Fine dust study

Accueil » Industries » Fine dust study

CFD study of dust and sand capture

- Site audit and source detection

- Impact study

- Improving workplace hygiene

- Sizing vacuum systems

- Guaranteeing capture efficiency

- Optimizing air duct networks

- Dust and fume extraction means

- Capture of fine dust (clinker)

- Pressure loss calculations

Our projects :

Airborne dust dynamics: origins, dispersion and environmental issues

Dust in the air: natural and human origins, filtration and control issues

Dusts are particles in the air with a diameter of less than 1,000 microns (1µm).

There are two types of dust in the atmosphere:

- Ofnatural origin, with the wind moving grains of silt and sand (pollen, wind erosion, spores, sodium chloride spray, etc.).

- Fromhuman activity: industry, heating, transport, agriculture (harvesting), etc.

Fine dusts have a diameter of less than 1 micron.

They can be assimilated to fumes, aerosols and smoke.

Because of their small size, they can be difficult to filter and control in environments.

Factors influencing dust dispersion and its impact on the environment

The tendency of dust to disperse and remain in suspension is directly linked to the intrinsic properties of materials, such as their composition (alluvial, eruptive, calcareous) and moisture content, which can vary according to the hydrophobic or hydrophilic nature of the material and weather conditions.

In addition, the shape of particles can also influence their ability to be carried away by the wind or to settle rapidly.

Thus, the dominant characteristics of dust are its nature and size, expressed by its granulometry.

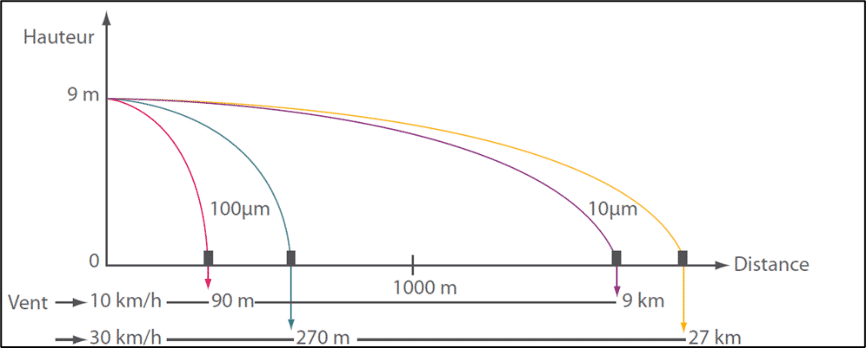

The following graph shows the distance covered by particles falling from a height of 9 m.

Effects of fine dust on health and the environment

Fine dust control is a recurring problem in the industrial sector.

Dust can damage products, impair quality and lead to additional costs or delays in industrial processes.

Fine dust poses many other problems, both for health and the environment.

Their impact on health depends on their nature : mineral dusts such as steel or concrete are more harmful than organic dusts.

Mineral dusts can damage the respiratory and cardiovascular systems by penetrating the lungs and then reaching the bloodstream.

Industrial workers exposed to high levels of fine dust in the air on a daily basis are more prone to respiratory problems, irritation and serious illnesses such as lung cancer.

On the environmental front, dust travels long distances and pollutes soil , water and vegetation, with harmful consequences for ecosystems.

To limit fine particles in the air, regulations and standards have been introduced.

The limit values for fine particles with a diameter of less than 10 microns(PM10) are 40 µg/m3 on an annual average, and those for fine particles with a diameter of less than 2.5 microns(PM2.5) are 25 µg/m3 over the year.

Where does fine dust come from?

Fine dust can occur in many industrial sectors as a result of the various activities that generate airborne particles:

- Wood industry: sawing, sanding, planing, cutting

- Metal industry: grinding, polishing, laser cutting, welding, metal casting.

- Chemical industry: mixing, grinding, sieving, drying, pulverizing products.

- Paper and printing industry: cutting, grinding, ink spraying, paper handling.

- Food industry: grinding, kneading, cooking, milling, food packaging.

- Construction industry: demolition, drilling, sanding, cutting, crushing.

- Mining: extraction, crushing, grinding, screening.

These dusts can contain coal, quartz, lead, wood, iron, aluminum, copper, zinc, nickel, etc.

The higher the level of production, the greater the quantities of dust emitted.

Secondly, production levels can influence dust levels measured over different periods.

