Simulation of saturated vapour capture on a continuous casting line

Simulation of saturated vapour capture on a continuous casting line

Year

2026

Customer

NC

Location

Germany

Typology

Industrial Process

Home » Industrial Process » Simulation of saturated vapour capture on a continuous casting line

EOLIOS ingénierie's mission: CFD simulation expertise and industrial fume capture

EOLIOS engineers, experts in controlling heat and air flows in industrial environments

EOLIOS’ expertise in CFD (Computational Fluid Dynamics) simulation and in the optimization of capture and industrial ventilation systems was mobilized to meet the challenges of managing saturated fumes on a continuous casting line in a steel mill. These phenomena, inherent to high-temperature processes, represent major constraints in terms of safety, working conditions and production continuity.

EOLIOS draws on recognized experience in the study of complex flows in industrial environments, gained from numerous field missions and CFD simulations applied to installations with high operational stakes. This expertise enables us to provide reliable, pragmatic and economically-optimized solutions for informed decision-making.

Capturing fumes: a safety issue in industry

Industrial fumes, a significant source of risk

Industrial fumes are a major multi-disciplinary issue, at the crossroads of operator safety, comfort and air quality, as well as process continuity and plant durability.

In the first instance, the presence of fumes, loaded with moisture – an essential element in electrochemical corrosion – causes risks of material degradation in the industry. When moisture is deposited on metal surfaces, it forms a film of water that allows chemical reactions to take place between the metal and oxygen. This attack is often accelerated by the presence of impurities dissolved in the mist, such as salts, acids or dust, which increase its conductivity and make the environment slightly corrosive. Repeated exposure to mist thus leads to cumulative effects: uniform corrosion, localized pitting and degradation of coatings or joints, reducing the durability and integrity of metal equipment.

Identifying corrosive steam clouds

This aspect of material deterioration constitutes a major risk to the operation of the industry. But beyond this aspect, fog also presents a health and safety risk for workers. The combination of humidity and heat generates plumes that can impair visibility, disrupt air flows and modify thermal conditions around work areas and equipment. These phenomena can increase the risk of accidents (reduced visibility, difficulties in handling equipment) and cause health problems (irritation, respiratory problems).

The presence of fumes thus acts as a global disturbance factor, likely to reduce the safety, performance and durability of industrial infrastructures.

EOLIOS was commissioned to install a continuous casting system at a steelworks in the Brandenburg region of Germany. In this industry, malfunctions in the existing capture system were causing a significant build-up of vapors under the floor of the first stage, leading to regular production stoppages. EOLIOS was called in to carry out a detailed analysis of the actual operation of the system, to identify the causes of the faults and to propose effective, long-term solutions.

Why use CFD?

In order to meet the challenges posed by industrial fumes, an approach combining on-site measurements (via an Audit) and numerical flow modelling (CFD – Computational Fluid Dynamics) is now favoured. CFD provides a three-dimensional, dynamic view of flows, essential for accurately identifying critical heat and vapor accumulation zones, air recirculation, source capture deficits and interactions between thermal plumes and ventilation systems. In this way, we can quantitatively assess the effectiveness of existing systems and understand their limitations under real operating conditions.

CFD modeling of thermal plumes and fumes

One of the main advantages of CFD lies in its ability to virtually test different scenarios for fitting out or modifying installations: repositioning or sizing collectors, adjusting flow rates, adding deflectors, modifying geometries or ventilation strategies. This rapid, non-intrusive numerical exploration enables us to objectively compare several solutions, optimize their performance before implementation, and significantly reduce the technical and financial risks associated with on-site testing.

In addition, CFD is a particularly relevant decision-making tool for reconciling aeraulic performance and energy efficiency. It enables us to anticipate the impact of proposed solutions on energy consumption, building thermal balance and operator comfort, thus contributing to a more sober and sustainable design of ventilation systems.

Study objectives

The main objectives of the study were to :

- understand the thermal and aeraulic phenomena that cause vapour leakage,

- analyze the actual operation of the existing capture network,

- evaluate the effectiveness of different improvement configurations,

- identify technically efficient and relevant solutions.

To achieve this, an approach combining on-site audit, duct network analysis and CFD numerical simulation was implemented.

At EOLIOS, a methodology based on observation and reality

On-site thermo-aerodynamic audit

An in-depth audit was carried out directly on the continuous casting line in order to precisely characterize the phenomena under actual operating conditions. Measurement campaigns were carried out around the machine to quantify air velocities, temperatures andhygrometry, providing a reliable and representative initial state. Smoke tests were also carried out to qualitatively visualize airflow trajectories and vapour leakage paths, and thus identify priority exhaust zones and malfunctions in existing capture devices.

Figure - Thermal camera image - Slab at slab exit

As well as collecting data, an on-site audit is a key stage in understanding how the plant actually operates, in an environment that is often complex and changing. It enables us to compare theoretical diagrams and existing plans with the reality on the ground, and to integrate the effects of operating practices, access constraints, transient situations and weather conditions, all of which are rarely fully documented. This detailed knowledge of the site is essential to correctly interpret observed phenomena and avoid simplifying modeling hypotheses that are far removed from reality.

Figure - Vapour plume generated by the machine

The field observations resulting from the audit formed an essential basis for feeding, calibrating and validating the CFD numerical model. They guarantee consistency between the simulation and the actual behavior of the system, reinforcing the reliability of the results and the relevance of the proposed solutions. The on-site audit is therefore an essential prerequisite for any sustainable analysis and optimization of industrial fume problems.

A 3D model representative of the existing situation

3D CFD modeling is based on a rigorous geometrical foundation, drawn up from existing plans and supplemented by surveys and observations made during the on-site audit. This stage is crucial, as the quality and representativeness of the model directly determine the relevance of the results obtained. The aim is to realistically reproduce the air paths, intake channels, duct networks and their interfaces with the fume generation zones, in order to best reflect the actual operation of the installation.

On the basis of the data collected and the documents supplied, EOLIOS developed a detailed 3D CFD model integrating the geometry of the machine under study, its immediate environment and all the equipment influencing the site’s aeraulics. This includes ventilation systems, heat sources, neighboring machines and all elements that obstruct or guide flows, such as aeraulic masks, screens or metal structures.

The level of geometric detail is carefully chosen to faithfully represent elements with a significant influence on velocity, temperature and vapor concentration fields, while rationalizing secondary details whose impact on flows is negligible. This balance between precision and simplification keeps calculation times under control, ensures the numerical robustness of simulations and guarantees results that can be used to analyze phenomena and aid decision-making.

An accurate CFD model is therefore a key step towards understanding the real mechanisms of mist dispersion and capture, reliably assessing the performance of existing systems, and exploring solutions for improvement under conditions representative of industrial operation.

Calibration of the model to actual observed phenomena

In practice, the CFD approach is part of an iterative process structured in several successive stages: construction of the geometric model, definition of boundary conditions and properties, numerical resolution, then detailed analysis of flow, temperature and humidity fields. This cycle is completed by a calibration phase based on field measurements, before iterations dedicated to the study of improvement configurations.

The calibration phase is a key step in the process, as it guarantees consistency between simulation results and actual system behavior. Its aim is to adjust the boundary conditions and modeling assumptions in order to obtain a satisfactory match between the calculated quantities and the measurements taken in situ during the audit, as well as the data supplied by the project manager.

This calibration is based on the development of a numerical model that faithfully reproduces the main physical phenomena at play, notably air flow, heat transfer and humidity evolution in the volume under study. The model integrates both internal sources linked to processes and equipment, as well as exchanges with the external environment, taking into account key parameters such as suction rates, element surface temperatures, meteorological conditions and steam generation mechanisms.

Once the model has been calibrated and validated, it can be used as a reliable predictive tool to study the impact of different modifications (changes in flow rates, geometries, collection or ventilation devices) and analyze new flow dynamics within the system, in support of technical decision-making.

Characterization of pressure losses in duct networks

Analysis of head losses in suction duct networks is a fundamental step in reliably determining the flow rates actually available at the collection points. In complex industrial installations, total head losses result from the combination of linear losses linked to duct lengths and singular losses induced by changes in cross-section, elbows, tees, tappings, control devices, as well as by the degree of soiling of internal walls. These cumulative effects can lead to head losses that are significantly higher than the initial design assumptions or the nominal values used during operation.

A detailed characterization of the network enables us to compare theoretical fan curves with actual operating conditions, to identify imbalances in flow distribution between the various branches, and to quantify discrepancies between expected and actually achievable capture rates. This approach is essential to establish a coherent aeraulic balance, evaluate the operating margins of ventilation equipment and highlight the structural limitations of the existing network.

For CFD simulations, this analysis enables realistic and physically representative boundary conditions to be defined, in line with the system’s actual suction capacities. It is therefore an essential prerequisite for ensuring the validity of numerical results, correctly interpreting observed phenomena and basing technical recommendations on a rigorous, quantitative assessment of the suction system’s performance.

Study of aeraulics around a machine generating saturated vapors

A problem linked to the origin of suction flows

The study showed that the efficiency of a capture system is not limited to the available suction flow rate alone, but also depends on the dynamics of the air flows and their origin. In some configurations, a significant proportion of the intake air may come from peripheral or non-critical areas. This supply of external air, lightly charged with mist or pollutants, reduces overall capture efficiency by mobilizing part of the suction capacity without contributing to the elimination of emissions from the zones actually concerned.

These results underline the importance of precise design and sizing of capture systems, integrating not only flow rates but also the actual circulation of air in the production environment. Targeted flow control enables extraction to be concentrated on fume-generating areas, improving overall system performance and limiting energy losses, while guaranteeing safe, optimized working conditions for operators.

Vapour behaviour in cabins and in the hall

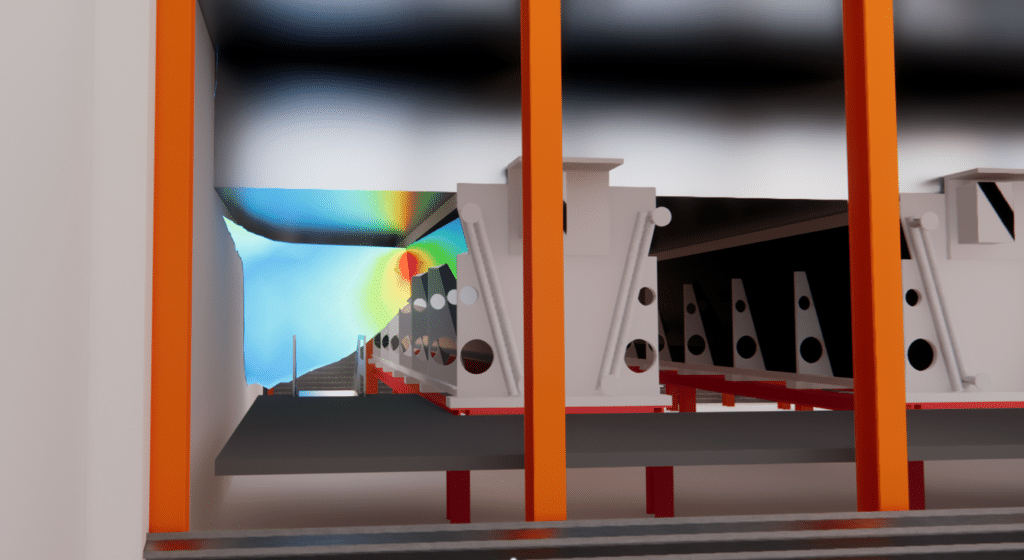

In the mist cabin, simulations show that the negative pressure generated is relatively low. As a result, some of the fumes produced on contact with the hot slabs escape between the segments, forming rising plumes that accumulate under the first-floor floor.

The mist-laden air is then forced to circulate around the floor, rushing into openings such as staircases and duct passages. This explains the significant stagnation observed under the platform and the presence of visible fumes in areas far from their initial source.

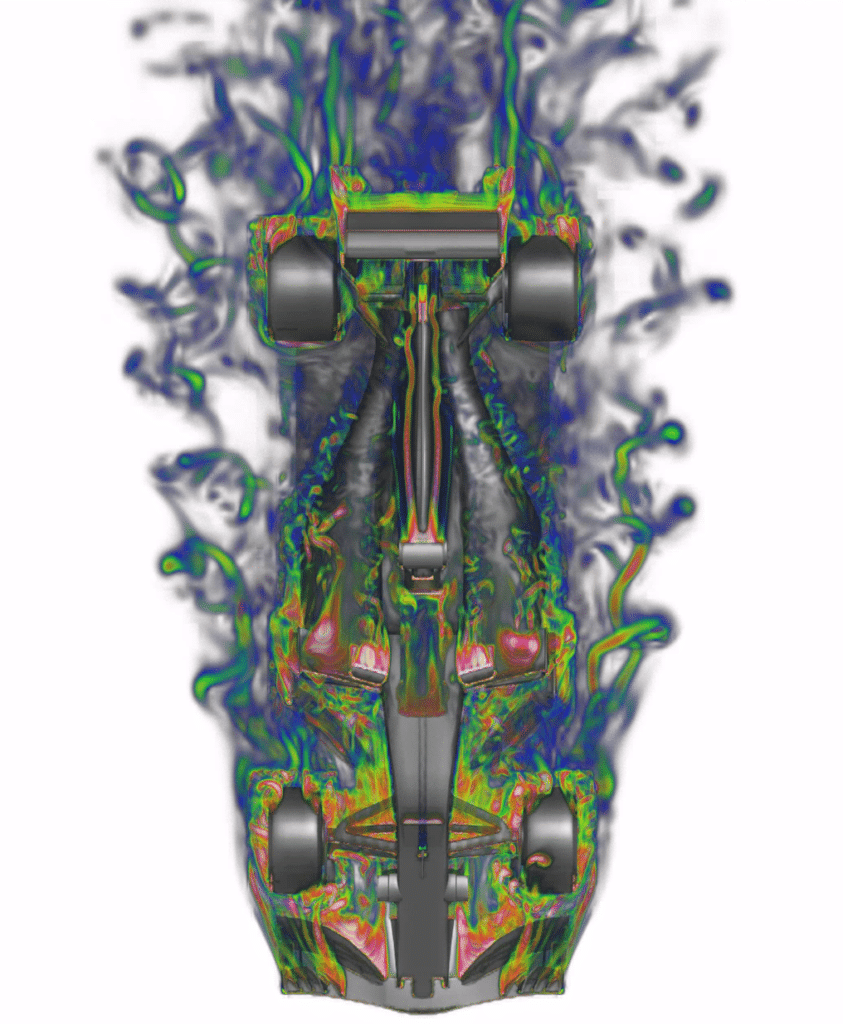

The results of CFD simulations faithfully reproduce these phenomena, in terms of air velocity, thermal stratification and humidity distribution, confirming the relevance and reliability of modeling for analyzing flows and guiding the optimization of capture systems.

Assessment of sustainable and reliable improvement solutions

Impact of simple structural improvements

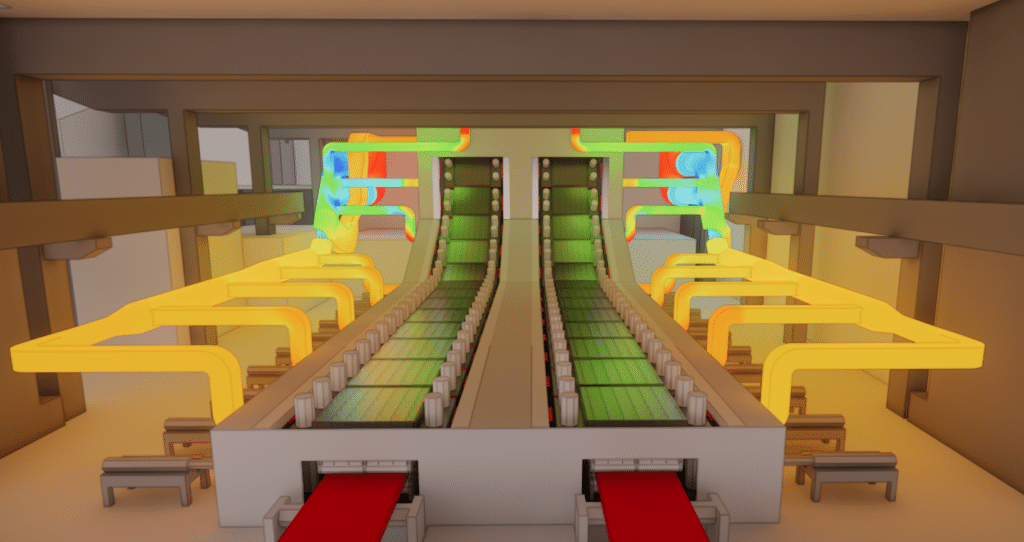

Following the initial simulations, a number of simple structural improvements were proposed, requiring no modification to the vapour collection system. The aim of these improvements was to reduce vapour outflow into the hall, and consequently improve the machine’s vapour capture. A number of beneficial effects emerged:

Firstly, an increase in cabin negative pressure is observed. Increased negative pressure improves the efficiency of vapour capture at source, by drawing in vapour-laden flows before dispersing them in the hall. This helps to limit leakage to adjacent areas, reduce build-up under floors, and improve visibility and working conditions for operators. It must, however, be carefully dimensioned to ensure optimum aeraulic balance and avoid undesirable impacts on comfort, flow stability or energy consumption.

Figure - Pressure plane in the fume cupboard - Before/After

This depression is accompanied by areversal of the aeraulic trend above the vapour cabins. The transition from ascending hot-air streams to descending cool-air streams counteracts the natural upwelling of fumes, containing their dispersion to higher levels. This aeraulic inversion helps to draw steam-laden flows down towards the capture zones, improves control of thermal plumes and helps to stabilize flow conditions around the cabin. It thus contributes to a significant improvement in visibility, thermal comfort and safety in adjacent work areas.

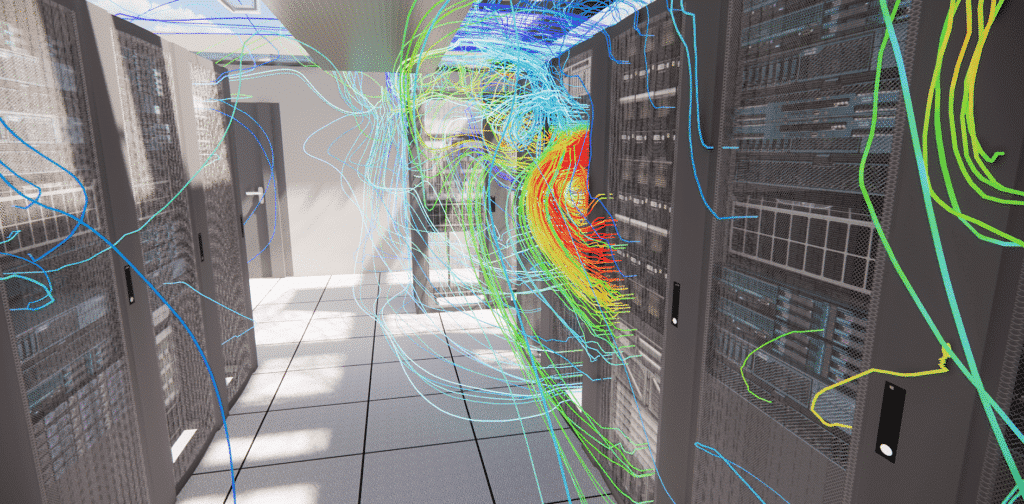

Figures - Current lines colored by temperature - Before / After

In short, these two elements enable most of the steam flowing into the hall to be captured by the extraction system. The cabin is then able to intercept the majority of fumes before they are dispersed into the environment. This significantly improves the overall efficiency of the system, limits leakage to neighbouring areas and reduces the load on the general ventilation systems. This contributes to better control of steam plumes, a lasting improvement in working conditions and a reduction in associated energy losses.

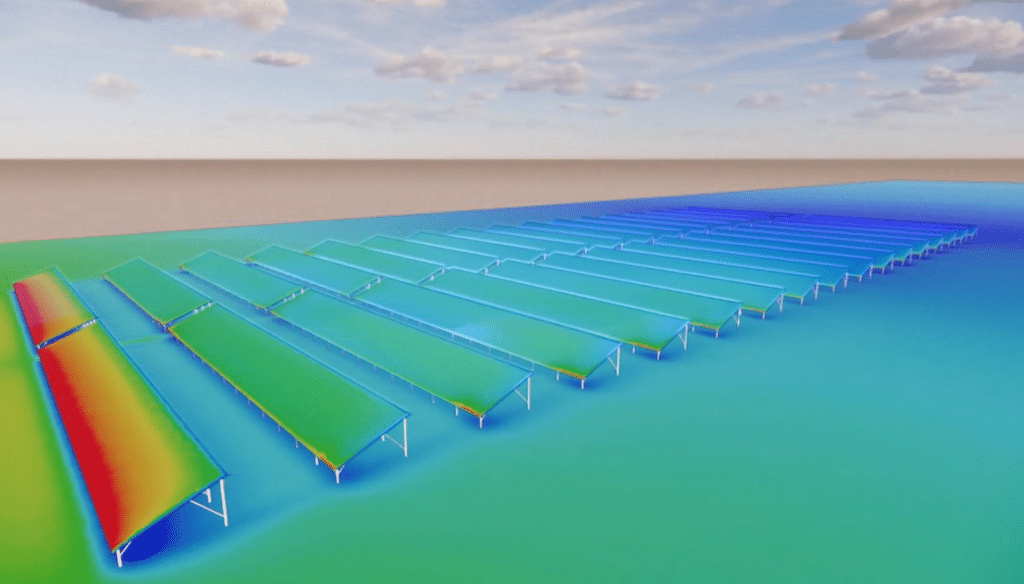

Figure - Relative humidity - Longitudinal section - Before / After

Figure - Relative humidity - Cross-section between two segments - Before / After

In addition, better control of heat and steam flows limits the accumulation of hot air under the roof. This reduction in upper-roof temperatures helps to preserve structures and equipment, limit condensation and corrosion, and improve the building’s overall thermal comfort. It also contributes to better aeraulic stability and can lead to a reduction in ventilation requirements and associated energy consumption.

Figure - Temperature - Cross-section between two segments - Before/After

Despite these improvements, a slight escape of fumes remains in the vertical part of the casting. However, this remains limited and does not call into question the overall efficiency of the system, as residual flows are rapidly diluted and do not significantly impair operating or safety conditions.

Benefit from more complex enhancements

A more advanced configuration, combining simple structural improvements with the addition of new capture devices, was also studied. This solution provides almost total fume control, including on the vertical part of the pour, with an overall efficiency close to 100%. It provides maximum performance and robustness in the face of operating variations, virtually eliminating the risk of residual exhaust.

However, this approach needs to be put into perspective with the simpler solution previously studied, which already made it possible to significantly reduce fume emissions and significantly improve operating conditions, at a much lower investment cost and much less complex to implement. This first solution thus offered a particularly relevant compromise between performance, simplicity and cost, while meeting the main challenges of safety and comfort.

The addition of supplementary devices is therefore mainly justified by the need for maximum performance or high operational requirements, when the aim is to virtually eliminate all residual emissions or to secure the plant against highly variable operating conditions. The choice between these two approaches is thus a matter of technical and economic arbitration, with the simple solution representing an effective and optimized response, while the enhanced solution provides a higher level of control at the cost of increased investment and complexity.

A rigorous study for an informed decision

The results of the study enabled us to identify simple, robust and economically optimized solutions, with the emphasis on controlling air flows and eliminating parasitic inlets before considering any increase in the power of ventilation systems. This approach prioritizes theefficiency of interventions, minimizes costs and immediately improves the performance of the existing system.

At the same time, additional analyses have revealed more complex solutions, offering even finer flow control and maximum efficiency, but requiring higher investment. These options enable almost total control of fumes and sustainable optimization of environmental conditions in the production hall.

EOLIOS’ involvement provided the client with a complete understanding of the physical phenomena involved, the priority levers for action and the expected gains. This structured approach contributes directly toimproving working conditions, operational reliability and safety, while enhancing the overall performance of the facility. It also provides a solid decision-making tool for choosing between immediate, cost-effective solutions or more ambitious, sustainable optimizations.

Find out more:

Video summary of the study

Summary of the study

The study carried out by EOLIOS enabled us to gain a detailed understanding of the mechanisms involved in generating, dispersing and capturing saturated fumes in a continuous casting plant. Based on an analysis of actual operating conditions and CFD simulations representative of existing conditions, the main malfunctions in the capture system were identified.

The work highlighted the fact that targeted structural improvements, without any significant increase in suction flow rates, could already lead to a very significant reduction in fume escapes and a marked improvement in operating conditions. More advanced solutions were also evaluated to achieve the highest level of control, providing the client with objective elements to arbitrate between performance, simplicity and investment.

This approach has resulted in robust technical recommendations tailored to the industrial context, contributing to operator safety, plant reliability and overall site performance.

Video summary of the mission