Commissioning: study and CFD modeling of load benches

Home » Data Center » Commissioning: study and CFD modeling of load benches

Thermal validation of loadbanks using CFD simulation

EOLIOS masters heat flow management from the very first stages of validation of your data centers.

- Validation of data center thermal testing strategy

- Assessment of thermal distribution in aisles

- Analysis of air temperatures at equipment inlet

- Study of the critical conditions that can trigger the

- Identification of hot air recirculation or stagnation zones

- Control of air distribution homogeneity

- Sizing the flow rates delivered by the benches according to load scenarios

- Recommendations for system setpoints

- Assessment and recommendations on pressure losses generated

EOLIOS is a leader in external CFD simulation for Data Centers. Our studies are based on feedback from measurement campaigns in real-life conditions and from a hundred or so simulated sites around the world.

How can CFD simulation be used for loadbanks?

Secure load-bed testing with advanced CFD modeling.

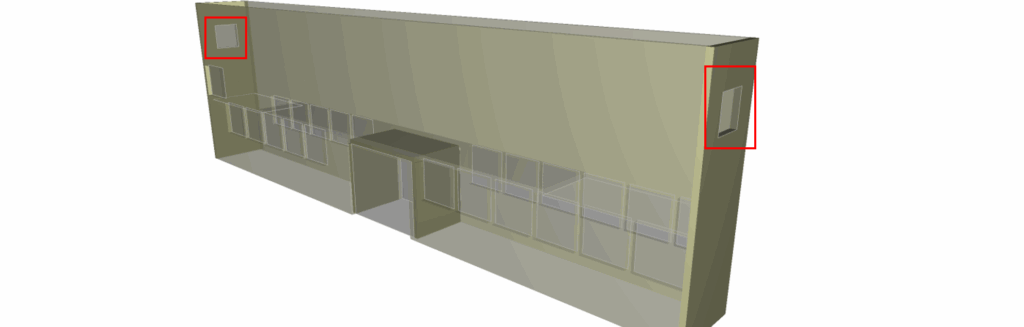

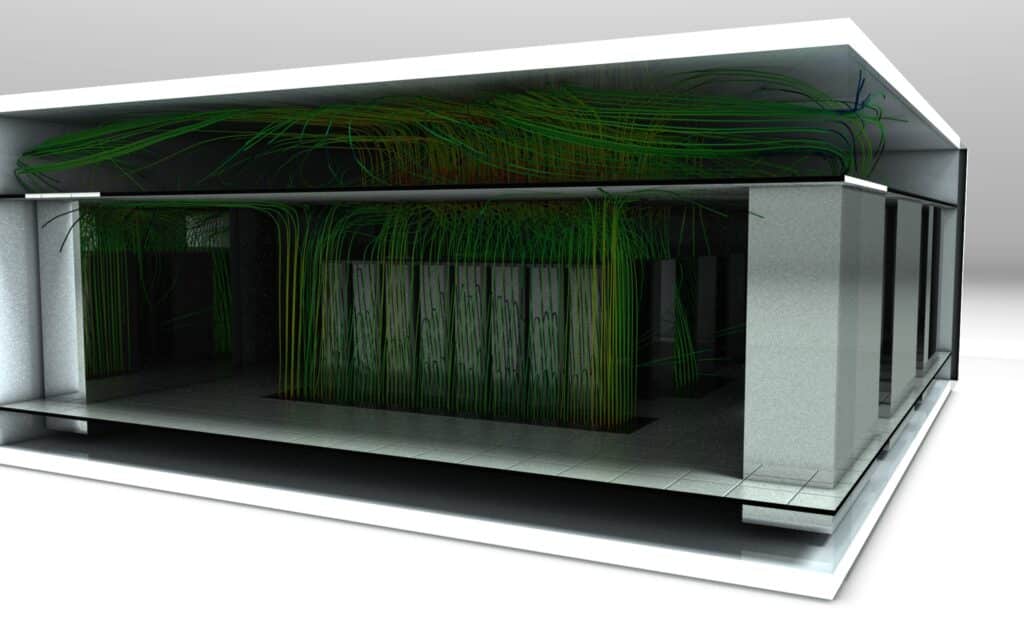

CFD modeling is used here upstream of commissioning, to validate the data center’s aeraulic and thermal behavior during the load bank test phase. This numerical simulation enables a detailed analysis of the interaction between the flows generated by the benches, the air handling systems (CRAH) and the fire safety systems (sprinkler). These analyses are used to adjust the configuration of the benches to ensure that thermal safety thresholds are not exceeded.

In a test environment, characterized by the presence of load benches with adjustable power ratings, non-definitive diffusion grids and artificially generated air flows, the aeraulic complexity becomes significant. Air movements are influenced by the pressure drop of each load bank, the room geometry , the CRAH settings, and the boundary conditions imposed.

Without modeling, it becomes difficult to predict the actual distribution of temperatures and pressures, and their impact on cooling system performance. Precise analysis of air distribution is therefore a priority lever for optimization. Not only does it guarantee a homogeneous supply of cold air to computer racks, but it also ensures that extracted calories are correctly evacuated, without any undesirable interaction with incoming flows or sprinkler systems.

Analyze and control thermal-air phenomena during testing

CFD simulation is not a generic solution, but a practical engineering tool adapted to real needs, capable of providing a detailed and operational understanding of thermo-aerodynamic phenomena in a temporary or unstable environment. In particular, it helps secure the test phase by ensuring that the room’s thermal behavior remains compliant with requirements, even under extreme load conditions or in the event of equipment failure.

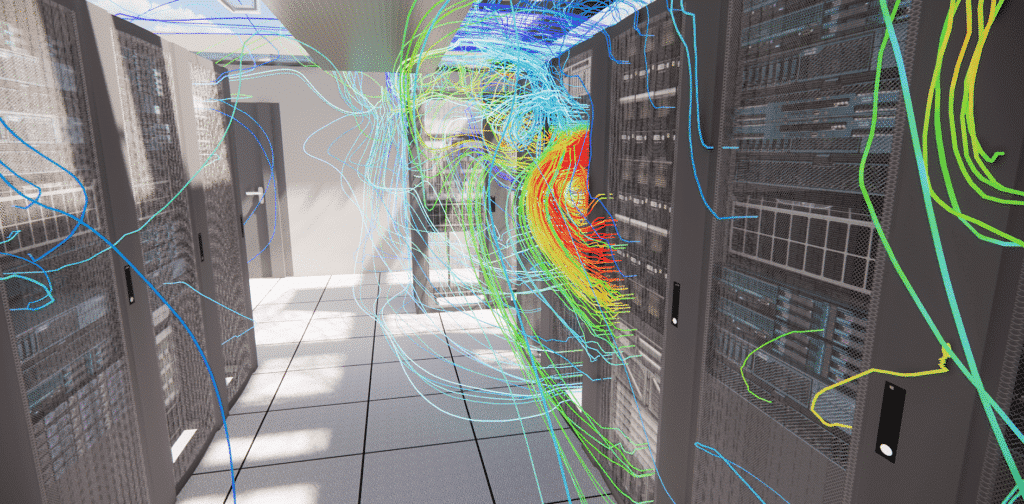

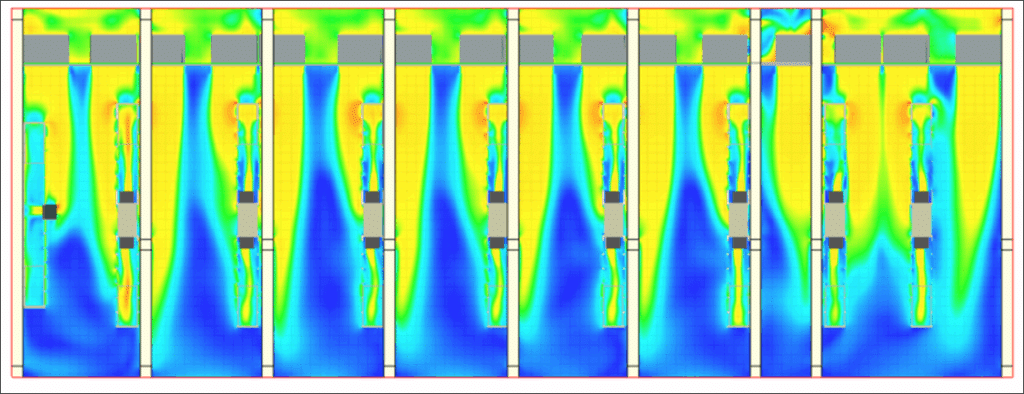

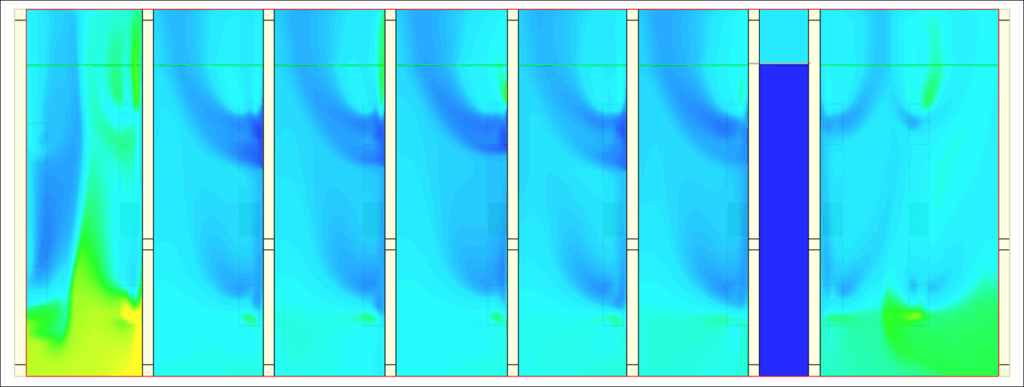

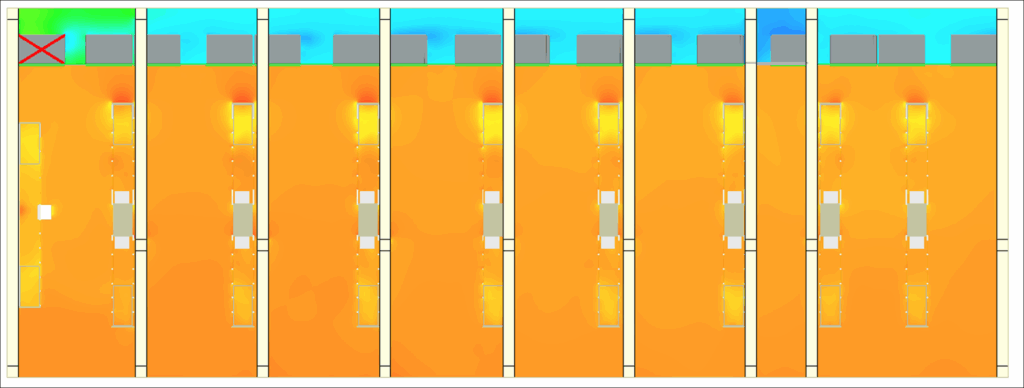

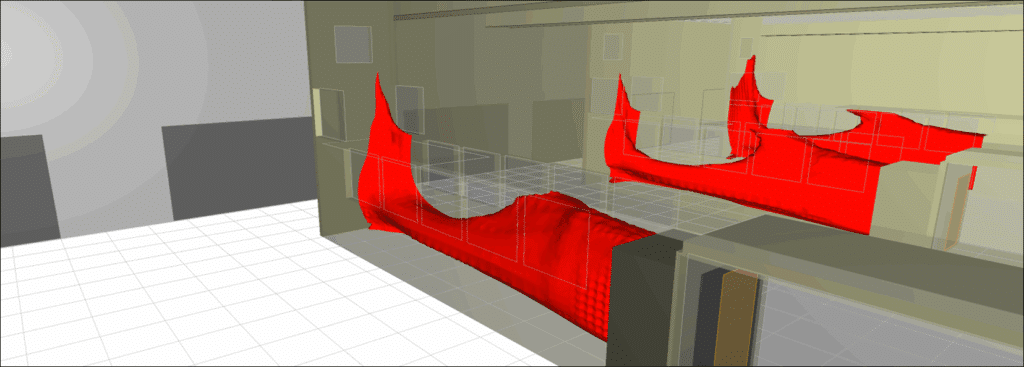

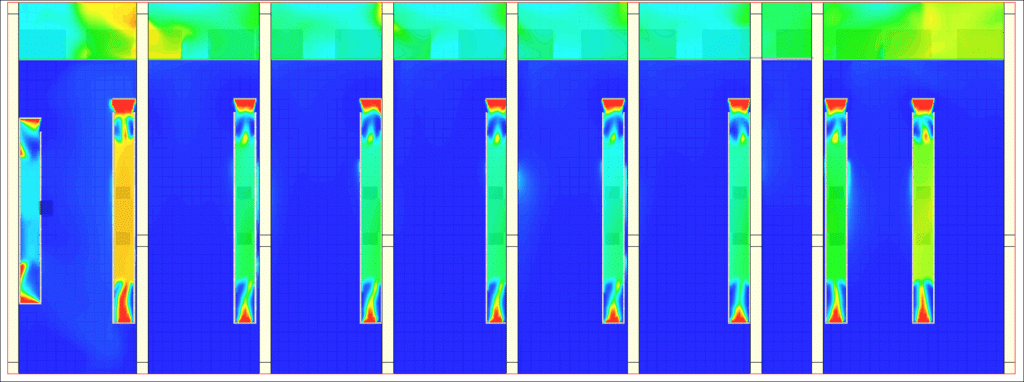

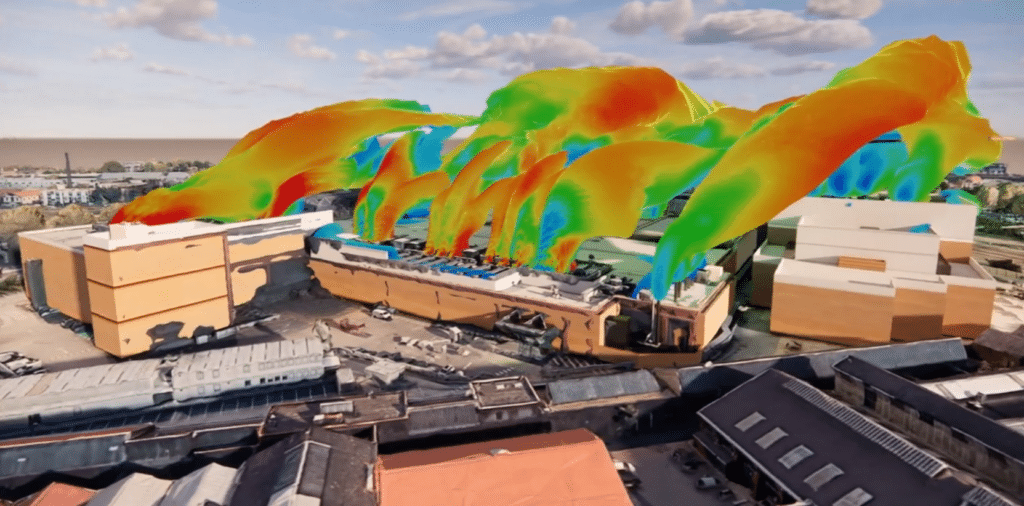

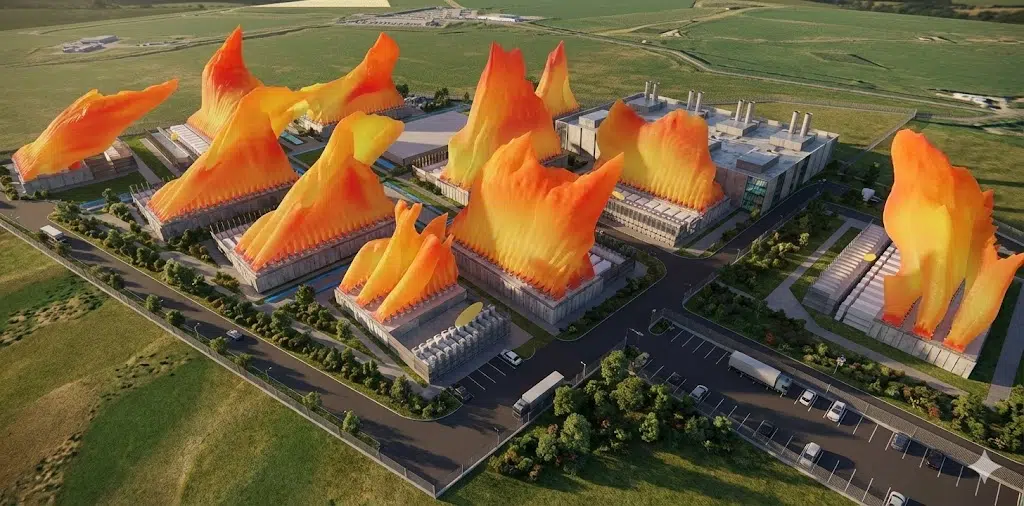

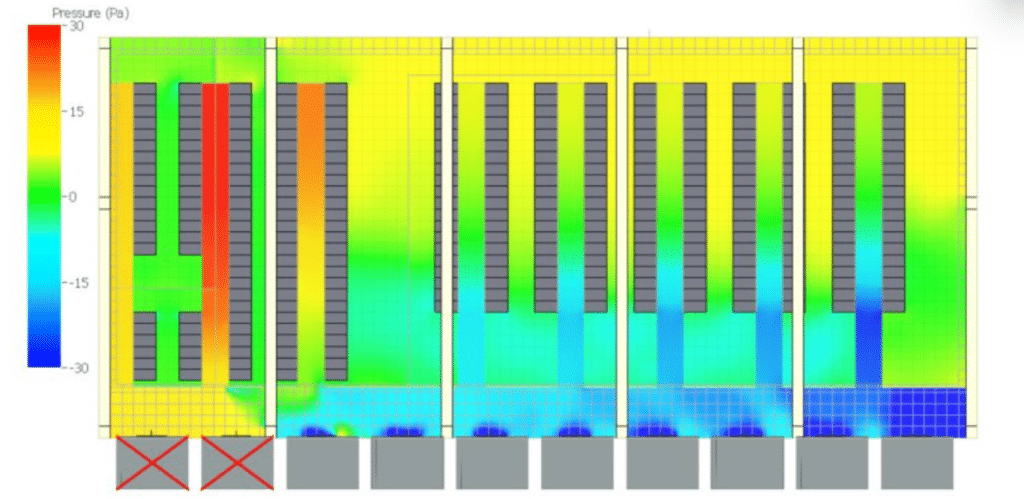

Our numerical modeling tools, and in particular Computational Fluid Dynamics (CFD) methods, enable us to accurately analyze the distribution of temperatures, air velocities and pressures in the room during load-bed testing. This approach makes it possible to graphically represent thermal plumes, recirculation zones, pressure gradients and flows induced by test equipment.

Lastly, it provides a lever for optimization, enabling us to fine-tune climatic setpoint settings, validate the positioning of load banks, and guarantee that the building’s thermal envelope will react as expected during final commissioning.

Load banks play a key role in the thermal validation of a data center before it goes into production. By reproducing the thermal dissipation of IT equipment, they enable the actual behavior of the cooling system to be tested in a controlled environment. However, their use creates complex transient conditions, often far removed from the final configuration. CFD simulation makes it possible to anticipate these effects precisely, to adjust test scenarios, and to ensure that load banks fulfill their full function without generating risks for the infrastructure.

EOLIOS CFD approach: securing load bank commissioning tests

Validation CFD simulation: anticipating risks before loadbench testing

When an EOLIOS engineer accompanies your team during the commissioning phase with loadbanks, he or she brings not only expertise in data center climate management, but also the ability to anticipate critical thermal behavior even before tests are carried out on site. This approach guarantees a controlled test campaign, with no risk to the infrastructure, and avoids technical problems or results that are difficult to interpret.

By simulating upstream crisis scenarios, such as the loss of a main air-conditioning unit or a momentary power cut to the load banks, it is possible to identify sensitive variables and the system’s thermal reactions. This makes testing safer by virtually testing extreme conditions that are difficult to reproduce in real-life tests.

Optimize bench placement and climatic conditions for reliable testing

CFD modeling plays a key role in test preparation. It enables us to optimize the placement and power of load banks, so as to faithfully reproduce the thermal behavior of future IT equipment. It also helps to validate the robustness of cooling systems under full or degraded load conditions, and to adjust control setpoints without compromising safety.

Our engineers study the restart sequences of emergency equipment, the thermal inertia of control loops, and transient temperature rises throughout the room. This enables us to identify the most unfavorable zones and calculate the maximum temperatures to be expected, so as to guarantee perfect control of thermal behavior throughout the tests, and ensure that no untimely triggering of the fire system can damage the building or interrupt operations.

Why carry out CFD simulation before load-bed testing?

An essential tool for safe data center commissioning

CFD simulation applied to the load-bed test phase represents an important step in validating the efficiency of the cooling system, optimizing testing and guaranteeing site safety. This initial investment enables us to visualize in three dimensions the distribution of air flows, temperatures and overpressures within the room, well before committing the equipment to a real heat dissipation campaign.

The CFD model generates clear images and videos, accessible to all those involved in the project – engineers, operators, safety managers – who can thus anticipate possible areas of overheating, recirculation or thermal tripping. This simplified but accurate representation of aeraulic behavior enables rapid, well-informed decisions to be taken, even before load banks are installed.

If necessary, sensitive data is protected: our models are only accessible through a secure reader, supplied with a proprietary EOLIOS driver, guaranteeing the confidentiality of project information.

Identify critical points before testing

The heat maps generated by the simulation accurately show the areas at risk These include heat stagnation at the bottom of the bay, imbalances between aisles, or local pressure increases that could activate a fire system. Even before the benches are triggered, it is possible to adjust the positioning of CRAH units, modify the layout of grilles or adapt heating sequences.

The build-up of hot air in the ceiling during testing can cause the sprinkler system to activate unexpectedly. EOLIOS uses CFD simulation to identify these critical areas, and recommends solutions such as the addition of extra grids to ensure effective, safe thermal control.

Our specific solutions for data centers :

CFD engineering for data centers

Find out more

Thermal storage study

Find out more

External CFD simulation for data center

Find out more

Data Center Fire Simulation

Find out more

Thermal study of technical premises

Find out more

Urban heat island impact study for data centers

Find out more

Audit, diagnosis and 3D modeling of existing data centers

Find out more

Designing your data center’s digital twin

Find out more

Energy optimization and PUE calculation for data centers

Find out more

Commissioning: study and CFD modeling of load benches

Find out more

Data center engineering

Initially created in France, EOLIOS Ingénierie is the benchmark thermal and aeraulic simulation consultancy for data centers in Europe and worldwide. The company supports operators, designers and project owners at every stage in the life of a data center: design, optimization, renovation or extension.

By combining cutting-edge scientific expertise, state-of-the-art simulation tools and in-depth knowledge of the data center ecosystem, EOLIOS Ingénierie is a trusted partner for ensuring the availability, security and energy performance of IT infrastructures, while anticipating sustainability issues.

EOLIOS

PARIS – LONDON – MILAN – MUNICH – MADRID – WARSAW – CASABLANCA – UNITED ARAB EMIRATES – USA