Laboratories – White Rooms

Home » Laboratories » Laboratories – White Rooms

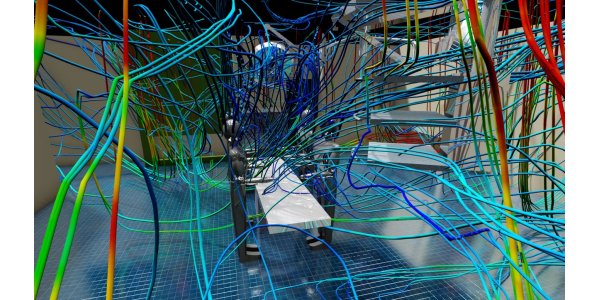

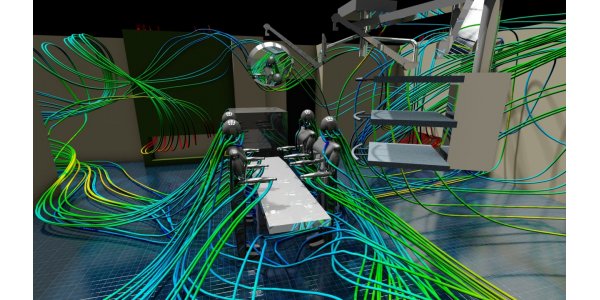

Studies of atmospheres specific to laboratories and clean rooms

- Dispersion of pollutants and gases

- Transitional critical scenario study

- Definition of decontamination times

- Study of contamination risks

- Laboratory P03 and P04

- Laminar flow control in clean rooms

- Pollution evacuation

- Fine temperature regulation

- Smoke analyzes

Continue navigation :

Our latest news :

Our projects :

Our areas of expertise :

CFD simulation of laboratories

Clean room aeraulics:

The requirements for indoor climatic conditions in laboratories are as varied as the activities carried out there. Many engineering fields such as the aerospace industry, the semiconductor industry, hospitals and pharmaceutical centers have clean rooms. A clean room (or clean room according to ISO 14644) is an enclosed space where the concentration of particulate matter is controlled to minimize the introduction, generation and retention of dust or other contaminants.

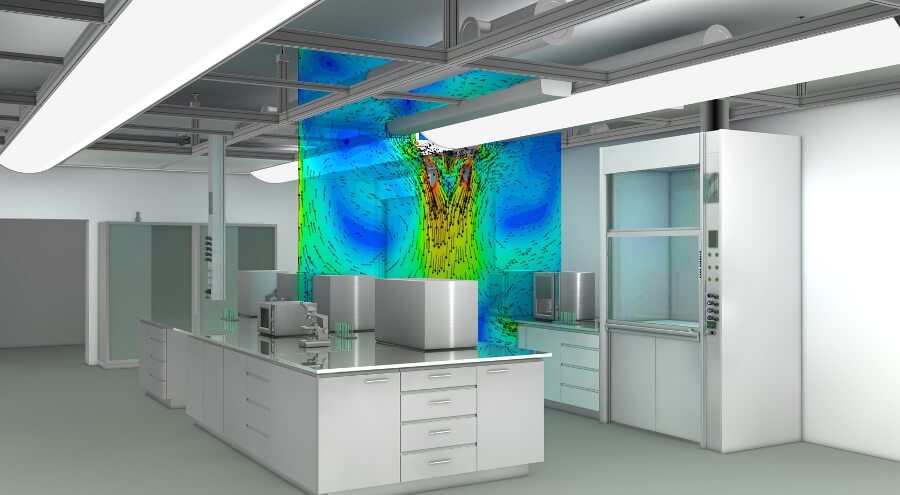

In chemical laboratories, for example, protecting people from the effects of harmful substances is a key safety issue. The retention capacity of laboratory fume cupboards deserves particular attention, depending not only on their construction, but also, in addition to the user’s behavior, on the interaction with the ambient air flow, which in turn is largely determined by the type and arrangement of the air outlets.

Special laboratories in laser research have special requirements such as temperature constancy, low flow velocities and the avoidance of dead flow zones (and thus particle deposits) in critical areas.

In all cases, CFD-based optimization of flow and temperature conditions can help improve the thermo-aerodynamic conditions of the space.

CFD simulation for clean rooms

Depending on the case studies we are led to study:

- the laminarity of the flows under the blowing ceiling , that is to say a vertical direction of the flow;

- the absence of dead zones, i.e. possible areas where the air would not be renewed and where the particles could accumulate;

- the absence of rising airflow, and therefore dust, along the walls or in the corners.

- the homogeneity of temperatures, particularly in the context of extreme scenarios.

- pollutant extraction scenarios, decontamination time.

CFD simulation for clean rooms

Since air transport in laboratory-type buildings accounts for a significant portion of the operating costs, it is always interesting to know whether the requirements can also be met with smaller amounts of air. A CFD simulation can be extremely useful in exploring this potential. There are solutions adapted according to the type of laboratory.

Our areas of expertise include:

- Design of systems for high stability in temperature and hygrometry

- Gas risk (toxic, flammable, anoxia)

- Risk Nanoparticles , specific confinements

- Biological risk and specific equipment

- Nuclear risk (hot laboratories)

- Sizing of specific systems

- Diffusion of nanoparticles

On the other hand, the technical data sheets of the manufacturers (Fume cupboards, hoods, PSM, BAG, PSPN, etc.) give via charts the thermo-aeraulic conditions of use of their systems. However, the simultaneous use of different systems in the same space can cause disruptions to recovery, limiting or even eliminating the expected efficiency of the systems. To avoid these problems, we carry out the digital qualification of fume cupboards in the design phase.