Audit, diagnosis and 3D modeling of existing data centers

Home » Data Center » Audit, diagnosis and 3D modeling of existing data centers

Data center audits and diagnostics

We support you in optimizing your infrastructures through targeted field audits

- Smoke tests for airflow analysis and leak identification

- Thermographic surveys to detect hot spots

- Mapping air and heat risk zones

- Verification of containment conformity (hot aisles / cold aisles)

- Support for room densification (assessment of additional IT workload potential)

- Support for numerical modeling (CFD) to simulate operating scenarios

Diagnostics are carried out by senior engineers specializing in thermo-aerodynamics for data centers throughout Europe.

Aeraulic characterization of data centers using smoke tests

Visualize real air trajectories

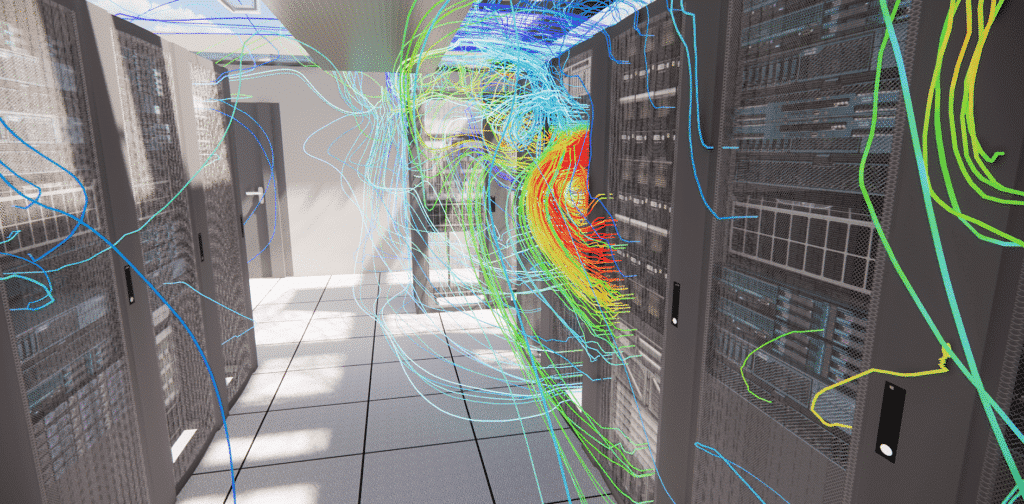

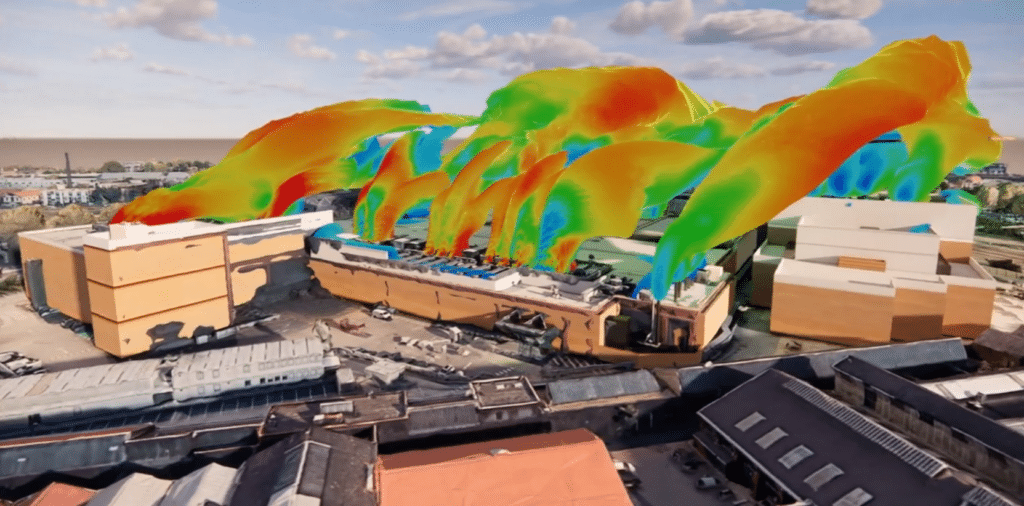

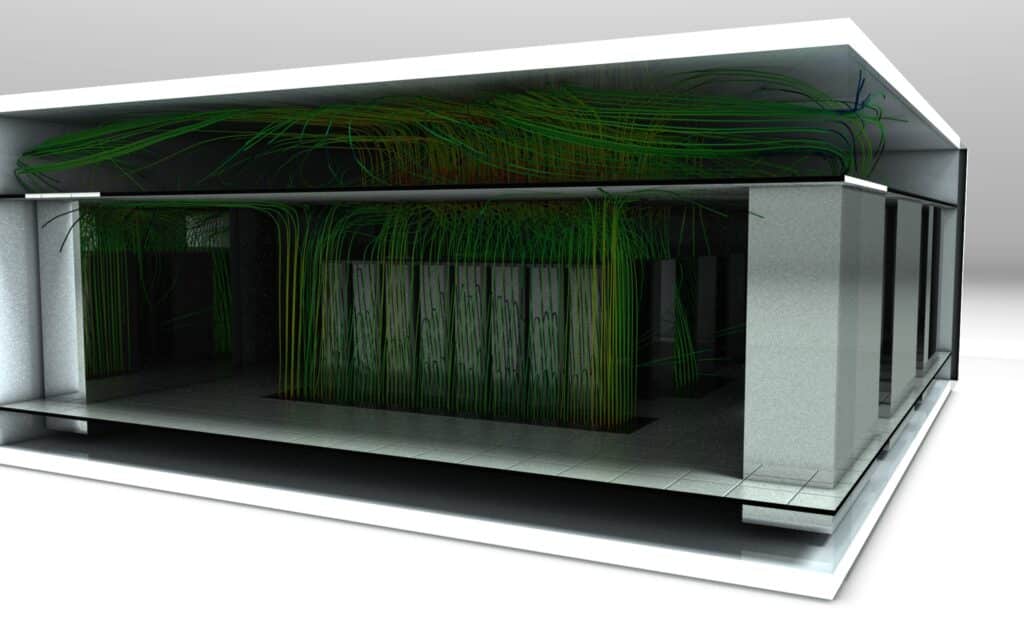

Modern data centers rely on a delicate balance between containment, pressurization and airflow management. Localized imbalances can lead to zones of overpressure, mixtures of hot and cold air, or recirculation loops invisible to the naked eye.

Smoke tests carried out by EOLIOS engineers enable concrete visualization of airflow patterns in datahalls. Conducted under real operating conditions and without interruption of service, these tests provide qualitative observations essential to a detailed understanding of the aeraulic behavior of the rooms.

Real-time visualization of smoke paths makes it possible toquickly identify leakage points or areas prone to hot airrecirculation, which could jeopardize cooling performance and equipment safety.

Smoke tests during a commissioning campaign with a load bank

These qualitative observations are then correlated with quantitative measurements of temperatures and flow rates, obtained by sensors and monitoring instruments. This dual approach enables EOLIOS experts to recommend targeted adjustments, whether to optimize rack layout, adapt ventilation unit flow rates or reposition containment partitions.

Ultimately, controlling airflow using smoke tests is part of an overall continuous improvement approach, guaranteeing the energy efficiency of the datacenter while ensuring the availability and durability of critical IT infrastructures.

Identify leaks and recirculations

As part of data center diagnostics, smoke tests are used to :

- Identify leaks in confined aisles

- Identify hot air rising from false floors

- Detect areas of low air circulation

- Identify recirculations between adjacent racks or short-circuit phenomena

In other cases, these tests can be used to study the operation of the data center’s smoke extraction systems:

A series of localized tests, filmed and documented, is used toestablish an aeraulic map of the site. These data are then integrated into our numerical models to maximize the reliability of CFD simulations.

Thermal diagnostics of data centers using infrared thermography

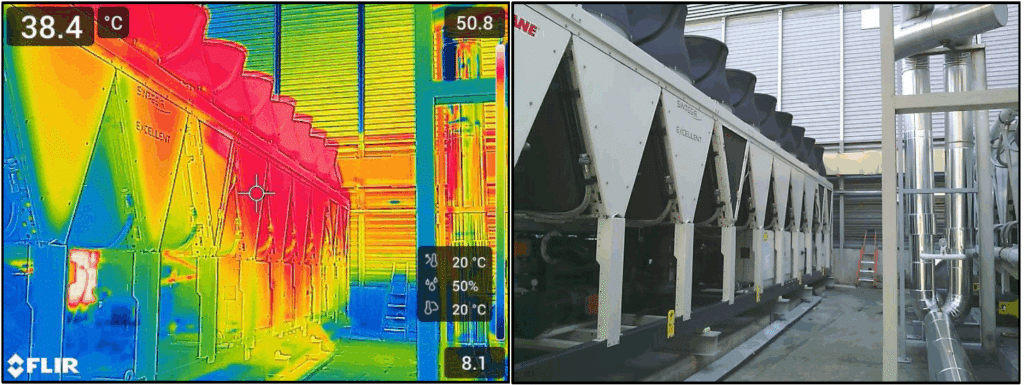

Detecting invisible thermal anomalies

Even with a well-designed cooling system, local imbalances can occur: punctual overloading, uneven air distribution, obstructions, or fan failure. These faults, often invisible to supervisory tools, can be spotted using infrared thermography.

Surveys are carried out using high-resolution infrared cameras, providing a precise view of the thermal behavior of equipment and its immediate environment. They are then used to produce a precise map of the thermal distribution of the load in the datahalls.

Characterize hot spots and their causes

Thermographic analysis highlights hot spots at the front and rear of the racks, revealing cooling imbalances. They also help identify abnormal temperature variations from one bay to another, often indicative of poor airflow distribution. In addition, these readings can be used toobserve localizedheat dissipation near active equipment, likely to cause occasional overheating.

Finally, they offer the possibility ofanalyzing the thermal behavior of the system during transient situations such as a load increase or ventilation degradation. By cross-referencing these observations with aeraulic data, it becomes possible toestablish a complete diagnosis of the datacenter’s thermal situation.

Assessing the IT load extension potential of data centers

Measure available airflow and thermal margins

The audits carried out by EOLIOS aim to characterize the residual capacity of the cooling system in the face of a future increase in load. This analysis is based on thermal readings, flow measurements and observation of actual operating conditions.

It enables us toanticipate constraints that could limit the installation of new IT equipment or degrade overall thermal performance.

Anticipating risks and optimizing development

Thanks to this assessment, it is possible to :

- Identify areas suitable for new high-density racks or servers

- Check the ability of confined aisles to handle increased loads

- Simulate the impact of a new configuration on return air temperatures

- Identify optimization needs (flow adjustment, containment, redundancy)

This approach contributes to secure planning of datacenter evolution, without compromising service continuity or energy drift.

Data center audit - CFD simulation support

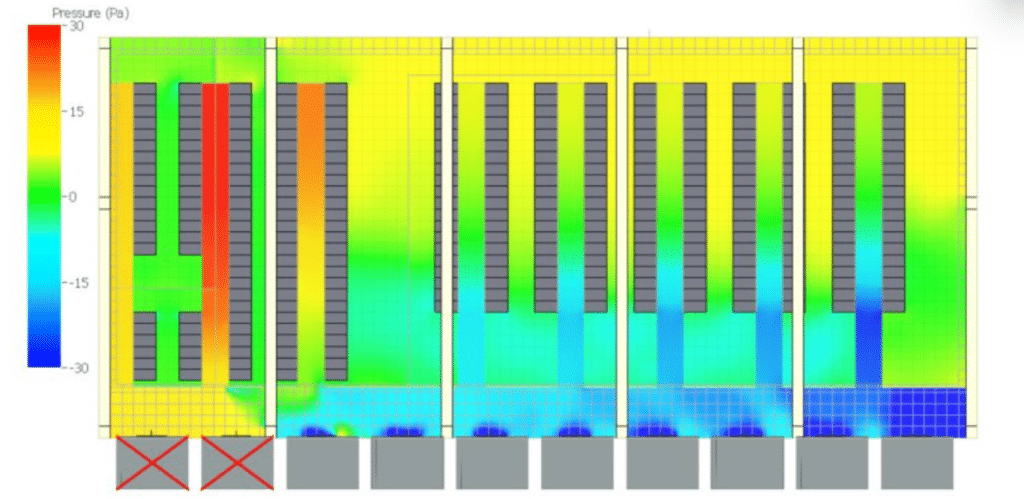

Calibrate models on reliable field data

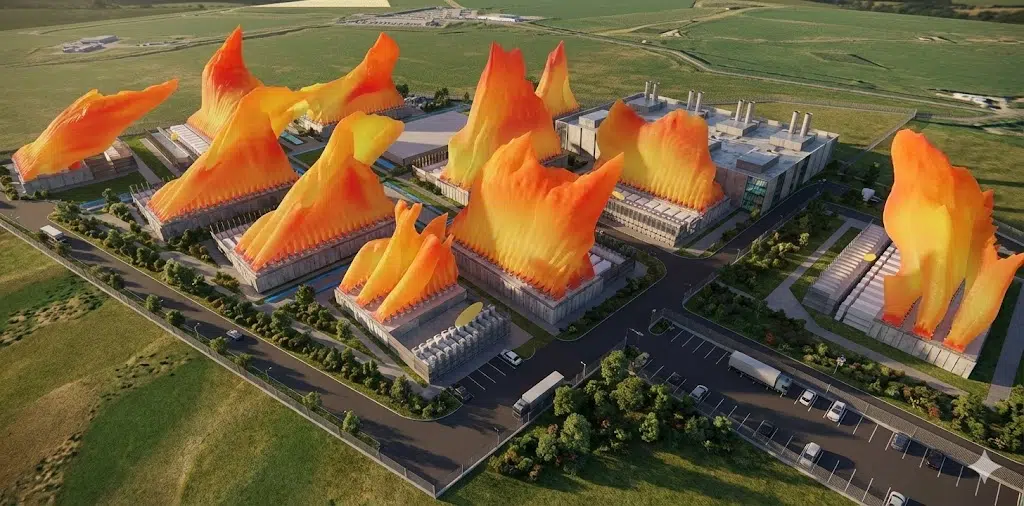

Air and heat audits provide essential data for building highly accurate CFD models. By integrating actual measurements (flow rates, temperatures, leak locations), simulations become a reliable decision-making tool.

This hybrid approach guarantees a faithful representation of the site’s aeraulic operation, enabling different configurations to be tested virtually.

Simulate, validate and plan improvements

CFD models can be used to validate the effectiveness of existing containment systems, by measuring their ability to channel air flows correctly. They also provide a framework for testing different cooling strategies, comparing their performance before implementation.

At the same time, these tools make it possible to simulate transient situations, such as equipment shutdowns, work phases or performance degradations, in order to anticipate their impact.

Based on these analyses, targeted recommendations can be formulated to guide corrective action or preventive maintenance. Simulation results are then rendered in the form of heat maps, speed profiles or 3D visualizations, making their interpretation intuitive and directly usable by operations and maintenance teams.

EOLIOS helps you build a better-controlled data center

At EOLIOS, our mission doesn’t stop with observation. We transform field observations into real optimization levers. Every audit we carry out – whether aeraulic, thermal or structural – is part of a global approach aimed at reinforcing the performance, security and resilience of your digital infrastructures.

Our services combine rigorous methodology, field instrumentation and digital simulation expertise. Thanks to CFD modeling, smoke tests, infrared thermography and containment analysis, we can give you

When you call on EOLIOS, you can rely on a multidisciplinary team working alongside operators, infrastructure managers and design offices to secure and ensure the long-term operation of your critical environments.

Find out more:

Our specific solutions for data centers :

CFD engineering for data centers

Find out more

Thermal storage study

Find out more

External CFD simulation for data center

Find out more

Data Center Fire Simulation

Find out more

Thermal study of technical premises

Find out more

Urban heat island impact study for data centers

Find out more

Audit, diagnosis and 3D modeling of existing data centers

Find out more

Designing your data center’s digital twin

Find out more

Energy optimization and PUE calculation for data centers

Find out more

Commissioning: study and CFD modeling of load benches

Find out more

Data center engineering

Initially created in France, EOLIOS Ingénierie is the benchmark thermal and aeraulic simulation consultancy for data centers in Europe and worldwide. The company supports operators, designers and project owners at every stage in the life of a data center: design, optimization, renovation or extension.

By combining cutting-edge scientific expertise, state-of-the-art simulation tools and in-depth knowledge of the data center ecosystem, EOLIOS Ingénierie is a trusted partner for ensuring the availability, security and energy performance of IT infrastructures, while anticipating sustainability issues.

EOLIOS

PARIS – LONDON – MILAN – MUNICH – MADRID – WARSAW – CASABLANCA – UNITED ARAB EMIRATES – USA