Radiation and ventilation study of an industrial ingot mould

Study of radiation and ventilation in an industrial ingot mould

Year

2025

Customer

NC

Location

France

Typology

Industrial process

Home » Industrial Process » Radiation and ventilation study of an industrial ingot mould

EOLIOS ingénierie's mission: expertise in CFD simulation and industrial ventilation

EOLIOS engineers specialize in structural temperature analysis and thermal comfort optimization.

EOLIOS’ expertise in CFD (Computational Fluid Dynamics) simulation and thermal analysis of structures played a decisive role in the study of an industrial furnace generating intense radiation on metal beams, leading to risks of deformation. Our know-how enabled us to map structural temperatures and predict areas of overheating, while assessing thermal comfort for employees. This approach has helped optimize plant safety and ensure acceptable working conditions in the factory.

Thermoaerulics project to optimize thermal and aeraulic conditions at an industrial silica production site

Radiation and ventilation study around a new electric furnace

On an industrial site dedicated to the manufacture of technical silicas used in various sectors such as tires and cosmetics, the process is based on the melting of sodium silicate at high temperature. Once heated to around 1,200°C, the molten material is transferred to ingot moulds, where it is cooled by water spraying before being temporarily stored in a pit.

As part of an energy transition, the site plans to replace an existing oil-fired furnace with a new-generation electric furnace, which is more efficient and less emissive. However, this technological evolution brings with it new challenges, particularly in terms ofincreased thermal power,higher radiated temperatures, and the risk of structural heating in a partially open hall.

It was against this backdrop that EOLIOS was called in to carry out a complete thermoaerulic study. The aim was to accurately assess the thermal impact of the future furnace on the immediate environment, based on advanced numerical modeling (CFD) and an in situ audit of existing conditions. The analysis was twofold: the first phase focused on the plant’s current configuration, serving as a benchmark for comparison, and the second on the project’s design, incorporating detailed simulations of radiation and air circulation.

The study was designed to meet a number of challenges: guaranteeing the mechanical strength of beams exposed to radiation, preserving the thermal comfort of operators, and anticipating any adjustment requirements in terms of natural or mechanical ventilation. In an environment with high thermal inertia, optimizing airflow behavior and passive protection becomes a strategic lever for performance and sustainability.

Thermal and aeraulic study around the silica furnace

Structural heating due to casting radiation

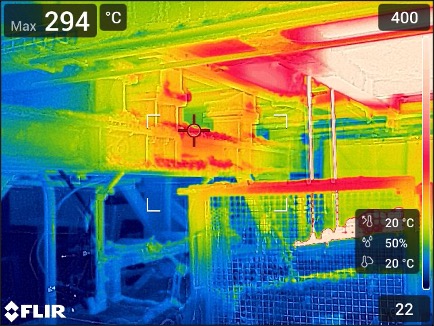

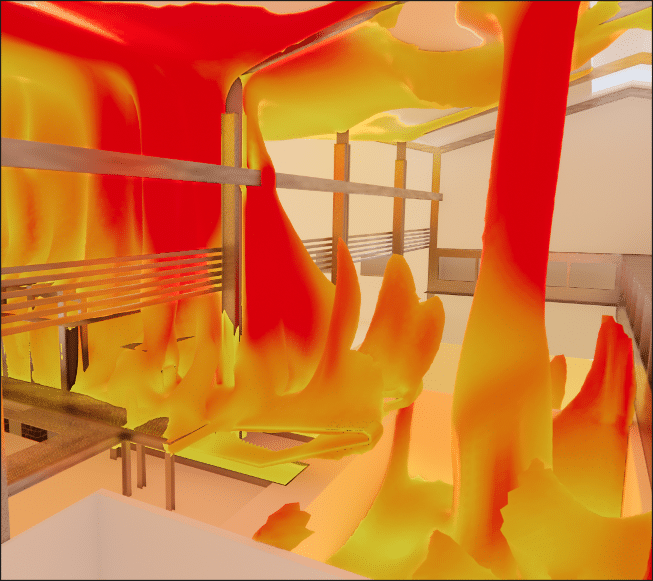

Replacing the oil-fired furnace with a higher-capacity electric furnace has led to an intensification of the thermal process, with melting temperatures remaining close to 1200°C and throughput doubling. The main issue identified concerns the thermal radiation generated by molten glass, particularly at the outlet of pouring nozzles. This radiation directly affects the building’s load-bearing structures, and in particular the steel beams above the ingot moulds. However, these elements are designed for temperature limits that can be locally exceeded, as shown by the thermographic surveys carried out during the initial audit. The risk is not only mechanical: it also concerns the durability of materials, the strength of fasteners and the reliability of nearby equipment.

Thermal images of the beams around the casting

Air circulation and thermal stagnation in the hall

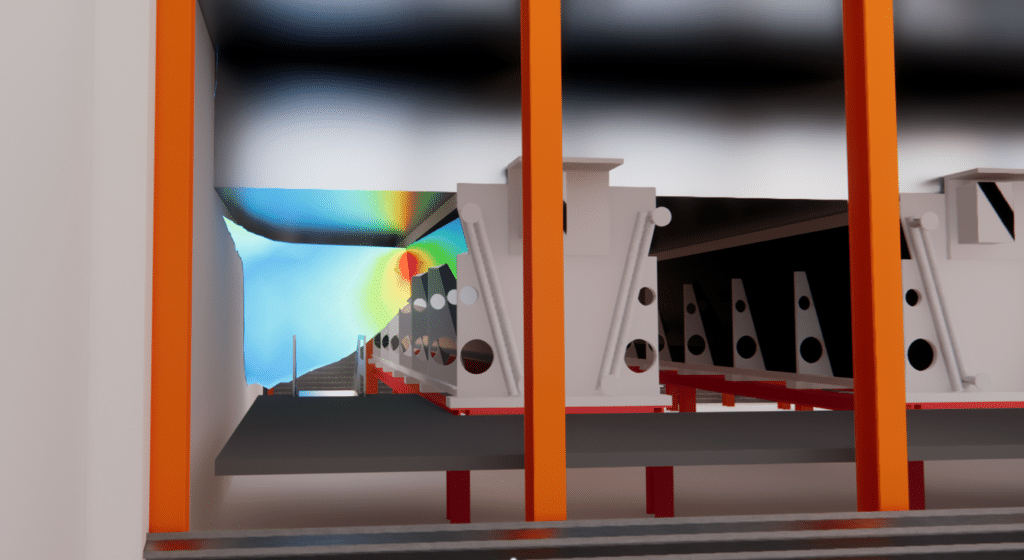

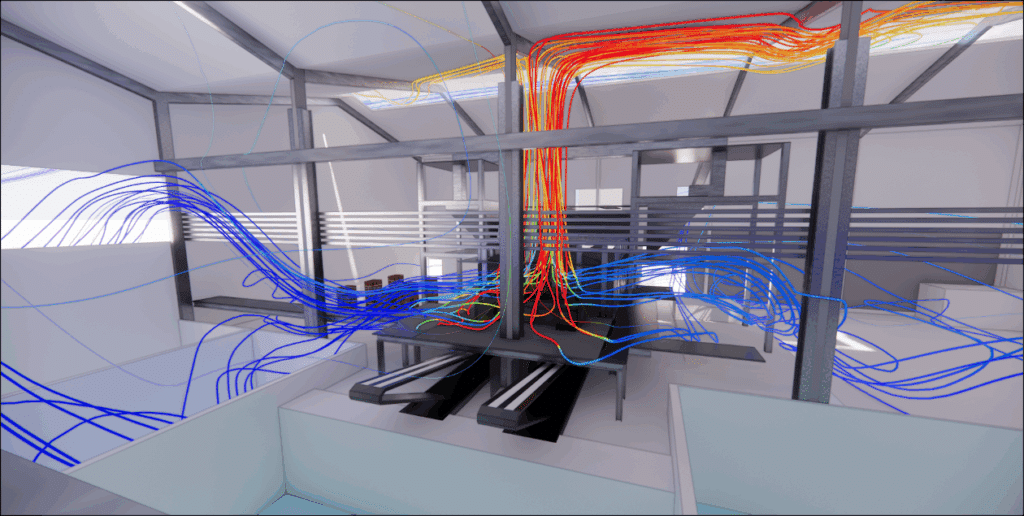

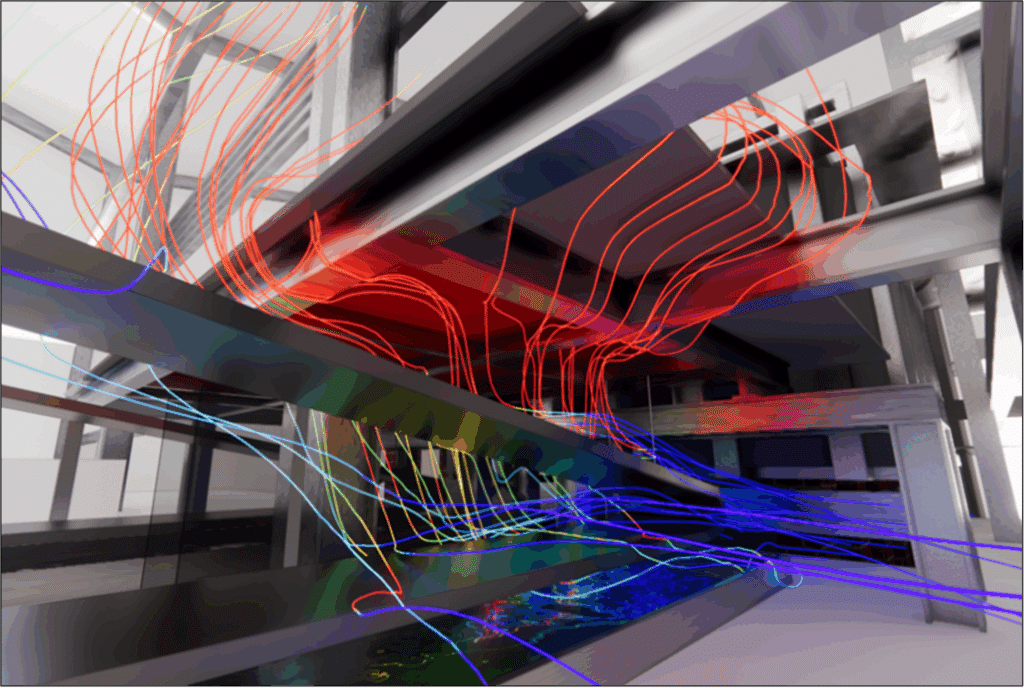

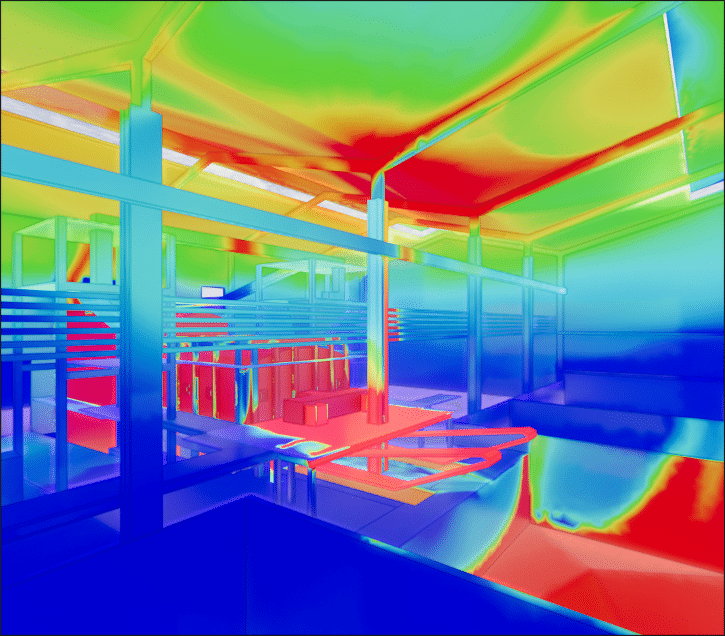

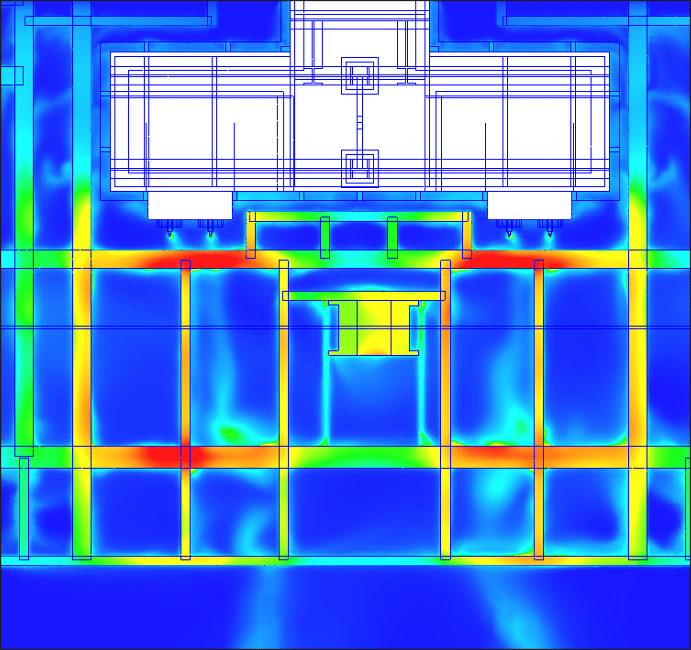

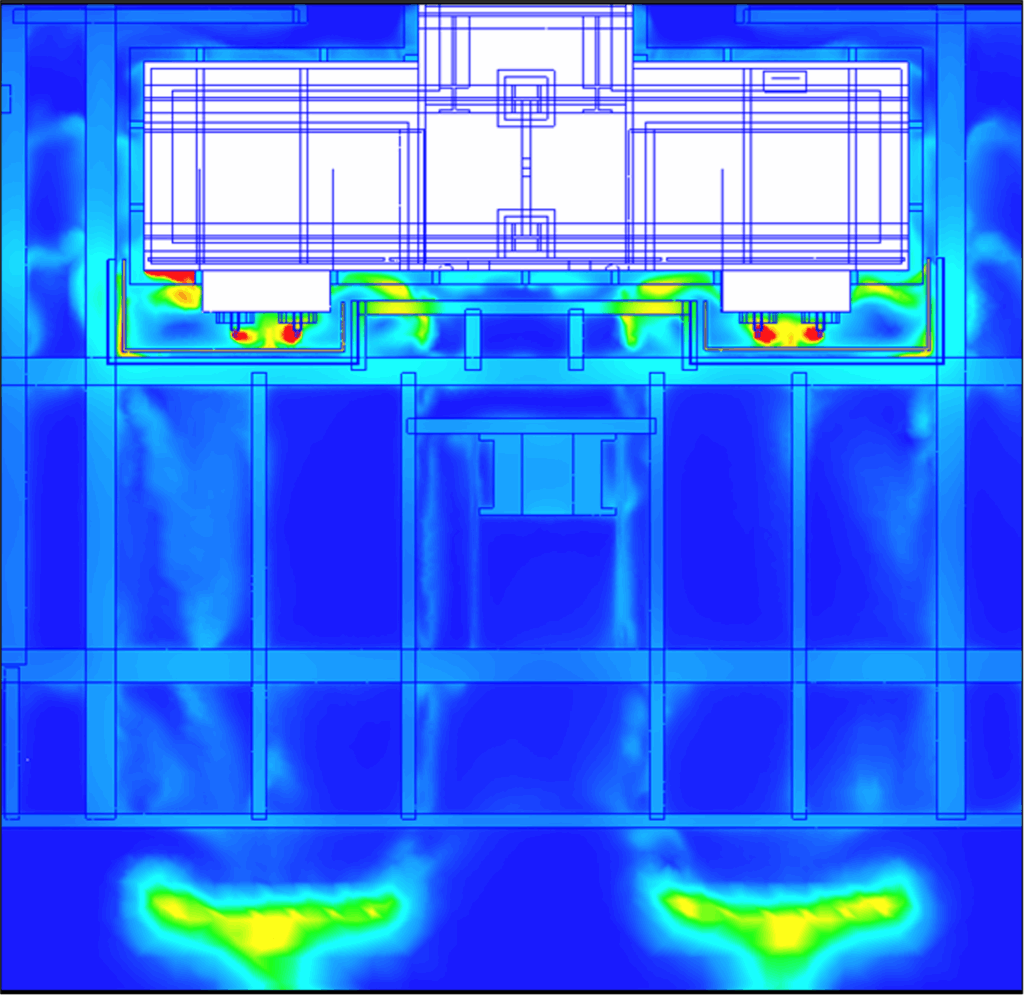

Alongside these radiation issues, furnace operation generates powerful upward air circulation, linked to intense heat release in a building that is largely open to the outside. Air flow dynamics are complex: natural thermal draught, wind speed, building shape, suspended platforms and mechanical obstacles interact to produce zones of recirculation or stagnation of calories in localized sectors, often critical to operation. Simulations have thus revealed hot air veins running along certain walls, residual heating in pit or ventilation zones, and significant differentiation between the north and south of the hall.

Automation plays a crucial role in the operational efficiency of hyperscale data centers. Automated systems supervise and manage almost every facet of daily operations, reducing the need for constant human intervention and minimizing the risk ofhuman error. This automation includes server management, energy consumption monitoring and preventive maintenance.

Operator comfort and environmental control

Finally, these phenomena have a direct impact on working conditions in occupied spaces. The absence of openings to the south, the addition of tarpaulins to limit dust, or the configuration of the pits can lead to localized overheating in certain sensitive areas of the building: pouring platforms, circulation zones, mezzanines or technical rooms. In some cases, temperature differences of +10 to +15°C compared with outside temperatures have been identified. This situation can lead to thermal discomfort for operators, and even stress on equipment, all the more so in the summer conditions modelled.

Methodological approach and numerical CFD simulations

Technical site audit and field surveys

Prior to any modeling,EOLIOS engineers carried out an aeraulic and thermal audit on site.

This initial phase made it possible to collect precise data on the actual operating conditions of the production hall.

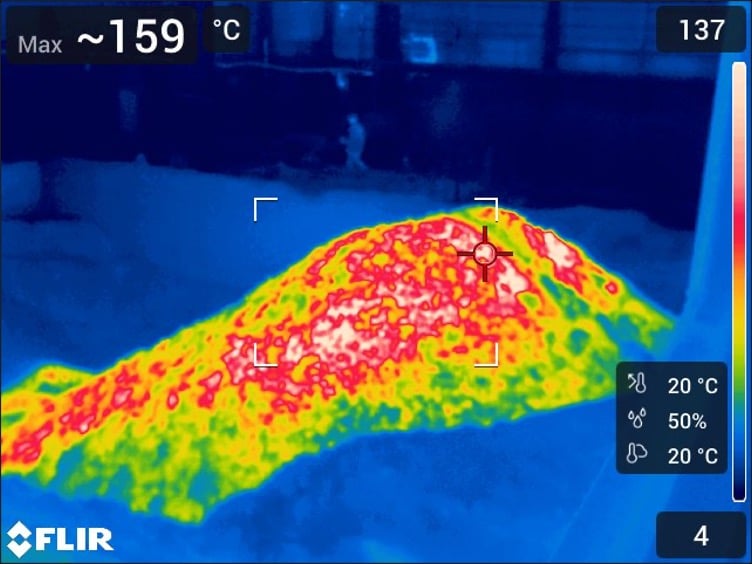

Thermographic camera surveys were carried out to identify areas subject to high temperatures, in particular around load-bearing beams, casting and pits.

In addition, smoke tests were carried out to visualize air flows, confirming the presence of ascending hot air veins and stagnation zones.

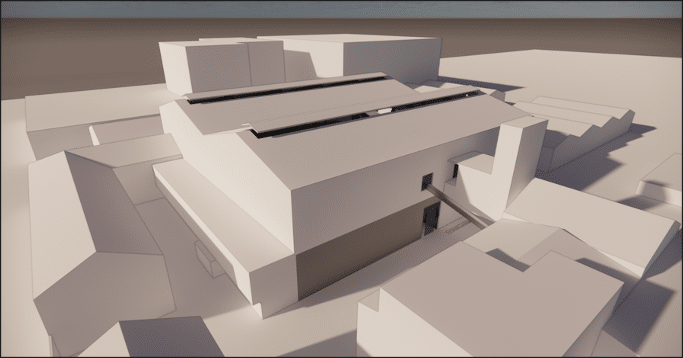

All this information, combined with geometric surveys using laser meters, was used as the basis for the 3D model.

Thermal images of the glass pit

Video of smoke tests

Construction of a realistic, targeted CFD model

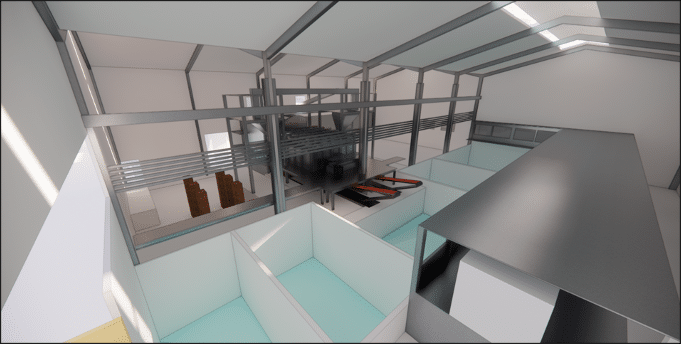

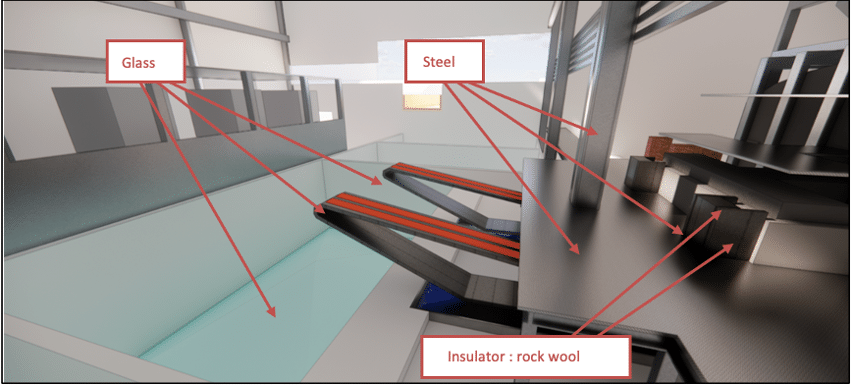

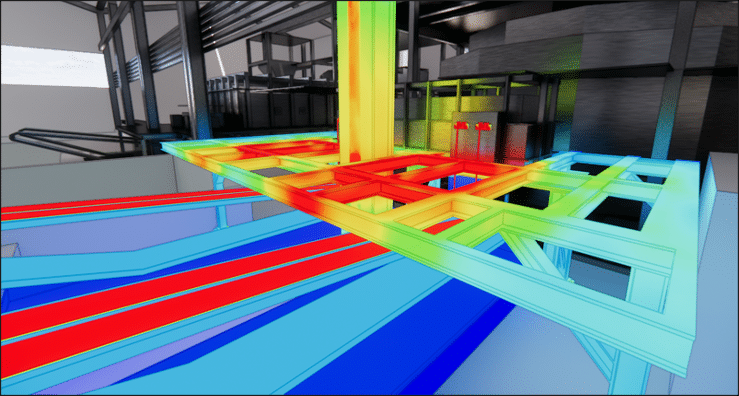

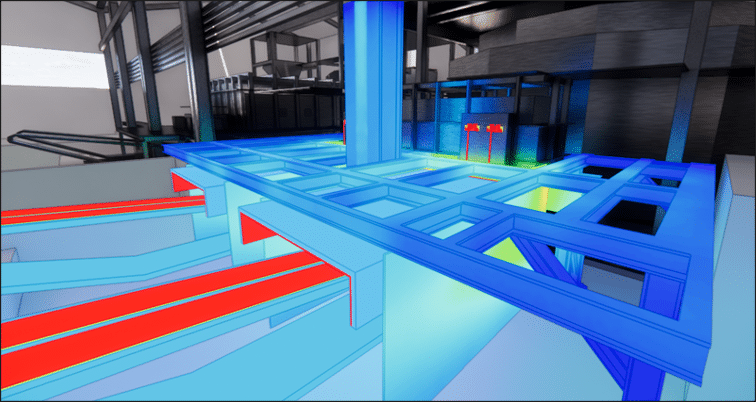

The CFD model was developed from the plans supplied, photos taken during the audit and a detailed site survey. The aim was to accurately represent the volumes, structures and equipment influencing airflow and heat exchange. The model incorporates platforms, beams, cooling pits, openings to the outside, curtains and future installations planned around the electric furnace.

The hybrid digital mesh comprises several tens of millions of cells, with local refinement in critical areas: around the pouring area, under the platforms and in the blast ducts. This level of detail ensures a faithful reproduction of thermal and aeraulic gradients, while guaranteeing the numerical stability of the calculation.

3D plant model adapted to CFD

Modeling assumptions and boundary conditions

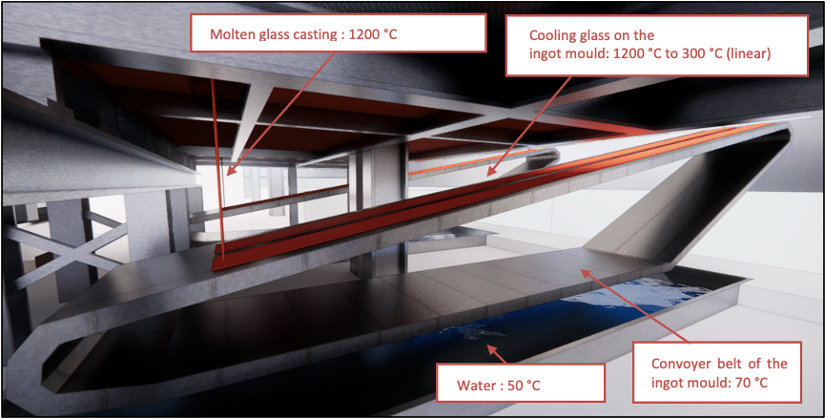

Boundary conditions were established on the basis of audit data and values supplied by the client. The main heat sources include :

- molten glass (modeled from 1200°C to 300°C along the length of the ingot mould),

- oven walls (around 80°C),

- pits (from 250°C to 50°C depending on the zone),

- moving equipment (such as 70°C conveyors).

ChatGPT said:

Convective exchanges with the walls, the nature of the materials (steel, silica, rockwool) and the outside temperature of 38°C were included in the calculation.

The simulation was carried out under steady-state conditions, allowing a stabilized reading of temperature and air velocity distributions throughout the building.

Multiple configurations were tested to compare different variants:

- presence or absence ofinsulation under the platforms,

- integration of radius barriers in a variety of shapes (trapezoidal, flat, U-shaped),

- whether or not to add localized fans,

- modification offaçade openings to improve air circulation.

Tools and turbulence model used

All simulations were carried out using an industrial CFD solver based on the Navier-Stokes equations, with a standard k-ε turbulence model, particularly suited to internal ventilation environments.

This model reproduces the phenomena of stratification, recirculation andacceleration of air masses in complex geometries such as that of the site studied.

Particular care has been paid to the convergence of calculations, with a precision threshold of 10-⁴ on residuals, guaranteeing the reliability of results and the stability of the model.

Proposed solutions: thermal comfort, safety and structural performance

Thermal impact of the furnace on existing structures

ChatGPT said:

Simulations carried out around the new electric furnace have shown a marked rise in temperatures in areas close to the casting.

In certain configurations, the metal beams beneath the platform reach temperatures in excess of 300°C, particularly when thehot air radiated cannot escape freely.

In the absence of protective devices, the most exposed beams are directly exposed to thermal radiation from the melt, with maximum values measured between 320°C and 480°C depending on the cases simulated.

These temperatures exceed the design limits of certain structures, creating potential risks of deformation, loss of mechanical strength or excessive expansion.

Effects of insulation and radiation shields on temperatures

The study compared several design variants to limit this heating. In cases where insulation is placed under the platform, temperatures underneath increase, due to reduced heat dissipation. Conversely, the addition of aluminum radiation shields with insulation reinforcement, placed between the casting and the beams, provides effective protection for the structure.

In addition, the shape of the radiation shield has a direct influence on thedirection of heat flow: inverted-U versions guide hot air masses towards dissipation zones, away from workstations. Solutions incorporating thermal insulation on top of radiation shields reduce secondary radiation to structures and effectively protect overhead elements such as gratings or conveyor arms.

Assessing thermal comfort in work areas

Simulations revealed significant thermal stratification throughout the hall, with temperatures ranging from 38°C to 52°C between the floor and the roof. The worst affected areas are to the south of the furnace, in initially poorly ventilated sectors, where stagnation of calories was observed. In these areas, the thermal delta can be as high as +12°C compared with the outside, affecting comfort and working conditions.

The addition of an opening on the south-east façade, recommended by EOLIOS, introduced a flow of fresh air into the simulations. This modification reduced temperatures in the critical zone to around 43°C, and significantly improved air circulation. In addition, thermal curtains positioned around the casting zones proved effective in protecting operators from direct radiation.

Performance of the proposed final technical solution

The final configuration, incorporating all the devices recommended by EOLIOS (U-shaped radiation shield with insulation, thermal curtains, localized fans, opening in facade), reduces beam temperatures to levels compatible with their current use, while ensuring acceptable atmospheres for personnel.

The results show beam temperatures below 100°C in the majority of cases, with a few peaks of 115-150°C in the areas closest to the pouring spouts. The ambient air in the work areas is generally close to the outside temperature (38-40°C), and heat plumes are well channelled to the roof, away from the workstations.

This balanced solution significantly reduces thermal stress on structures, while maintaining a high level of thermal comfort in the immediate process environment.

EOLIOS ingénierie's expertise in solving thermo-aerodynamic problems in industry

Recommendations tailored to each project

EOLIOS expertise in thermal performance and industrial safety

Thanks to its expertise in thermal-air engineering and the use of advanced numerical simulation tools (CFD), EOLIOS enabled the silica production site operator toaccurately anticipate the thermal effects associated with the installation of a new high-power electric furnace.

The study highlighted areas susceptible to overheating and complex air flow dynamics within the hall, while identifying concrete levers for improvement to enhance structural safety, operator comfort and equipment durability.

By proposing a global solution incorporating optimized radiation barriers, appropriate natural and mechanical ventilation, and improved façade openings, EOLIOS helped to ensure the project’s success in the context of a controlled energy transition.

This intervention illustratesEOLIOS ‘ abilityto support manufacturers in their most demanding projects, by combining field analysis, high-level numerical modeling and applied engineering to transform thermal complexity into safe, sustainable performance.

Find out more:

Video summary of the study

Summary of the study

The thermoaerulic study carried out by EOLIOS has enabled us to accurately characterize the effects of the new electric furnace on the site environment, in terms of both and operator comfort. Thanks to detailed CFD modelling and an in-depth field audit, the zones of overheating, air stagnation and excessive radiation have been identified. The technical solutions proposed – radiation shields, ventilation improvements and thermal protection – now ensure that the safety of structures, control of working environments and durability of installations. This study illustrates the ability of EOLIOS to support manufacturers in the transition towards more efficient and sustainable processes.

Video summary of the mission