Accueil » Industries » Glassware » Glassworks – Cognac

Glassworks – Cognac

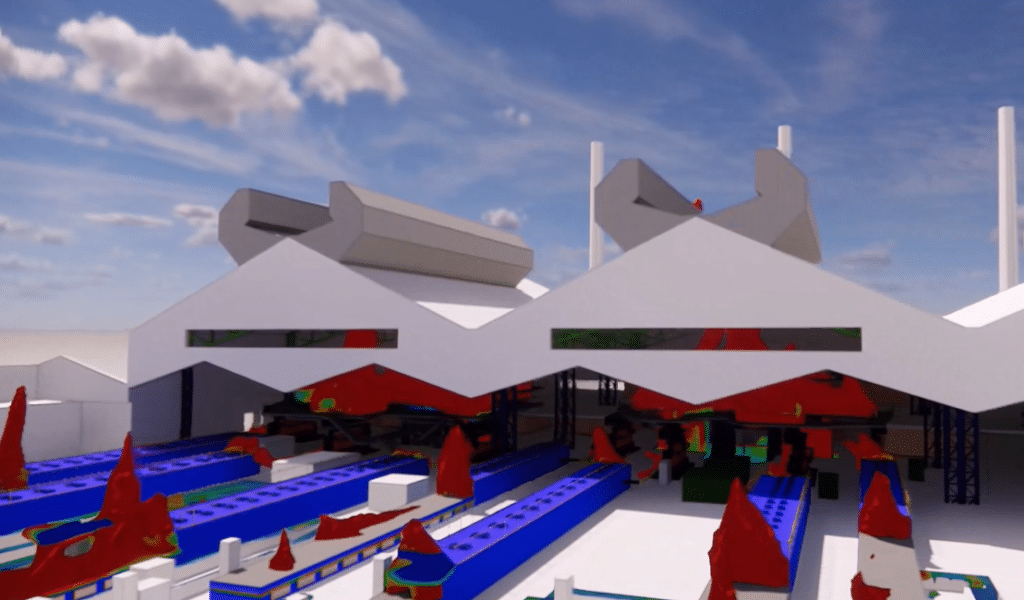

Optimizing thermal comfort for operators at the Verallia Cognac plant

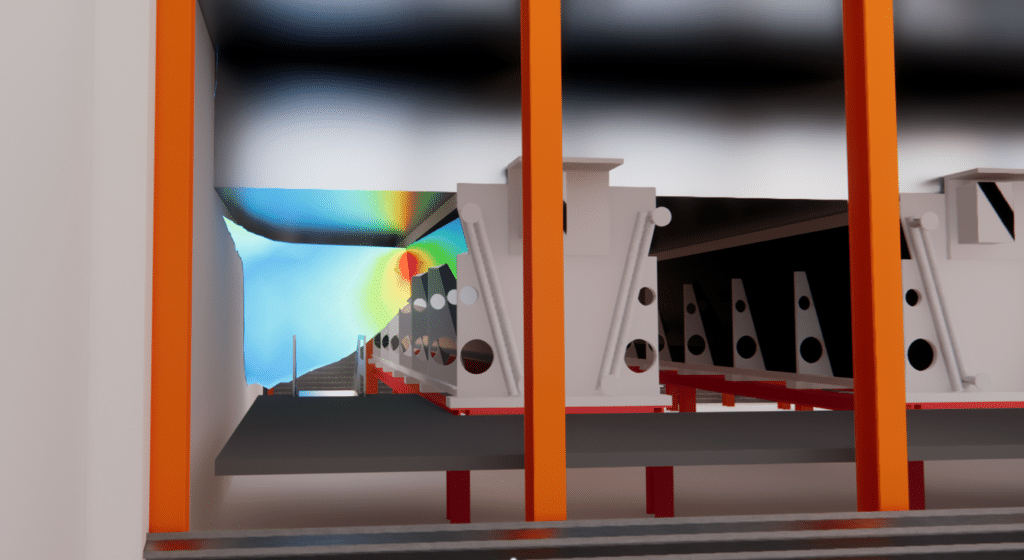

Themain aim of the study is to implement solutions to optimize thermal comfort for operators around their workstations, in both the cold and warm ends of the plant. This also includes optimizing energy consumption linked to the plant’s climate management. Particular attention is paid to the design of specific air inlets when replacing a gas furnace with an electric one.

A secondary objective is to limit the effects of draughts in sensitive process areas, which can have a negative impact on production operations and cause recurring faults.

The complexity of thermal-air phenomena in dimensioning is due to numerous factors such as radiant wall temperatures, thermal draught, wind pressure, internal resistance to vertical air flow, characteristics of building envelope openings, local terrain and wind protection. In this environment, where the building is not thermally regulated, room control is mainly achieved by supplying fresh air via natural draught to static roof ventilators and forced ventilation (extraction or insufflation).

Verrerie de Cognac

Year

2024

Customer

Location

France

Typology

Verrerie

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

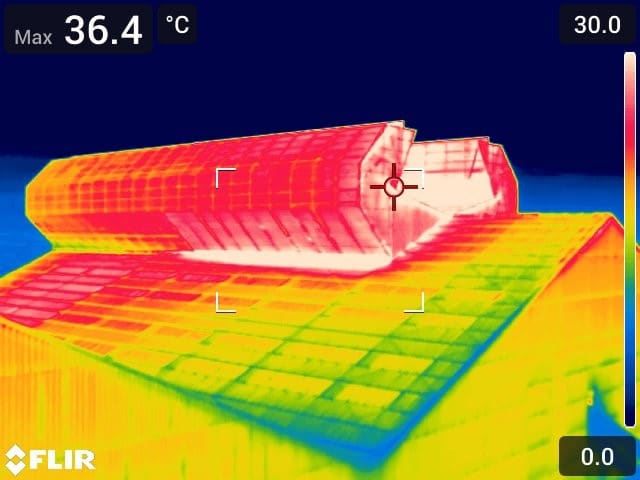

Preliminary measurements for thermo-aerodynamic analysis

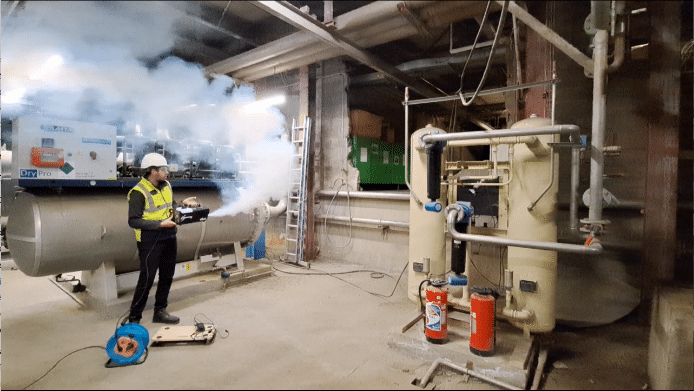

Thermo-aerodynamic audit of the site

Theaeraulic audit highlighted areas where improvements are needed to optimize ventilation, temperature and air quality in the plant. Recommendations were formulated to remedy the problems detected and thus improve working conditions for operators and the energy efficiency of installations.

Smoke audit of systems

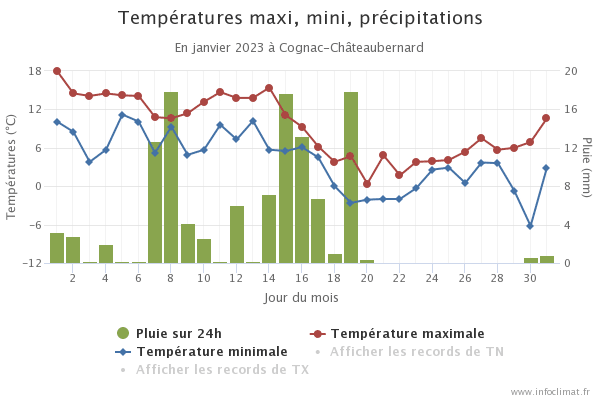

Weather analysis

Climatological data from the Cognac-Châteaubernard weather station are used to define the outdoor climatic conditions required to study the plant’s ventilation systems.

Wind speed and direction, mean minimum temperature in winter and mean maximum temperature in summer were recorded, along with the most extreme temperature peaks reached.

