Production hall

Accueil » Industries » Production hall

CFD simulation for heavy industry

EOLIOS helps manufacturers solve specific problems related to air and heat exchange.

- CFD modeling of processes

- Operator comfort

- Smoke site audits

- Thermal radiation study

- Monitoring of pollutant extraction

- Air quality improvement

- Dust studies

- Customized systems design

- Study of the risks of thermal shocks

- Energy optimization

Continue navigation :

Our latest news :

Our projects :

Our areas of expertise :

Technical files :

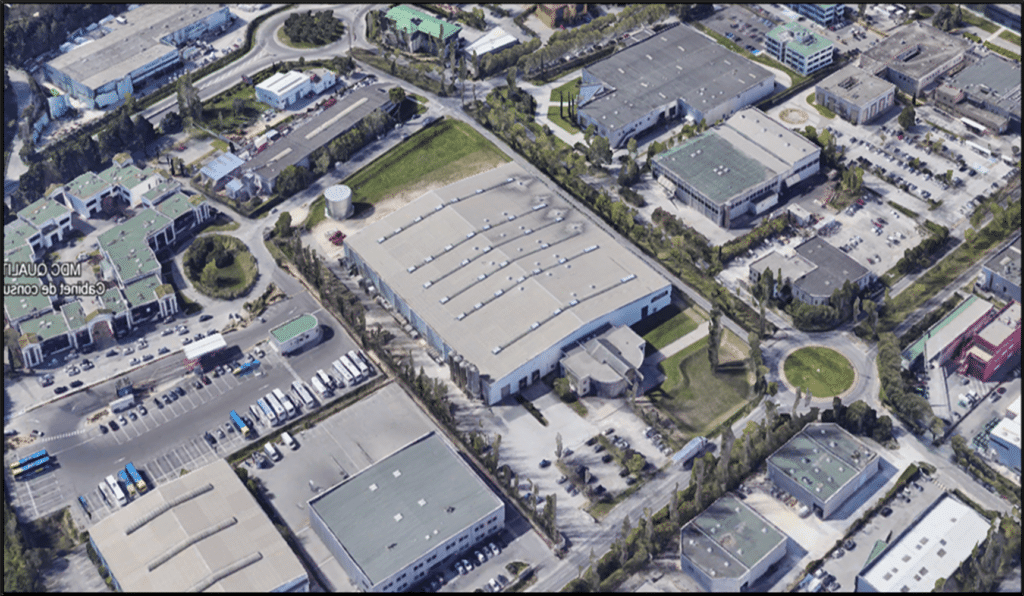

Aeraulics for production halls

Steel mill - Aluminum smelter - Rolling mill

Production halls place very different demands on ventilation technology, depending on the type of work process. The questions posed to the flow simulation are consequently different.

