Air audits in cleanrooms and controlled environments

Home » Laboratories » Air audits in cleanrooms and controlled environments

Airflow audit in cleanrooms

The importance of airflow audits in laboratories and controlled environments

Guaranteeing the performance of a cleanroom involves much more than simply installing ventilation: we need to understand how theair actually circulates, and how it affects particle cleanliness and process safety. An on-site aeraulic audit measures air flows, pressures and air quality, to detect contamination risks, anticipate malfunctions and optimize installations.

- Visualization of air flows with neutral smoke

- On-site anemometric and thermal measurements

- Contamination testing and particle monitoring

- Air quality control and filter efficiency

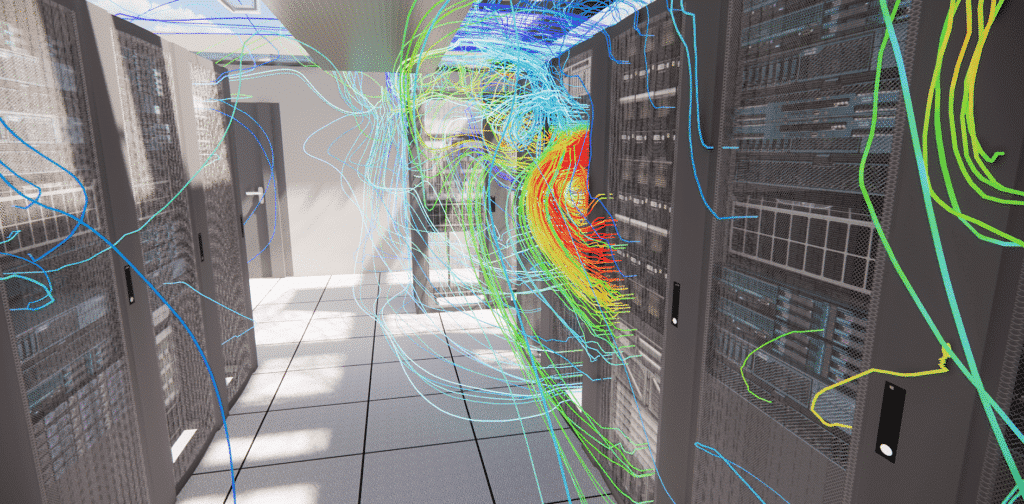

- Verification of consistency between measurements and CFD simulation

- Concrete recommendations for plant optimization

EOLIOS helps laboratories and controlled environments control their aeraulic flows thanks to its expertise in fluid mechanics and advanced aeraulic auditing.

Objectives of a cleanroom aeraulic audit

Study air flows and contamination risks

Theaeraulic audit provides a complete and objective view of cleanroom performance, highlighting areas of stagnation, undesirable recirculation or flows inconsistent with the design. Not only does this information enable you to detect hot spots to reduce the risk of contamination, it also verifies the stability of pressure gradients between clean and less clean areas, and identifies areas of turbulence that disrupt laminar flows.

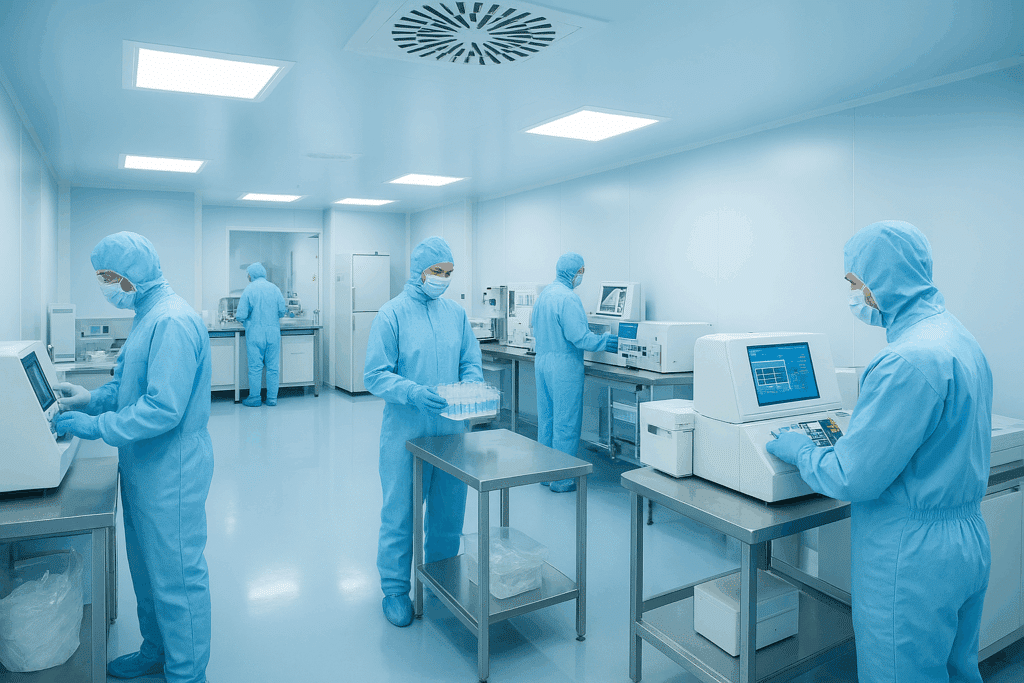

Pharmaceutical laboratory clean room

Field measurements are also used as a reference to check consistency with CFD simulation models and identify complex areas requiring special attention. Finally, the data collected facilitates decision-making and corrective action planning, offering concrete added value for cleanroom performance, safety and reliability.

Cleanroom audit procedure

General approach to a ventilation audit

Theaeraulic audit combines rigorous visual inspection, precise on-site measurements and targeted contamination testing to provide a comprehensive and reliable view of actual cleanroom behavior. This approach makes it possible to compare theoretical design with operational conditions, identify areas at risk and understand how air flows throughout the space.

By simultaneously analyzing different aspects of operation, the audit provides objective, measurable information on plant performance, flow stability and air cleanliness control. The data collected forms a solid basis for guidingoptimization decisions and ensuring the safety of sensitive processes.

Plant inspection and airflow assessment

Equipment, blowers, recovery systems, doors, airlocks and containment devices are checked to ensure that they are working properly and are watertight. Particular attention is paid to laminar flow continuity and areas at risk of cross-contamination.

Air and heat measurement

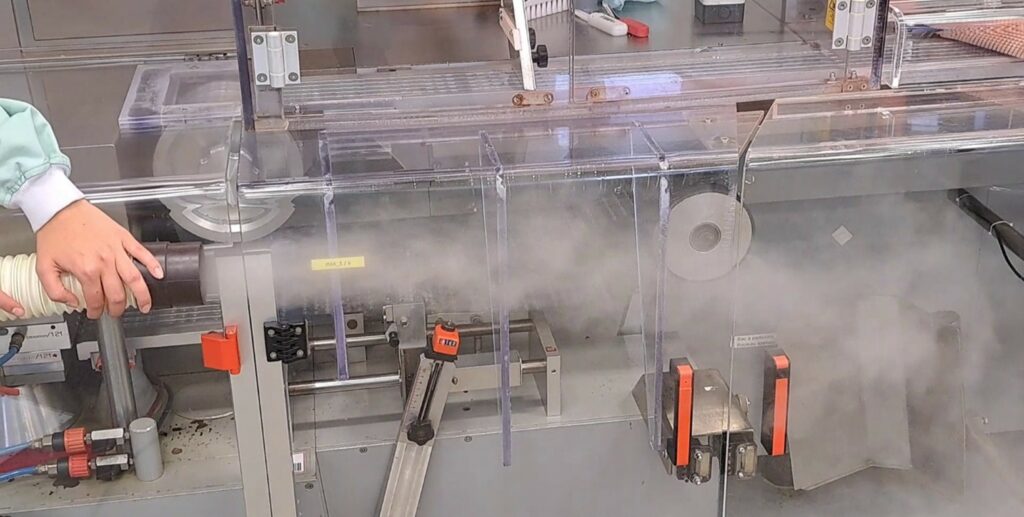

To get an overall view of air behavior in the cleanroom, smoke machines using non-toxicglycol water are used.

Audit smoke test

To complete this visualization, precision anemometers are used to measure air velocities and flows at various strategic points in the room. These measurements enable us to quantify flow behavior, detect stagnation or recirculation zones, and evaluate theefficiency of supply and return air systems. They provide a precise cartography that complements themacroscopic observation provided by smoke.