This data is essential for determining actual climatic conditions and adapting ventilation and air-conditioning strategies toensure the comfort of plant operators all year round.

CFD study of thermal-air phenomena in the plant

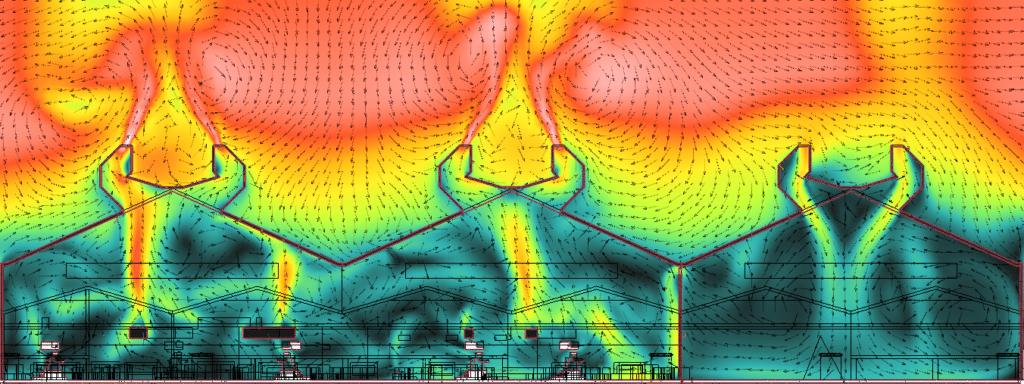

Numerical simulation of air movements and temperatures

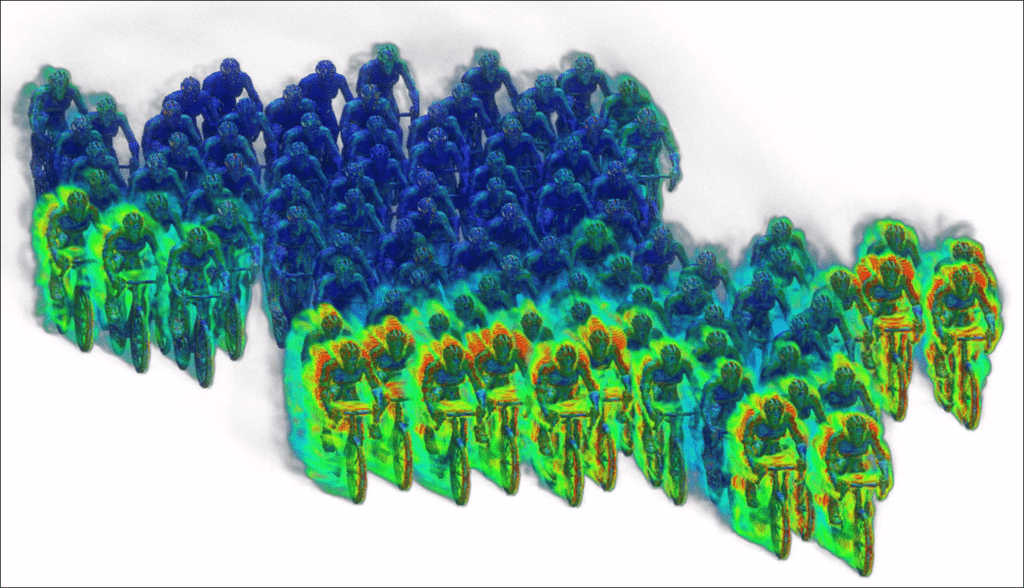

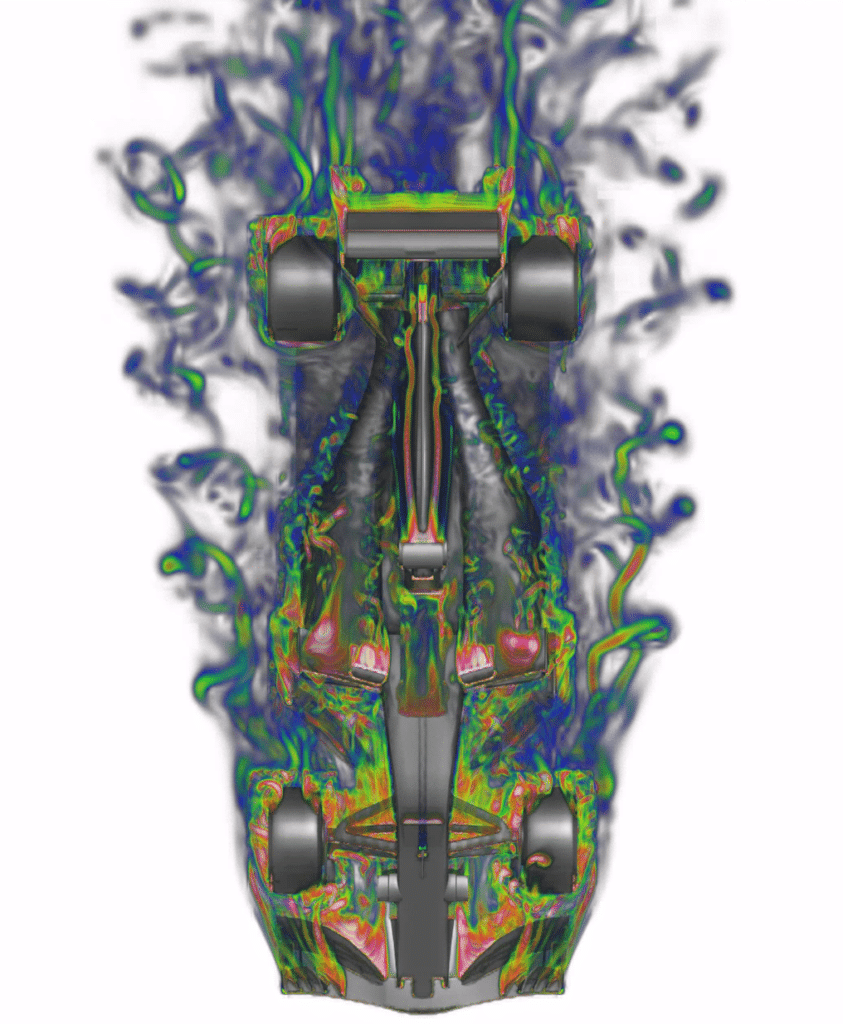

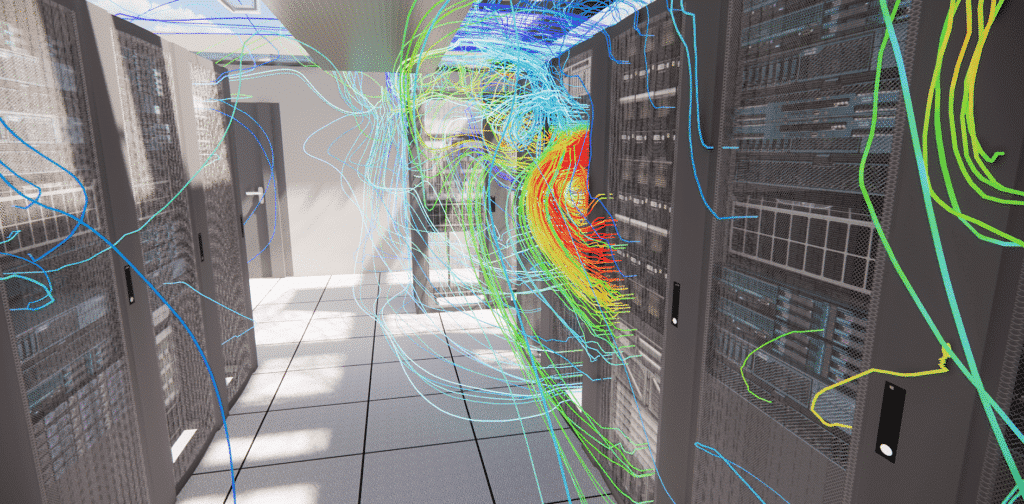