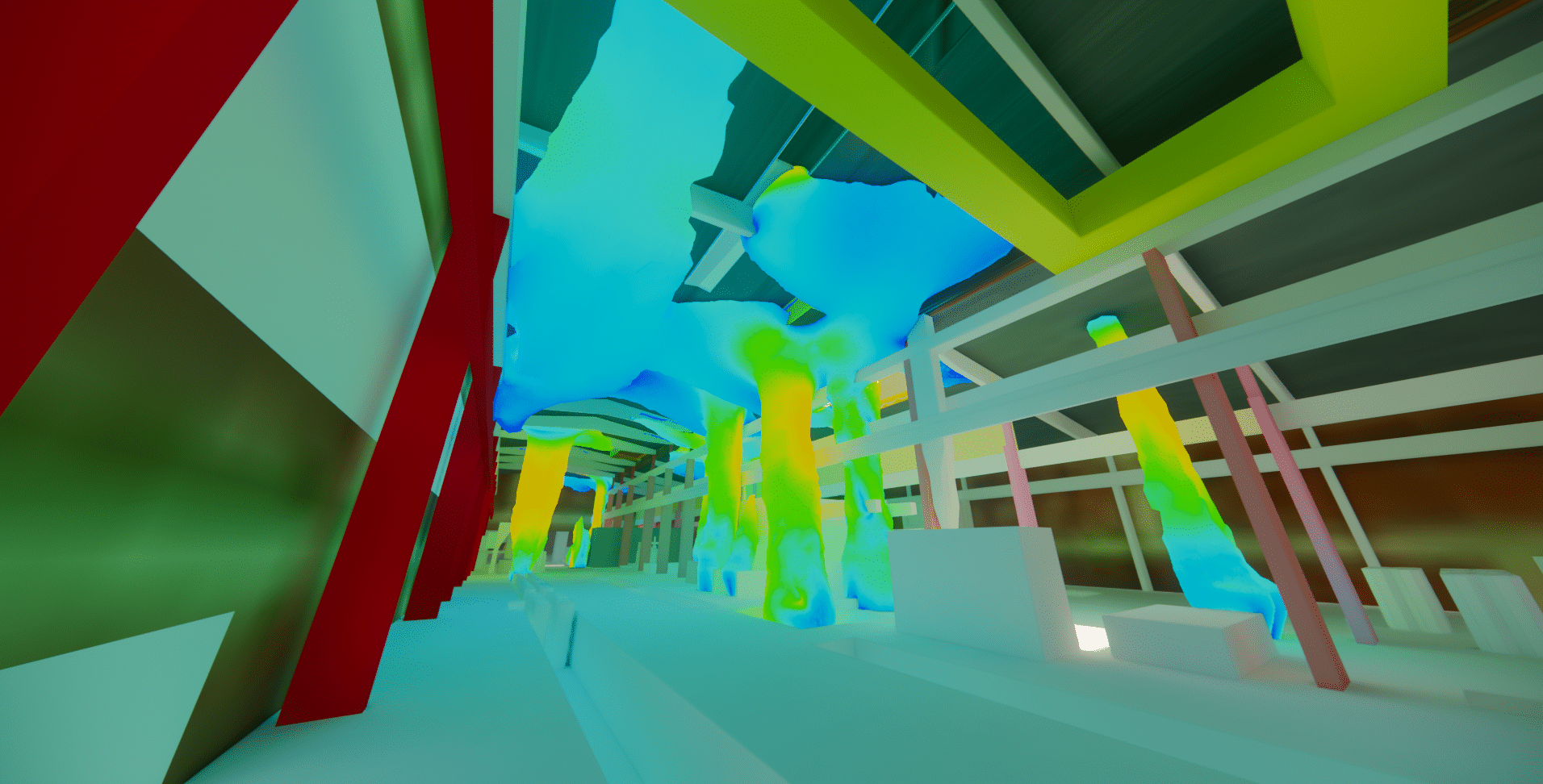

In conventional heavy industry (e.g. rolling mills, steel construction companies), the problem is often the collection and disposal of smoke, dust and heat. Local exhaust ventilation in combination with appropriate hall ventilation must ensure that minimum values for airborne dust are met. The flow velocities on the welding units should not be too high so that the shielding gas atmosphere is not blown away. In machine tool halls with precision production, it is often a question of climatic consistency in order to ensure the dimensional accuracy of the products.

Video - Steel mill suction hood

EOLIOS: mastering thermo-aerodynamic phenomena

The profession of aeraulicist specializes inaeraulics, the science of air circulation. Air engineers must be able to understand the aeraulic phenomena specific to a steel mill.

These include the management of atmospheric pollutants emitted by industrial processes, such as dust, toxic gases and fumes. Air engineers need to be able to design ventilation systems capable of efficiently capturing and transporting these pollutants and calories outside the steelworks or through appropriate systems.

Video - Smoke audit in a steel mill

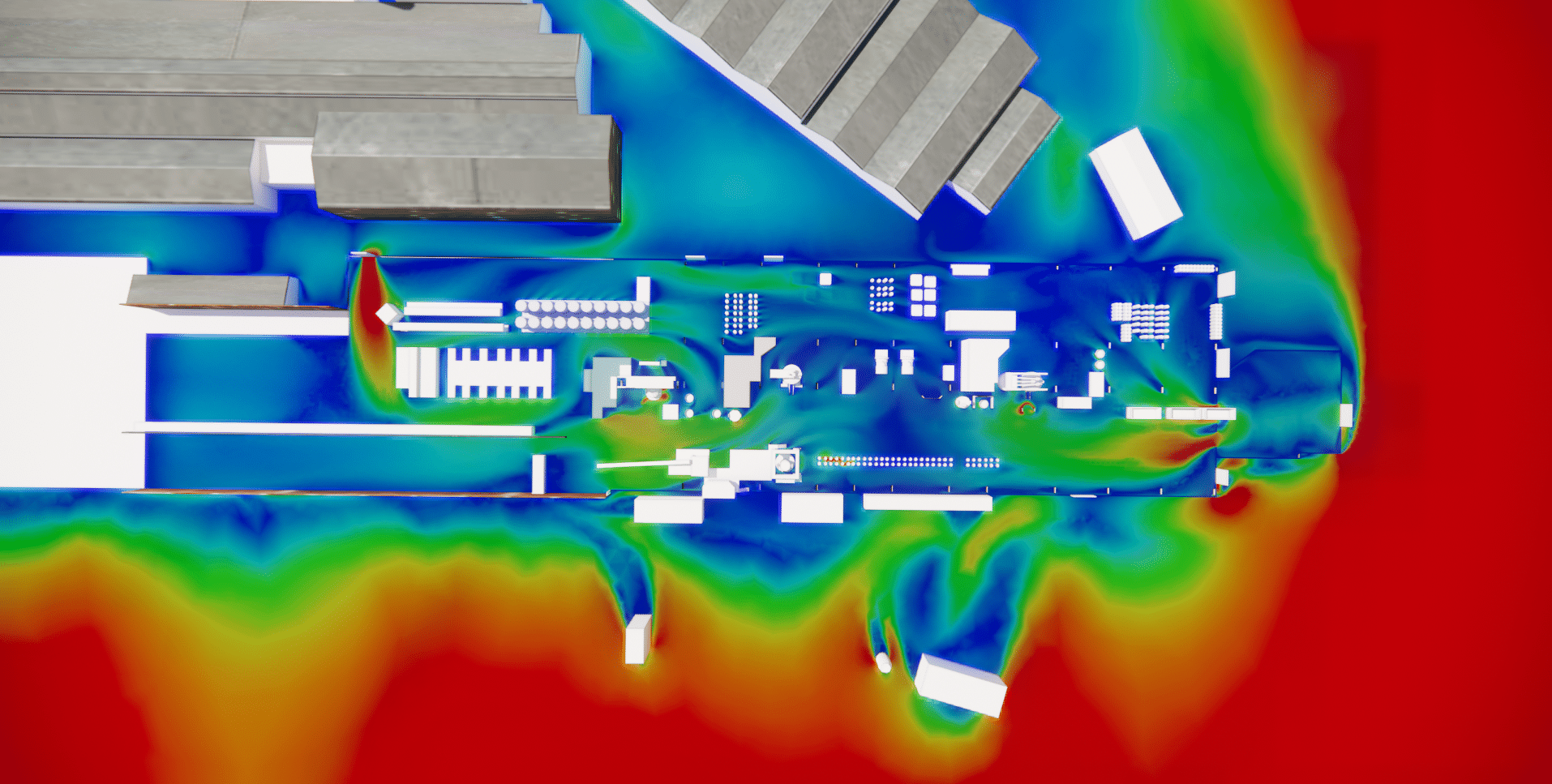

Large-scale CFD simulation for industry

EOLIOS: mastering thermo-aerodynamic phenomena

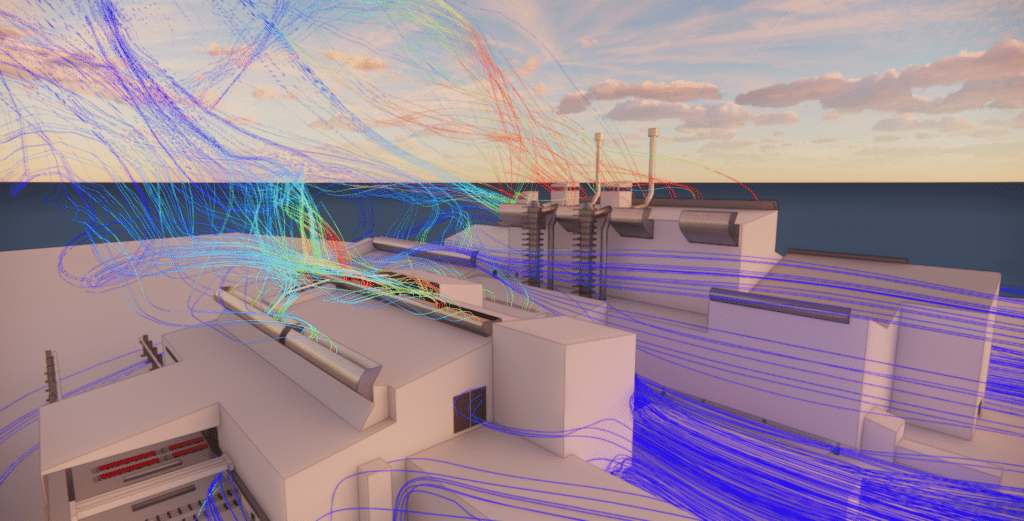

EOLIOS specializes in fluid mechanics and is recognized for its expertise in CFD (Computational Fluid Dynamics) simulation for companies. We offer our know-how tooptimize air flows,improve natural ventilation, guarantee thermal comfort for workers and reduce air pollution.

The use of CFD simulation enables EOLIOS to model andanalyze air flows inside plants, taking into account the various constraints and parameters specific to each installation. This technology makes it possible to visualize flow rates, measure speeds and temperatures, and detect any malfunctions or air circulation problems.

CFD simulation for industry

In the industrial environment of steel mills, control of airflow and heat exchange is of the utmost importance. Our team of experts uses CFD simulation to model and analyze air flows inside plants, taking into account the specific parameters and constraints of each installation. This technology makes it possible to visualize flow rates, measure velocities and temperatures, andidentify potential air circulation problems.

Natural ventilation for industry

Natural ventilation is a crucial aspect of any business. It regulates temperature,evacuates fumes and toxic gases, and ensures acceptable air quality for workers. Thanks to CFD simulation, we can model and optimize heat exchanges between the different parts of the steel mill, to propose natural ventilation solutions adapted to each specific case.

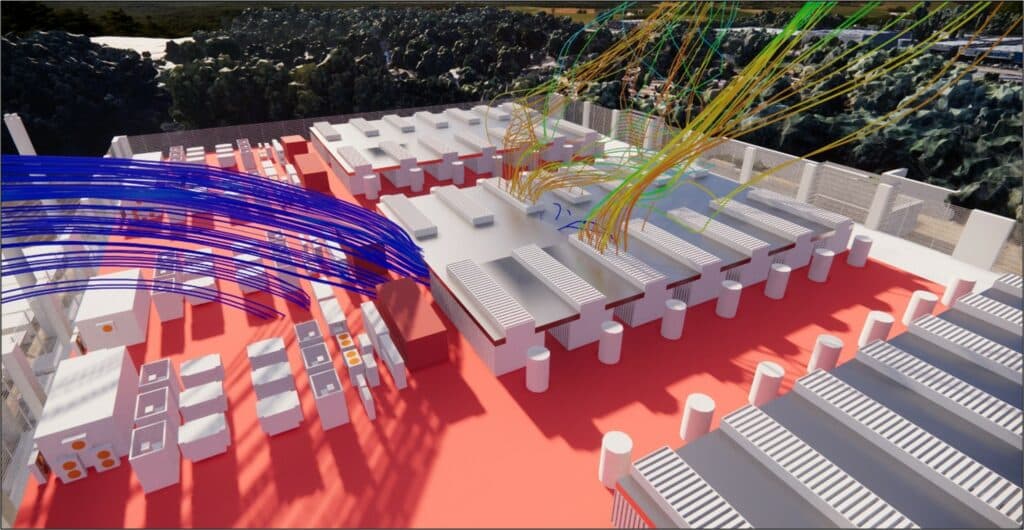

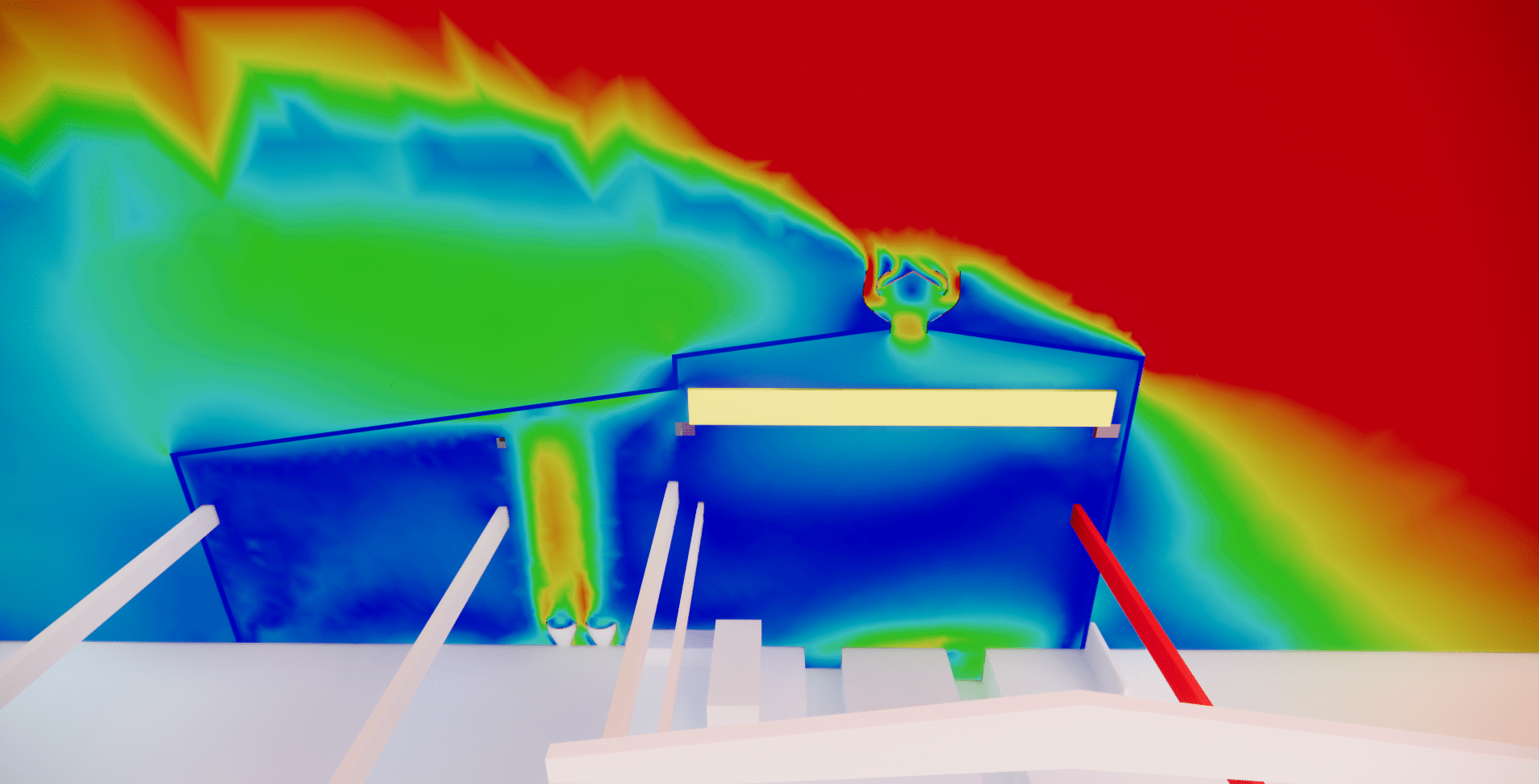

Development of specific vacuum systems

Extraction hoods are used in production buildings to capture fumes and gases at source. They are generally placed over production areas where pollutant emissions are highest. The design of these hoods requires particular attention to ensure effective capture of emissions. CFD simulation makes it possible to model air flows around the hood,analyze velocities and temperatures, andadjust the design according to the results obtained. Thisimproves extraction efficiency and minimizes risks to workers.

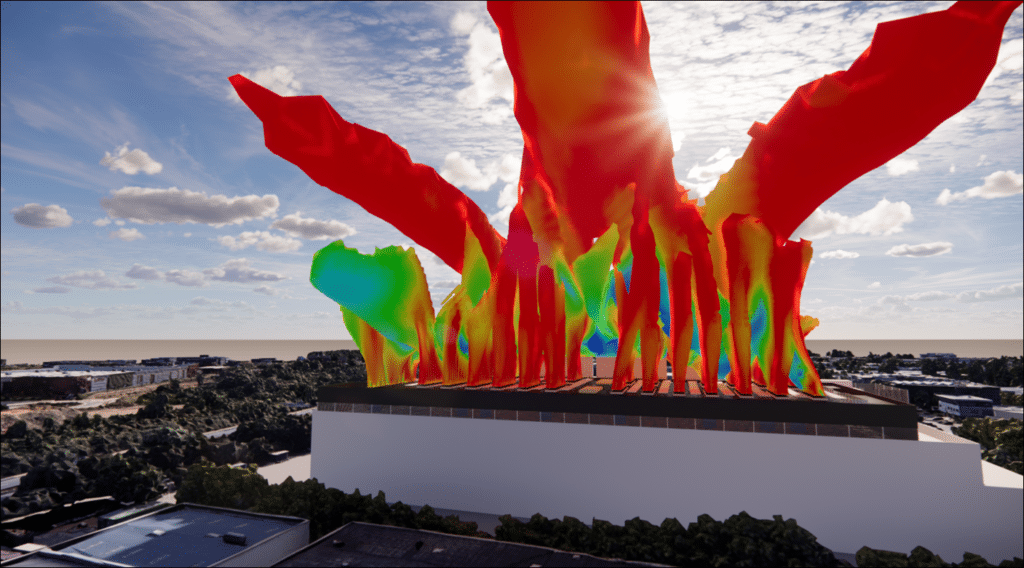

Development of heat extraction chimneys and natural draft furnace gases

Development of heat and gas extraction systems for natural ventilation.

