Home » Air quality improvement – Plant

Air quality improvement – Plant

Optimizing the extraction of VOC emissions in a refrigerated truck plant

The Jean Chéreau plant is a refrigerated vehicle production facility located in Ducey-Les-Chéris, Normandy. Opened in 1981, the plant’s ventilation system has since been improved and reworked, but is still based on an old-fashioned design. The plant’s production line emits several types of pollutants (gelcoat, resin) at various points, potentially harmful to workers if present in excessive quantities in the air.

Themain objective is to improve the efficiency of the current ventilation system, while respecting the plant’s constraints.

EOLIOS contributed its technical expertise in the understanding and modeling of aeraulic movements, in order to analyze the problems identified and propose appropriate solutions to correct them.

Air quality improvement - pollutant ventilation process

Year

2025

Customer

NC

Location

FR

Typology

Industries

Continue navigation :

Our other projects :

Latest news :

Technical file :

Our expertise:

Ventilation system and manufacturing process in the plant

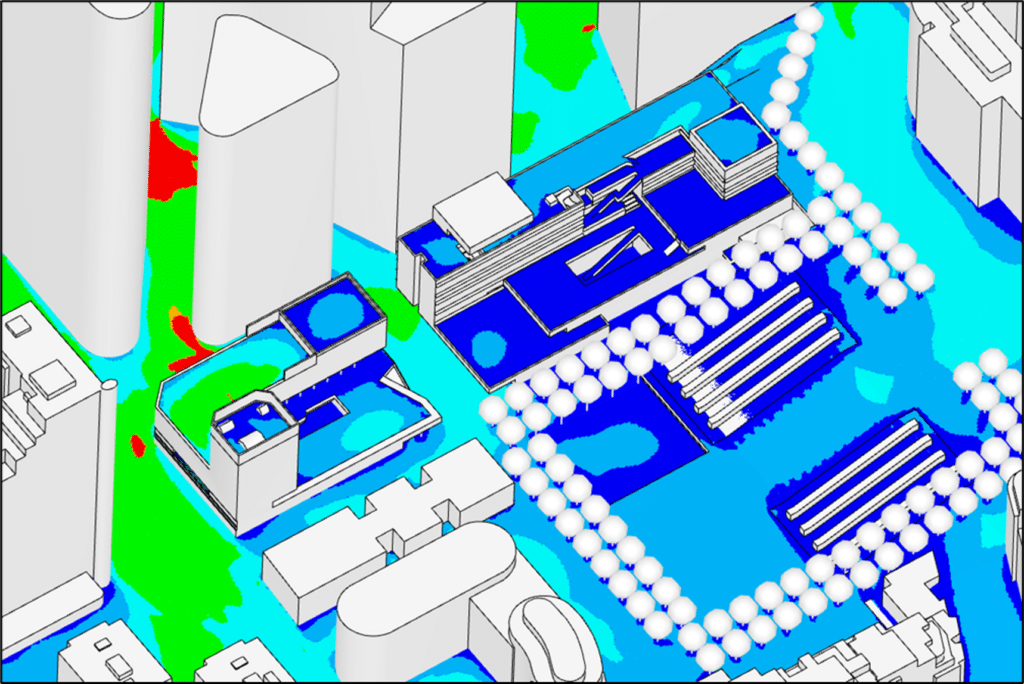

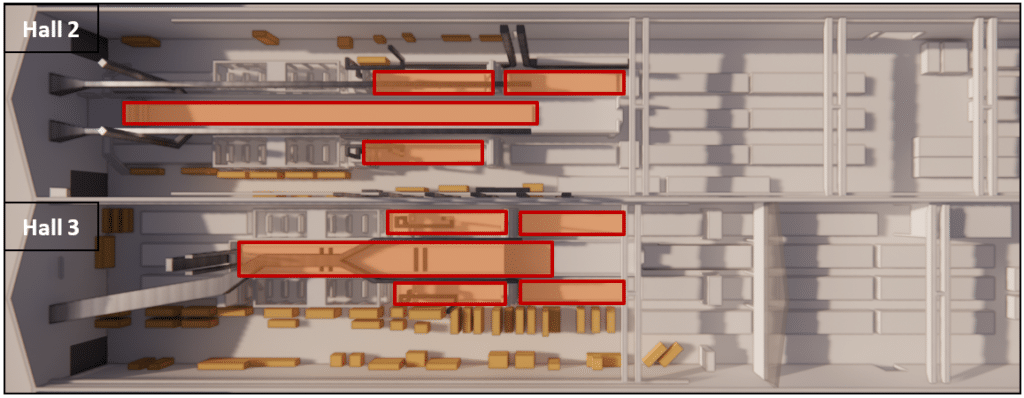

Tables affected by VOC emissions in the study area are shown in red on the diagram.

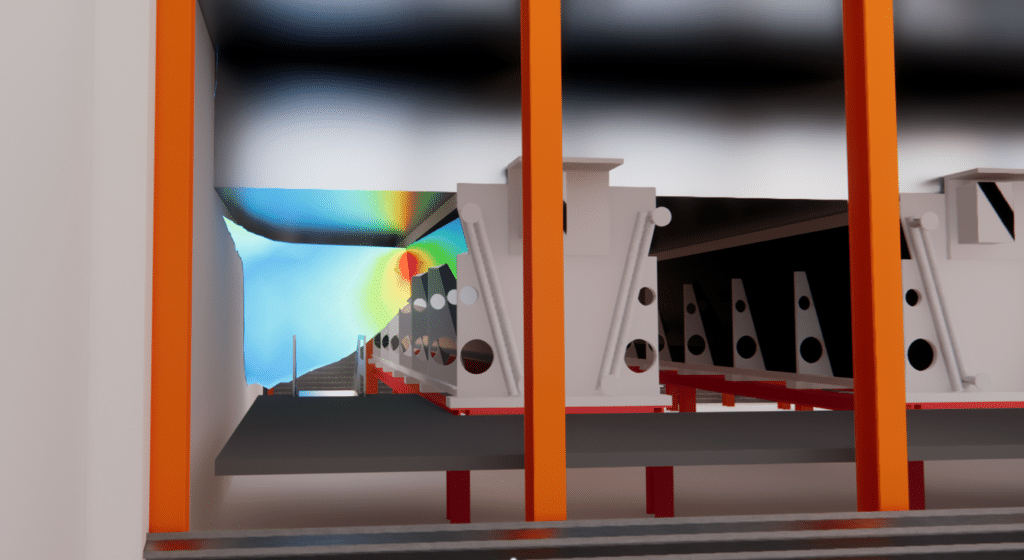

Significant pollutant emissions occur during gelcoat and resin spraying, as well as during the manufacture of truck skins. Operations taking place in halls 2 and 3, chosen for the study.

The ventilation system comprises separate supply and return air zones for halls 2 and 3. In hall 2, fresh air is supplied via two nozzle ducts, which also operate during gelcoat drying. Hall 3 has

Aeraulic expertise: audit, 3D modeling and smoke tests

EOLIOS puts its expertise to work by taking precise measurements using equipment adapted to each situation.

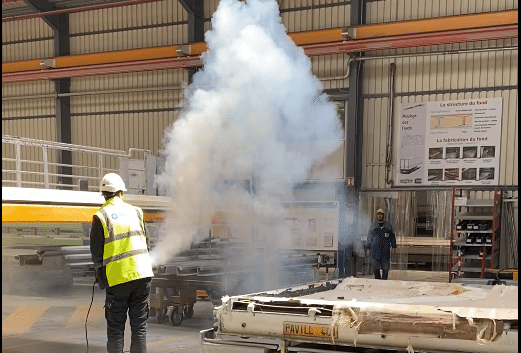

During thesite aeraulic audit, the engineers present carried out detailed measurements, 3D modeling of the plant and smoke tests for a complete assessment.

External weather conditions were also recorded to ensure accurate simulations.

Smoke tests to define aeraulic trends in the workshop - Pollutant capture study

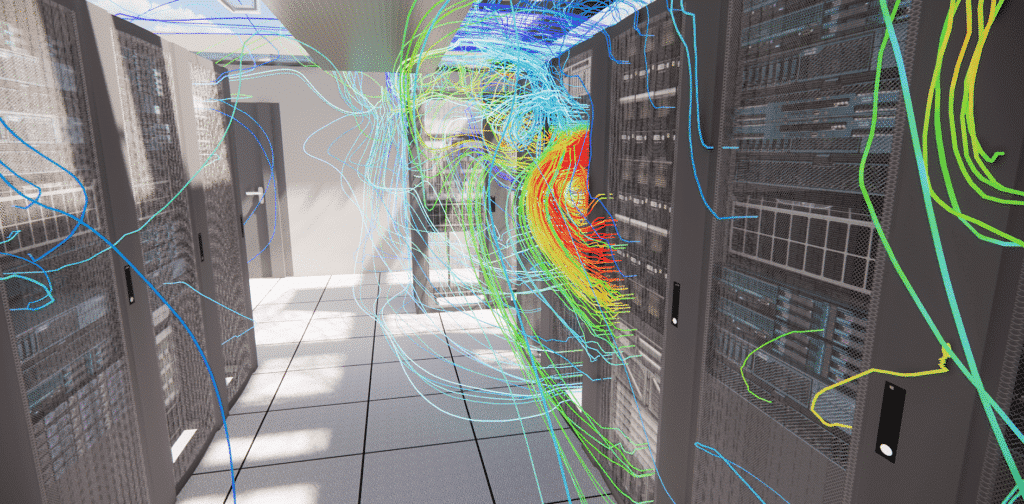

The results showed that overall air movement in the plant is mainly influenced by the blowers. In hall 2, air tends to converge towards the spray tables, creating disturbances and air lift under the roof, which hampers efficient extraction. In hall 3,

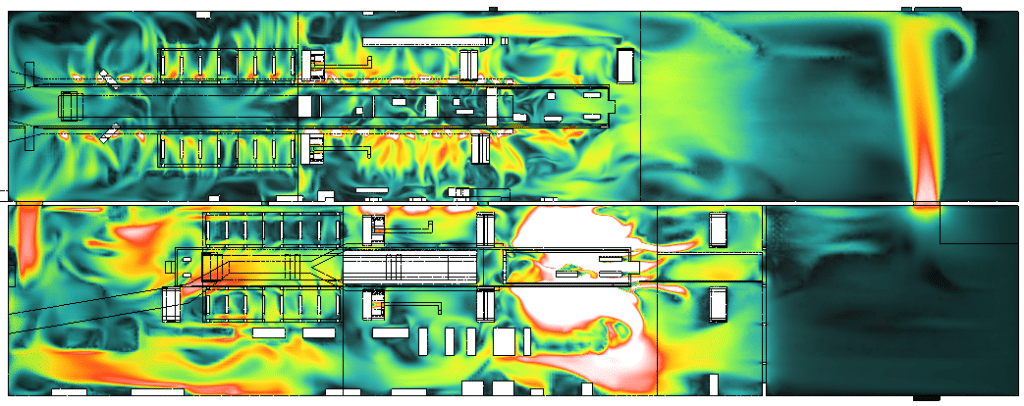

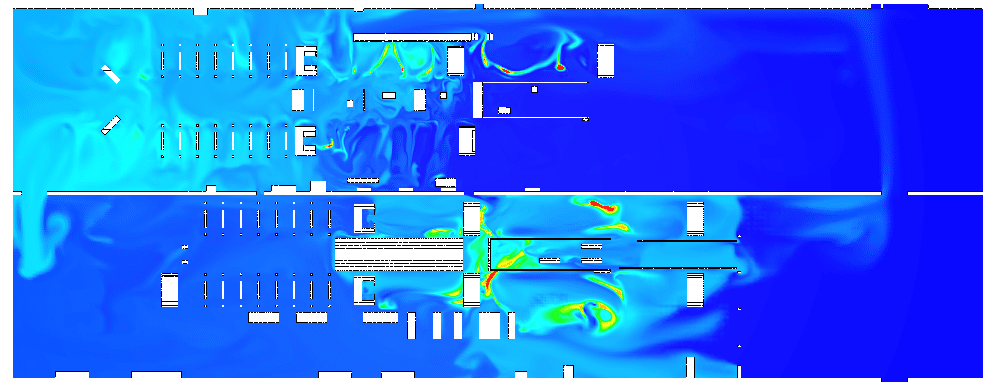

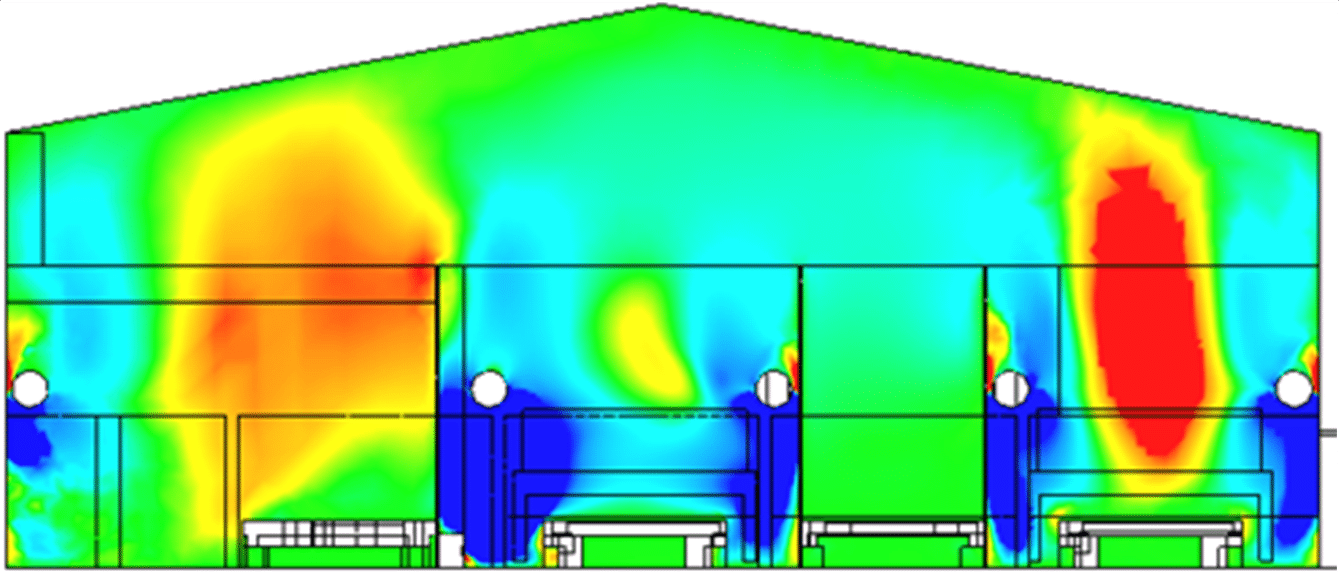

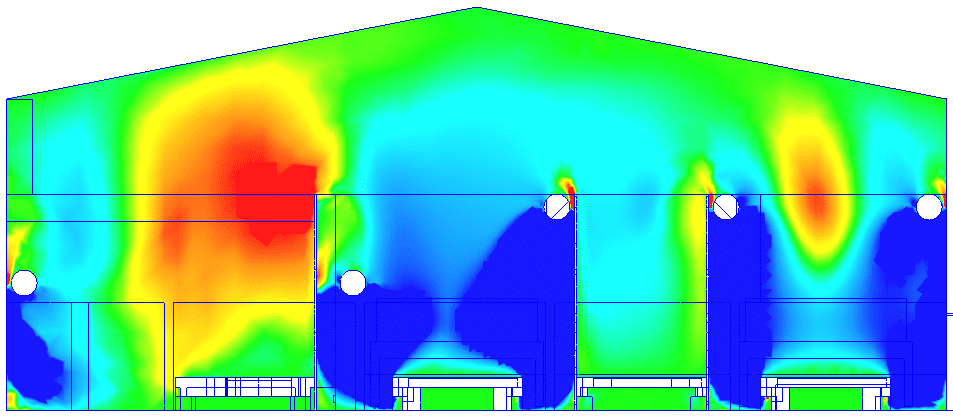

Simulation of the plant, with doors closed, was carried out using theoretical ventilation rates and on-site measurements. The results showed a high degree of concordance between simulations and actual measurements, with significant aeraulic movements similar in both cases. Air flows from the eastern end of the halls to the west, with transverse air loops in hall 2 and complex movements in hall 3. High concentrations of VOCs are observed to the west of hall 2 and to the east of hall 3, due to inadequate ventilation which prevents the proper capture of emitted VOCs.

Understanding Volatile Organic Compounds (VOCs) - Danger and the importance of ventilation

Volatile Organic Compounds, better known by the acronym VOC, are organic molecules that evaporate easily into the air at room temperature. Present in many everyday products such as paints, glues, cleaning products and building materials, VOCs are a source of indoor pollution that can have harmful consequences for human health and the environment.

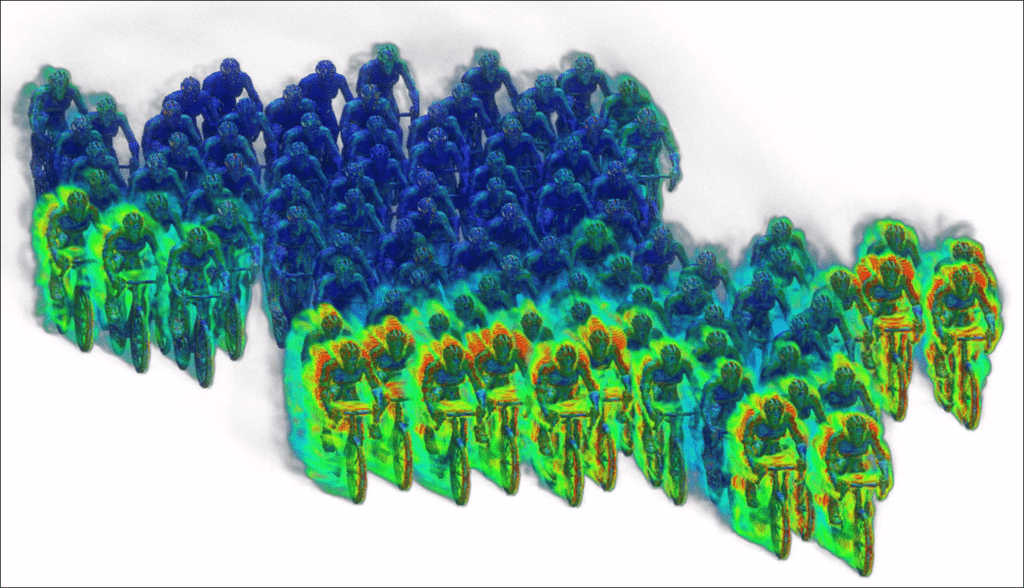

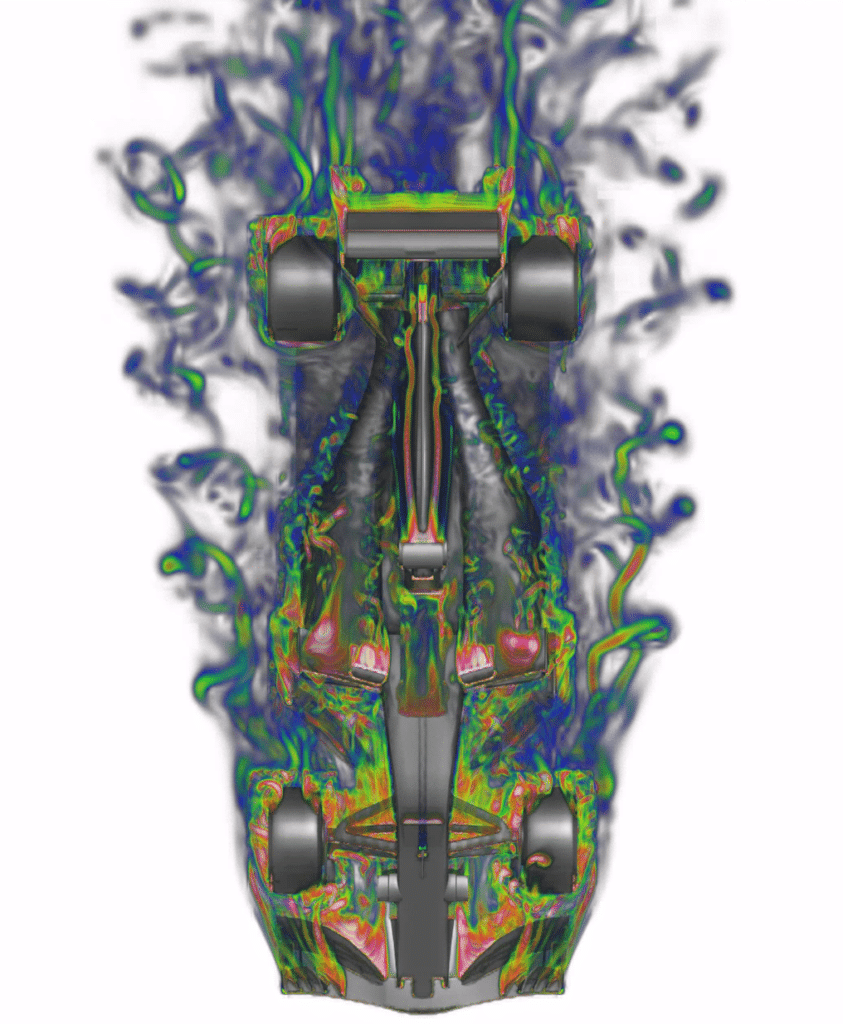

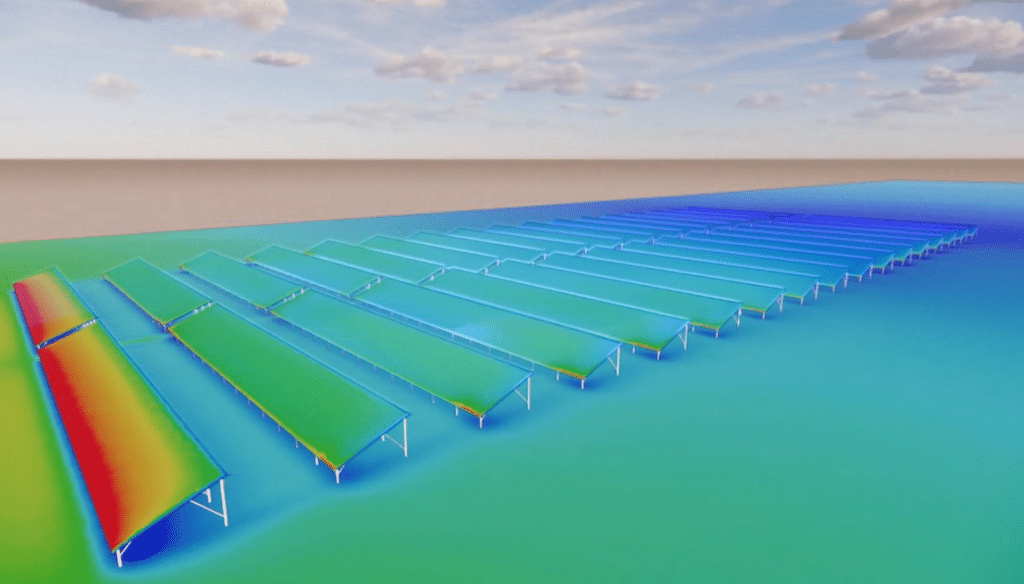

VOCs are released into the air via vaporization processes or during the incomplete combustion of fuels. Understanding the behavior of VOCs in indoor environments is essential to their effective management. EOLIOS uses CFD techniques to model VOC dispersion. CFD makes it possible toanalyze air movements and predict the concentrations of these compounds in different areas of a building, thus ensuring optimized ventilation and evacuation.

Prolonged exposure to VOCs can lead to a variety of health problems, including irritation of the eyes, nose and throat, headaches, allergic reactions and even damage to the liver, kidneys and central nervous system. Some VOCs are also classified as carcinogens. Consequently, the management and reduction of VOCs in confined spaces is essential to ensure a healthy environment.

The key to minimizing exposure to VOCs lies in effective evacuation. This starts with good ventilation of spaces, controlled and improved through the use of CFD technologies to ensure that air circulates correctly and that VOC concentrations remain below dangerous thresholds. EOLIOS specializes inoptimizing ventilation systems and implementing tailor-made solutions to guarantee indoor air quality.

Compliance and safety of ventilation systems: a standards-based approach

EOLIOS places compliance with standards at the heart of our approach, because we know that it is essential to guarantee effective, safe solutions that comply with regulatory requirements. Every study we conduct, including this one, is carried out with a

This rigorous approach minimizes risks and optimizes working environments, while complying with the highest industry standards.

Advanced CFD airflow efficiency

Following a study of the standards, two designs were proposed to optimize airflow management and ambient air quality. The first design incorporates major improvements over the basic configuration, such as theimplementation of partitions around VOC emission zones, uniform low-velocity blowing by textile ducts, and adjustments to return points. These modifications are designed to keep VOC levels below 25% of the VLEP by using PPE in confined areas.

The VLEP, or Occupational Exposure Limit, is a regulatory standard defining the maximum concentration of a chemical substance to which a worker may be exposed in the workplace. This value is used to prevent health risks by setting tolerance thresholds that must not be exceeded during a given period, generally a working day. It is set to protect workers against the harmful effects of hazardous substances present in theworking environment.

Ventilation rates were adjusted to avoid excessive diffusion of VOCs, thus controlling air circulation and reducing their concentration at workers’ faces. The concentrations measured show a clear improvement in operator safety.

The second configuration, developed to overcome the limitations identified in the first, introduces suction ducts under the resin and gelcoat tables, eliminating lateral suctions generating space constraints for workers. This designmakes suction more efficient, especially on previously less efficient tables. Supply air ducts have been repositioned for more efficient vertical sweeping of fresh air, eliminating undesirable upward air movements. This approach guarantees more homogeneous air velocities and follows a controlled descent, reducing the dispersion of VOCs outside the targeted zones. Simulations show a reduction in VOC concentrations at breathing height, avoiding accumulation between tables and partitions.

This study effectively tested both configurations: one focused onoptimizing rework, and the other also aimed to take into account the clutter and difficulties of employee work, while maintaining a clear separation between work zones, thus improving air quality and worker safety.

Comparison of vertical velocity component between design with side suction (left) and design with under-table suction (right)

Collaborative approach - practices in the field

Visit ability to listen, compromise and dialogue are at the heart of our collaborative approach between engineers and workers throughout the study. We recognize the importance ofintegrating technical expertise with practical realities in the field. As a result regular visits were organized at every stage of the project to ensure that all perspectives were taken into account.

Our engineers have demonstrated the ability to listen attentively, enabling the emergence of solutions that were not only aeraulically optimal, but also practical for the workers. This participatory approach has enabled us to create a safe and effective solution, while remaining aligned with the needs and expectations of the various stakeholders.

EOLIOS can help you solve your air quality problems

At EOLIOS, we work with you to improve the extraction of VOCs and other pollutants in your plants, taking into account the ventilation systems, filters and equipment in place. We ensure optimum air flow and uniform distribution, minimizing stagnation zones where VOCs can accumulate. By analyzing air flows, we identify critical areas with the greatest risk of VOC concentration.

Our use of CFD also enables us toassess the efficiency of filtration systems by detecting any leaks of contaminated air. Thanks to our expertise, we can validate and optimize the performance of ventilation systems on the premises, ensuring that the required emission levels are met and maintained, in line with the most stringent environmental and safety standards.

Continue on this topic

Video summary of the study

Summary of the study

The aim of the study was to improve air quality at the Jean Chéreau plant, by optimizing its ventilation system.

Video summary of the mission

Discover other projects

Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Radiation and ventilation study of an industrial ingot mould

Study of natural ventilation – Steelworks

Air quality improvement – Plant

Sizing – Chimney – Laboratory

High-temperature process plant

Natural ventilation – Metallurgy

Glassworks – Cognac

Natural ventilation – Aluminium Dunkerque

Smoke treatment system – CO2

VOC treatment process improvement

Sizing an industrial chimney – Furnace

Improving thermal comfort – Steelworks

Plant – Wind turbine

Industrial Workshop – Mexico

Factory – glove production

Stratification of a thermal storage tank

Generator sets – GE1

Glassworks – Hauts De France

Sizing of natural draft extractor hoods