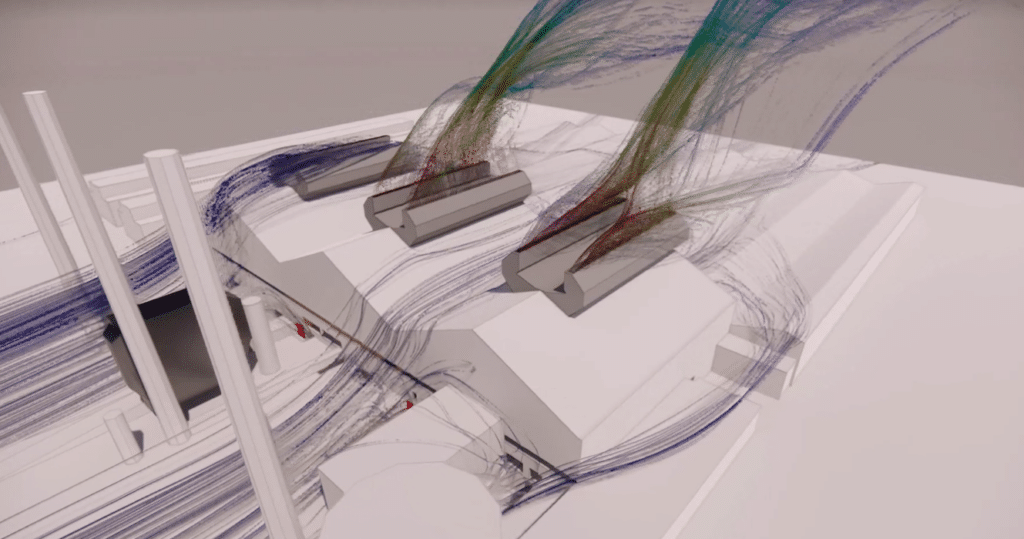

Computational Fluid Dynamics (CFD) covers all the numerical methods used to study fluid flows in a given environment. The equations governing these flows cannot be solved analytically, so the finite element method is used to solve them numerically.

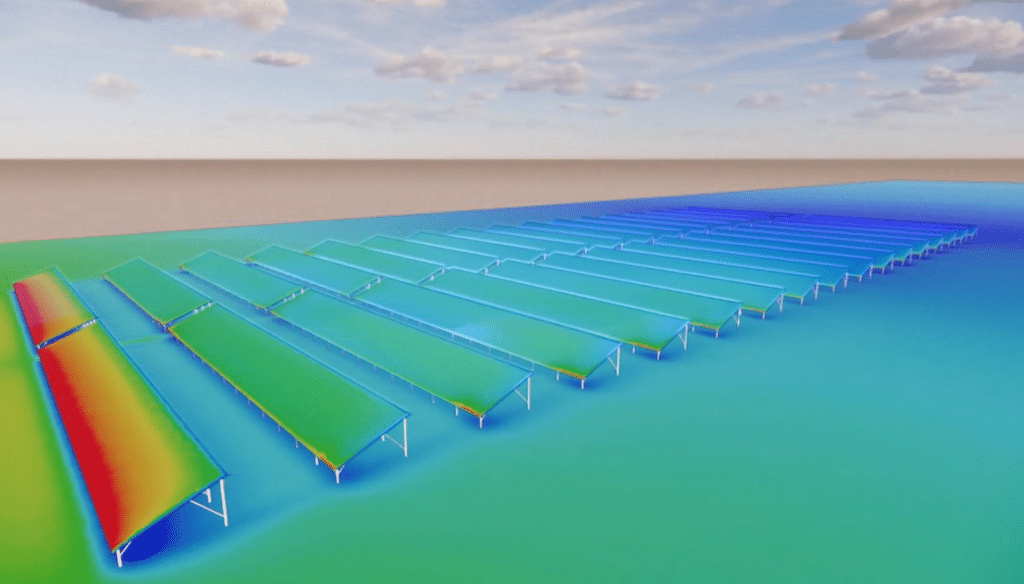

In the building sector, a CFD study can provide designers with precise information on the air velocities, pressures and temperatures that will occur in and around the systems under study. This type of study is particularly useful for studying the design of ventilation and air-conditioning systems in large spaces. Theyoptimize interior comfort by checking that air inlets and outlets ensure adequate ventilation of the volume, guaranteeing optimum comfort for occupants. These simulations are essential for effective design, helping to improve energy efficiency and user well-being.