Chimneys are used to evacuate fumes and gases to the outside. They must be designed to ensure efficient dispersion of emissions into the atmosphere, in order to minimize their impact on the environment. CFD simulation can be used toanalyze air flows around the stack, predict pollutant dispersion and ensure that emissions are discharged safely and in compliance with current regulations.

CFD simulation can also be used tooptimize specificsuction systems in terms of positioning, air flow, speed and pressure. It enables different configurations to be modeled, different options to be tested, and the most suitable solution to be found in terms ofefficiency and performance.

Thermal comfort for workers

The thermal comfort of workers in steel mills is essential to ensure their well-being and safety. Working conditions in these environments can be extreme, with high temperatures and strong air flows. Thanks to CFD simulation, we can strike a balance between the ventilation needed to remove heat and atmospheric contaminants, while ensuring optimum thermal comfort for operators.

We can recommend improvements in equipment layout, cooling systems or heating systems to achieve these thermal comfort objectives.

Air pollution reduction: internal and external

Production halls are often singled out for their emissions of greenhouse gases and fine particles. At EOLIOS, our expertise in CFD simulation enables us to model and quantify these emissions, in order to propose solutions aimed at reducing their impact on the environment.

In this way, we can optimize the operation of exhaust stacks, set up efficient filtration systems and suggest ways of limiting pollutant emissions.

Companies are often faced with air pollution problems due to greenhouse gas and fine particle emissions. CFD simulation can be used to model these emissions and predict their dispersion in the environment. This enables preventive measures to be put in place to reduce emissions and minimize the impact on air quality.

In short: what can CFD simulation do for you?

- To take into account the inequalities of localized heat sources and hazards and their effect on temperature and airflow in the room volume

- To take into account the influence of radiation of surface heat exchanges on the air temperature in the room, convective flows are formed in the volume of the workshops.

- Tracking pollutants emitted by a specific process to its capture system

- Study and optimize extreme scenarios (failures, overheating...)

- Studies of cold air currents on processes

- Study the propagation of dust and fine particles

CFD simulation for industrial production

CFD simulation of manufacturing processes

By integrating CFD simulation into the design andoptimization of production processes, it is possible toimprove theefficiency, quality and profitability of industrial activities.

At EOLIOS, we put our CFD simulation expertise at the service of our customers to help them optimize their production processes, improve their performance and achieve their economic and environmental objectives.

CFD process simulation

Thanks to advanced numerical simulations, CFD makes it possible tostudy in detail the various aspects of materials production and manufacturing, in order toimprove processefficiency, quality and sustainability.

-

Fluid flow analysis: CFD simulation enables us to model and understand fluid flows within industrial plants, whether liquids or gases. This helps optimize the sizing of ducts, pipes and equipment, to minimize pressure losses and ensure smooth, efficient flow.

-

Optimizing heat distribution: In many industries, it is essential to control heat transfer to maintain optimum production conditions. CFD simulation can be used to model heat exchanges within cooling, heating or reaction systems. This makes it possible to identify areas of overheating or undercooling, so that corrective measures can be taken to achieve a more even heat distribution.

- Improving combustion: CFD simulation is also widely used in industries where combustion is a key process. It is used to optimize the design of burners, combustion chambers and fuel injection systems, to ensure efficient, stable and clean combustion. Analysis of gas flows and temperature distribution helps maximize energy efficiency and minimize pollutant emissions.

- Modeling gas and liquid flow rates in steel converters: CFD can be used to study gas and liquid flow rates in steel converters, enabling a better understanding of heat transfer, chemical reactions and phase separation. This helps to optimize converter design and improve the quality of the steel produced.

- Simulation of cooling processes: CFD can be used to model air or cooling gas flows in steel cooling processes, such as quenching or spray cooling.

This makes it possible to predict and optimize cooling rates, cooling zones and thermal stresses, in order to produce steels with specific properties and minimize defects.