Finally, air and surface temperatures are analyzed using thermal cameras and temperature probes. This enables us to identify thermal gradients that can influence flows and cause unexpected air movements. This information is essential for understanding how temperature variation impacts particle dispersion and room cleanliness, and serves as a reference for validating or refining simulation models.

Photo taken with a thermal camera during an audit

Smoke testing and particle tracing in cleanrooms

To check that airflows and containment systems are working properly, contamination tracing tests can be carried out.

Smoke contamination test

All these tests and measurements are essential for :

- Check theeffectiveness of containment systems.

- Detecting propagation paths

- Prioritize corrective actions to limit contamination.

- Provide essential field feedback to validate flows and cleanroom design, as well as to refine any CFD simulation studies if necessary.

Identifying critical areas in cleanrooms

Airflow analysis for flow control and process safety

In a cleanroom, not all zones present the same risk to air cleanliness and product safety. Identifying and mapping

- Dead” or insufficiently ventilated spaces

Certain peripheral areas or areas behind obstacles are poorly swept by the air and can become points ofparticle accumulation. These dead zones represent a risk of silent contamination. The audit identifies these areas and proposes either flow readjustments or targeted technical interventions (adjustment of diffusers, repositioning of furniture).

- Flow convergence zones

When several air flows meet, turbulence and recirculation can occur, leading to stagnation or uncontrolled dispersion of particles. Audits target these areas to assess the coherence of flows and propose corrections where necessary, such as repositioning diffusers or adjusting air nozzles.

Flow convergence zone

- Workstations and sensitive surfaces

Areas where critical operations take place (production, assembly, packaging, analysis) are particularly exposed. Any turbulent flow, recirculation or stagnation can deposit particles on products or equipment. The audit focuses on the uniformity of laminar flow over the workstations, air trajectories and the presence of any turbulent zones that could compromise cleanliness.

- Hoods and isolators

These local containment devices are designed to protect the product, the operator or both. Audits check that incoming and outgoing flows follow the intended paths, that smoke or particles do not escape, and that the air inside the hood or isolator is renewed correctly. The junction zones between the hood and the room are also critical points to observe, as any leaks can contaminate adjacent spaces.

- Airlocks and transition zones

Airlocks, high-speed doors or passageways between rooms with different levels of cleanliness represent a major risk of cross-contamination. Opening and closing doors causes pressure disturbances and can introduce particles into clean areas. Audits analyze these transitions to ensure that pressure differences and door operation maintain the desired flow.

- Zones around bulky or hot equipment

Equipment that generates heat or occupies a large volume (fans, ovens, production lines, automated machines) creates micro-turbulence and disrupts laminar flow. The audit measures flow rates and temperatures around these obstacles to detect any undesirable effects and recommend adjustments or additional protection.

- Intensive crossing points

Aisles, corridors and areas through which staff frequently pass are critical zones, since constant movement can generate aerodynamic disturbances and lead to the propagation of particles. The audit enables us to assess the impact of these passageways, and if necessary propose improvements (additional airlocks, barriers, staff training).

Carry out your aeraulic audit with EOLIOS

A cleanroom aeraulic audit does more than simply note discrepancies: it provides an in-depth understanding of the actual operation of your facilities, identifies critical points and proposes concretecorrective actions . This approach contributes directly to the reliability of your processes and the safety of your sensitive environments.

Our experts are on site to take precise measurements, analyze your flows and help youoptimize your cleanrooms. Depending on your needs, the audit can also be completed by a CFD study, to simulate different scenarios andanticipate the future performance of your installations.

Find out more:

Laboratories : on the same subject

Data center engineering

Initially created in France, EOLIOS Ingénierie is the benchmark thermal and aeraulic simulation consultancy for data centers in Europe and worldwide. The company supports operators, designers and project owners at every stage in the life of a data center: design, optimization, renovation or extension.

By combining cutting-edge scientific expertise, state-of-the-art simulation tools and in-depth knowledge of the data center ecosystem, EOLIOS Ingénierie is a trusted partner for ensuring the availability, security and energy performance of IT infrastructures, while anticipating sustainability issues.

EOLIOS

PARIS – LONDON – MILAN – MUNICH – MADRID – WARSAW – CASABLANCA – UNITED ARAB EMIRATES – USA