Home » HVAC » Climatic engineering of high rise premises » Heating/Cooling system design for a pharmaceutical plant

Heating/Cooling system design for a pharmaceutical plant

Energy optimization and thermal comfort: renovation of a pharmaceutical plant

As part of the renovation of a pharmaceutical plant, our study uses an innovative CFD (Computational Fluid Dynamics) simulation approach to transform energy challenges into opportunities for sustainable performance. Dynamic thermal simulation (DTS ) plays a central role in precisely quantifying the impact of architectural design on heating requirements and thermal comfort, particularly during the summer season.

The main objectives of this analysis include thedetailed estimation of energy requirements, theassessment of specific winter and summerclimatic conditions, as well as thedevelopment of suitabletechnical solutions to improve comfort. The project is being carried out in several phases, and involves the progressive replacement of various machines in order to optimize industrial processes. The study aims to dimension a technical solution that creates an optimal thermal environment for employees, while guaranteeing superior energy efficiency and an eco-responsible approach. Thanks to our expertise in CFD simulations, we are committed to delivering innovative and sustainable solutions for the industrial sector.

Conception du système Chauffage/Climatisation d'une usine pharmaceutique

Year

2025

Customer

NC

Location

France

Typology

Génie Climatique

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

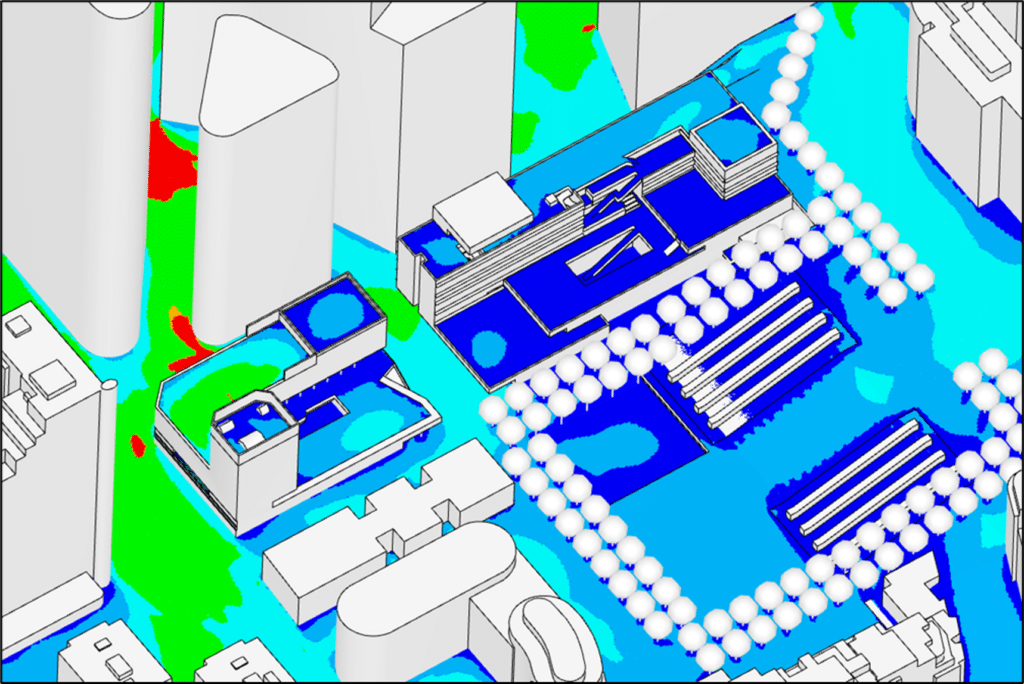

Using meteorological data for increasingly accurate CFD simulations

The immersive use of CFD

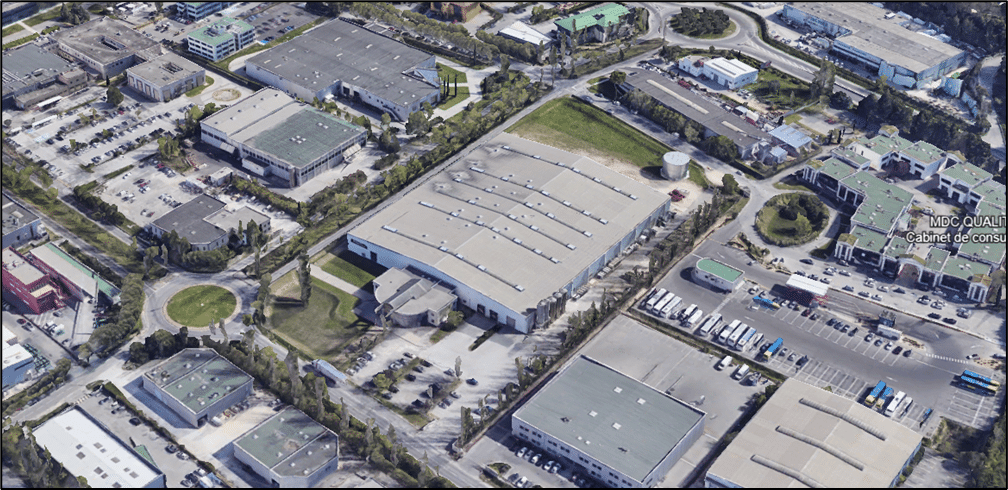

As part of the renovation of the pharmaceutical plant, the immersive use of CFD simulation relies on reliable and representative meteorological data, taken from the nearby town of Carnoux-en-Provence. This information, supplied by infoclimat®, forms the basis of our reference climate model, ensuring accurate analysis of thermal conditions throughout the year.

Our analysis is not limited to an overview. It also includes a detailed monthly inspection to differentiate between summer and winter conditions. By recreating a “real” climatic year, we include in our CFD simulations critical variations such as heat waves, episodes of intense cold and other exceptional events. This approach enables our solutions to respond optimally to the region’s climatic hazards, reinforcing our commitment toenergy efficiency and thermal comfort.

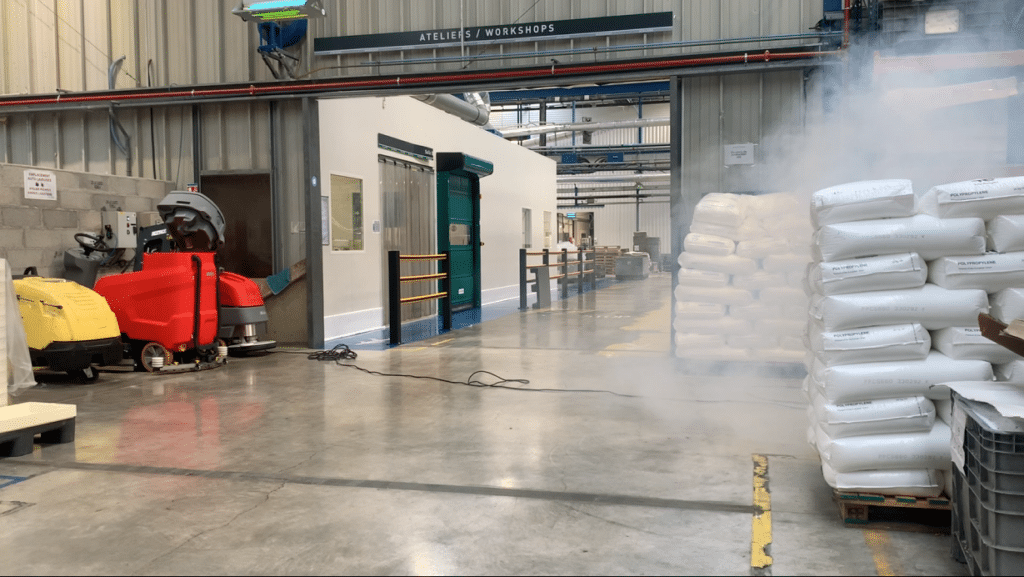

Audit - Thermal analysis and airtightness: Smoke tests and thermal tests

Carrying out smoke tests in support of CFD

As part of the energy renovation of the pharmaceuticalplant, we are using dynamic thermal simulations (DTS) and CFD (Computational Fluid Dynamics) modeling to assess the building’s energy performance and internal climate.

Smoke tests play a crucial role in this audit, enabling the visualization of aeraulic flows and the detection of unwanted air leaks within the plant. They identify areas ofair infiltration that could compromise the building’senergy efficiency. Thermal testing provides a detailed analysis of surface temperatures on machines and installations. This helps locate potential sources of heat loss or overheating. Together, these tests provide essential data for optimizing the CFD simulation model and improving the climate control system.

Thermal testing for simulation purposes

The thermal properties of the walls were deduced during the on-site audit with the aid of thermal tests, revealing a varied composition, ranging from breeze-block and sheet-metal internal walls to external walls with 5 cm of insulation. The ceiling and interior walls are structured to guarantee thermal insulation through the use of rock wool, complemented by a mechanical ventilation system and skylights. Inside the building,thermal inertia is mainly ensured by a concrete slab, significantly influencing the building’s response to temperature variations.Air-tightness is an essential feature, minimizing unwanted air flow, which is crucial to maintaining energy efficiency.

Internal heat gains, which have a direct impact on the risk of summer overheating, are mainly due to electrical equipment with high heat dissipation, notably the presses and theLED lighting systemtriggered by motion detection.

Survey of site climate control system configuration to improve CFD study parameterization accuracy

The audit also highlighted the importance of climate control systems, such as Air Handling Units (AHUs). Their configuration and placement are strategic for the supply of fresh air and necessary cooling, especially in the card and cleanroom areas, which require a rigorously controlled indoor climate due to their continuous operation. Press operation, heat build-up due to limited ventilation, and storage area doors are key air entry points influencing plant climate.

The data collected and the assumptions used for our thermal simulation underline the importance of a precise approach adapted to actual site conditions. This exhaustive analysis feeds our model to evaluate climate control solutions and guarantee an optimal, sustainable and energy-efficient working environment. We ensure that all critical information is completed in collaboration with the operator to fine-tuneenergy efficiency and improve comfort inside the plant.

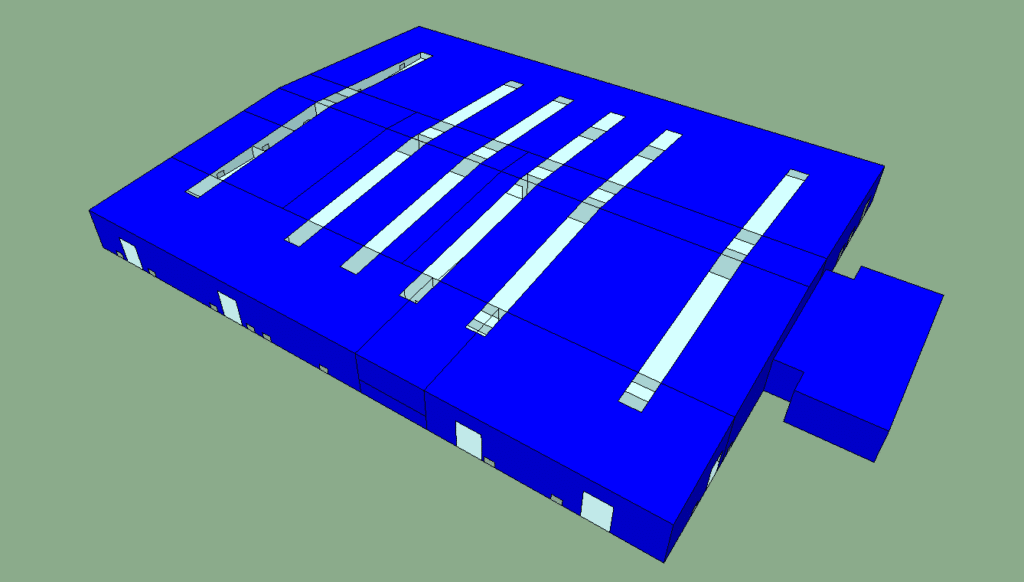

Dynamic thermal simulation (DTS): an essential tool for energy optimization

Advanced digital simulation for optimum thermal management of buildings

Dynamic thermal modeling (DTM ) is an essential IT tool for simulating and predicting a building’s thermal behavior throughout the year. By integrating complex interactions between the building, its heating, ventilation and air-conditioning (HVAC) systems, and the surrounding climatic conditions, this model provides an in-depth vision of energy performance.

Thanks to sophisticated mathematical equations and advanced algorithms, it accurately represents the physical characteristics of the building, such asfaçade orientation, thermal properties of materials, and theefficiency of HVAC systems.

The model also integrates crucial parameters such asinsulation,air tightness and internal heat sources, while taking into account natural or mechanical ventilation, solar gain and air infiltration. These invaluable simulations are used to optimize thermal comfort, reduce energy consumption and guarantee a sustainable, high-performance built environment.

STD study results: Impact of insulation and extractors on thermal performance

The STD study highlighted the significant impact of variations in roof insulation thickness and extractor management on the building’s energy performance. By adjusting the flow rate of the extractors as required, it was observed that the maximum reduction inoutside air extraction improved air-conditioning efficiency, resulting in a 36% gain in cooling capacity.

In addition, doubling thethickness of the insulation resulted in an additional 8.5% gain in cooling capacity. These modifications demonstrate that optimizinginsulation and the ventilation system can significantly reduce energy consumption and improve occupant comfort.

The study also recommended the application of a clear, reflective paint on the roof to further reduce the heat input from solar radiation, providing an additional energy gain of around 10%. These results underline the importance of integrated management of thermal systems to maximize theenergy efficiency of industrial buildings.

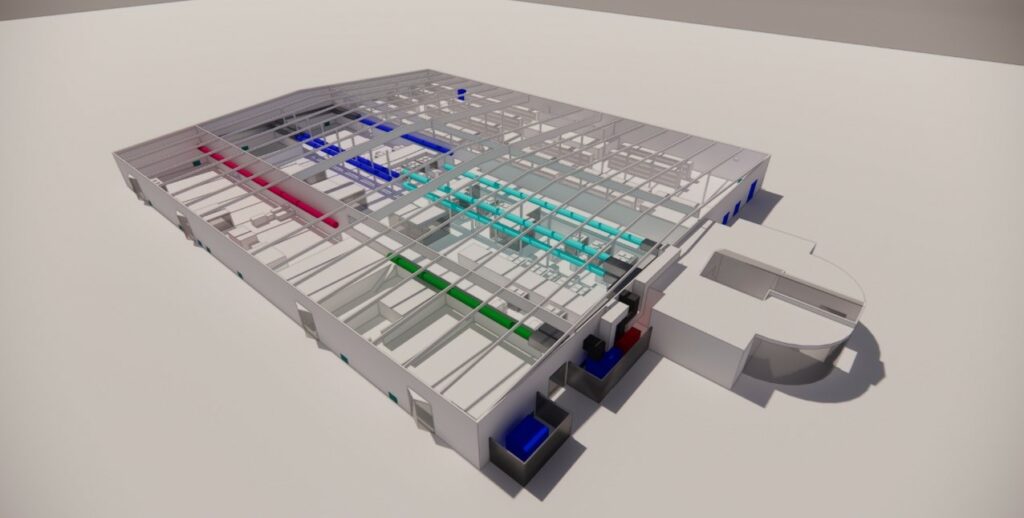

CFD modeling to improve aeraulic performance

Creating a digital twin - CFD basics

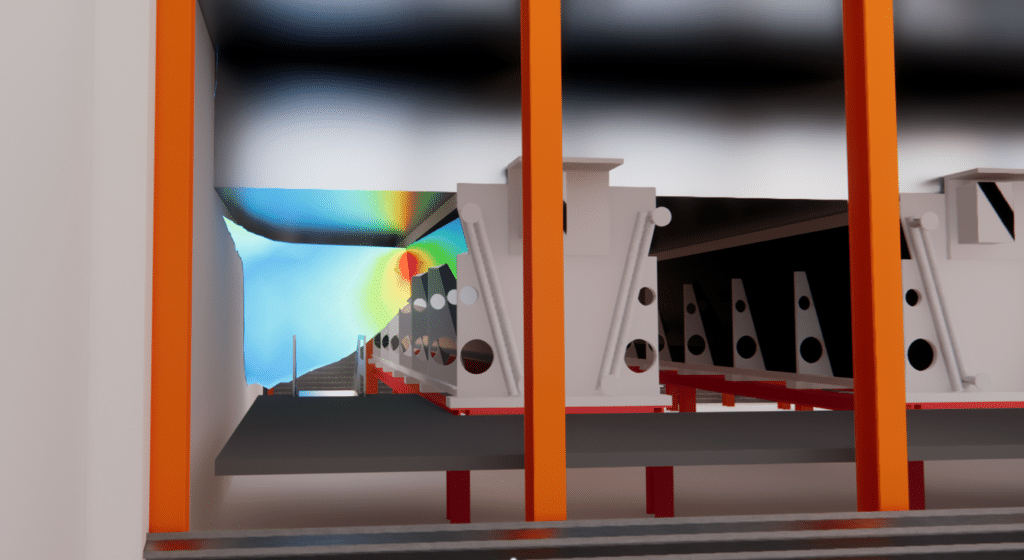

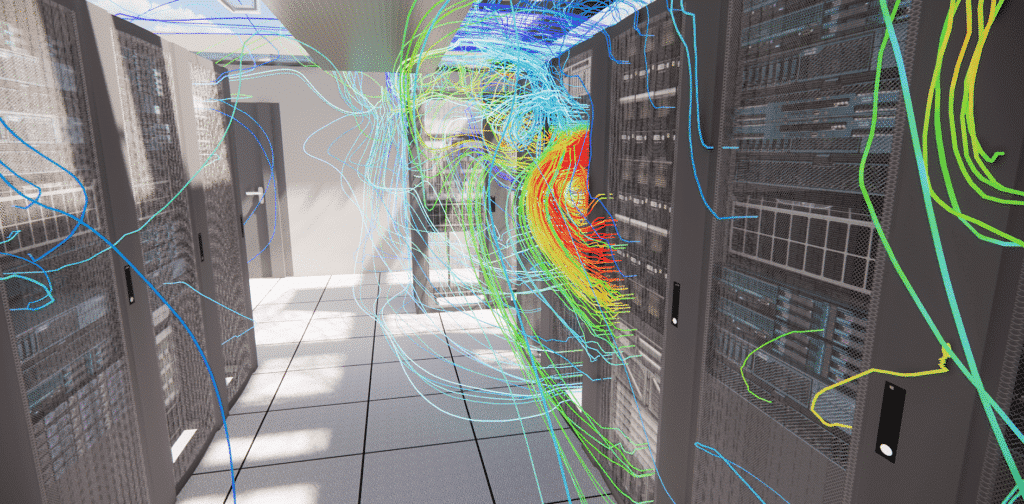

As part of the project, CFD focuses on simplifying the internal volume of the site by eliminating systems that do not directly affectaeraulics and temperature. This strategic approach pursues two major objectives: it enhances the accuracy of the model by lightening the computer load, and it concentrates the analysis on the decisive elements for ventilation and thermal management. By focusing on the essentials, the CFD model offers a more streamlined and accessible representation, enabling reliable and exploitable conclusions.

When modeling the internal volume, the resolution of the partial differential equations is conditioned by the rigorous establishment of boundary conditions. These are partly determined by the on-site measurement campaign and by information supplied by the project management teams. By anchoring calculations firmly to these parameters, CFD simulation becomes a powerful tool for optimizing the aeraulic and thermal performance of buildings.

Study of different ventilation scenarios: energy efficiency and plant comfort

The aim of the simulation was to design a technical solution to improve thermal comfort for workers, while optimizing the plant’senergy efficiency. To achieve this objective, ten nozzle ducts were installed in critical areas of the plant, where temperatures were excessively high in hot weather. Three distinct scenarios were tested, each with different configurations ofextractors and blowing temperatures.

In the first scenario, the extractors were operated at low speed with an average supply temperature. In the second scenario, the supply temperature was reduced, while the extractors were kept at low speed. In the third scenario, the extractors were shut down completely, with a lower discharge temperature. To ensure constant cooling performance, the supply air flow rate was adjusted for optimum supply temperature.

Analysis results and customized solutions with EOLIOS ingénierie

Velocity analysis revealed a homogeneous circulation of fresh air with no dead zones, particularly in clean rooms and mechanical areas. This optimization ensured uniform distribution of fresh air throughout the plant.

Thermal mapping of the first scenario identified three distinct zones: the map zone had the lowest temperature, followed by the clean rooms with a temperature around 2°C higher due to high machine density, and the storage zone, not equipped with ducts, with a temperature around 4°C higher than the map zone. These results suggest that a reduction in blowing temperature could further homogenize temperatures and lower those in the lower part.

The analysis also suggestsshutting down the extractors and closing the ventilators in the lower part of the plant to improve thermal comfort. Inside the cells, simulations show rather high temperatures, assuming perfect airtightness, which is pessimistic, as airtightness defects make thermal dispersion more likely. Finally, the blower ceilings show a relatively high inlet temperature, which could be optimized to further improve environmental comfort.

EOLIOS - Thermal management expertise for industrial renovation

At EOLIOS, we support you in the design and optimization of your plant’s cooling and ventilation systems, ensuring maximum energy efficiency and improved thermal comfort for your facilities. With our CFD expertise, we analyze thermoaerodynamics for optimal temperature management.

Thanks to our mastery of numerical simulations, we identify critical air flows and areas likely to create unwanted bypasses. By integrating these analyses, we guarantee homogeneous air distribution, reducing the risk of overheating in sensitive areas and improving theoperational efficiency of your systems.

We carry out rigorous assessments to validate and optimize the efficiency of your cooling systems, even in the most complex scenarios. This approach ensures the longevity and performance of your installations, enabling you to operate in optimal, sustainable conditions.

Continue on this topic

Video summary of the study

Summary of the study

The study aims to improve the thermal comfort andenergy efficiency of a pharmaceutical plant undergoing renovation. Using dynamic thermal simulation (DTS ) and CFD simulation, the building’s performance is accurately analyzed, integrating local climatic data. A thermal audit and smoke tests were carried out to identify heat loss and leaks. Several ventilation scenarios were tested, leading to technical recommendations such asoptimizing insulation, adjusting extractors and modifying supply air temperature. These solutions are designed to guarantee optimum comfort for employees while reducing energy consumption.

Video summary of the mission

Discover other projects

Study of aeraulic comfort – Middle school

Wind comfort study – Rooftop

Wind impacts on high-rise buildings: Tours Olympiades in Paris

Comfort – Rooftop of a palace – Casablanca

Tour Liberté – La Défense

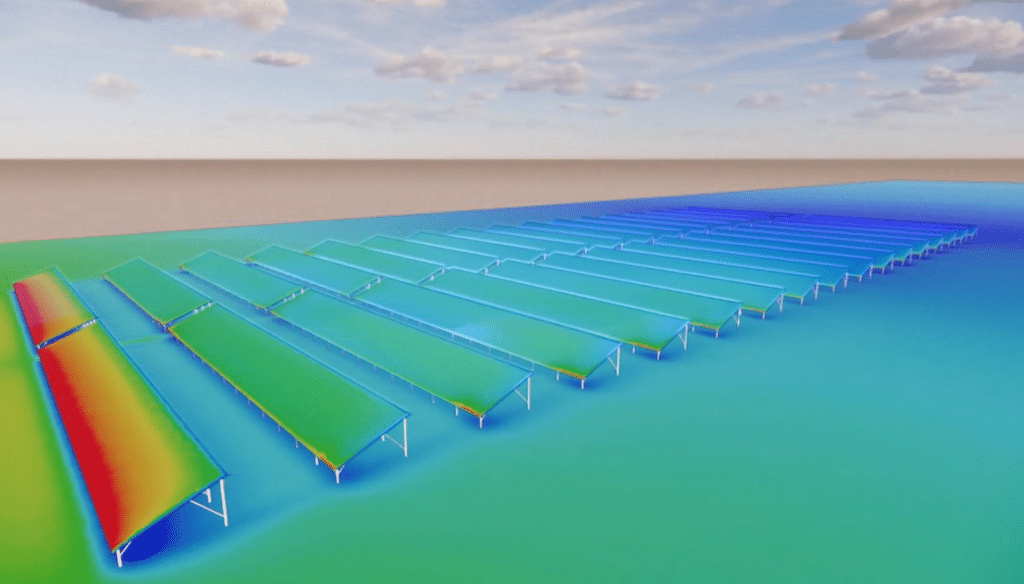

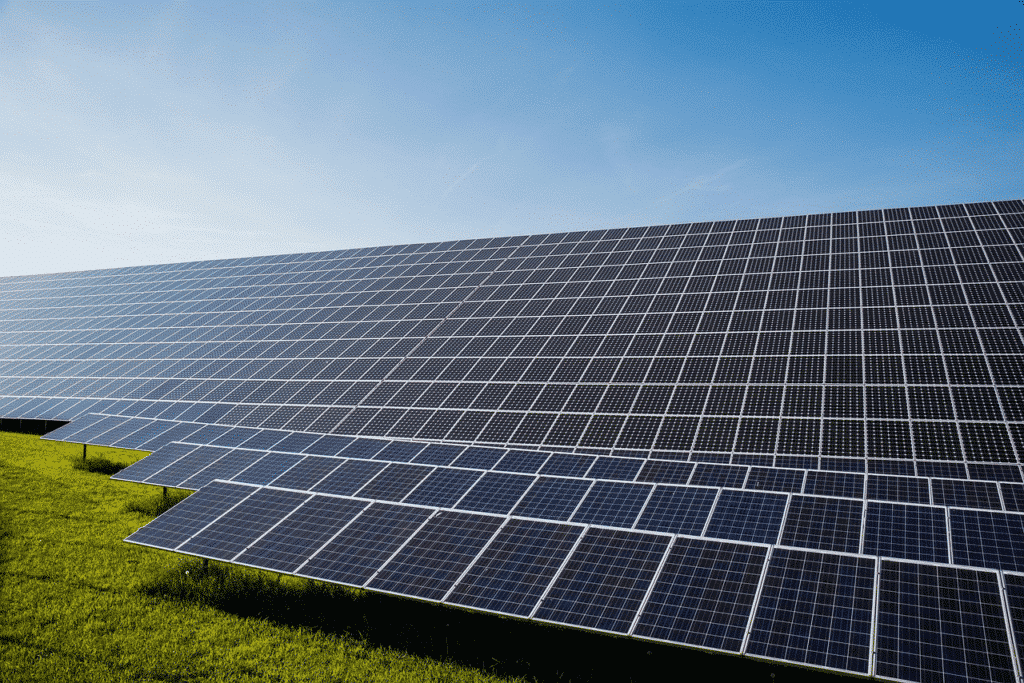

Impact of wind on a solar power plant

Cooling towers – ICPE

Pedestrian comfort study – La Défense

Confort au Vent – PSG training center

Wind study – La Défense

Fine particle capture in a metro station

Sharaan by Jean Nouvel resort

Air coolers – Critical study – Heat wave

Fine dust measurements

Balenciaga – Wind potential