is essential to ensure adequate coverage of the area to be protected. The standard thus establishes guidelines for theoptimum spacing of sprinkler heads to ensure uniform distribution of the extinguishing agent.

The performance test procedure is also defined in the standard. It specifies the methods and protocols to be followed to check that the sprinkler system is operating in accordance with requirements and technical specifications.

It is important to note that the NF S61-932 standard is regularly updated to take account of technological developments and best practices in the fire protection industry.

Beforeinstalling a sprinkler system, it’s essential to take the necessary administrative steps by submitting a dossier to the relevant safety commission. This commission will be responsible for examining the project and ensuring its compliance with fire safety regulatory requirements, including those relating to sprinklers. This step is crucial to obtaining authorization to install the system, and ensuring its compliance with current standards.

Systems maintenance

Before installing a sprinkler system, it’s essential to take the necessary administrative steps by submitting a dossier to the relevant safety commission. This commission will be responsible for examining the project and ensuring its compliance with fire safety regulatory requirements, including those relating to sprinklers. This step is crucial to obtaining authorization to install the system, and ensuring its compliance with current standards.

Once the sprinkler system has been installed, it must be regularly inspected by an approved body. The purpose of these periodic inspections is to check that the overall system is operating correctly, and to ensure that equipment is maintained in good working order. Approved inspectors will examine sprinkler heads, detection systems, control valves, water supply systems, and carry out tests to verify their performance. These regular inspections are essential to maintain the reliability andefficiency of the sprinkler system.

After each successful inspection visit, a certificate of compliance will be issued to certify that the sprinkler system meets regulatory requirements. This certificate is proof of the system’s compliance and ability to ensure the building’s fire safety. It’s important to note that inspection visits and certifications are an integral part of the monitoring and maintenance process for installed sprinkler systems. These measures ensure that the system remains operational and efficient throughout the life of the building, helping to provide ongoing fire protection.

Simulating sprinkler systems

SDS simulation

Fire Dynamics Simulator (FDS) sprinkler simulation is an advanced method for assessing theeffectiveness of sprinkler systems in firefighting.

FDS is anumerical modeling software package for fire phenomena that uses the conservation of mass, momentum and energy equations to simulate the interactions between smoke, heat, combustible gases and the dispersion of extinguishing water.

SDS simulation of a fire outbreak

Using precise data on sprinkler characteristics such as flow rate, velocity and spray pattern, FDS simulation can predict the behavior of the sprinkler system under different fire conditions, such as fire size and location.

Thanks to this advanced technique, designers and engineers can optimize the design and positioning of sprinklers, ensuring effective fire protection and occupant safety.

Smoke control : on the same subject

Brandschutztechnik

Smoke extraction in underground parking lots

Fire safety engineering

Data center fire safety: Automatic Gas Extinguishing Systems (IEAG)

File: applying IT263 – smoke extraction from atriums

File: applying IT246

The ESSOC law for fire safety

The objectives of smoke control

Dynamic modeling of the evacuation of people