Thermal storage study

Home » Industrial Process » Thermal storage study

EOLIOS optimizes thermal storage tanks:

- Design, analysis, optimization

- Temperature distribution

- Thermocline thickness

- Study of compartmentalization

- Transient study

- Energy optimization

- PAC optimization

- Calculating pressure losses

- Laminar flow

Thermal reservoir study

Thermal storage by buffer tank

A buffer storage tank is a widely proven technology for storing excess heat energy (hot or cold) during off-peak hours. This type of thermal reservoir can be coupled with cooling systems (heat pump) making it possible to use this stored energy at peak load times, thus minimizing consumption costs and smoothing out power demand peaks.

How it works

Water thermal storage

In the case of a chilled water storage system, the system stores thermal energy in the form of chilled water. This requires a thermal energy storage device known as a buffer tank.

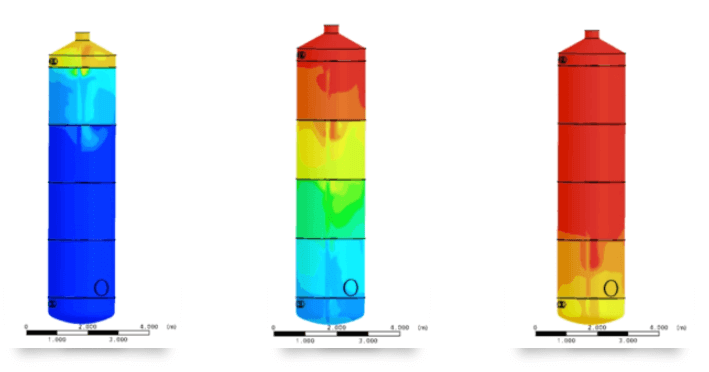

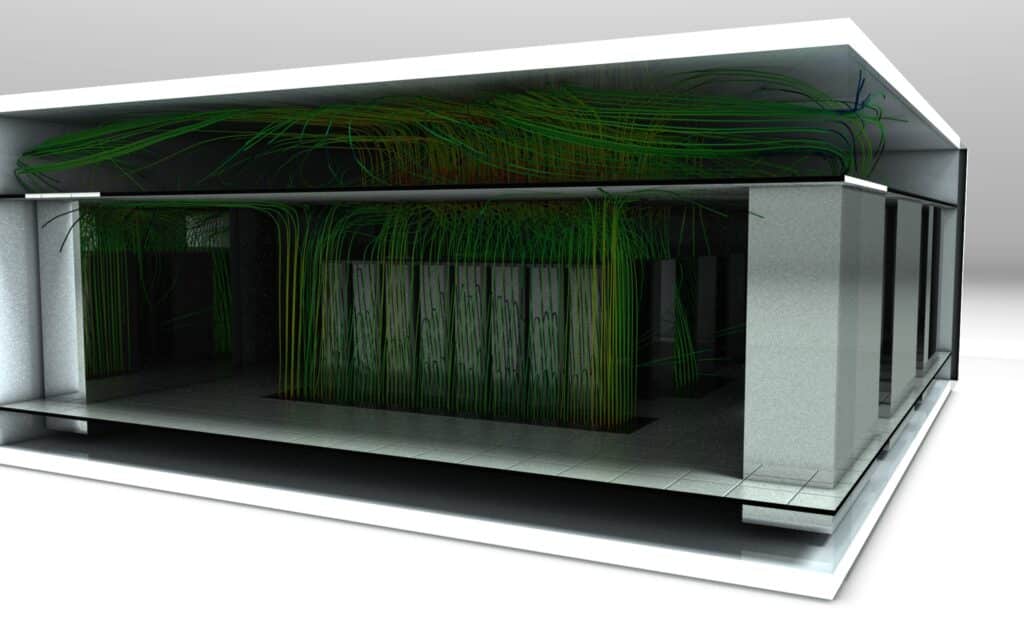

The stratified storage tank works by storing cold and hot (return) water in a single tank. During charging, chilled water is pumped to the lower part of the tank through the networks connected to the tank, while an equal amount of hot water is extracted from the upper section. During unloading, chilled water is drawn from the bottom, while an equal amount of hot water is filled from the top. During the charging and discharging operations, a natural phenomenon called thermal stratification occurs, i.e. hot water (low density) remains at the top while cold water (high density) settles to the bottom of the tank.

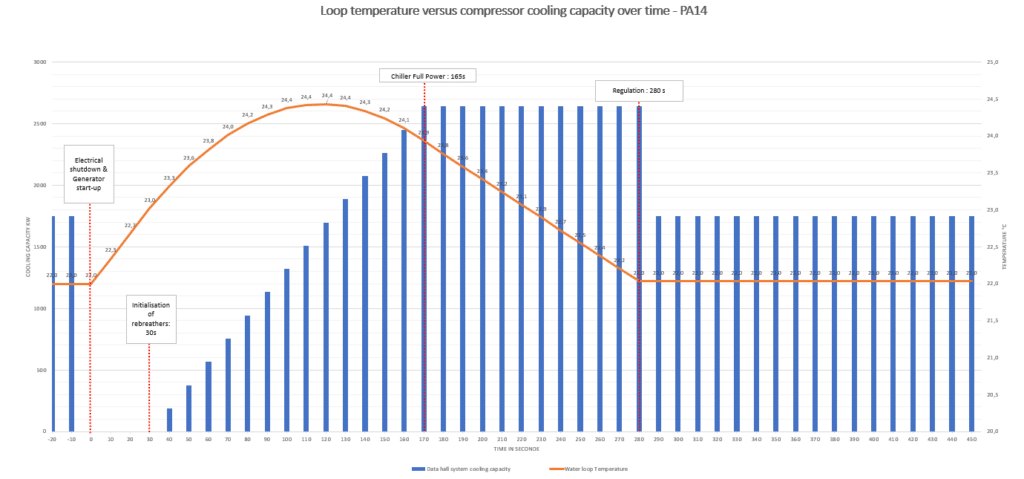

Thermal storage over time

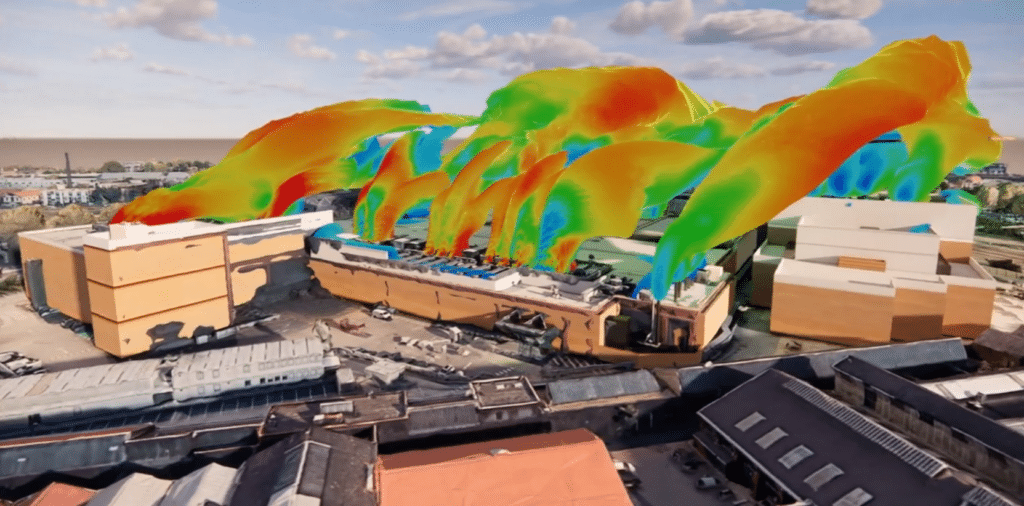

CFD simulation of temperature distribution over time

How to optimize a thermal storage tank?

Optimizing thermocline height

As a result of thermal stratification, a transition region (temperature gradient) called the thermocline is formed between the hot and cold regions with a temperature between the chilled water supply and the chilled water return. This warm area has little energy value. The Thermocline will gradually move from bottom to top while charging and from top to bottom while discharging. The thickness of the thermocline represents the inefficiency of the buffer tank. The more efficient the buffer tank, the thinner the thermocline.

Buffer tank performance depends solely on thermal stratification, which is influenced by these factors:

- Temperature loss in the environment due to conduction. (Incorrect insulation)

- Reservoir design. (Desired height and diameter – for better stratification)

- Inlet and outlet design of the diffuser. (This allows laminar flow to prevent mixing of the fluid regions thus promoting stratification)

- Implementation of physical compartmentalization, and selection of specific diffusers to promote laminar flow.

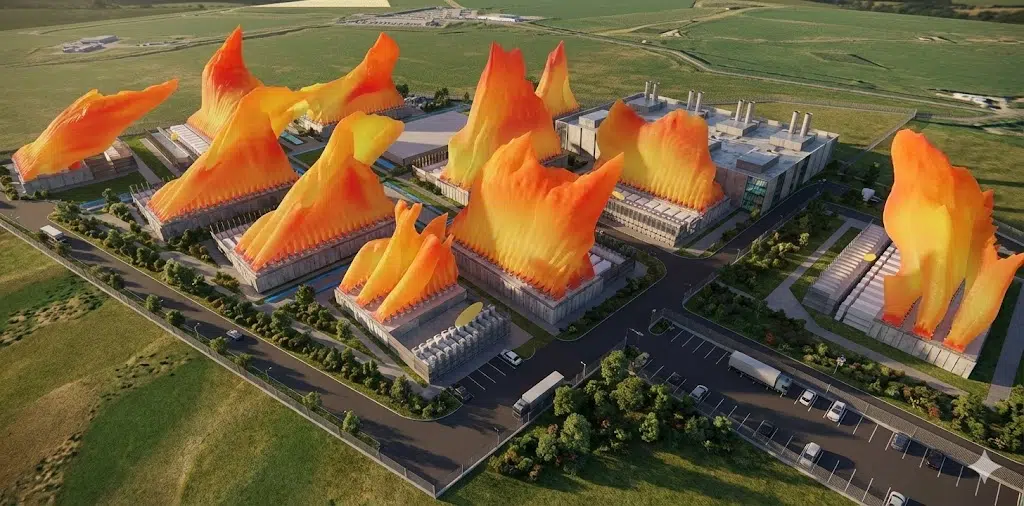

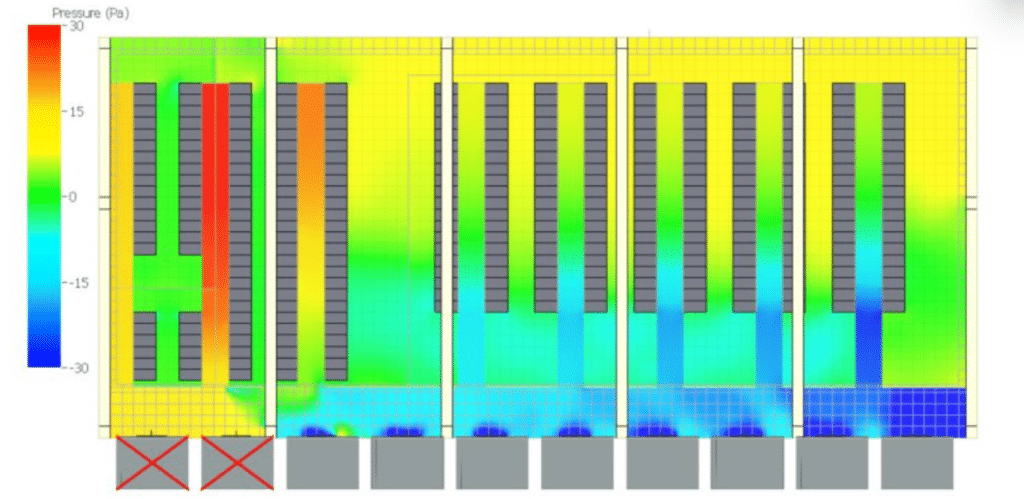

Optimization using CFD simulation

Using computational fluid dynamics (CFD) simulation, EOLIOS can help you design your storage tanks.

- Reservoir temperature distribution can be mapped.

- Prediction of thermocline thickness, which can be optimized with test simulations.

- Balloon design, analysis and optimization

- Visualization of fluid flow physics throughout the buffer tank

- Design and optimization of the number of compartments,

- Temperature, velocity and pressure at any point in the reservoir can be predicted at any time during the process.

- Other observations and conclusions can be drawn from any given design condition.

CFD simulation of a thermal water storage tank

Study of the temperature evolution of the water loop

To calculate the temperature evolution of a water loop at the outlet of a thermal storage tank, several physical phenomena need to be taken into account. Here are the main steps in the calculation:

- Storage tank energy balance: The first step is to carry out an energy balance of the storage tank to determine the energy exchanged between the water and the tank. This generally takes into account the thermal capacity of the water, heat losses from the storage tank, and energy gains or losses from heat exchangers inside the tank.

- Heat losses: Heat losses from the storage tank must be calculated on the basis of its design, insulation and the temperature difference between the inside and outside of the tank. These losses may vary according to the heat exchange surface, the thermal conductivity of the material and other environmental conditions.

- Water flow rate in the loop: To take into account the temperature evolution of the water loop leaving the storage tank, it is necessary to know the water flow rate in the loop. This flow rate can be influenced by a number of factors, such as heat exchanger capacity, the temperature difference between inlet and outlet water, and the hydraulic resistance of the loop.

- Heat exchange with the environment: As water circulates through the loop, it can also lose or gain thermal energy depending on environmental conditions. For example, if the water loop is exposed to a cold air flow, the water may cool down more quickly. Heat exchange with the environment must therefore be taken into account when calculating temperature evolution.

Depending on these various factors and the dynamics of the water loop, mathematical modelling can be carried out to calculate the temperature evolution over time. This modeling can be complex, requiring differential equations to take account of all the variables and physical phenomena involved.

Process Industriel : on the same subject

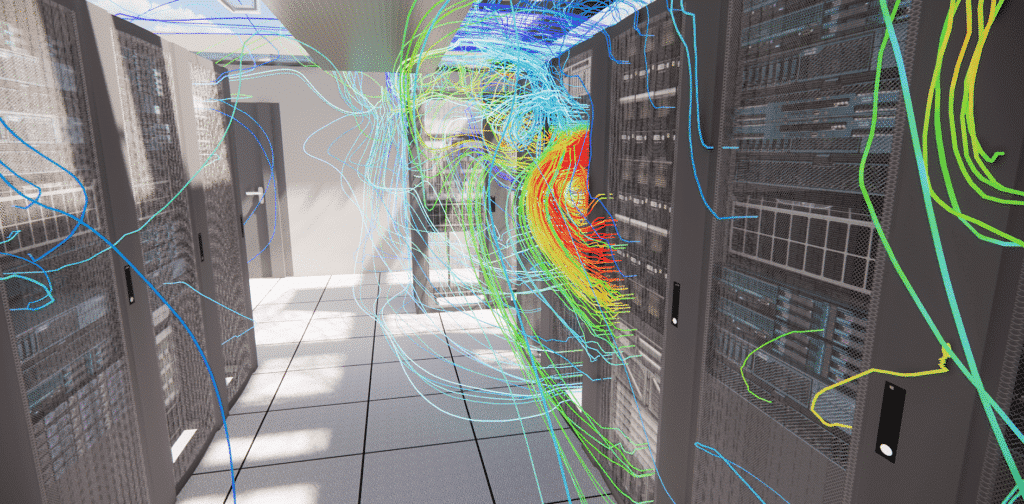

CFD engineering for data centers

Find out more

Thermal storage study

Find out more

External CFD simulation for data center

Find out more

Data Center Fire Simulation

Find out more

Thermal study of technical premises

Find out more

Urban heat island impact study for data centers

Find out more

Audit, diagnosis and 3D modeling of existing data centers

Find out more

Designing your data center’s digital twin

Find out more

Energy optimization and PUE calculation for data centers

Find out more

Commissioning: study and CFD modeling of load benches

Find out more

Data center engineering

Initially created in France, EOLIOS Ingénierie is the benchmark thermal and aeraulic simulation consultancy for data centers in Europe and worldwide. The company supports operators, designers and project owners at every stage in the life of a data center: design, optimization, renovation or extension.

By combining cutting-edge scientific expertise, state-of-the-art simulation tools and in-depth knowledge of the data center ecosystem, EOLIOS Ingénierie is a trusted partner for ensuring the availability, security and energy performance of IT infrastructures, while anticipating sustainability issues.

EOLIOS

PARIS – LONDON – MILAN – MUNICH – MADRID – WARSAW – CASABLANCA – UNITED ARAB EMIRATES – USA