Dust dispersion study – Geology laboratory

Dust dispersion study - Geology laboratory

Year

2025

Customer

NC

Location

Paris

Typology

Laboratories

Home » Laboratories » Study of dust in clean rooms » Dust dispersion study – Geology laboratory

The mission carried out by EOLIOS Ingénierie: expertise in CFD simulation and aeraulic control.

EOLIOS engineers are experts in airflow modeling and particle dispersion.

EOLIOS’ expertise in CFD (Computational Fluid Dynamics) simulation has enabled us to accurately analyze particle dispersion phenomena in a geology laboratory. Using realistic 3D modeling and a rigorous scientific approach, the study highlighted the areas at risk and assessed the effectiveness of existing capture devices.

This approach has helped optimize operator safety and sustainably improve air quality in a demanding work environment.

EOLIOS is a leading player in CFD simulation applied to complex indoor environments, drawing on extensive feedback from measurement campaigns and numerous studies carried out on real sites.

Preserving health at the heart of laboratories: a crucial challenge

Air as a risk vector in confined spaces

In paleontological laboratories, ambient air quality plays a fundamental role in preserving the health of operators. Behind the meticulous scientific manipulations, often carried out using mechanical or pneumatic tools, lies a much less visible but potentially dangerous phenomenon: the diffusion of fine dust from fossils or rock matrices.

As in hospital or pharmaceutical environments, geological preparation areas are associated with filtration requirements. The dust generated when fossils are released can be abrasive, irritating and even toxic, depending on its composition. Controlling their dispersion is therefore imperative, not only to guarantee working comfort, but also to prevent any health risks associated with chronic exposure.

Impactors, dust and propagation: a trio to watch out for

At the heart of the fossil-clearing process, the tools used act as powerful vectors for suspending particles. This is particularly true of pneumatic percussion pens, used to delicately fragment the rock around samples. These tools generate an air flow of around 1 m/s at their outlet, mechanically propelling the dust into the immediate environment.

In the absence of effective capture at source, these emissions can disperse freely throughout the room volume, crossing the workspace and reaching users’ respiratory tracts. This problem is exacerbated by the presence of several workstations operating simultaneously, and by restrictive room geometry, where air flows may encounter obstacles or create recirculation loops.

Faced with this configuration, conventionalwall-mounted extraction or general room air renewal systems often prove insufficient. A targeted, localized approach is required.

A CFD study to objectivize performance and guide technical choices

This is the background to the study carried out by EOLIOS. It is based on the use of computational fluid dynamics (CFD ) to analyze, quantify and visualize particle dispersion phenomena in the geology laboratory.

The aim of this modeling is twofold:

- Validate the capture performance of the existing fume cupboard, checking that face velocities meet regulatory requirements(EN 14175 standard) and that pollutant containment is under control.

- Evaluate the comparative effectiveness of several configurations for controlling dust generated at workstations: absence of mobile capture, addition of suction arms, and installation of frontal protection.

By modeling these different scenarios and visualizing the trajectories of the particles emitted, the study makes it possible to identify areas at risk, quantify the volumes impacted by dust, and steer technical choices towards proven, pragmatic and economically viable solutions.

Understanding for better protection: why model with CFD?

Simulate to visualize the invisible

Numerical simulation using fluid mechanics (CFD) has become an indispensable tool for controlling complex indoor environments. In an enclosed space such as a geological laboratory, where air flows, physical obstacles and particulate emissions are constantly interacting, only accurate three-dimensional modeling can provide an understanding of real air and dust dynamics.

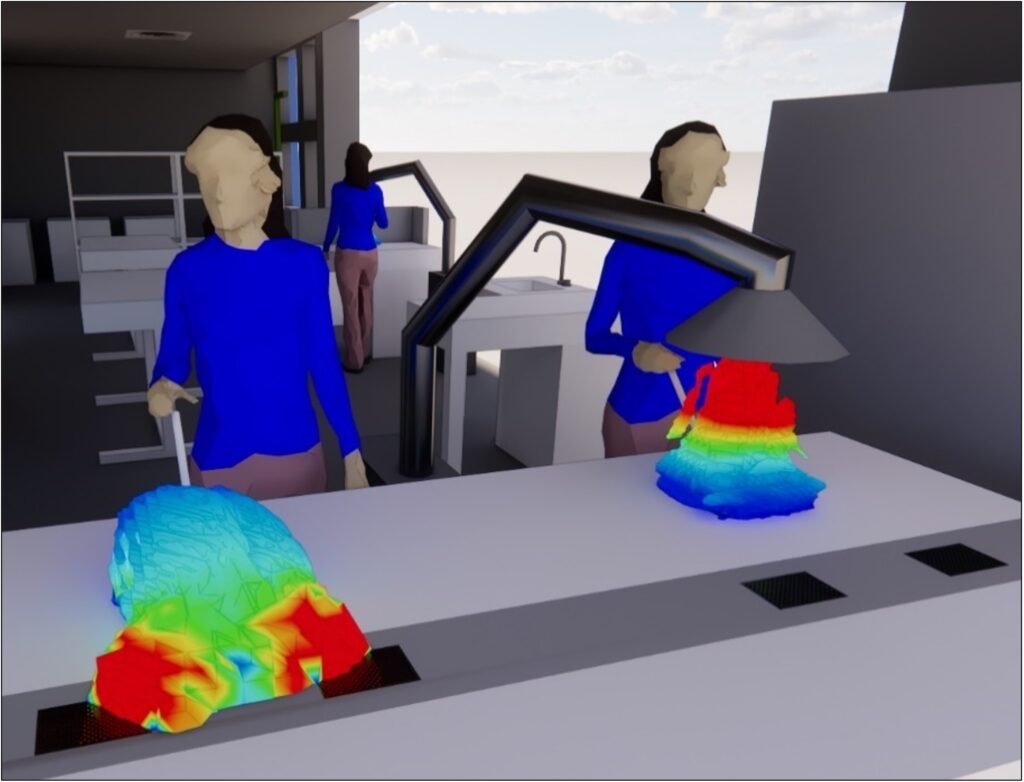

The approach developed by EOLIOS is based on detailed modeling of the paleontological preparation laboratory, integrating the geometries of the furniture, the technical characteristics of the aeraulic equipment and the sources of particle emissions. From this base, representative steady-state scenarios were simulated to reproduce numerically theflow and dispersion behaviors observable in real-life conditions.

Detailed consideration of air quality maintenance systems - Sorbonne

An objective comparison of capture solutions

One of the main objectives of the study was to visualize the different scenarios and check compliance with current standards:

- The fume cupboard in nominal (low flow) and intensive (maximum flow) operation, to validate compliance with regulatory face velocities and theeffectiveness of pollutantcontainment.

- Wall-mounted extraction grilles, positioned at the back of the room, assessed for their ability to evacuate particles diffused into thegeneral environment.

- Mobile suction arms, to estimate their efficiency at source when handling fossils.

- The presence or absence of frontal protection on workstations, to assess its role in local containment of projected dust.

The CFD simulation identifies air velocities, dust concentrations (via a diffusion scalar) and emission trajectories at each point in the room. Each solution is analyzed factually and quantified.

Detect risk areas to guide improvements

In addition to simple air velocities, modeling can be used to identify critical zones: dust stagnation, recirculation loops, vertical ascent or transverse diffusion. These phenomena, often invisible to the naked eye, can be the source of secondary contamination or recontamination in the absence of appropriate containment.

Thanks to this approach, it becomes possible toanticipate design or usage faults, and propose targeted improvements: whether this involves repositioning arms, adjusting flow rates or adding passive devices such as protective screens.

Diving into the heart of the laboratory: a precisely modeled environment

3D modelling true to reality

The accuracy of CFD results depends above all on the fidelity of the digital model. For this study, theEOLIOS team reconstructed the paleontological preparation laboratory in detail, using DWG drawings of the site and technical data sheets for the equipment supplied. Every element influencing flow was integrated: volumes, partitions, furniture, work surfaces, and diffusion and extraction systems.

The resulting3D environment is a realistic representation of the laboratory, in line with current operating conditions. This precision makes it possible toanticipate real air flows and the complex interactions between emission sources, physical obstacles and ventilation systems.

Complete integration of capture equipment

All the actual air handling devices in the room have been modeled:

- The fume cupboard used for high-risk handling operations was simulated in two representative configurations: reduced flow with the window down, and maximum flow with the window fully open, in order to assess its containment performance.

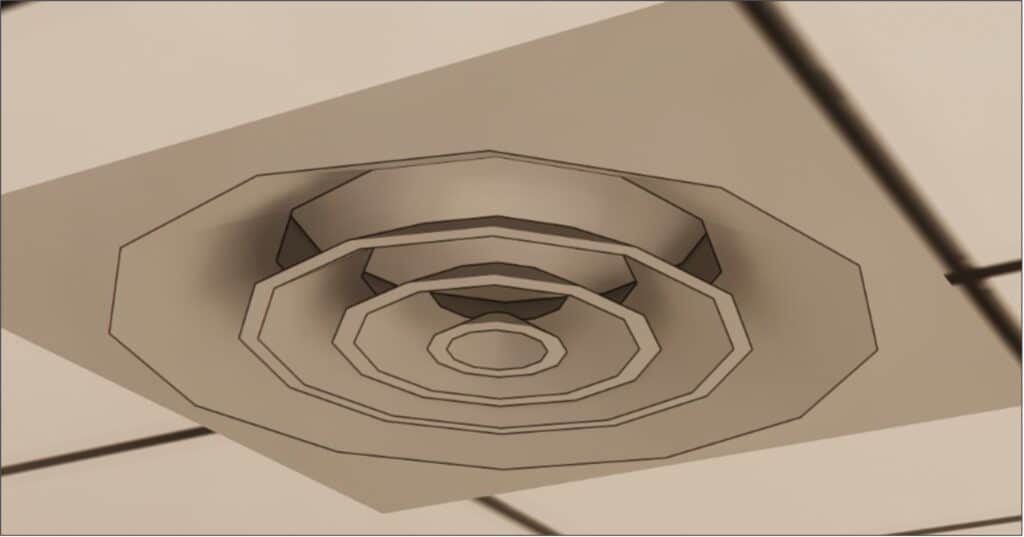

- Ceiling-mounted air diffusers supply fresh air. Their special design ensures controlled diffusion, with minimal disruption to local air flows.

- Twelve wall-mounted extraction grilles, arranged on two levels behind the workstations, help toevacuate residual particles from the environment, and compensate for the activation or non-activation of the fume cupboard.

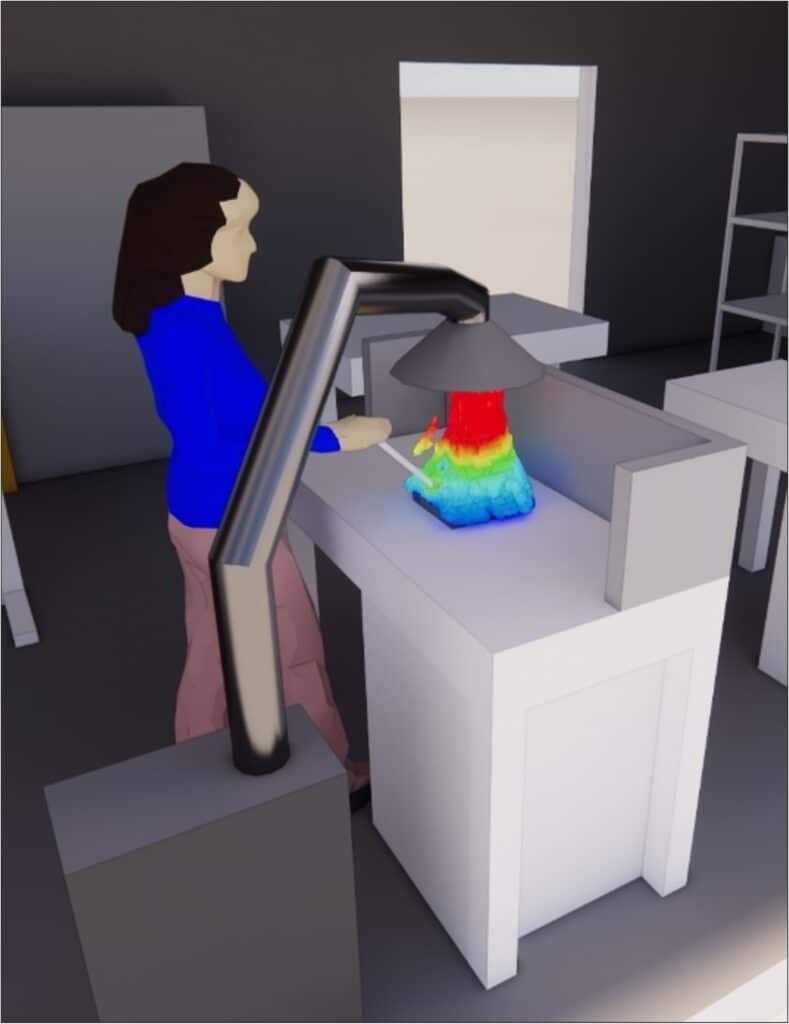

- Two mobile suction systems with articulated arms were positioned as close as possible to the fossils. They play an essential role in source capture.

Finally, to faithfully reproduce the emission scenario, a striker pen blowing at 1 m/s continuously was modeled at the fossil level, at each workstation. This device simulates the release of dust during mechanical processing of the parts.

Rigorous CFD simulation methodology

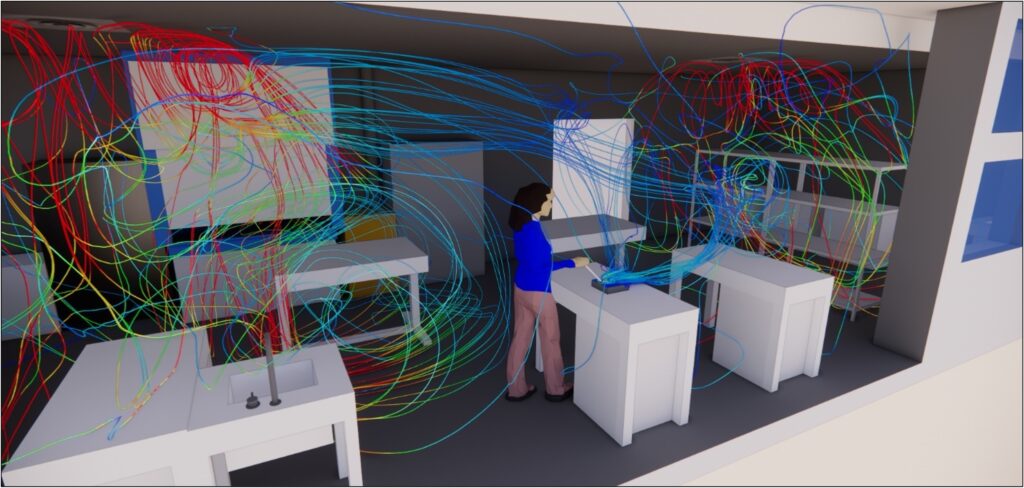

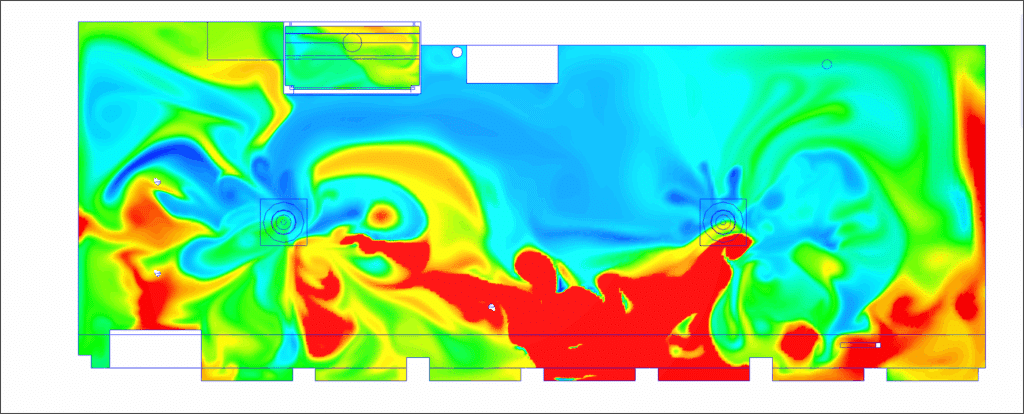

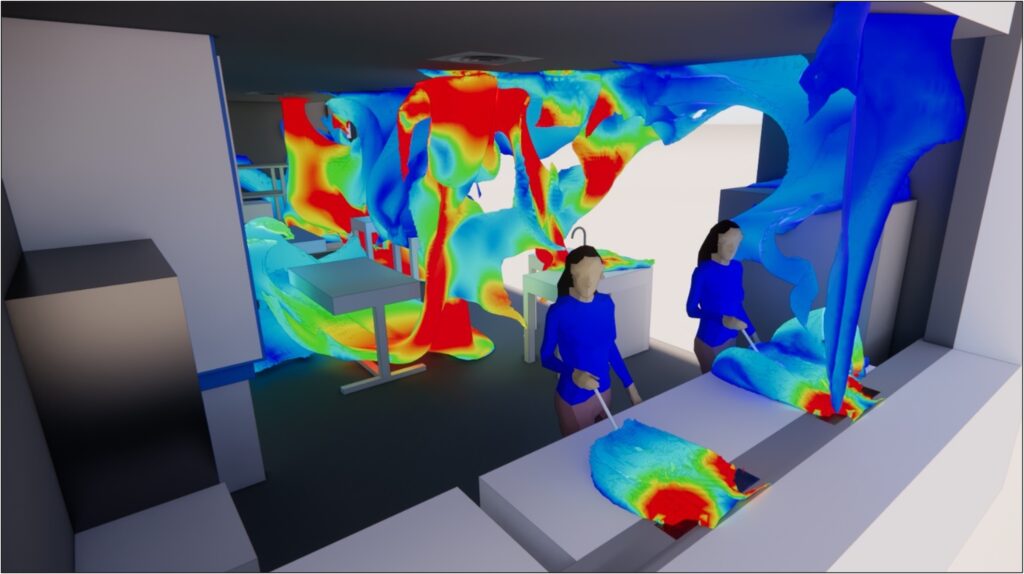

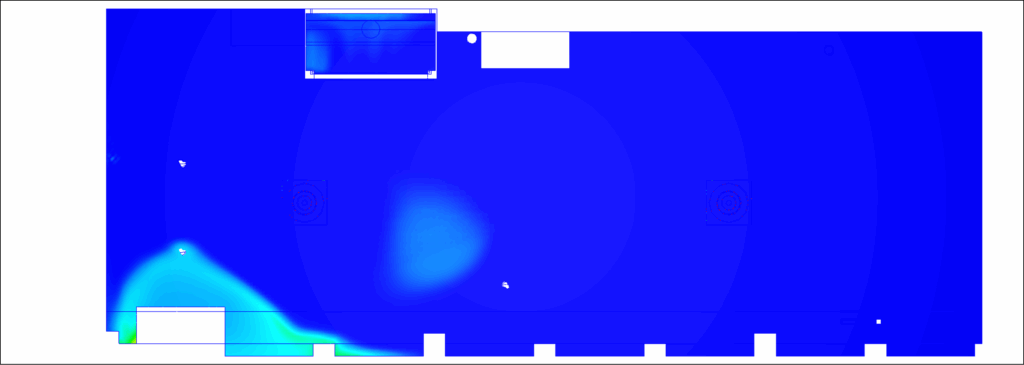

Passive scalars were used to simulate particle concentration in the air, with iso-surfaces and cross-sectional planes to visualize dissipation or accumulation depending on the configuration.

The results of CFD simulations provide an accurate picture of particle dispersion phenomena in the laboratory. Thanks to cross-visualization (velocity planes, scalar sections, iso-surfaces and current traces), each configuration was analyzed in detail. The aim is to identify at-risk areas, quantify the effectiveness of capture systems, and guide technical choices towards the most effective solutions.

What the simulation reveals: trajectories, speeds, concentrations

Unprotected reference state: uncontrolled particle diffusion

In a first configuration, the laboratory is shown without any mobile extraction system, equipped only with wall-mounted extraction grilles. This situation corresponds to theoriginal state, before the addition of the targeted capture devices.

The results show rapid, uncontrolled dissipation of dust as soon as it is emitted. Particles generated at the level of the fossils (modeled by a passive scalar) propagate widely in space, rapidly reaching the lateral and upper zones, particularly at the level of the operators’ faces (planes at a height of 1.70 m).

Air recirculation occurs in the central area of the laboratory, fuelled by theinteraction between blown air from the diffusers and the room’sinternal architecture. These stagnation zones encourage theaccumulation of particles and their prolonged suspension.

Wall-mounted extraction grilles, although distributed over a wide area, are of limited effectiveness. They do not effectively capture particles as soon as they are emitted. The result: the majority of pollutants follow floating trajectories, and several critical threshold iso-surfaces confirm persistent contamination ofambient air.

Mobile suction arms: a clear improvement

The introduction of two mobile suction arms radically transforms the laboratory’s aeraulic landscape.

As soon as they were installed above the workstations, a clear reduction in particulate concentrations was observed in the scalar sections. Particles are captured as soon as they are emitted or very shortly afterwards, limiting their diffusion in space.

The current traces show an immediate orientation of the flows towards the collection nozzles. The particle path becomes short and controlled. On longitudinal and transverse planes, scalars drop drastically, and critical iso-surfaces shrink around emission zones.

Effectiveness depends on the correct position of the arms, which should ideally be positioned a few dozen centimetres from the point of impact of the percussion pens. Sensitivity to positioning is notable, and misalignment could drastically reduce performance.

Adding front protection to the central station: the decisive factor

To furtheroptimize containment, a front guard was added to the central workstation, acting as a physical barrier complementary to the extraction systems.

Thecombined effect of the movable dome and the front baffle results in a significant improvement in containment. Particles are not only captured by the arm, but also trapped by the restricted volume defined by the partition. Thestale air remains confined around the table and no longer spills out into the atmosphere.

Scalar planes at 1m70 reveal a virtual absence of particles in the breathing zones. Concentrations fall below detection limits over most of the room. Iso-surfaces become almost non-existent, and current traces follow trajectories oriented exclusively towards extraction zones.

This system demonstrates a strong synergy between mechanical capture and the physical structuring of space. The addition of the guard transforms the suction arm into a locally confined system, whoseefficiency approaches that of an encapsulated workstation.

Cross-sectional, iso-surface and current trace analysis

The richness of the analysis is based on a combination of graphical representations that allow us to qualify both the behavior of flows and that of suspended particles:

- The velocity sections show the flow dynamics generated by the diffusers, collection systems and openings.

- Scalar cross-sections, in vertical and horizontal projection, visualize the spatial distribution of particulate concentrations.

- Iso-surfaces identify problematic volumes, where the risk of contamination is greatest.

- Current traces, initiated at the point of particle emission, illustrate the path followed by the particles. They highlight areas of stagnation and any backflow, as well as theefficiency of capture in the presence of arms or protection.

This integrated approach offers a complete, visual diagnosis of thework environment. It not only validates existing systems, but also makes precise recommendations on possible improvements, such as equipment positioning, ventilation rates or workstation geometry.

What the survey can do: validate, adjust and secure sustainable dust control

CFD in the service of operator health

TheCFD study conducted by EOLIOS in the geology laboratory provides a precise and operational insight into the dust phenomena associated with fossil removal operations. Thanks to realistic modeling of theenvironment, equipment and particulate emissions, the results obtained can be used to validate existing systems, detect weaknesses and propose concrete adjustments to enhance operator safety.

This study illustrates the added value of numerical simulation in understanding high-risk environments. Thanks to a rigorous approach and advanced calculation tools, invisible phenomena such as particle dispersion, air flows and stagnation zones can be visualized and targeted.

CFD is a real decision-making tool. Not only does it enable equipment to be validated , it alsoanticipates any faults in layout, sizing or use. By making flows visible, it transforms prevention into concrete action.

An approach to prevention and performance

Over and above aone-off analysis, this study is part of a broader approach to health and performance engineering. By identifying levers for improvement, proposing simple solutions and objectifying their effectiveness, simulation helps tooptimize working environments while ensuring operator safety.

For scientific, industrial and hospital establishments, it has become a strategic tool: reducing dust at source, controlling flows, and designing safe spaces adapted to tomorrow’s requirements.

EOLIOS Ingénierie's expertise in air quality and operator safety in laboratory environments

The study carried out by EOLIOS in the geology laboratory illustrates the added value of CFD simulation in mastering sensitive environments. By making invisible phenomena visible, the team was able to demonstrate the real impact of capture solutions and guide technical choices towards high-performance, pragmatic devices.

This approach, at the crossroads of scientific research andapplied engineering, confirms EOLIOS’ ability to support its partners in finding tailor-made solutions that reconcile safety, energy efficiency and regulatory compliance.

Thanks to this study, the laboratory now benefits from optimized dust control, guaranteeing a healthier and more sustainable working environment for its operators.

Find out more:

Study summary

Summary of the study

The CFD study carried out by EOLIOS validated the performance of the existing fume cupboard and the laboratory’s extraction systems, while comparing different capture configurations – from the absence of moving arms to the addition of frontal protection on workstations. The results highlighted areas at risk of recirculation and accumulation, and demonstrated the importance of precise positioning of extraction devices to ensure effective capture at source.

Based on these observations, concrete optimizations were proposed, notably in terms of flow rates and workstation geometry, enabling a significant reduction in dust concentrations in breathing zones. This study has enabled us toobjectivize airflow performance, ensure the long-term safety of the working environment and reinforce the prevention of health risks for operators.

Discover other laboratory projects

Contamination study – Pharmaceutical production lines

Dust dispersion study – Geology laboratory

HVAC – Medical equipment warehouse

VOC treatment process improvement

Cleanroom aeraulics

Pharmaceutical Laboratory – Dust

Qualification of fume cupboards – Laboratory

Study of a clean room