Thermal and aeraulic analysis of transformers and conversion buildings

Electrical conversion building & electrical transformer rooms

We are experts in the thermo-aerodynamic dimensioning of electrical transformers and other installations with high calorific potential.

- Study of thermal plumes

- Validation of maximum air temperature at equipment inlet

- Selection of equipment adapted to climatic conditions

- Study of critical failure scenarios

- Identification of bypass and recirculation air flows

- Generator impact study

- Validation of installation layout

- Optimizing placement and control of air handling systems

- Tailor-made solutions

Our industrial projects :

Climate management for electrical converter stations

Overview of electrical converter stations

These stations, present in various types of power plant, including thermal and renewable, ensure the transformation of electricity, making it accessible to consumers of all sizes, from households to large-scale industry. However, the thermal and aeraulic management of these installations is crucial to the smooth operation of the equipment, requiring precise control of temperatures and air velocities.

Computational fluid dynamics (CFD) is a key tool for modeling and optimizing these air flows. Thanks to our expertise, EOLIOS is able to propose appropriate technical solutions, guaranteeing plant performance and safety. This study will highlight these challenges and the innovative solutions implemented to improve thermo-aerodynamic conditions in electrical converter stations.

What is an electrical conversion station?

Definition and function

An electrical conversion station is a site that converts electricity from one form to another to facilitate the transport and distribution of electrical energy. In particular, these stations convert electricity back into alternating current, so that it can be injected into the RTE transmission network for use by all French people in their daily lives.

Main components: converter towers

Within this station, converter towers can be found, which are essential devices in the electrical conversion process. Converter towers are used to modify the characteristics of electricity, such as voltage, frequency or signal shape, in order to adapt them to the specific needs of the power network. This study helps to ensure the operational efficiency of the electrical converter station, and to anticipate potential problems linked to thermal and aeraulic constraints.

Thermo-aerodynamic constraints of a converter station

Temperature control

Thermal control of converter stations poses a number of challenges. First and foremost, it is essential to ensure optimum temperature to avoid overheating. As conversion towers generate a large quantity of calories, it is essential to maintain the room at a reasonable temperature.

Air speed control

Another major challenge lies in controlling air speeds. The systems present on converter towers are often very sensitive to high air speeds, which can lead to malfunctions. It is therefore crucial to keep air speeds below a precise threshold value.

Temperature uniformity

Last but not least, it’s essential to maintain uniform temperatures throughout the room, to avoid problematic air movements caused by thermal stratification. This means striking a balance between sufficient fresh air flow to ensure the necessary cooling and sufficiently low air velocities at all points in the room. Taking these different phenomena into account enables better control of thermo-aerodynamic conditions, ensuring optimum performance and greater plant safety.

What can CFD contribute to the design of these stations?

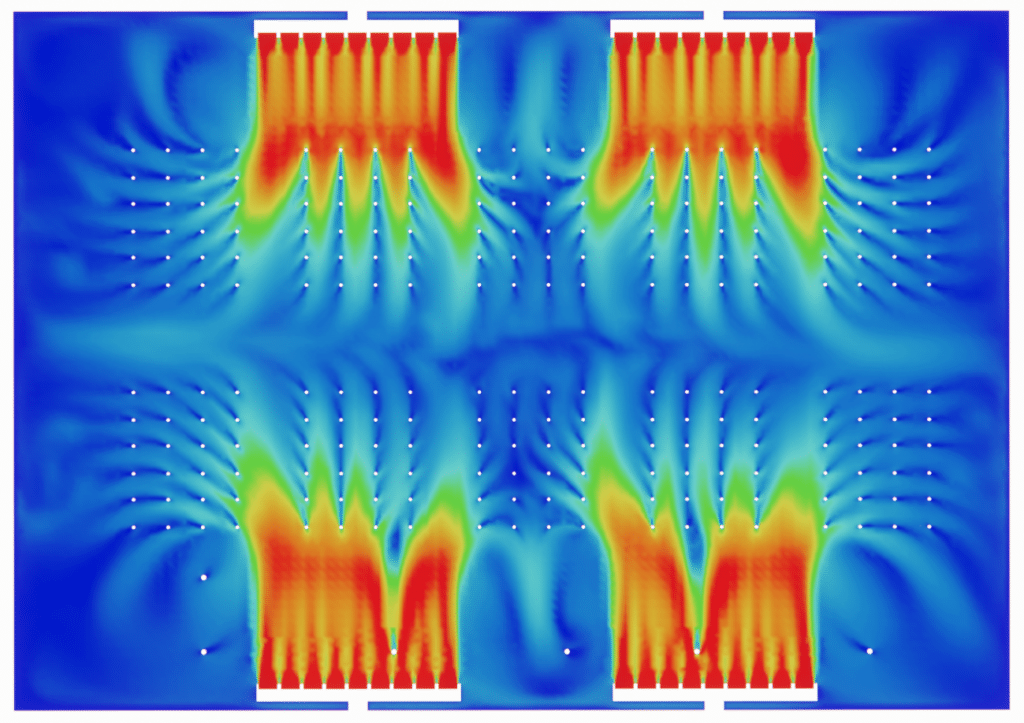

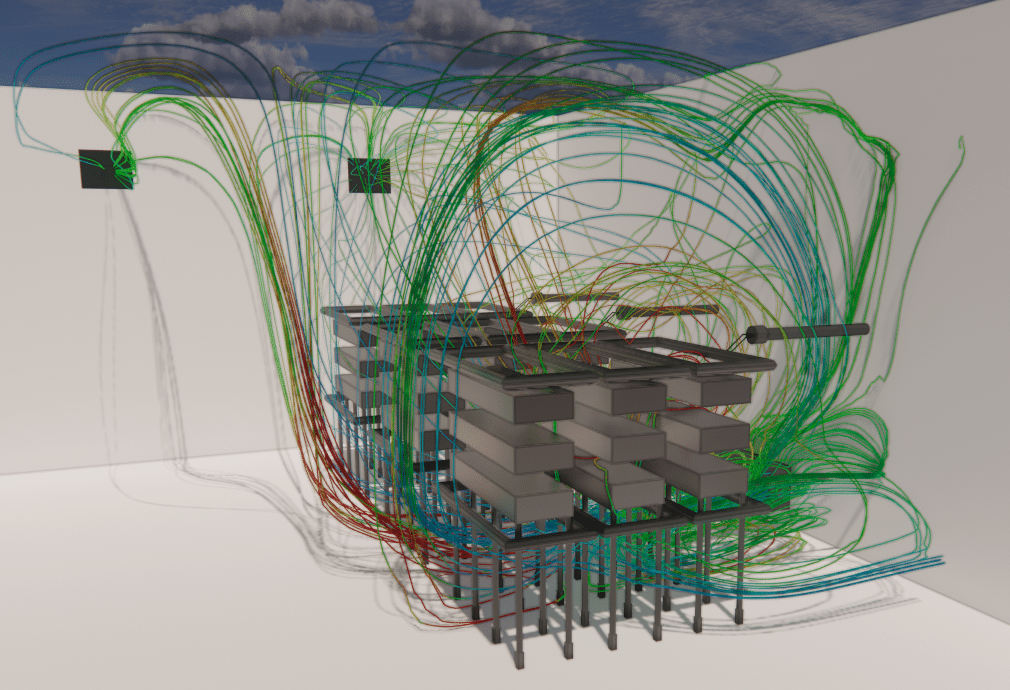

Airflow modeling and simulation

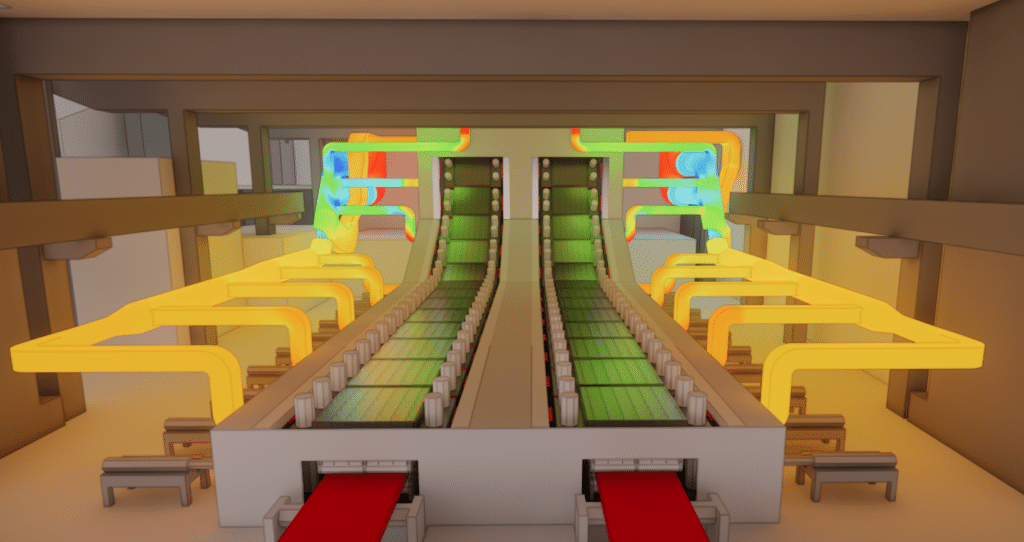

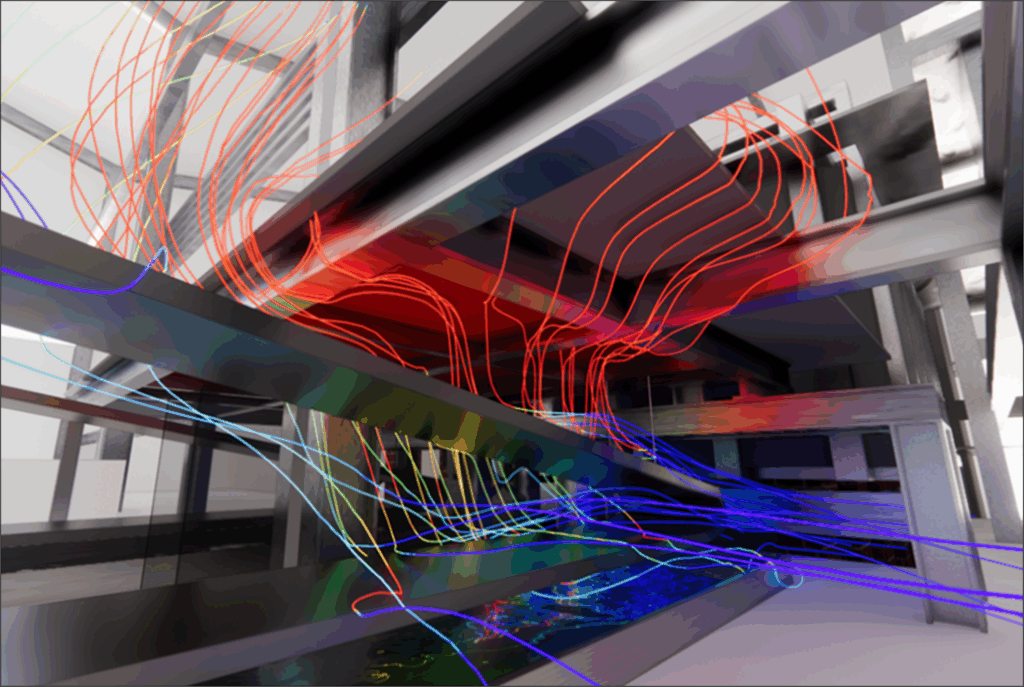

CFD (Computational Fluid Dynamics) brings significant advantages to the design of these converter stations. Firstly, it enables air flows, temperatures and velocities in the various zones of the station to be accurately modeled and simulated. This enables detailedanalysis and understanding of air circulation and heat transfer phenomena inside the station.

Optimizing ventilation systems

CFD makes it possible tooptimize the design of ventilation systems by simulating different layouts and configurations. This makes it possible to visualize air flows,identify stagnation, overheating or overspeed zones, andadjust the characteristics of ventilation tools (such as supply grilles) to ensure better heat exchange and temperature distribution within the room.

Predicting the thermal performance of equipment

CFD can also be used to predict the thermal performance of equipment and heat exchangers, helping tooptimize their design and ensure their efficiency. It can also be used to calculate the heat flows generated by converter towers, in order to size the cooling systems required.

In short, CFD is a powerful tool in the design of converter stations, making it possible to model, simulate andoptimize air flows, heat transfer and equipment performance. It thus contributes to improving theefficiency, safety and sustainability of installations. In particular, EOLIOS uses this tool to support its customers in the optimal design of their converter stations.

What technical solutions are available?

There are several types of technical solutions for improving and optimizing the thermo-aerodynamic conditions of a converter station:

Use of suitable ventilation systems

It’s essential to install efficient, properly dimensioned ventilation systems. These systems can include supply grilles, air extractors, fans or air conditioners. Depending on the station’s specific needs, technologies such as controlled mechanical ventilation (CMV) or variable flow air conditioning (VAAC ) can be implemented.

Optimized pipe and route design

Ventilation ducts must be designed to minimize pressure drop and resistance to air flow. This may involve using ducts of appropriate shape and diameter, as well as minimizing elbows and obstructions that can impede airflow.

Use of thermal control strategies

Precise temperature control is important to maintain a uniform temperature in the converter station. This can include the use of temperature sensors to adjust air flow, air conditioning or heating equipment according to needs and temperature variations.

Optimized air circulation

Good airflow management can help improve thermo-aerodynamic conditions. This can be achieved by using baffles, air ducts, supply and extraction grilles at strategic points to promote uniform air distribution and avoid stagnant or overheated zones.

Air speed control

It is important to maintain air velocities at appropriate levels to avoid any malfunction of sensitive equipment. This may require the use of control devices such as velocity-controlled grilles or diffusers, calibrated air diffusion systems or air barriers to reduce disturbance effects.

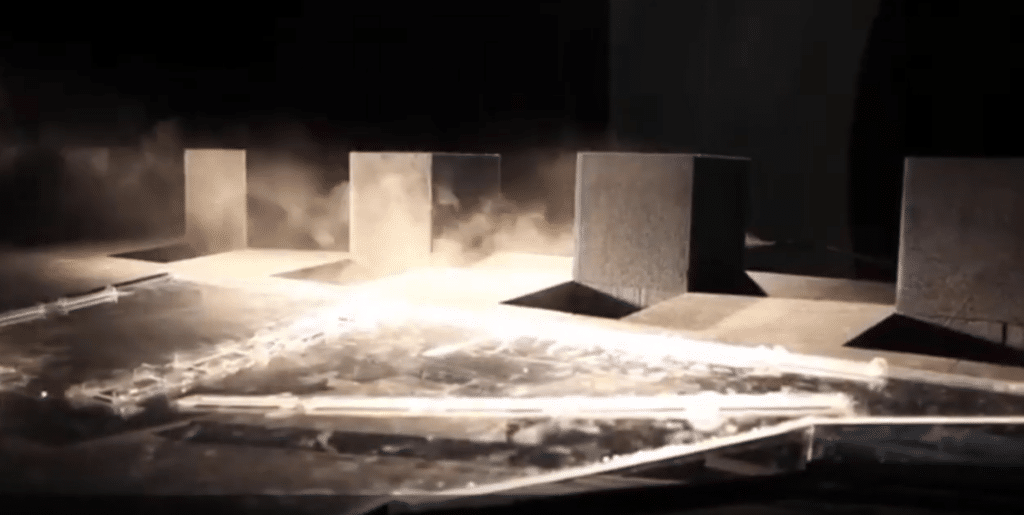

Indoor fire simulation in industrial premises

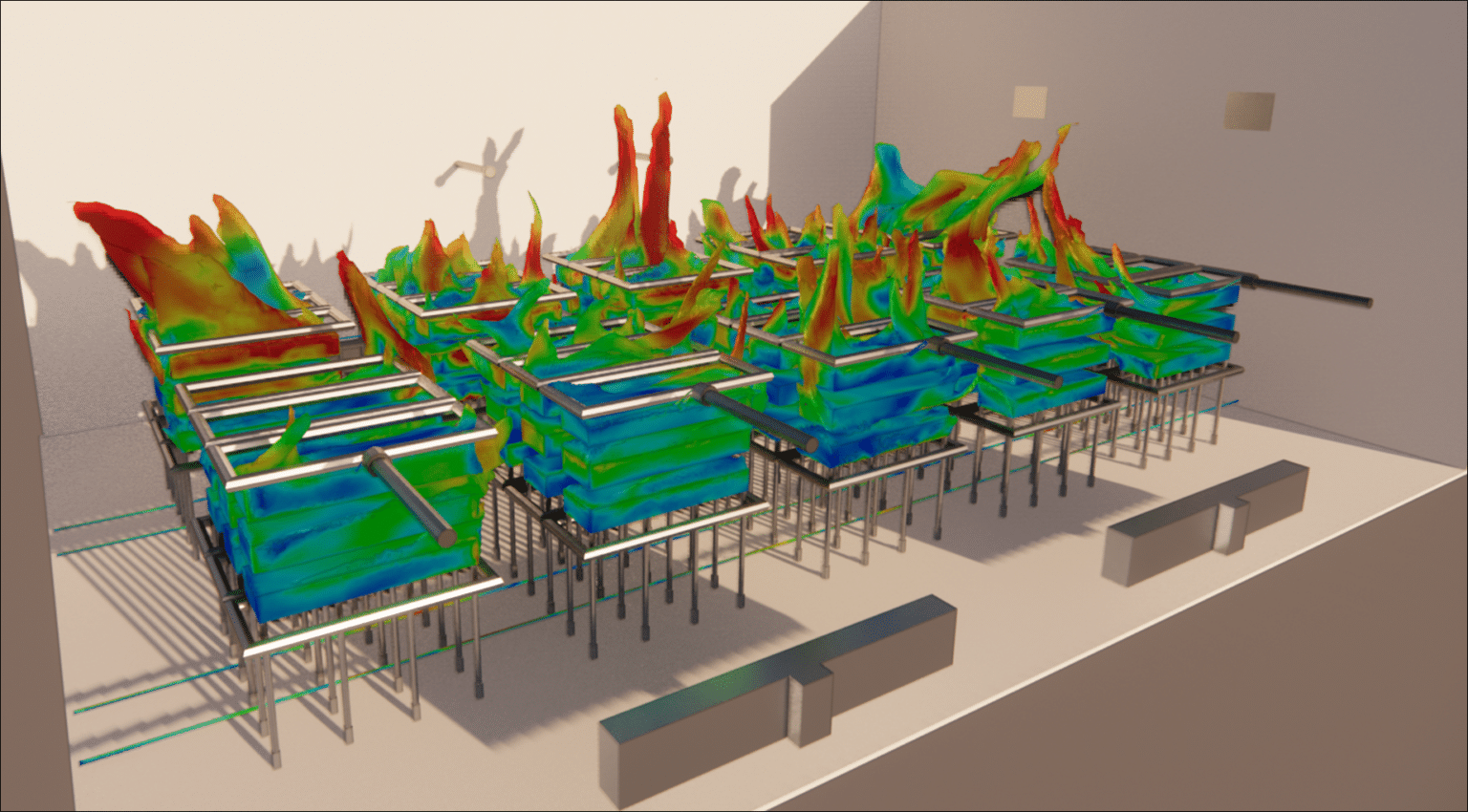

Modeling fire scenarios

In addition to thermal and aeraulic management solutions, we are able to carry out detailed studies of fire outbreaks in converter stations and equivalent buildings. These studies are essential to anticipate and prevent fire risks, thus ensuring the safety of infrastructures and people.

Thanks to advanced tools such as CFD, we can model potential fire scenarios and their propagation in different configurations. This technology enables us to analyze thermal behavior and smoke dispersion in detail, providing crucial data for the development of fire prevention and management systems.

Our studies integrate several aspects, including

Assessing the efficiency of smoke ventilation systems

We analyze the ability of smoke extraction systems to evacuate the toxic fumes and heat generated by a fire, ensuring safe visibility and evacuation for occupants.

Distribution of smoke detectors

By modeling different fire scenarios, we identify the optimum locations for smoke detectors, ensuring fast, reliable detection.

Fire propagation analysis

By simulating fire propagation through the various sections of the converter station, we can identify weak points in the infrastructure and suggest structural improvements or fire-resistant materials.

Our approach not only provides technical recommendations for improving infrastructure fire safety, but also ensures compliance with current standards. By anticipating fire risks and optimizing prevention and management systems, we ensure maximum protection for people and property, thereby enhancing the reliability and resilience of converter stations and equivalent facilities.

Impact on equipment performance and safety

Diagnosis and optimization via CFD

This converter hall study demonstrates the effectiveness and relevance of CFD for diagnosing and optimizing ventilation systems in a variety of industrial environments. The solutions proposed not only ensure optimum equipment performance, but also contribute to a safe and efficient working environment. CFD has thus established itself as an essential tool forclimate engineering and thermal management in industrial environments.

Thanks to this tool, we are able to offer tailor-made solutions that guarantee plant performance, safety andenergy efficiency. Our commitment toinnovation and theoptimization of thermo-aerodynamic conditions reinforces our position as a trusted partner in the design ofhigh-performance industrial infrastructures.