Consequently, the industrial sector requires the implementation of appropriate control and prevention measures to limit the formation and dispersion of fine dust.

A significant amount of dust comes from the industrial sector, but there are many different sources.

Air naturally contains suspended particles called aerosols (erosion), complemented by fine dust from other human activities (combustion dust, traffic dust, etc.) which form a background.

Factors influencing dust dispersion

Some fine dusts are more likely to end up in the ambient air.

Their emission depends on several factors:

- Dust particle size: the smaller the particle diameter, the more likely it is to be suspended in the air, and the longer it will remain there.

- Dust shape: a flat particle takes longer to fall to the ground than a spherical one (analogy with a leaf that settles slowly to the ground).

Air diameter has a major influence on particle fall speed. - Product properties: the drier the product, the more likely it is to diffuse into the air (when compressed, for example).

- Weather conditions: wind, drought and precipitation play a major role in dusting the site.

The most unfavorable conditions for dust dispersion are flat terrain, absence of vegetation, low humidity and precipitation, and strong winds.

CFD simulation of fine dust

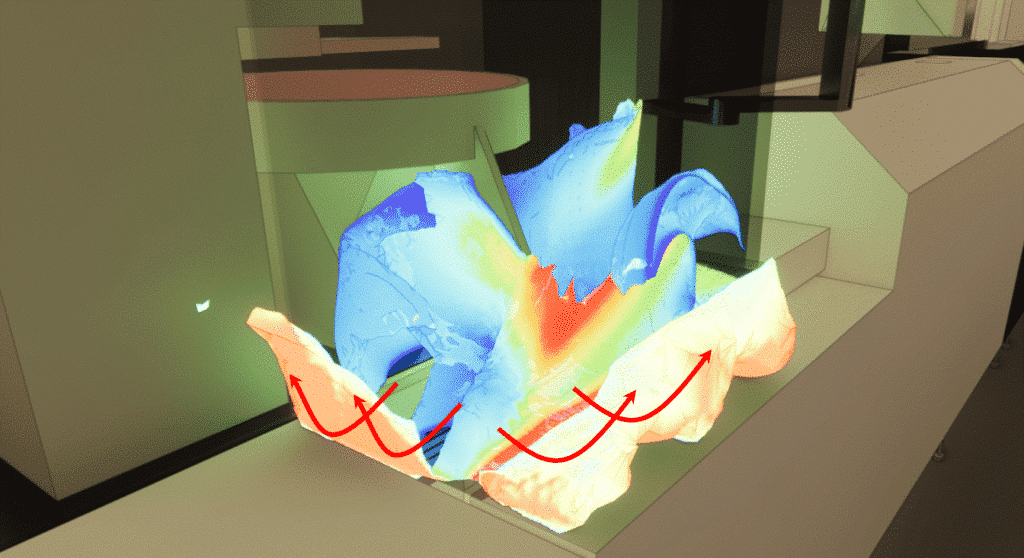

CFD simulation enables us tostudy aeraulics with precision, tracing dust in the air and its diffusion in space, as well as its interactions with structures and systems.

Using this branch of CFD engineering, it is possible to predict dust movement and design appropriate systems to limit the amount of dust in an environment.

We carry out CFD dimensioning studies atplant orsystem scale.

Our studies enable us to study design variants thatoptimize dust capture, thus limiting its diffusion in the air.

The simulation of dust propagation is a special CFD discipline involving the physical characteristics of fine dust or aerosols.

It can be used to model the behavior of air and particles and then predict their distribution in the area under study.

CFD can also be used to determine the time required to limit dust diffusion.

This helps to minimize risks to personnel and production by finding appropriate solutions.

Solutions envisaged by EOLIOS

EOLIOS is able to provide solutions to fine dust problems on all the processes studied, taking into account all the systems involved.

This large-scale analysis is possible and unique thanks to CFD and EOLIOS know-how.

We carry out internal studies in buildings or factories, as well as external studies on the scale of a city, conurbation, port, etc. We can even study the aeraulic phenomena of a particular process.

We can also study the aeraulic phenomena of a particular process.

Our team can help you check andoptimize your various processes.

To this end, we are able to carry out on-site measurement campaigns to obtain dust emission measurements.

These preliminary studies enable us to verify the particle rate in the air, and consequently determine the air quality on site.

Multi-criteria sizing of dust collection systems can then be carried out: