Accueil » Industries » Production hall » Natural ventilation – Metallurgy

Natural ventilation – Metallurgy

Recommendations for optimal ventilation and effective pollutant dispersion - Steelworks

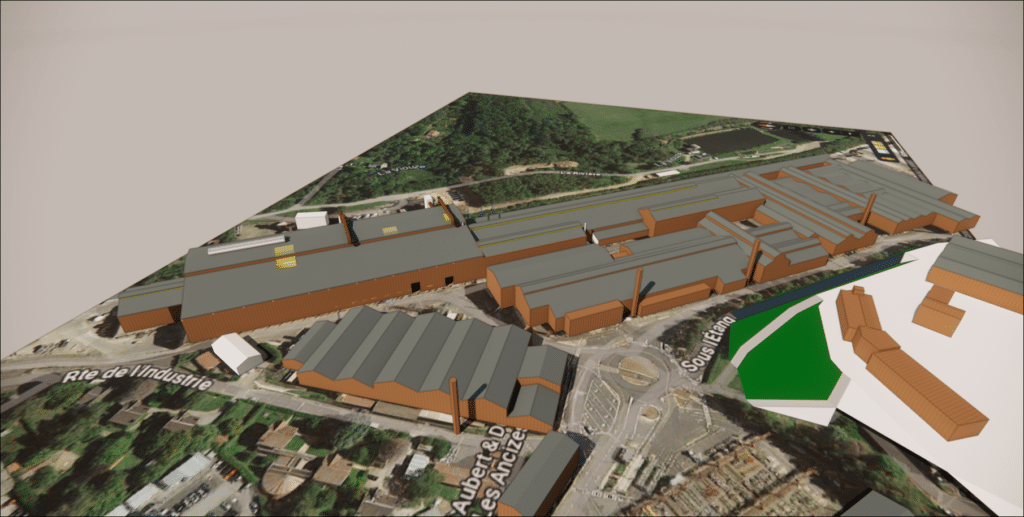

The project carried out by EOLIOS for the Aubert et Duval steelworks consisted of a sizing and location study for a new static aerator (Robertson) on the roof. The main objective of this dimensioning study is to ensure efficient ventilation of the steel mill by determining the optimum dimensions of the static aerator.

Recommendations for optimum ventilation and effective dispersion of pollutants in steel mills

Year

2024

Customer

Aubert et Duval

Location

France

Typology

Steelworks

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

Assessing the suitability of the ventilation system for roof renovation projects

EOLIOS is carrying out a project for the Aubert et Duval steelworks, involving a study of the sizing and location of a new static ventilator on the roof. The main objective is to ensure efficient ventilation of the steelworks by determining the optimal dimensions of the ventilator. This will make it possible to comply with pollutant emission standards,optimize aeraulic and thermal comfort, andimprove air quality.

The study also includes an in-depth analysis of air movements in the steel mill to better understand the distribution of dust and smoke generated by industrial operations. This analysis will enable us toassess the impact of the aerator on the dispersion of these particles, and to propose pollution prevention and control measures.

The results of this study will be essential in defining the exact dimensions of the aerator and its optimal position on the roof. What’s more, they will enable us to formulate recommendations to limit the dispersion of dust and smoke, thus guaranteeing better air quality and reducing pollution risks.

It should be noted that the study takes into account several different scenarios, with different configurations and airflows. The objectives of the study are therefore to size the aerator to suit each scenariowhile complying with emission standards and improving air quality

Preliminary measurements for thermo-aerodynamic analysis

Use of smoke tests and temperature measurements to assess air circulation in the plant

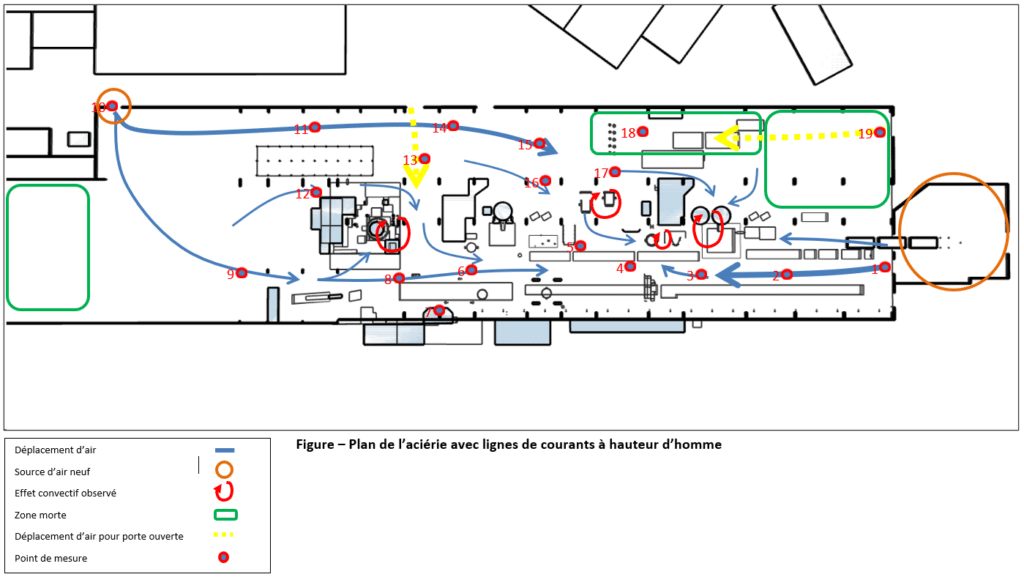

In the course of the study carried out for the Aubert et Duval steel mill, several activities were carried out to gain an understanding of the site’s thermoaerulic phenomena.

An overall tour of the plant enabled us to visualize the different processes and understand the specific issues.

Surveys were carried out to determine the location and dimensions of the louvers and openings in the steel mill’s three halls.

From thermal images were taken to measure wall temperaturewhile measurements were taken to 3D modelling of missing parts.

Smoke tests for in-depth analysis of on-site air flows

Smoke tests have become an essential tool for assessing thermoaerulic phenomena on industrial sites. These tests enable air flows to be visualized andany stagnation zones to be identified, providing a precise analysis of air circulation in a given environment.

Illustration of the smoke test campaign

These smoke tests play a key role in theanalysis of the site’sthermoaerodynamic phenomena. They enable us toidentify sensitive points and propose appropriate solutions to improve air circulation and the quality of the thermal environment.

Carried out recently on the industrial site, these tests highlighted the different air paths, from the heat source to the ventilation outlets, via all the building’s components. Thanks to these observations, the engineers were able to identify hot spots and areas where the air was poorly ventilated.

Special fumes were used to carry out these tests. These were generated from a non-polluting water- and glycol-based liquid, guaranteeing harmlessness for the environment and the health of people on site.

The results detected areas where the air was stagnant, creating hot draughts and unpleasant microclimates for workers.

Thanks to this information, improvements have been made to the site’s ventilation, creating a safer, more pleasant working environment.

Thermal image analysis to identify heat sources

Thermal images were then used to highlight the main sources of thermal phenomena and the various zones of varying heat density.

The measured temperatures were compared with the results of the CFD simulations to verify their consistency. The emissivity of the various surfaces was taken into account when estimating temperatures.

Infrared thermography of heat sources in the plant

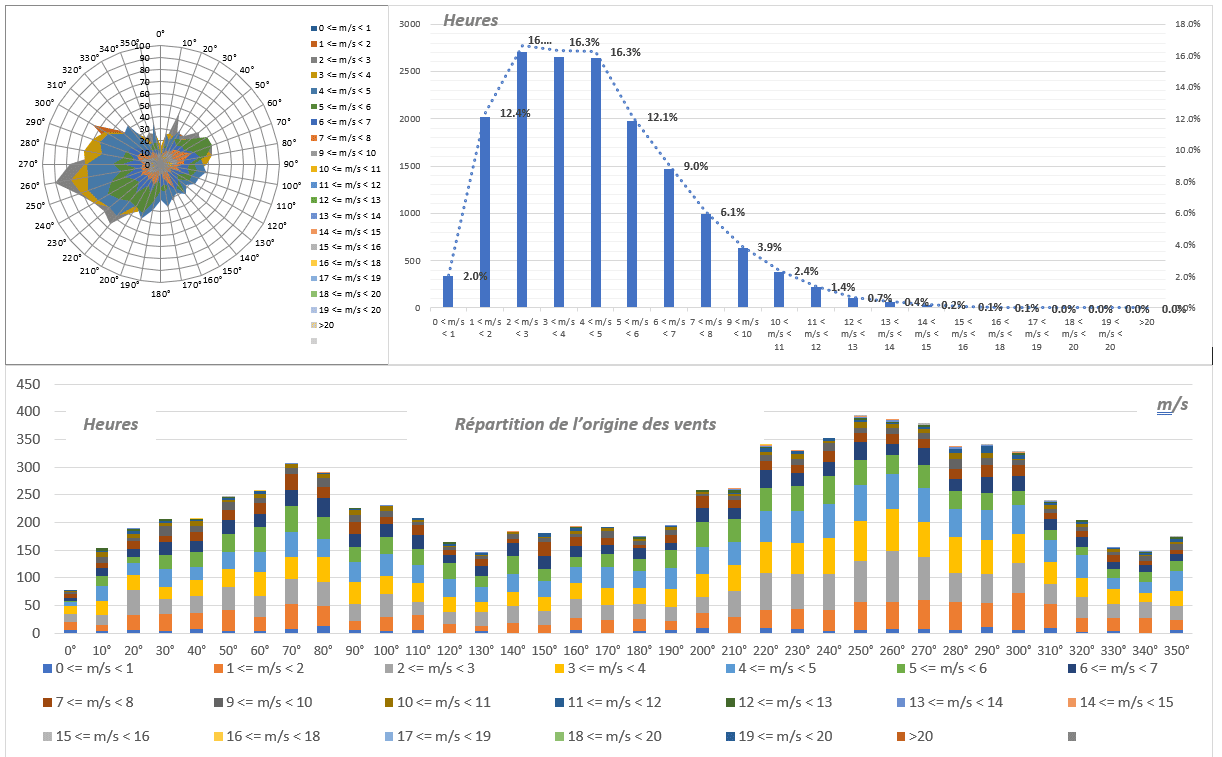

Weather analysis

During two site visits, the outdoor weather conditions were recorded, to serve as a basis for the basic simulations. Next, meteorological data from the nearest weather station to the site were collected over a 12-month period.

This precise information on the weather records will enable us to select the appropriate climatic conditions according to the objectives of the study. The conditions recorded during the second visit were used for the first modeling run to confirm the correct implementation of the conditions in the model.

Information collected includes wind speed and direction, as well as average minimum temperature in winter and average maximum temperature in summer. In addition, the most extreme temperature peaks recorded are also taken into account.

This data plays a crucial role in adapting ventilation strategies to ensure optimum comfort for plant operators all year round.

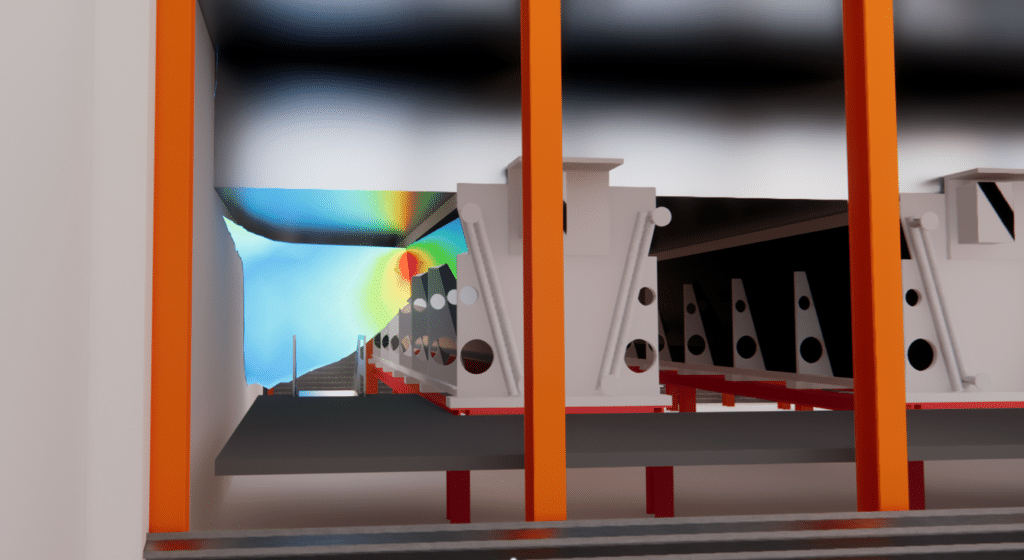

CFD numerical simulation of thermal conditions in the plant

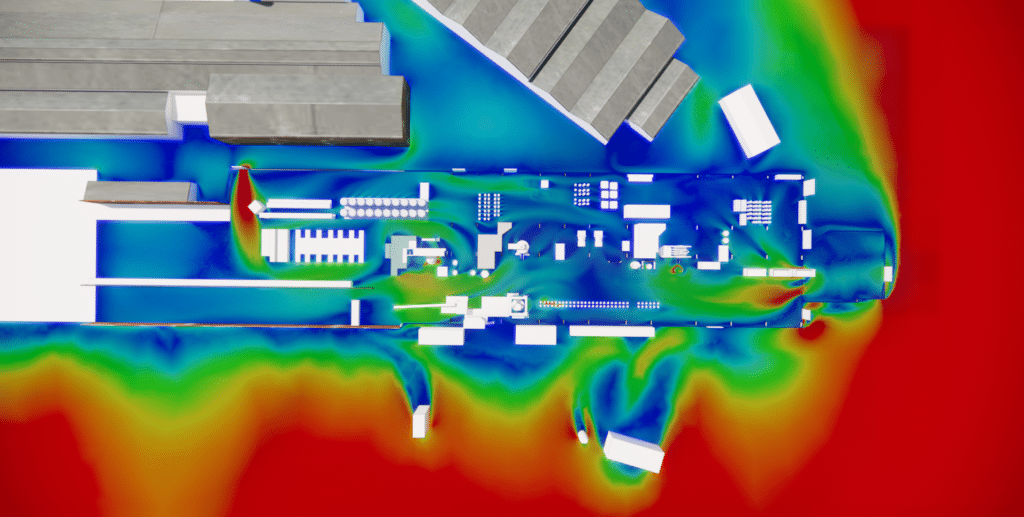

Creation of a 3D digital model of the plant

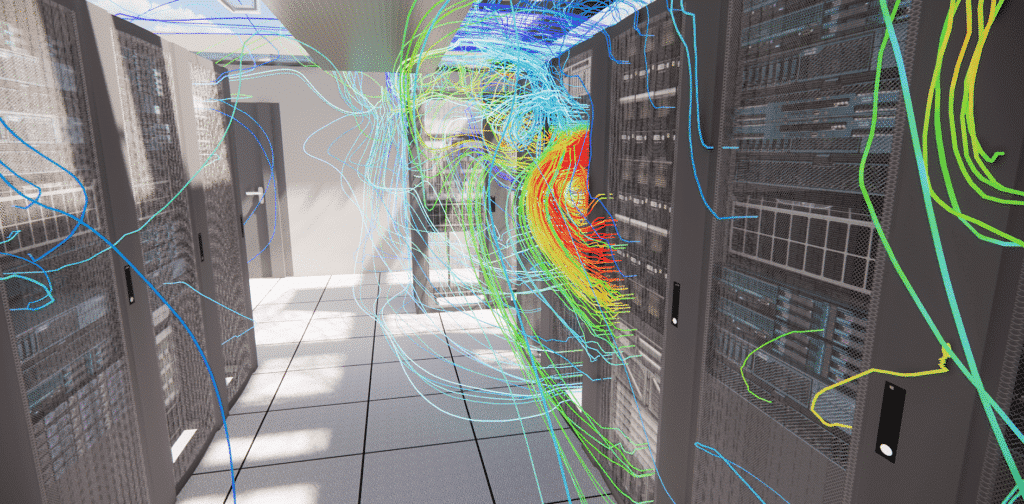

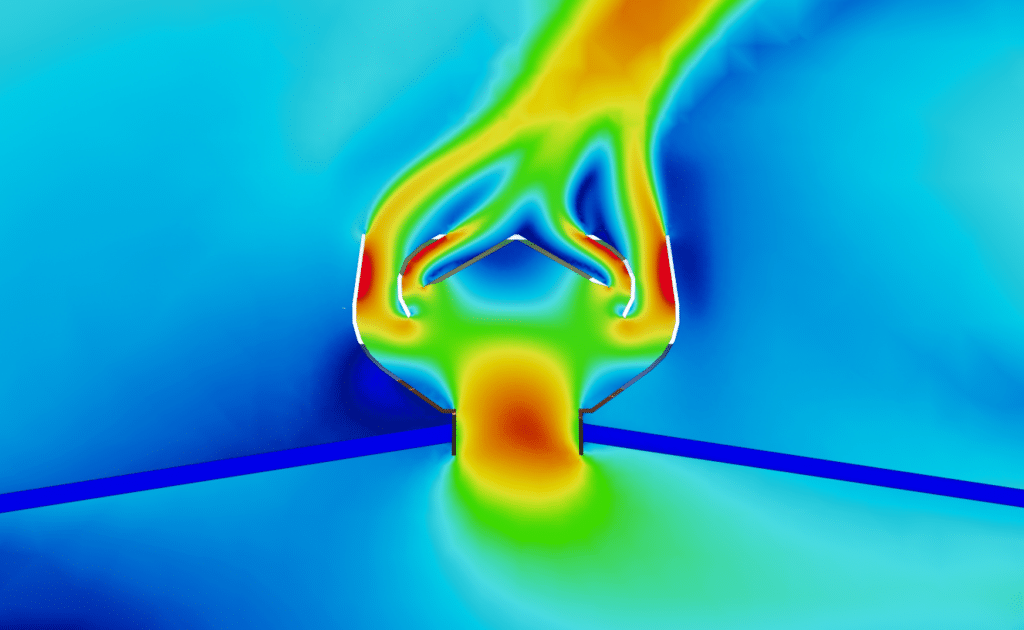

The simulation was carried out using CFD (Computational Fluid Dynamics), a method for analyzing and predicting the movements of fluids such as air and gases. This virtual approach simulates thermoaerodynamic phenomena in the steel mill, taking into account interactions between different surfaces, heat sources and air flows. Thanks to CFD, flows, temperatures and gas concentrations can be visualized and analyzed in detail, contributing to a better understanding of processes and optimizing plant performance and safety.

Geometric modeling is a key step in CFD simulations.

It enables us to accurately represent the geometry of the site or building under study, and to define boundary conditions such as walls, openings to the outside, and internal heat gains.

Geometric modeling also simplifies the model by eliminating irrelevant elements, making it easier tointerpret the results.

CFD simulation

The simulation was carried out using CFD (Computational Fluid Dynamics), a method for analyzing and predicting the movements of fluids such as air and gases. This virtual approach simulates thermoaerodynamic phenomena in the steel mill, taking into account interactions between different surfaces, heat sources and air flows. Thanks to CFD, flows, temperatures and gas concentrations can be visualized and analyzed in detail, contributing to a better understanding of processes and optimizing plant performance and safety.

The simulation was carried out using CFD (Computational Fluid Dynamics), a method for analyzing and predicting the movements of fluids such as air and gases. This virtual approach simulates thermoaerodynamic phenomena in the steel mill, taking into account interactions between different surfaces, heat sources and air flows. Thanks to CFD, flows, temperatures and gas concentrations can be visualized and analyzed in detail, contributing to a better understanding of processes and optimizing plant performance and safety.

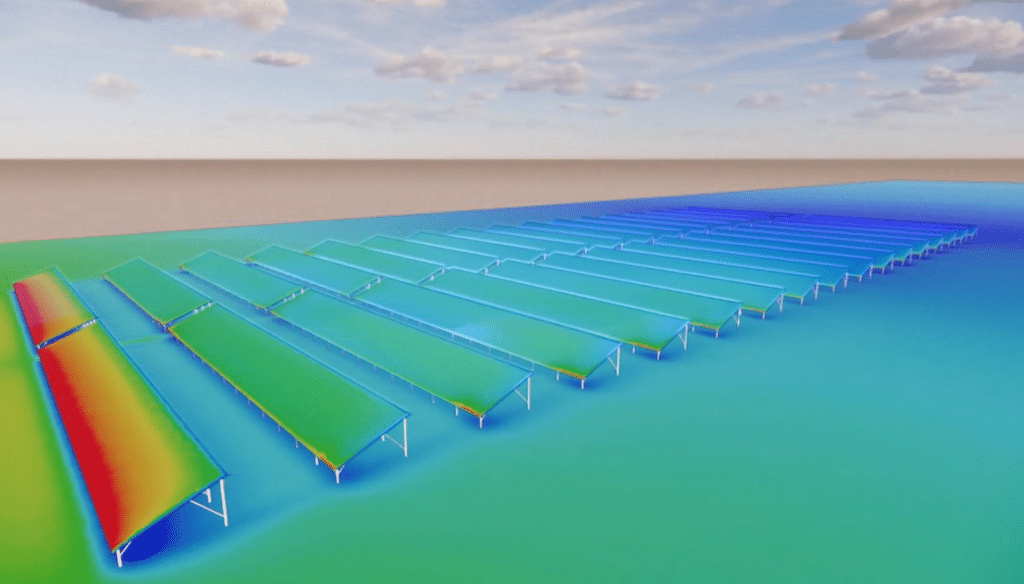

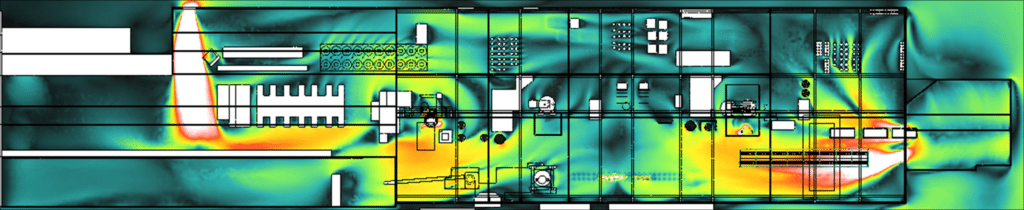

Visualization of CFD simulations for natural ventilation optimization

In the context of buildings, CFD is used to study air velocities, pressures and temperatures in and around construction spaces. This provides a better understanding of aeraulic and thermal conditions, particularly for the design of ventilation and air-conditioning systems. CFD simulations are particularly useful for improving indoor comfort by optimizing air flows, thus contributing to greater energy efficiency and occupant well-being.

CFD simulation of natural ventilation

Study of air velocity distribution according to different natural ventilation modes

In this study, two configurations were examined to assess the effectiveness of dust extraction in the case of the open-door furnace. The first configuration was the basic one, while the second included the addition of static aerators and the closure of the inappropriate ventelle.

The results showed that in the second situation, dust extraction was much higher than in the basic configuration, enabling faster evacuation closer to the source of emission. This helps ensure a cleaner, safer working environment.

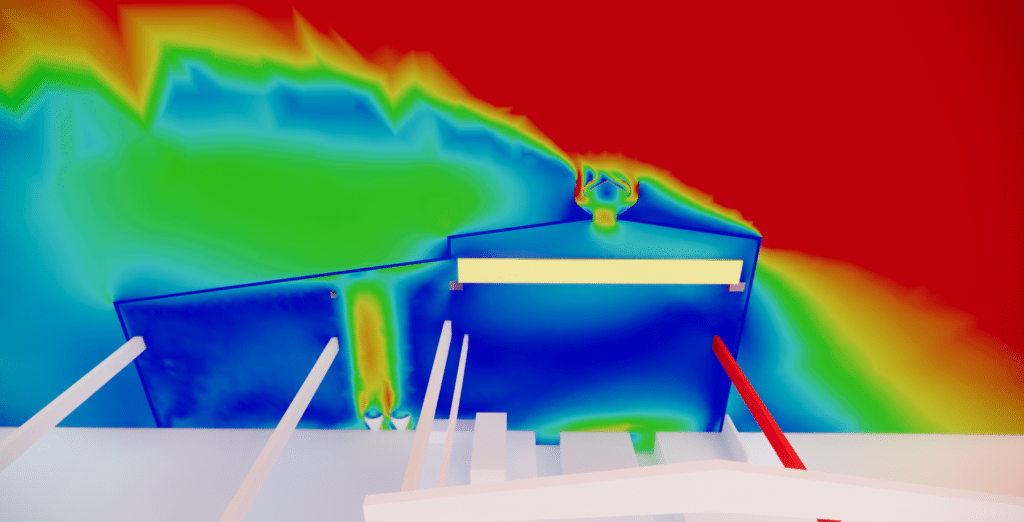

Study of thermal plumes

One of the main challenges of this study is to understand how heat is distributed within the plant and how it affects the different work areas. It is necessary to identify areas where temperatures can be excessively high, and to put in place measures to mitigate the impact of heat on employees.

"The importance of the correct placement of ventilation openings: Strategy to promote efficient thermal draft and optimal hot air evacuation".

A study of the plant’s initial configuration revealed poor air circulation in certain areas, resulting in high temperatures. This can be due to factors such as the location of heat sources, the layout of equipment or air circulation in the space. The addition of static aerators in the second configuration remedied this problem.

These aerators helped to increase air circulation throughout the plant by facilitating the evacuation of hot air and encouraging the entry of fresh air. This has had two beneficial effects. Firstly, the homogenization of air velocities has reduced areas of low circulation, contributing to better heat distribution in the plant. This has led to a reduction in temperature amplitudes between the different work zones, improving thermal comfort for employees. In addition, temperature homogenization has reduced high temperatures, particularly in summer conditions, when outside temperatures can be higher.

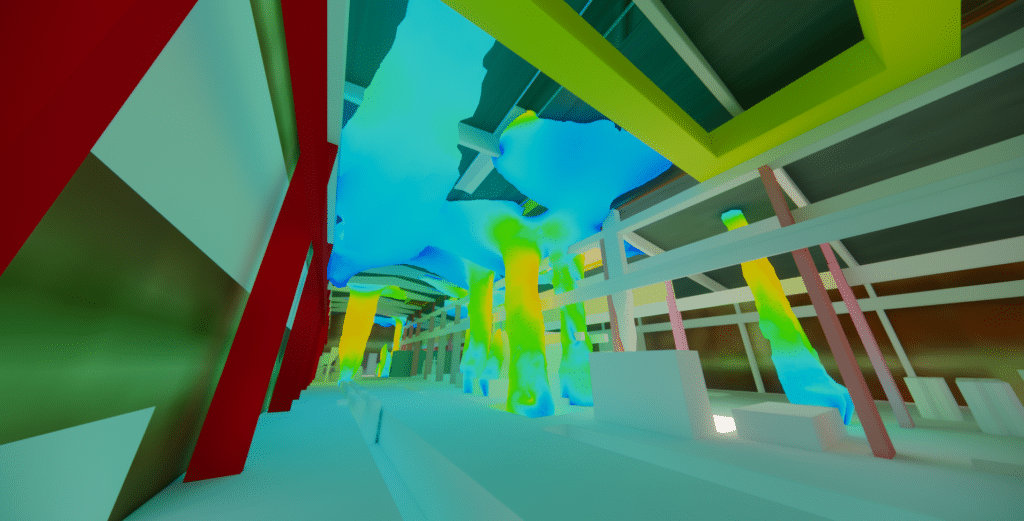

Dust and pollutant distribution study

The study of dust and pollutant distribution in the plant highlighted the effectiveness of evacuation systems such as static aerators and hoods. These devices are designed to reduce the presence of dust and pollutants in the plant air. The plant’s initial configuration showed high concentrations of dust and pollutants, mainly in the vicinity of the furnaces. However, in the rest of the plant, dust and pollutant concentrations were relatively uniform.

The second configuration improved the dispersion of air movements in the lower part of the plant, reducing areas of high dust and pollutant concentration. This suggests that optimizing the evacuation systems has contributed to a better distribution of particles and pollutants throughout the plant, enabling easier evacuation. These results underline the importance of proper design of plant exhaust and ventilation systems. By identifying the main sources of dust and pollutants, it is possible to set up effective collection and evacuation systems to reduce their dispersion in the plant air.

Study of the evolution of the neutral pressure plane according to different natural ventilation configurations

Neutral pressure plans play a crucial role in the design of natural ventilation systems for buildings. They are used to determine the strategic locations where air inlet and outlet openings should be placed to optimize air circulation. A neutral pressure plane is an imaginary surface within the ventilated space where static pressure is balanced. This means that the forces exerted by the air entering and leaving this area are equal. In most cases, air inlet openings are located at the bottom of the ventilated space, where the pressure is higher.

The higher pressure is generally due to temperature differences between inside and outside the building, as well as air density. These inlet openings allow fresh air to enter the ventilated space. On the other hand, the air outlet openings are located at the top, where the pressure is lower. This is attributed to the difference in height between the inlet and outlet openings, as well as to air currents created by external factors such as wind.

Evolution of neutral pressure plane according to different ventilation configurations

By positioning the outlet openings at the top of the ventilated space, stale air is evacuated more efficientlythus guaranteeing better indoor air quality. Respecting neutral pressure planes, designers can ensure effective natural ventilation and uniform distribution of fresh air throughout the space.

Sizing static aerators

The simulations then included the installation of a new carpenter aerator above furnace 8. Simulation results showed that the newly added carpenter aerator had a significant impact on air flows. The flow directed from furnace 8 to the small carpenter aerators already present disappears.

In terms of temperature distribution, the results show a distribution similar to that of the previous scenarios, but with a clear drop in temperature under the roof thanks to the presence of the carpenter aerator.

The temperature under the roof thanks torapid evacuation of warm air charged with calories by the carpenter aerator. The results also show that the total extraction rate remains globally constantwith a slight increase compared with the existing configuration. These results demonstrate the effectiveness of the carpenter aerator added above furnace 8 for rapidly evacuate calorie-laden hot air. This modification therefore contributes to improve airflow and thermal conditions in the building.

Summary of plant thermo-aerodynamic analysis

Analysis of thermal conditions: Identification of risk zones and recommendations for improving worker comfort

Theaim of the study was to size and position the new static ventilation system on the steelworks roof. It also sought to map air movements and temperature distribution throughout the steel mill, as well as analyze dust/smoke distribution at the aerator.

Velocity planes at ground level showed a relatively uniform distribution, independent of external conditions. Convective motion caused by hot elements such as furnaces, third-party ingots, slag pans and ladles is the main aeraulic engine of the steel mill.

At the static aerator (Robertson), velocity patterns demonstrated efficient evacuation along its entire length, with a relatively uniform distribution.

The distribution of pollutants in the static aerator section revealed a zone of high concentration slightly offset towards the furnace, while the rest of the Robertson showed a uniform distribution, independent of its geometry.

The study carried out by EOLIOS provided valuable recommendations for sizing and optimizing the steel mill’s static aeration system. These recommendations will ensure better ventilation, effective dust/smoke dispersion and an overall improvement in the indoor climate. This will help improve employee comfort, maintain facilities in optimum condition and comply with current environmental standards.

Continue on this topic

Video summary of the study

Summary of the study

EOLIOS is carrying out a sizing and location study for a new static ventilator on the roof of the Aubert et Duval steel mill. The aim is to ensure efficient ventilation of the steelworks, while complying with pollutant emission standards and improving air quality. The study includes an in-depth analysis of air movements in the steel mill to understand the distribution of dust and smoke generated by industrial operations. Smoke tests and thermal images are used to assess air circulation and identify sensitive points. The results of the study will be used to define the optimum dimensions of the ventilator and its optimal location on the roof, as well as to formulate recommendations for limiting the dispersion of dust and smoke. CFD simulations are also carried out to analyze fluid movements and optimize natural ventilation.

Video summary of the mission

Discover other projects

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods