Sizing static aerators

Accueil » Industries » Sizing static aerators

EOLIOS designs static aerators and natural ventilation systems for industrial sites

- Selecting equipment according to use

- Sizing air inlets to suit site conditions

- Aerator flow calculation

- Study of critical scenarios

- On-site flow measurement

- Improved air distribution and cooling efficiency

- Study of pollution levels

- Location optimization

- Study of associated air treatment systems

Static aerators are used to evacuate gases, fumes or heat from a closed system.

EOLIOS helps manufacturers design static aerators.

Continue navigation :

Our latest news :

Our projects :

Our areas of expertise :

Technical files :

Static aerator sizing principle

Define the quantity of air required to operate the workshop:

The first step in sizing static aerators is to determine the workshop’s ventilation requirements.

It is necessary to determine the volume of fresh air required to replace stale air and maintain acceptable air quality in the workshop.

This air volume depends on the size of the workshop, the number of occupants, the types of pollutants present and local regulations.

It is also essential to define the air change rate, i.e. the number of times per hour the air must be changed in the workshop.

Facilitate the elevation of natural air flows:

It’s important to take advantage of the natural air flow in the workshop to facilitate air circulation.

Temperature differences between indoor and outdoor air are an essential driver of natural ventilation.

To facilitate the rise in air flow, it is advisable to create marked thermal variations.

Static aerators should be positioned to take advantage of natural air currents, such as prevailing winds or pressure differences due to temperature variations.

Avoid pollution zones:

Pollution zones, where pollutants are generated or accumulate in greater quantities, need to be identified and taken into account when arranging aerators.

Aerators need to be positioned close to these areas to capture and remove contaminants efficiently.

Static aerators should also be positioned to facilitate the removal of stale air.

Aerators should be placed in the highest areas of the workshop to allow hot air and contaminants to escape easily.

Improve ventilation uniformity :

It’s important to ensure uniform ventilation throughout the workshop.

Static ventilators should be distributed so as to cover the entire workspace simultaneously, especially dead zones where air does not circulate efficiently.

Avoid obstacles and facilities:

It’s essential to take obstacles and shop layouts into account when choosing a location for static aerators.

Obstructions such as machinery, shelving or equipment can disrupt airflow and reduce the efficiency of the aerators.

Comply with fire regulations:

Thestatic ventilator is a passive device used to promote smoke evacuation in buildings.

It operates on the principle of the pressure difference between the inside and outside of the building.

By exploiting this pressure difference, the aerator enables toxic fumes and combustion gases produced during a fire to be evacuated.

It is important to comply with local fire safety regulations.

Some regulations may impose specific requirements in terms of size and location of static aerators, depending on the type of activity or occupancy of the workshop.

Complying with current regulations and choosing the right static aerators are therefore essential for fire prevention and personal protection.

How to choose the right size and type of static aerators for natural ventilation?

Choosing a location for static aerators :

Thelocation of static aerators is a key factor in ensuring effective ventilation in industrial workshops.

The choice of location must take several parameters into account to ensure optimum air circulation in the workspace.

Define the optimum size :

The size of static aerators is also an important criterion to take into account when sizing.

It’s essential to choose aerators with sufficient airflow to meet the workshop’s ventilation needs.

It is also essential to ensure that the maximum air speed at the aerator outlet remains within its optimum operating range.

Determine the number of aerators:

The location of static aerators is a key factor in ensuring effective ventilation in industrial workshops.

The choice of location must take several parameters into account to ensure optimum air circulation in the workspace.

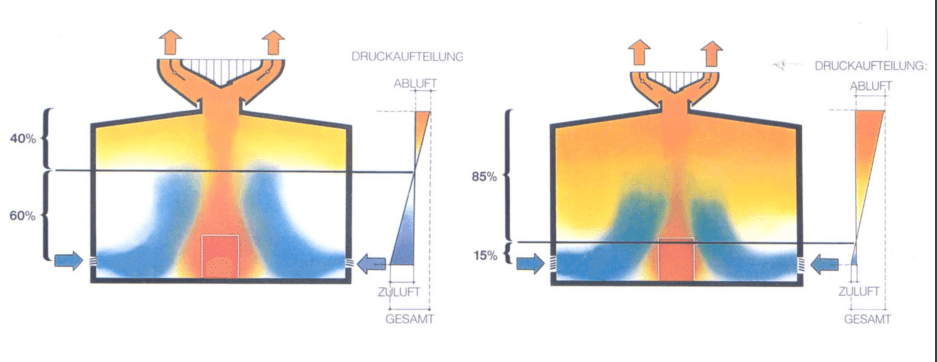

Take into account existing mechanical insufflation or extraction systems:

Before sizing static aerators, it’s important to understand the operation of mechanical insufflation or extraction systems already present in the workshop.

These systems are generally used to control temperature, humidity or air quality in a confined space or for process purposes.

Workshops are often equipped with fans or air extractors to generate an air flow in the workspace.

The sizing of static aerators must be adapted to the characteristics of the mechanical systems already present in the workshop.

It is essential to take into account the airflows generated by these systems in order to achieve an optimum balance between mechanical and natural airflows.

Precise sizing of static aerators will ensure balanced ventilation throughout the workshop.

A thorough analysis of mechanical systems helps optimize natural ventilation and ensure harmonious collaboration between static aerators and mechanical systems.

By combining the advantages of both methods, it is possible to guarantee efficient, balanced ventilation on the shop floor.

The expertise of a fluid mechanics specialist is essential for the successful integration of static aerators with existing mechanical systems.

Size according to existing or future air inlets:

When sizing static aerators, it is essential to take into account the sizing of air inlets.

Air inlets are responsible for bringing fresh air into an enclosed space, in addition to the static ventilators which ensure the exit of stale air.

Consider other factors such as acoustics and ease of maintenance:

In addition to the above-mentioned criteria, it is important to take other factors into account when sizing static aerators.

Depending on the site, it’s advisable to choose quieter aerators, so as not to disturb industrial neighbors.

It is also advisable to choose energy-efficient aerators, to reduce operating costs.

In addition, the issue of volatiles and parasites may arise depending on the industry’s activity.

Finally, it’s best to choose aerators that are easy to install and maintain, to facilitate day-to-day use.

How do you accurately size static aerators?

Which physical principles need to be studied?

Sizing static aerators is a crucial step in the design of an efficient natural ventilation system.

Several factors need to be taken into account, such as the neutral pressure plane, pressure coefficients and the distribution of static surface pressures.

In this chapter, we will analyze these aspects in detail, to provide a better understanding of static aerator sizing.

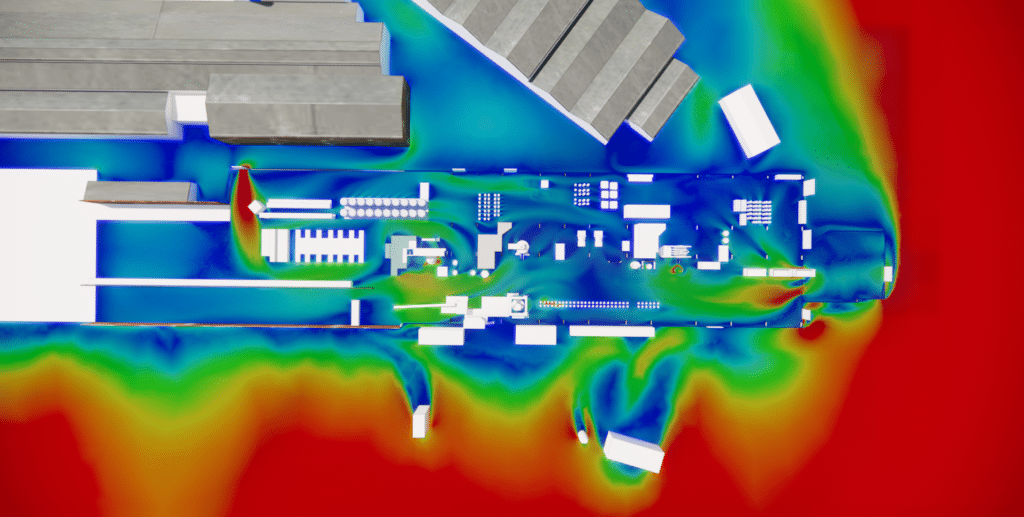

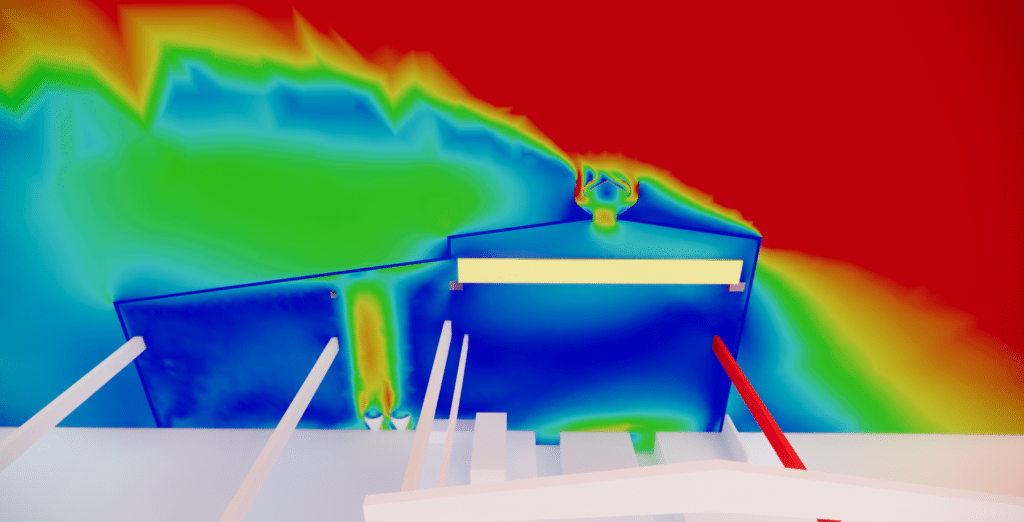

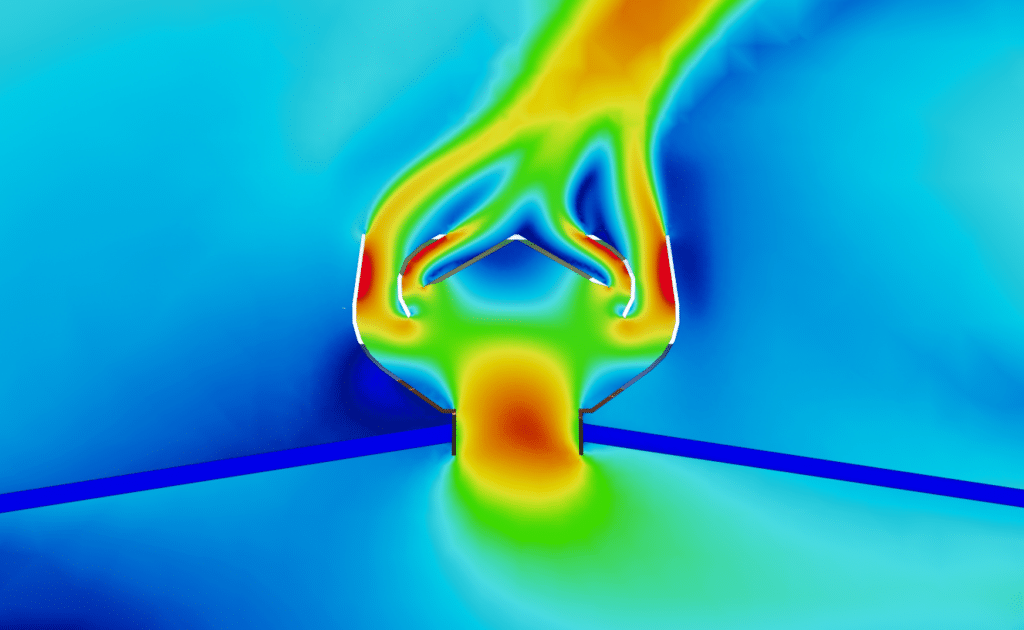

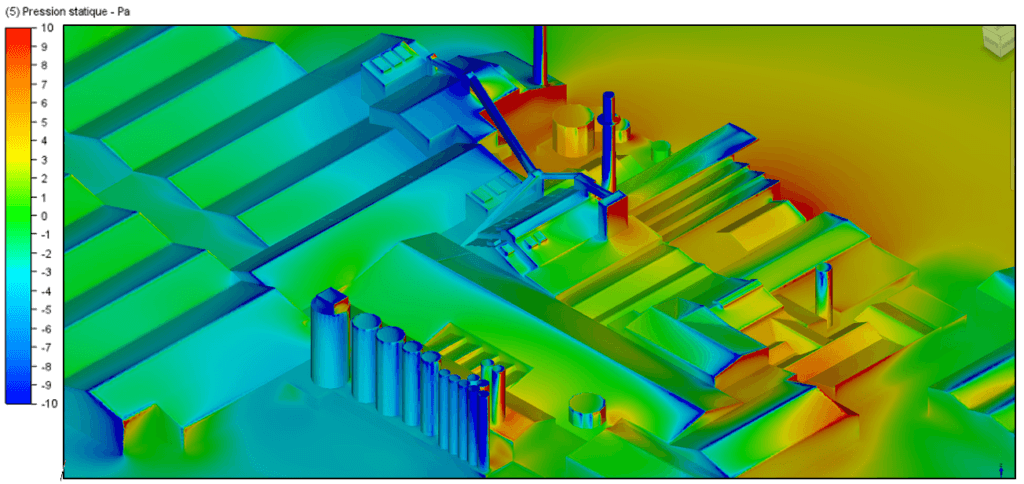

CFD study of pressure coefficients

Wind exerts a force on static aerators, which can have a significant impact on their operation.

It is therefore essential to take these effects into account when sizing these devices.

When the roof is exposed to the wind:

- An overpressure is created on the side exposed to the wind.

- A depression is created on the opposite slope.

Air pressure difference :

- The negative pressure on the opposite side draws air from inside the building.

- An overpressure is created in the volume, proportional to the force of the wind.

- This creates a natural circulation of indoor air.

Overpressure and underpressure zones :

- Over-pressurized zones encourage air ingress.

- Depressed zones encourage air outflow.

Distribution of static surface pressures

- Depressions at the outlets are the driving force behind the building’s natural ventilation.

- The negative pressure in the roof must be high enough to convert all lower vents into air inlets.

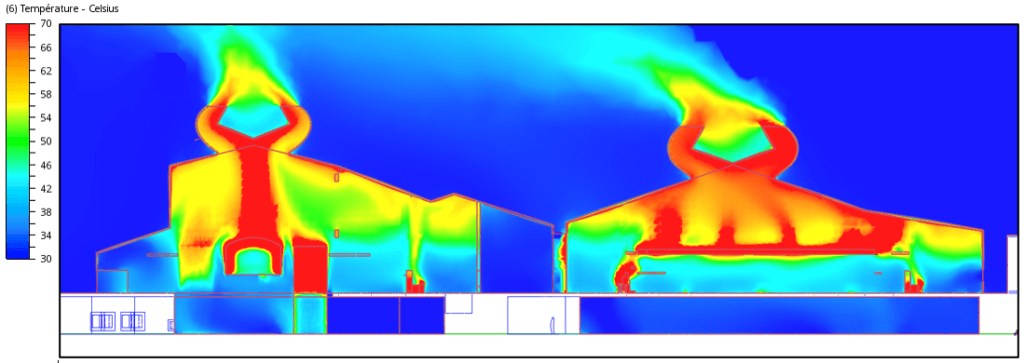

What is thermal draft?

Thermal draft is based on the fundamental principle of the difference in density between warm and cold air.

When a heat source, such as a fireplace or boiler, heats the air inside a confined space, this warm air becomes less dense and rises naturally.

Thermal draft is an essential element to consider when sizing static aerators, as it directly influences their efficiency.

Thermal draft can be calculated on the basis of several parameters, such as the temperature difference between indoor and outdoor air, the height of the exhaust stack and the configuration of the static aerator.

It’s important to note that thermal draft can be influenced by atmospheric conditions, particularly the presence of wind.

Indeed, wind can modify thermal flows and create turbulence that can affect the operation of static aerators.

It is therefore necessary to take this interaction into account when sizing aerators.

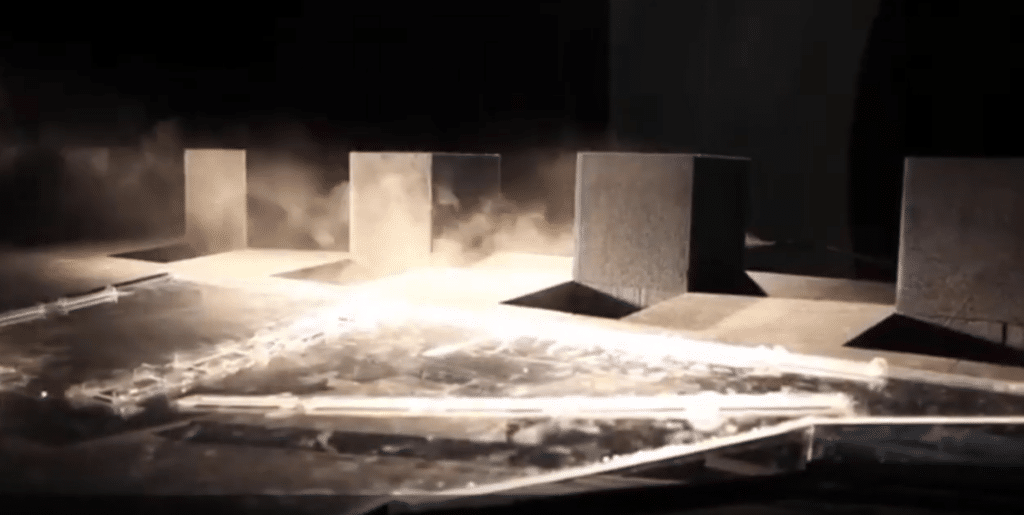

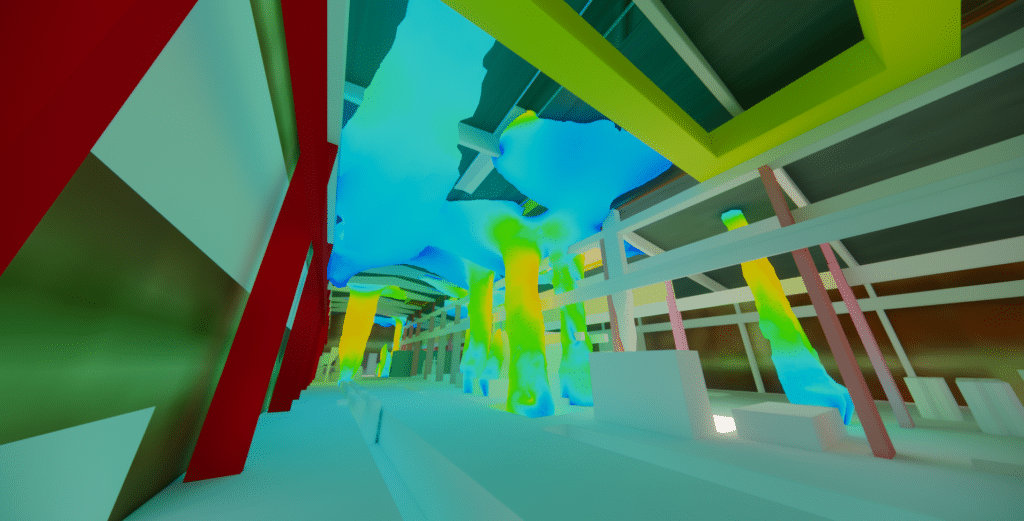

Video - Temperature isosurfaces - Steelworks

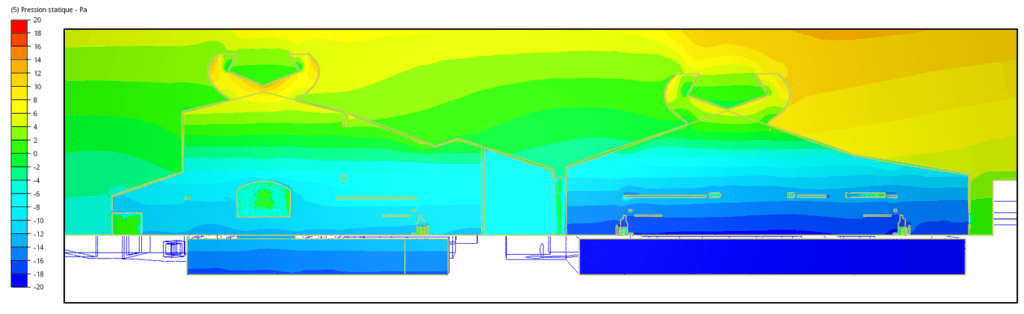

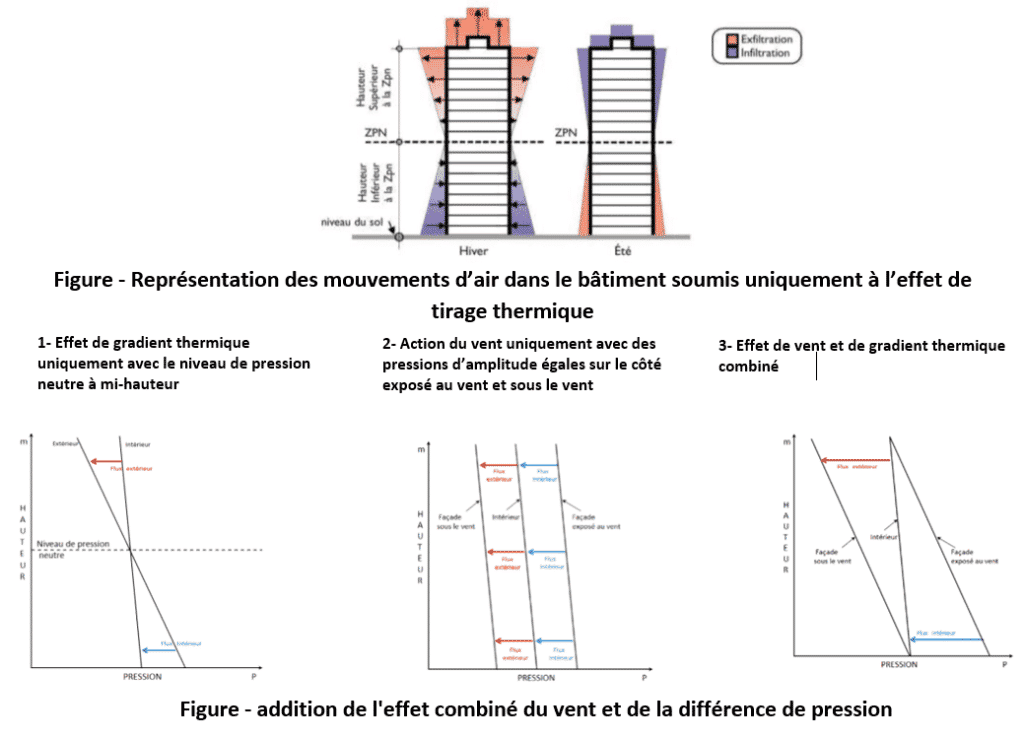

Analysis and principle of the neutral pressure plane

What is the neutral pressure plane?

The neutral pressure plane is a crucial factor in sizing natural ventilation openings subject to thermal draught effects.

It is an imaginary horizontal plane where the internal pressure is equal to the external atmospheric pressure.

At the level of the neutral plane, air inlets are not very effective, as the internal pressure is balanced with the external atmospheric pressure.

Above this plane, on the other hand, internal pressure is higher than external pressure, making it an ideal zone for air outlets.

Below the neutral plane, a zone of depression is created, making it a preferential location for air inlets.

Key points to remember about the neutral pressure point :

- In the neutral plane, the air intake and exhaust ports are not very efficient.

- Above the neutral plane, internal pressure is higher than external atmospheric pressure.

That’s why air outlets should always be located here.

Please note, however, that wind effects can occasionally cancel out thermal draught effects. - Below the neutral plane, a low-pressure zone is created, making this location ideal for air inlets and grilles.

When designing a natural ventilation system :

- The height of the neutral plane must be predetermined.

- The proportion of pressure difference available must be distributed between the air inlet and outlet ports.

- The precise position of the neutral plane and the arrangement of the air inlets can only be verified by an iterative method.