As part of the study, a 3D model was created from the plans and sections provided, including the geometry of the site and its surroundings within a 300-meter radius. For this study, wall types, surfaces open to the outside, supply and return air points, and any system identified during the audit that rejects heat into the space, are accurately modeled and taken into account.

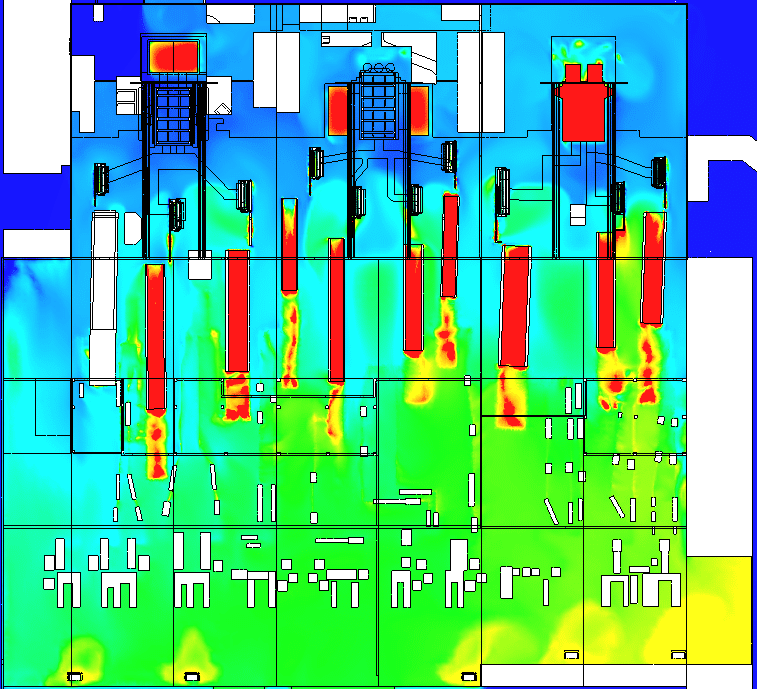

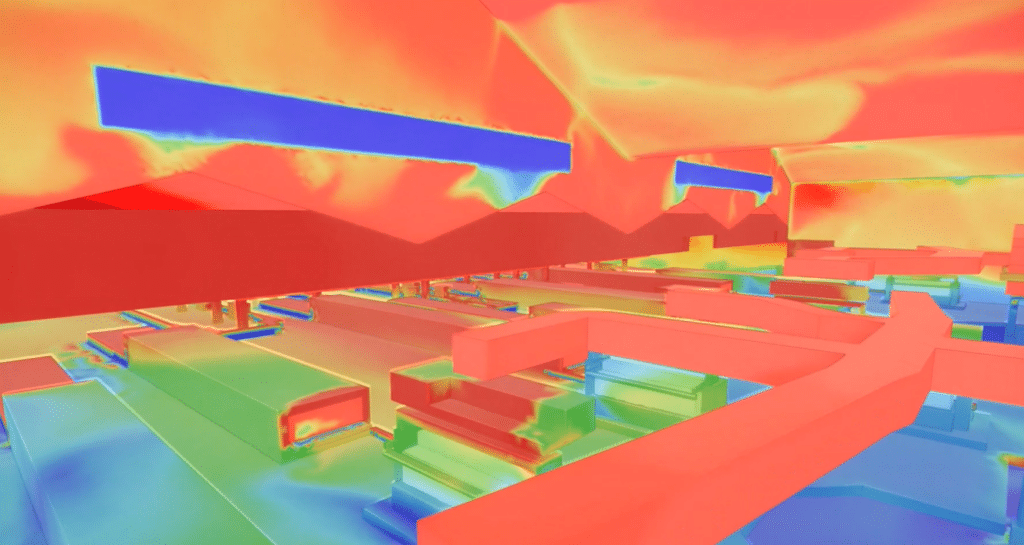

Identifying sources of thermal discomfort

After checking the accuracy andefficiency of the simulation model used for the CFD study, by comparing the initial results with the measurements taken on site during the audit, simulations are carried out on the plant’s current configuration in winter conditions. It appears thatshutting down the gas furnace reduces the thermal draught, so thestatic aerator enters the air intake and brings in fresh air and pollutants, as well as disrupting air flows in the plant.

What’s more, our studies have also shown that the main problems for operators’ thermal comfort stem from the lack of regulation on the ventelles, generating undesirable air intakes in winter. Another cause of these problems is theconsiderable opening between the hot end and the cold end, creating large air displacements between one and the other, greatly disrupting the air flows of the cold end heating systems, resulting in dead zones and discomfort for operators.

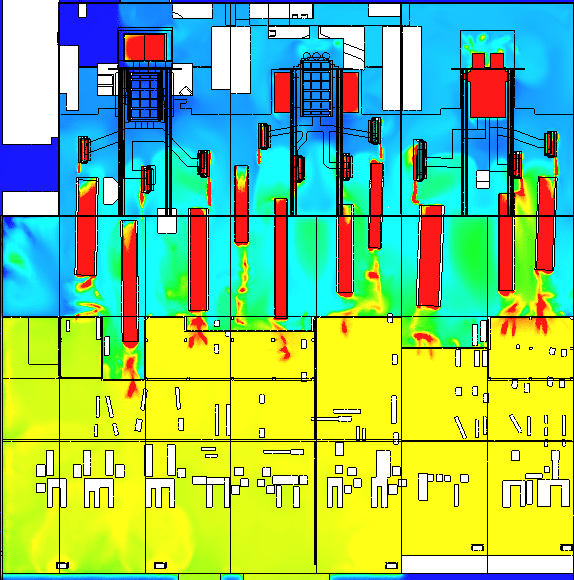

Optimizing existing design to improve winter thermal comfort

A new winter simulation was carried out, involving the addition of solutions to block the propagation of fresh air entering through the vents, as well as partitioning to separate the warm end from the cold end more effectively. This simulation shows a clear improvement in the efficiency of the heating systems in the area where the operators work, thanks to the technical solutions proposed.

A further simulation also showed that, when the new electric furnace is activated, the thermal draught is sufficient for thestatic aerator to operate correctlyin air extraction mode, eliminating the parasitic air flow previously generated in the work area.

Optimize summer ventilation to prevent heat stagnation

Climatological data from the Dunkirk meteorological station are of vital importance in defining the outdoor climatic conditions required to study the plant’s ventilation systems. Information collected includes wind speed and direction, as well as average minimum temperature in winter and average maximum temperature in summer.

In addition, the most extreme temperature peaks recorded are also taken into account. This data plays a crucial role in adapting ventilation and air-conditioning strategies to ensure optimum comfort for plant operators all year round.

Energy optimization for a glass factory building

This type of CFD study on building thermoaerodynamics can greatly improveenergy efficiency by minimizing energy losses and maximizing the use of the heat generated, thus improving the overall energy performance of the production process. There are many advantages tooptimizing the energy efficiency of a glass factory building. First and foremost, this reduces energy costs by optimizing installations, heating processes and heat exchange between the hot and cold ends, thus saving on the energy bill for heating the cold end.

Energy optimization also helps to reduce greenhouse gas emissions by lowering energy demand and limiting emissions of CO2 and other pollutants from fossil fuel combustion. Finally,improving the company’senvironmental sustainability throughenergy optimization measures helps to meet the expectations of customers and stakeholders in terms of sustainable practices, thus strengthening the company’s image.Energy optimization at a glassworks therefore offers significant benefits in both economic and environmental terms.

Continue on this topic

Video summary of the glassworks CFD study

Summary of the study to optimize air quality and thermal comfort for operators

The study aims to improve thermal comfort for operators while enhancingenergy efficiency. The transition from gas to electric furnaces is planned to optimize thermal conditions. Reducing draughts in sensitive areas is an additional objective to avoid disruption to production.

All the complexities of thermoaerulic phenomena are studied, taking into account factors such as wall temperatures, thermal draught and wind pressure. In this thermally unregulated context, the supply of fresh air via roof vents and forced ventilation are key strategies for regulating the environment.

Video summary of the mission

Discover other projects

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods